lock VAUXHALL MOKKA 2015.5 Service Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: MOKKA, Model: VAUXHALL MOKKA 2015.5Pages: 229, PDF Size: 6.45 MB

Page 159 of 229

Driving and operating157

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Rear axle load The permissible axle loads (see

identification plate or vehicle

documents) must not be exceeded.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Stowage of coupling ball bar

The bag with the coupling ball bar is

stowed in the rear stowage

compartment on the floor.

Place the strap through the lashing

eye, wrap around twice and tighten

the strap to secure the bag.

Fitting the coupling ball bar

Loosen both locking pins by using a

screwdriver.

Page 160 of 229

158Driving and operating

Remove both locking pins.

Pull cover forwards out of the

brackets and remove.

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

■ Red marking on rotary knob must

point towards green marking on

coupling ball bar.

■ The gap between the rotary knob and the coupling ball bar must beapprox. 6 mm.

■ The key must be in position c.

Otherwise, the coupling ball bar must be tensioned before being inserted:

■ Unlock coupling ball bar by turning key to position c.

■ Pull out rotary knob and turn

clockwise as far as it will go.

Inserting the coupling ball bar

Page 161 of 229

Driving and operating159

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

■ Green marking on rotary knob must

point towards green marking on

coupling ball bar.

■ There must be no gap between the

rotary handle and the coupling ball

bar.

■ The coupling ball bar must be firmly

engaged in the opening.

■ The coupling ball bar must be locked and the key removed.9 Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball

bar

Page 162 of 229

160Driving and operating

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Attach the cover and insert both

locking pins.

Page 164 of 229

162Vehicle care

■ Open the bonnet, close all doorsand lock the vehicle.

■ Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are not functional, e.g. anti-theft alarm

system.

Putting back into operation When the vehicle is to be put back into

operation:

■ Connect the clamp to the negative terminal of the vehicle battery.

Activate the electronics of the

power windows.

■ Check tyre pressure.

■ Fill up the washer fluid reservoir.

■ Check the engine oil level.

■ Check the coolant level.

■ Fit the number plate if necessary.

End-of-life vehicle

recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on ourwebsite, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

Page 173 of 229

Vehicle care171

3. When fitting a new bulb, engagethe lugs in the recesses on the

reflector.

4. Reinstall the headlight assembly. 5. Place headlight protective cover in position and close.

Sidelights

1. Remove the socket from the assembly by turning

anticlockwise.

2. Remove bulb socket from reflector.

3. Detach plug connector from bulb.

4. Remove bulb from socket.

5. Insert new bulb.

6. Plug connector onto bulb.

7. Insert socket in reflector.

8. Reinstall the assembly.

Xenon headlights

9 Danger

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Cornering lights

1. Remove the protective cover.

Page 174 of 229

172Vehicle care

2. Remove the bulb socket bypulling.

3. Remove the bulb from the bulbsocket and replace the bulb.

4. When fitting a new bulb, engage the lugs in the recesses on the

reflector.

5. Reinstall the headlight assembly.

6. Place headlight protective cover in position and close.

Fog lights

Have bulbs replaced by a workshop.

Front turn signal lights

1. Rotate bulb holder anticlockwise and disengage.

2. Push bulb into socket slightly,rotate anticlockwise, remove and

renew bulb.

3. Insert bulb holder in reflector, rotate clockwise to engage.

Tail lights

Left-hand side

1. Remove both covers and unscrew

screws. Remove the panel.

Page 176 of 229

174Vehicle careSide turn signal lights

If the lights do not operate, have themchecked by a workshop.

Centre high-mounted

brake light

If the centre high-mounted brake light does not operate, have it checked by

a workshop.

Number plate light

1. Prise the light out with a screwdriver.

2. Remove bulb housing downwards, taking care not to pull

on the cable.

Rotate bulb holder anticlockwise

to disengage.

3. Remove bulb from holder and renew bulb.

4. Insert bulb holder in bulb housing and rotate clockwise.

5. Insert bulb housing and secure using a screwdriver.

Page 179 of 229

Vehicle care177

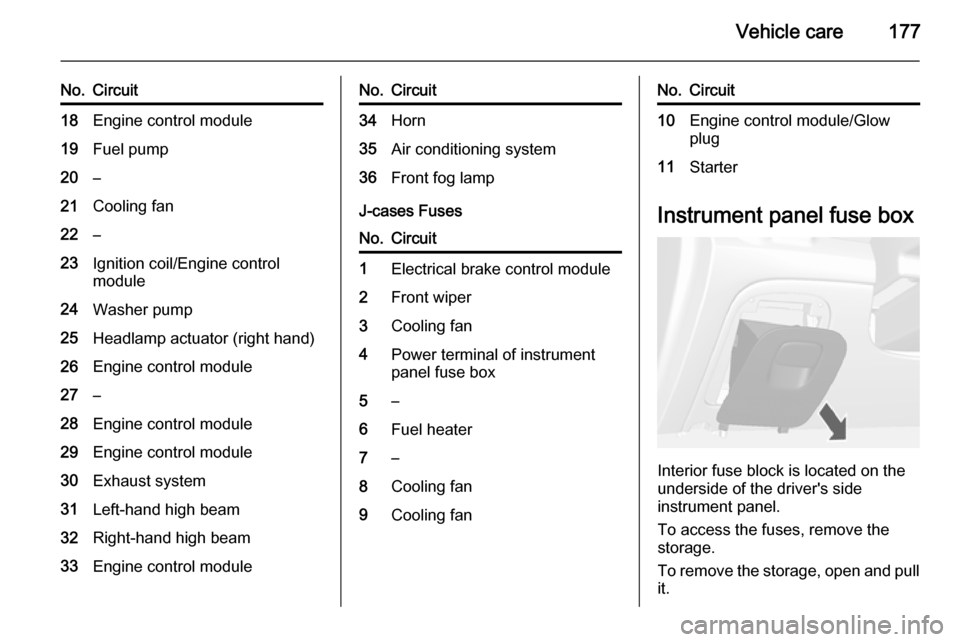

No.Circuit18Engine control module19Fuel pump20–21Cooling fan22–23Ignition coil/Engine control

module24Washer pump25Headlamp actuator (right hand)26Engine control module27–28Engine control module29Engine control module30Exhaust system31Left-hand high beam32Right-hand high beam33Engine control moduleNo.Circuit34Horn35Air conditioning system36Front fog lamp

J-cases Fuses

No.Circuit1Electrical brake control module2Front wiper3Cooling fan4Power terminal of instrument

panel fuse box5–6Fuel heater7–8Cooling fan9Cooling fanNo.Circuit10Engine control module/Glow

plug11Starter

Instrument panel fuse box

Interior fuse block is located on the

underside of the driver's side

instrument panel.

To access the fuses, remove the

storage.

To remove the storage, open and pull it.

Page 189 of 229

Vehicle care187Tyre chains

Use tyre chains only on front wheels.

9Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 195/70 R16.

Always use fine mesh chains suitable

for sport utility vehicles that add no

more than 12 mm to the tyre tread and the inboard sides (including chain

lock).

On tyres of size 215/55 R18, special

snow chains are only permitted when

they are designed with a rotating

chain belt on the tyre tread, no chain

links on the wheel inboard sides and

the chains add no more than 12 mm

to the tyre tread. For further

information regarding correct snow

chain usage for this tyre size, contact a specialized vehicle parts dealer or

snow chain manufacturer.

Tyre chains are not permitted on tyres of size 205/70 R16, 215/65 R16,

215/60 R17 and 225/45 R19.

The use of tyre chains is not permitted

on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

The tyre repair kit is located in the

right side of rear compartment.