light VAUXHALL MOKKA 2014 Workshop Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014, Model line: MOKKA, Model: VAUXHALL MOKKA 2014Pages: 217, PDF Size: 5.9 MB

Page 165 of 217

Vehicle care163

2. Remove the bulb socket bypulling.

3. Remove the bulb from the bulb socket and replace the bulb.

4. When fitting a new bulb, engage the lugs in the recesses on the

reflector.

5. Reinstall the headlight assembly.

6. Place headlight protective cover in position and close.

Fog lights

Have bulbs replaced by a workshop.

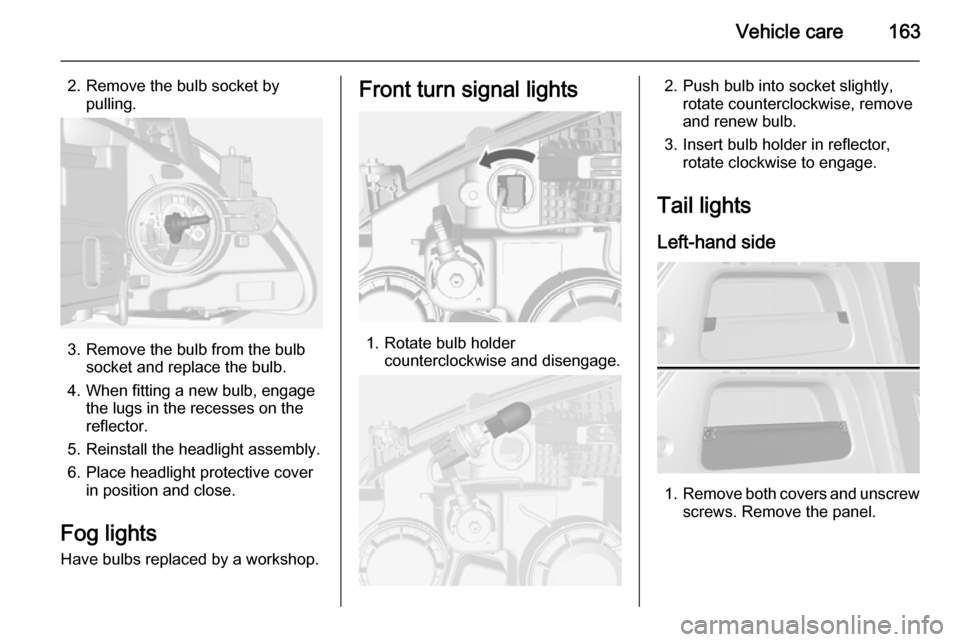

Front turn signal lights

1. Rotate bulb holder counterclockwise and disengage.

2. Push bulb into socket slightly,rotate counterclockwise, removeand renew bulb.

3. Insert bulb holder in reflector, rotate clockwise to engage.

Tail lights

Left-hand side

1. Remove both covers and unscrew

screws. Remove the panel.

Page 166 of 217

164Vehicle care

2. Remove the cover.

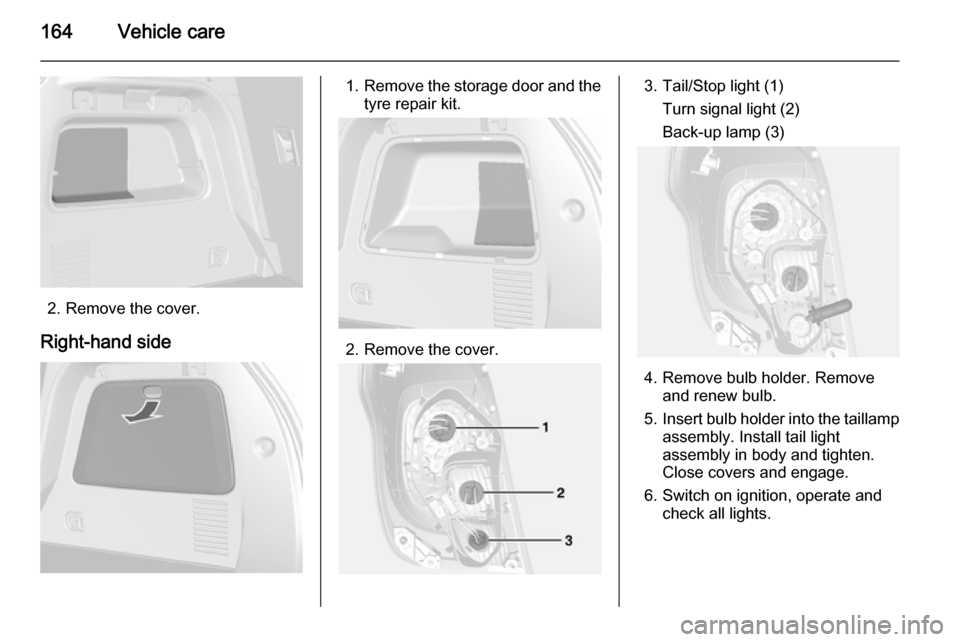

Right-hand side

1. Remove the storage door and the

tyre repair kit.

2. Remove the cover.

3. Tail/Stop light (1)

Turn signal light (2)Back-up lamp (3)

4. Remove bulb holder. Remove and renew bulb.

5. Insert bulb holder into the taillamp

assembly. Install tail light

assembly in body and tighten.

Close covers and engage.

6. Switch on ignition, operate and check all lights.

Page 167 of 217

Vehicle care165Side turn signal lights

If the lights do not operate, have themchecked by a workshop.

Centre high-mounted

brake light

If the centre high-mounted brake light does not operate, have it checked by

a workshop.

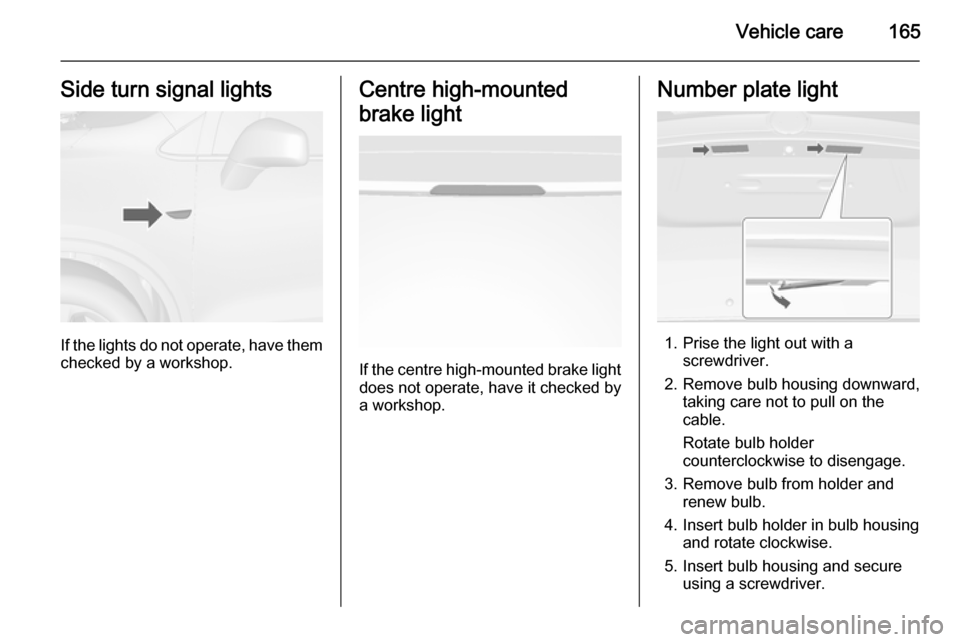

Number plate light

1. Prise the light out with a screwdriver.

2. Remove bulb housing downward, taking care not to pull on thecable.

Rotate bulb holder counterclockwise to disengage.

3. Remove bulb from holder and renew bulb.

4. Insert bulb holder in bulb housing and rotate clockwise.

5. Insert bulb housing and secure using a screwdriver.

Page 168 of 217

166Vehicle careInterior lightsCourtesy lights 1. To remove it, prise the opposite side of the light switch using a flat-blade screwdriver.

2. Remove the bulb.

3. Replace the bulb.

4. Reinstall the light assembly.

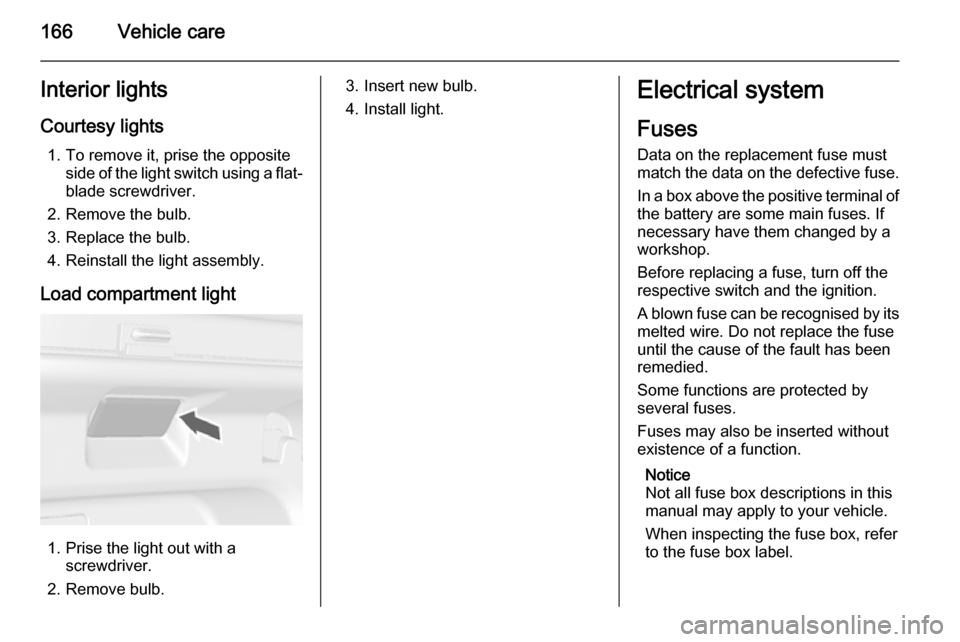

Load compartment light

1. Prise the light out with a screwdriver.

2. Remove bulb.

3. Insert new bulb.

4. Install light.Electrical system

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

In a box above the positive terminal of the battery are some main fuses. If

necessary have them changed by a

workshop.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its

melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Notice

Not all fuse box descriptions in this

manual may apply to your vehicle.

When inspecting the fuse box, refer

to the fuse box label.

Page 169 of 217

Vehicle care167

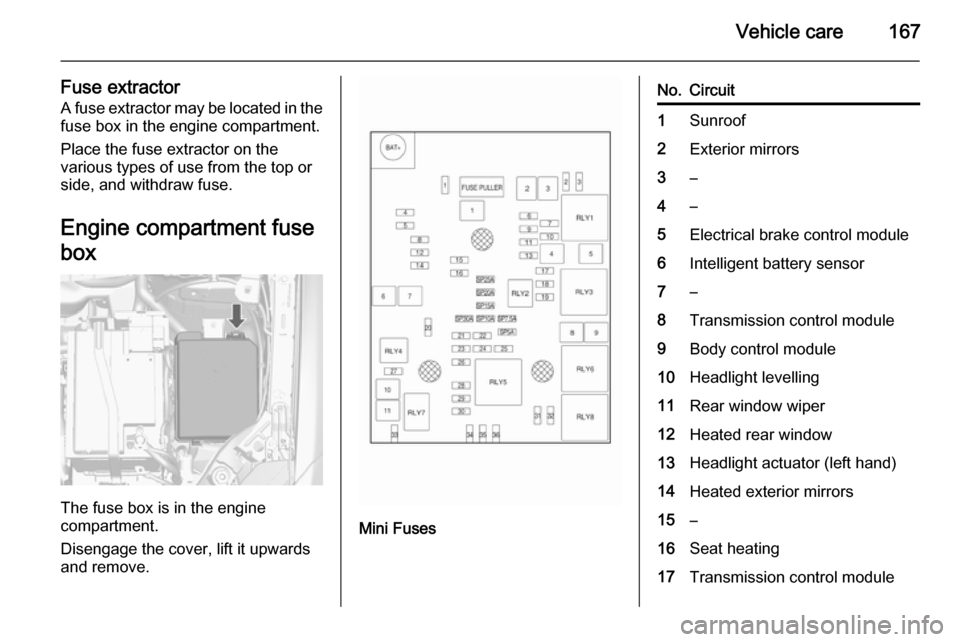

Fuse extractorA fuse extractor may be located in the fuse box in the engine compartment.

Place the fuse extractor on the

various types of use from the top or

side, and withdraw fuse.

Engine compartment fuse

box

The fuse box is in the engine

compartment.

Disengage the cover, lift it upwards

and remove.

Mini Fuses

No.Circuit1Sunroof2Exterior mirrors3–4–5Electrical brake control module6Intelligent battery sensor7–8Transmission control module9Body control module10Headlight levelling11Rear window wiper12Heated rear window13Headlight actuator (left hand)14Heated exterior mirrors15–16Seat heating17Transmission control module

Page 171 of 217

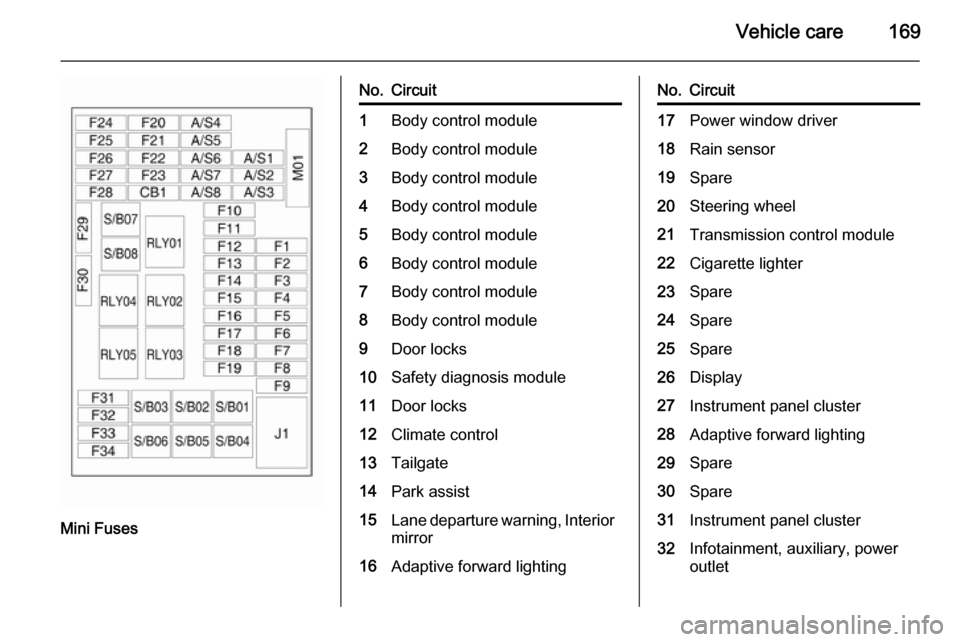

Vehicle care169

Mini Fuses

No.Circuit1Body control module2Body control module3Body control module4Body control module5Body control module6Body control module7Body control module8Body control module9Door locks10Safety diagnosis module11Door locks12Climate control13Tailgate14Park assist15Lane departure warning, Interior

mirror16Adaptive forward lightingNo.Circuit17Power window driver18Rain sensor19Spare20Steering wheel21Transmission control module22Cigarette lighter23Spare24Spare25Spare26Display27Instrument panel cluster28Adaptive forward lighting29Spare30Spare31Instrument panel cluster32Infotainment, auxiliary, power

outlet

Page 173 of 217

Vehicle care171

No.Circuit1Seat, lumbar support, driver2Seat, lumbar support,

passenger3Amplifier4Trailer socket5All-wheel drive6Display7Spare8Trailer9Spare10Spare11Trailer12Navigation13Heated steering wheel14Trailer socket15Steering wheel16Water in fuel sensorNo.Circuit17Interior mirror18Spare

S/B Fuses

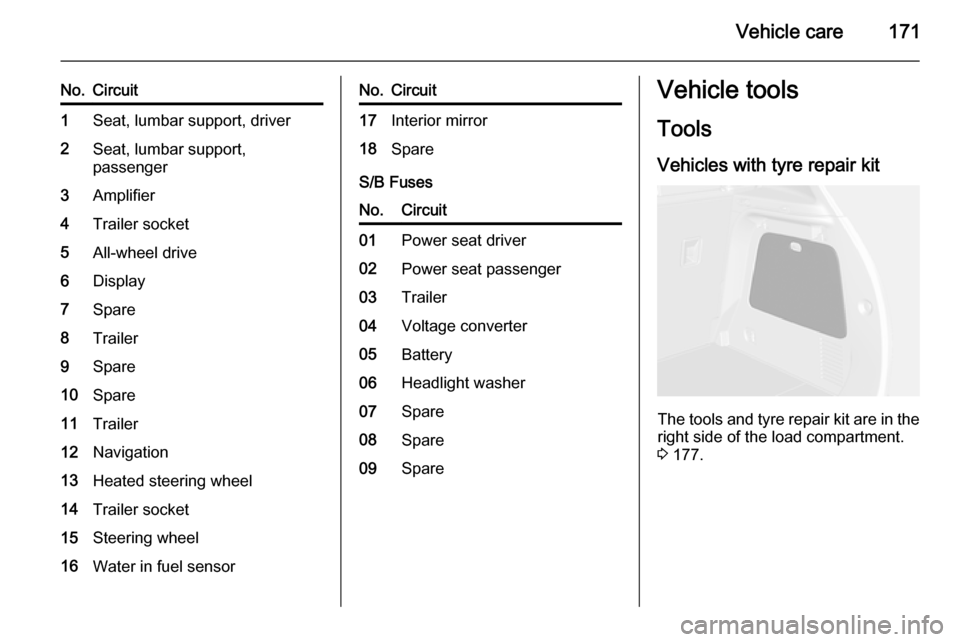

No.Circuit01Power seat driver02Power seat passenger03Trailer04Voltage converter05Battery06Headlight washer07Spare08Spare09SpareVehicle tools

Tools

Vehicles with tyre repair kit

The tools and tyre repair kit are in the

right side of the load compartment.

3 177.

Page 176 of 217

174Vehicle care

When the system detects a

malfunction, w will flash for approx.

one minute and then remain

continuously illuminated. This

sequence will continue upon

subsequent vehicle start-ups as long as the malfunction exists.

When w is illuminated, the system

may not be able to detect or signal low tyre pressure as intended.

Tyre Pressure Monitoring Operation The TPMS is designed to warn the

driver when a low tyre pressure

condition exists. TPMS sensors are mounted onto each tyre and wheel

assembly, excluding the spare tyre

and wheel assembly. The TPMS sensors monitor the air pressure in

the tyres and transmit the tyre

pressure readings to a receiver

located in the vehicle.

When a low tyre pressure condition is

detected, w illuminates. Stop as soon

as possible and inflate the tyres to the

recommended tyre pressure 3 172.

Additionally a warning message or a

warning code is displayed in the

Driver Information Centre 3 93.

The low tyre pressure control

indicator and a warning message or

code come on at each ignition cycle

until the tyres are inflated to the

correct tyre pressure.

TPMS Malfunction Indicator and

Message Code

The TPMS will not function properly if

one or more of the TPMS sensors are missing or inoperable. When the

system detects a malfunction, w

flashes for approx. one minute and then illuminates. Additionally a

warning message or code is

displayed.

The indication by the TPMS

malfunction indicator and a warning

message or code will come on at each ignition cycle until the problem iscorrected. Some of the conditions

that can cause these to come on are:

■ One of the tyres has been replaced

with the spare tyre which does not

have a TPMS sensor.

■ The TPMS sensor matching process was not done or not

completed successfully after

rotating the tyres. The malfunction

light and the warning message or

code should go off after

successfully completing the sensor

Page 177 of 217

Vehicle care175

matching process. See "TPMS

Sensor Matching Process" later in

this section.

■ One or more TPMS sensors are missing or damaged. The warning

message or code and the

malfunction light should go off

when the TPMS sensors are

installed and the sensor matching

process is performed successfully.

Consult your workshop for service.

■ Replacement tyres or wheels do not match the original equipment

tyres or wheels. Tyres and wheels other than those recommended

could prevent the TPMS from

functioning properly.

■ Operating electronic devices or being near facilities using radio

wave frequencies similar to the

TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning

properly, it cannot detect or signal

a low tyre condition. Consult your

workshop for service if the TPMS

malfunction light and a warningmessage or code come on and stay

on.

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/

wheel position after rotating the tyres

or replacing one or more of the TPMS

sensors. The TPMS sensor matching process should also be performed

after replacing a spare tyre with a

road tyre containing the TPMS

sensor.

The malfunction light and the warning

message or code should go off at the

next ignition cycle. The sensors are

matched to the tyre/wheel positions,

using a TPMS relearn tool, in the

following order: driver side front tyre,

passenger side front tyre, passenger

side rear tyre, and driver side rear.

Consult your workshop for service or

to purchase a relearn tool. There are

two minutes to match the first tyre/

wheel position, and five minutes

overall to match all four tyre/wheelpositions. If it takes longer, the

matching process stops and must be

restarted.

The TPMS sensor matching process

is:

1. Apply the parking brake.

2. Turn the ignition on.

3. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Use the thumbwheel to scroll to the tyre pressure menu.

5. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should display.

6. Press the SET/CLR button again

to confirm the selection. The horn

sounds twice to signal the receiver is in relearn mode.

7. Start with the driver side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp

Page 181 of 217

Vehicle care179

6.Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery,

we recommend running the

engine.10. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 205 . When the correct pressure

is obtained, switch off the compressor.If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure

indicator.

Do not run the compressor longer than 10 minutes.