tow VAUXHALL MOKKA 2015 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: MOKKA, Model: VAUXHALL MOKKA 2015Pages: 223, PDF Size: 6.2 MB

Page 128 of 223

126Driving and operating

take up to 25 minutes. Typically it

needs between 7 and 12 minutes.

Autostop is not available and fuel

consumption may be higher during

this period. The emission of smells

and smoke during this process is

normal.

Under certain driving conditions, e.g.

short distances, the system cannot

clean itself automatically.

If cleaning of the filter is required and if previous driving conditions did not

enable automatic cleaning, it will be

indicated by control indicator %.

% illuminates when diesel particle

filter is full. Start cleaning process as

soon as possible.

% flashes when diesel particle filter

has reached the maximum filling level. Start cleaning process

immediately to avoid damage to the

engine.

Cleaning process To activate cleaning process,

continue driving, keep engine speed

above 2000 revolutions per minute.

Shift down if necessary. Diesel

particle filter cleaning is then started.

If control indicator g also

illuminates, cleaning is not possible:

seek the assistance of a workshop.Caution

If the cleaning process is

interrupted, there is a risk of

provoking severe engine damage.

Cleaning takes place quickest at high engine speeds and loads.

The control indicator % extinguishes

as soon as the self-cleaning

operation is complete.

Catalytic converter

The catalytic converter reduces the

amount of harmful substances in the

exhaust gases.Caution

Fuel grades other than those listed on pages 3 148, 3 205 could

damage the catalytic converter or

electronic components.

Unburnt petrol will overheat and

damage the catalytic converter.

Therefore avoid excessive use of the starter, running the fuel tank

dry and starting the engine by

pushing or towing.

In the event of misfiring, uneven

engine running, a reduction in engine performance or other unusual

problems, have the cause of the fault

rectified by a workshop as soon as

possible. In an emergency, driving

Page 133 of 223

Driving and operating131Drive systems

All-wheel drive The All-Wheel Drive (AWD) system

enhances driving characteristics and stability, and helps to achieve the best possible driveability regardless of

ground surface. The system is always

active and cannot be deactivated.

The torque is distributed steplessly

between the wheels of the front and rear axle, depending on the driving

conditions. Additionally the torque

between the rear wheels is distributed

depending on the surface.

For optimum system performance,

the vehicle's tyres should not have

varying degrees of wear.

When using a temporary spare

wheel, the AWD system is

automatically disabled.

The AWD system will also be

temporarily disabled to protect the

system from overheating if there is

excessive wheel spin. When the

system cools down, AWD will be

restored.The deactivation of the AWD system

will be indicated by a message on the

Driver Information Centre.

If a service message or warning

code S73 is displayed on the Driver Information Centre, there is a

malfunction in the AWD system. Seek the assistance of a workshop.

Vehicle messages 3 95, Towing the

vehicle 3 191.Brakes

The brake system comprises two

independent brake circuits.

If a brake circuit fails, the vehicle can

still be braked using the other brake

circuit. However, braking effect is

achieved only when the brake pedal

is depressed firmly. Considerably

more force is needed for this. The

braking distance is extended. Seek the assistance of a workshop before

continuing your journey.

When the engine is not running, the

support of the brake servo unit

disappears once the brake pedal has been depressed once or twice.

Braking effect is not reduced, but

braking requires significantly greater

force. It is especially important to bear this in mind when being towed.

Control indicator R 3 85.

Antilock brake system Antilock brake system (ABS)

prevents the wheels from locking.

Page 144 of 223

142Driving and operatingCaution

Performance of the sensor can bereduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

systems can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles involved (e.g.

off-road vehicles, mini vans,

vans). Object identification in the upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross section, like objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist will not avoid a

collision with objects which are out

of the detection range of the

sensors.

Notice

The parking assist system

automatically detects factory-fitted

towing equipment. It is deactivated

when the connector is plugged in.

The sensor may detect a non-

existent object (echo disturbance)

caused by external acoustic or

mechanical disturbances.

Notice

The parking assist is deactivated

when the rear carrier system is

extended.

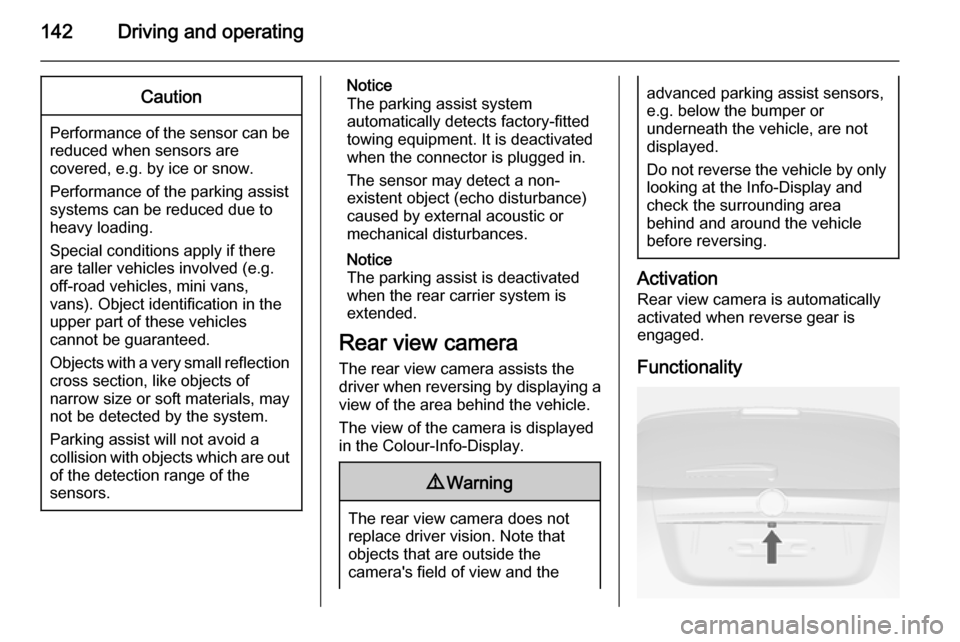

Rear view camera

The rear view camera assists the

driver when reversing by displaying a view of the area behind the vehicle.

The view of the camera is displayed

in the Colour-Info-Display.9 Warning

The rear view camera does not

replace driver vision. Note that

objects that are outside the

camera's field of view and the

advanced parking assist sensors,

e.g. below the bumper or

underneath the vehicle, are not

displayed.

Do not reverse the vehicle by only looking at the Info-Display and

check the surrounding area

behind and around the vehicle

before reversing.

Activation

Rear view camera is automatically

activated when reverse gear is

engaged.

Functionality

Page 146 of 223

144Driving and operating

FaultFault messages are displayed with a9 on the top line of the Info-Display.

The rear view camera may not

operate properly when:

■ the surrounding is dark,

■ the sun or the beam of headlights is

shining directly into the camera

lens,

■ ice, snow, mud, or anything else covers the camera lens. Clean the

lens, rinse it with water, and wipe it

with a soft cloth,

■ the tailgate is not closed correctly,

■ the vehicle had a rear end accident,

■ there are extreme temperature changes.

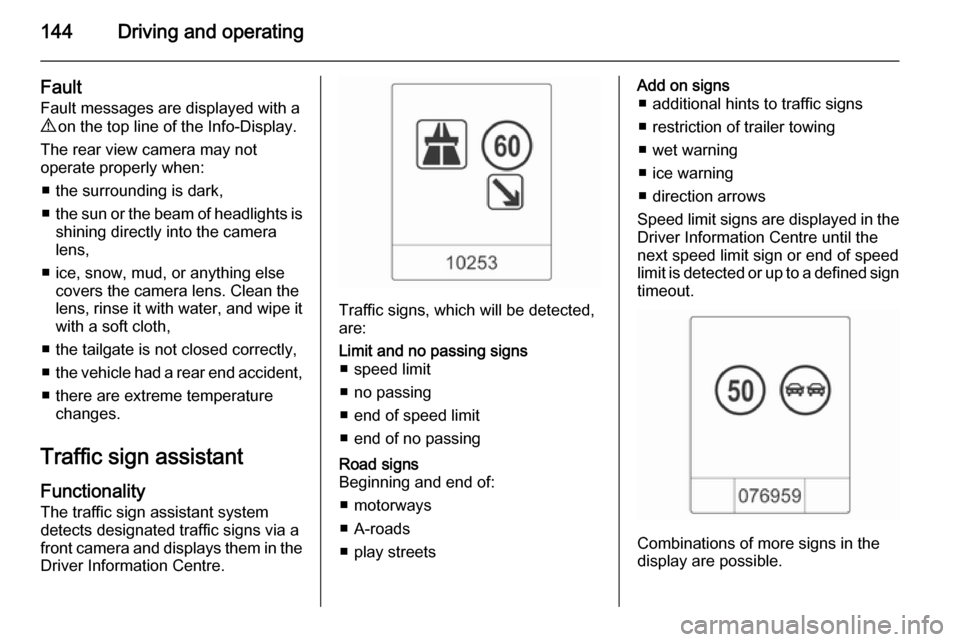

Traffic sign assistant Functionality

The traffic sign assistant system

detects designated traffic signs via a

front camera and displays them in the Driver Information Centre.

Traffic signs, which will be detected,

are:

Limit and no passing signs ■ speed limit

■ no passing

■ end of speed limit

■ end of no passingRoad signs

Beginning and end of:

■ motorways

■ A-roads

■ play streetsAdd on signs ■ additional hints to traffic signs

■ restriction of trailer towing

■ wet warning

■ ice warning

■ direction arrows

Speed limit signs are displayed in the

Driver Information Centre until the

next speed limit sign or end of speed

limit is detected or up to a defined sign timeout.

Combinations of more signs in the

display are possible.

Page 154 of 223

152Driving and operating

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

Page 156 of 223

154Driving and operatingFuel consumption - CO2-

Emissions

The values for fuel consumption

(combined) of the model Vauxhall

Mokka is within a range of 37 to

63 mpg.

The values for CO 2 emission

(combined) is within a range of 158 to 120 g/km.

For the values specific to your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

General information The official fuel consumption and

specific CO 2 emission figures quoted

relate to the EU base model with

standard equipment.

Fuel consumption data and CO 2

emission data are determined

according to regulation

R (EC) No. 715/2007 (in the latest

applicable version), taking intoconsideration the vehicle weight in running order, as specified by the

regulation.

The figures are provided only for the purpose of comparison between different vehicle variants and mustnot be taken as a guarantee for the

actual fuel consumption of a

particular vehicle. Additional

equipment may result in slightly

higher results than the stated

consumption and CO 2 figures.

Furthermore, fuel consumption is

dependent on personal driving style

as well as road and traffic conditions.Trailer hitch

General information Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case, use the coupling ball

bar for towing. Always keep the

coupling ball bar in the vehicle.

Driving characteristics and

towing tips Before attaching a trailer, lubricate

the coupling ball. However, do not do so if a stabiliser, which acts on thecoupling ball, is being used to reduce

snaking movements.

For trailers with low driving stability

and caravan trailers with a permitted

gross vehicle weight of more than

Page 157 of 223

Driving and operating155

1000 kg a speed of 50 mph must not

be exceeded; the use of a stabiliser is recommended.

If the trailer starts snaking, drive more

slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 210.

Trailer towing Trailer loads The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In

general, they are valid for gradients

up to max. 12 %.The permitted trailer loads apply up to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases as altitude increases due to the airbecoming thinner, therefore reducing

climbing ability, the permissible gross train weight also decreases by 10 %

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8 %, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 200.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (75 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Rear axle load The permissible axle loads (see

identification plate or vehicle

documents) must not be exceeded.

Page 158 of 223

156Vehicle careVehicle careGeneral Information...................156

Vehicle checks ........................... 157

Bulb replacement .......................164

Electrical system ........................170

Vehicle tools .............................. 175

Wheels and tyres .......................176

Jump starting ............................. 189

Towing ....................................... 191

Appearance care .......................193General Information

Accessories and vehicle

modifications

We recommend the use of genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

■ Wash and wax the vehicle.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve the rubber seals.

■ Fill up fuel tank completely.

■ Change the engine oil.

■ Drain the washer fluid reservoir.

■ Check the coolant antifreeze and corrosion protection.

■ Adjust tyre pressure to the value specified for full load.

■ Park the vehicle in a dry, well ventilated place. Engage first orreverse gear or set selector lever to P . Prevent the vehicle from rolling.

■ Do not apply the parking brake.

Page 185 of 223

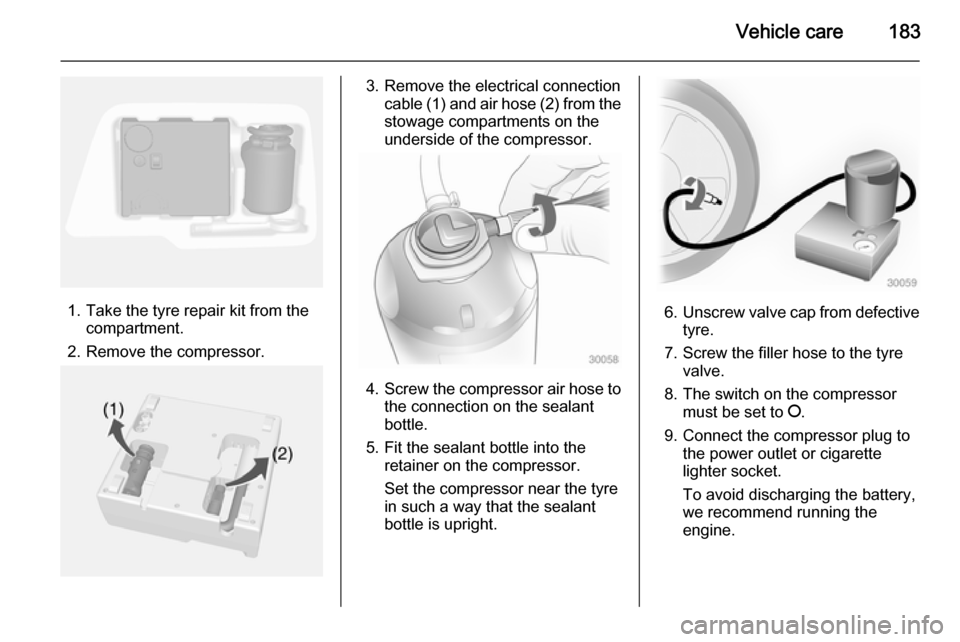

Vehicle care183

1. Take the tyre repair kit from thecompartment.

2. Remove the compressor.

3. Remove the electrical connection cable (1) and air hose (2) from the

stowage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery, we recommend running the

engine.

Page 186 of 223

184Vehicle care

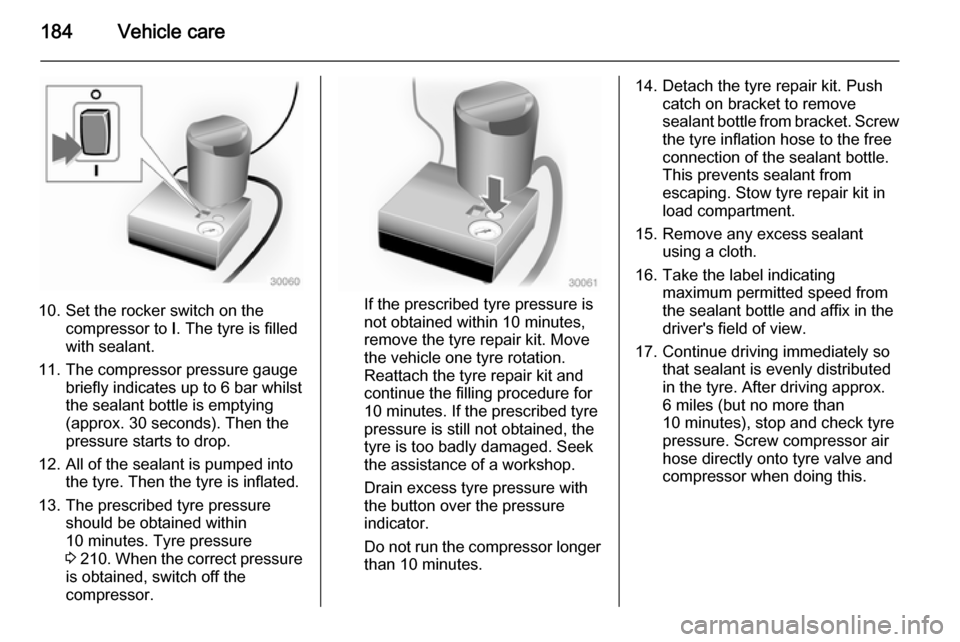

10. Set the rocker switch on thecompressor to I. The tyre is filled

with sealant.

11. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

12. All of the sealant is pumped into the tyre. Then the tyre is inflated.

13. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 210 . When the correct pressure

is obtained, switch off the

compressor.If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for 10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.

Drain excess tyre pressure with

the button over the pressure indicator.

Do not run the compressor longer than 10 minutes.

14. Detach the tyre repair kit. Push catch on bracket to remove

sealant bottle from bracket. Screw

the tyre inflation hose to the free

connection of the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit in

load compartment.

15. Remove any excess sealant using a cloth.

16. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

17. Continue driving immediately so that sealant is evenly distributedin the tyre. After driving approx.

6 miles (but no more than 10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.