Code 89 VAUXHALL MOKKA 2016 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016, Model line: MOKKA, Model: VAUXHALL MOKKA 2016Pages: 231, PDF Size: 6.55 MB

Page 187 of 231

Vehicle care185Tyre designations

E.g. 215/60 R 16 95 H215:tyre width, mm60:cross-section ratio (tyre height

to tyre width), percentageR:belt type: RadialRF:type: RunFlat16:wheel diameter, inches95:load index e.g. 95 is equivalent to 690 kgH:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropiate for the

maximum speed of your verhicle.

The maximum speed is achievable at

kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 214.

Directional tyres

Fit directional tyres such that they roll

in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

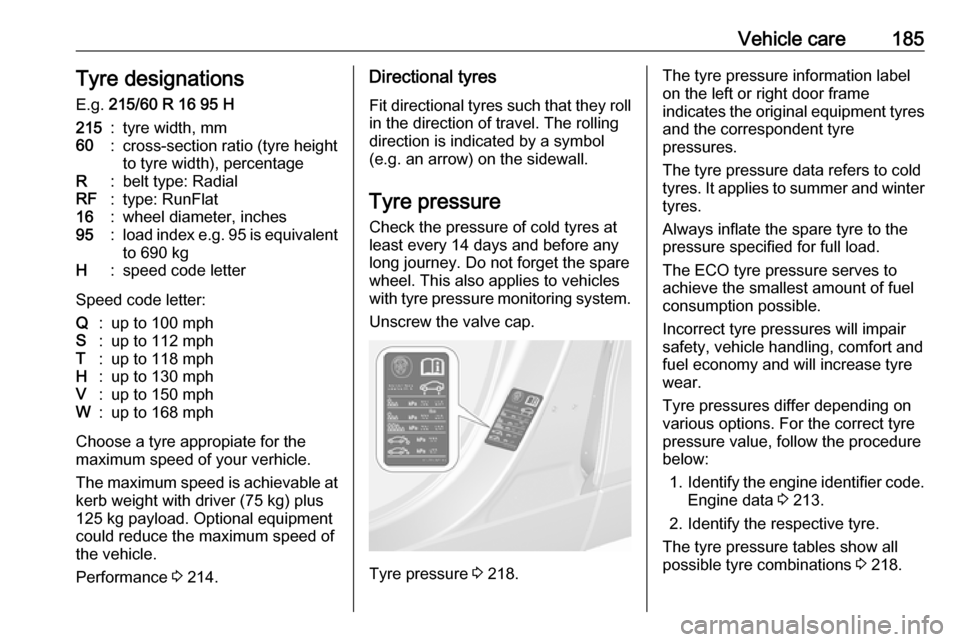

Unscrew the valve cap.

Tyre pressure 3 218.

The tyre pressure information label

on the left or right door frame

indicates the original equipment tyres

and the correspondent tyre

pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 213.

2. Identify the respective tyre.

The tyre pressure tables show all possible tyre combinations 3 218.

Page 190 of 231

188Vehicle careEach time the tyres are replaced, tyrepressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor, replace

valve core and sealing ring. For

clipped sensor, replace complete

valve stem.

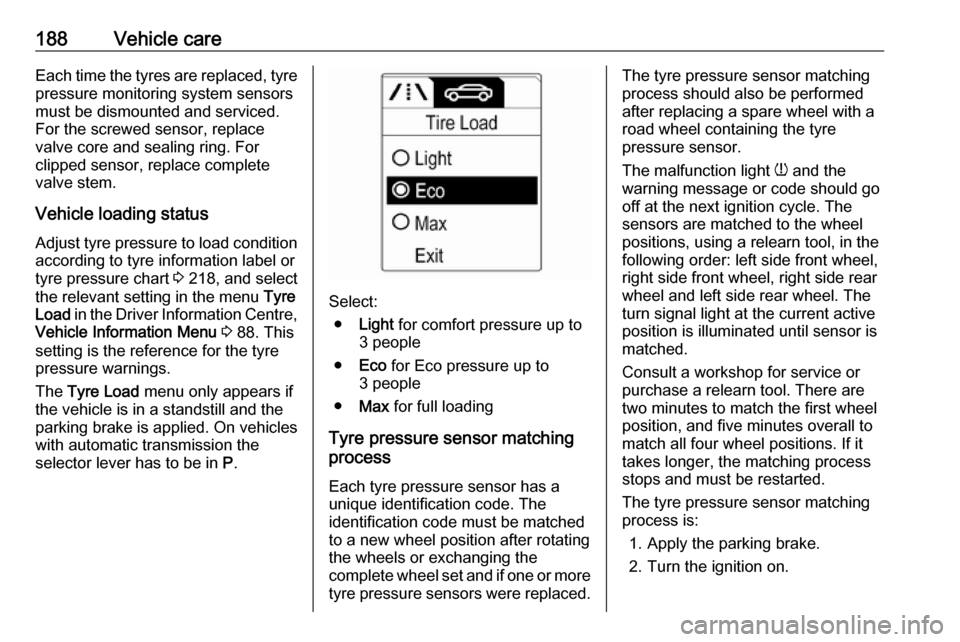

Vehicle loading status

Adjust tyre pressure to load condition according to tyre information label or

tyre pressure chart 3 218, and select

the relevant setting in the menu Tyre

Load in the Driver Information Centre,

Vehicle Information Menu 3 88. This

setting is the reference for the tyre

pressure warnings.

The Tyre Load menu only appears if

the vehicle is in a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Select:

● Light for comfort pressure up to

3 people

● Eco for Eco pressure up to

3 people

● Max for full loading

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating the wheels or exchanging the

complete wheel set and if one or more tyre pressure sensors were replaced.

The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing the tyre

pressure sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a relearn tool, in the following order: left side front wheel,

right side front wheel, right side rear

wheel and left side rear wheel. The

turn signal light at the current active

position is illuminated until sensor is

matched.

Consult a workshop for service or

purchase a relearn tool. There are

two minutes to match the first wheel

position, and five minutes overall to

match all four wheel positions. If it

takes longer, the matching process stops and must be restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

Page 191 of 231

Vehicle care1893. On vehicles with automatictransmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Press MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should display.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to signal the receiver is in

relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this tyre and wheel

position.10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate the sensor

identification code has been

matched to the driver side rear

wheel, and the tyre pressure

sensor matching process is no

longer active.

13. Turn off the ignition.

14. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

information label.

15. Ensure the tyre loading status is set according selected pressure

3 88.

Tread depth

Check tread depth at regular

intervals.Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Page 211 of 231

Technical data209Information on identification label:1:manufacturer2:type approval number3:vehicle Identification Number4:permissible gross vehicle weightrating in kg5:permissible gross train weight

in kg6:maximum permissible front axle

load in kg7:maximum permissible rear axle

load in kg

Engine identification

The technical data tables show the

engine identifier code. Engine data

3 213.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.

The Certificate of Conformity shows

the engine identifier code, other

national publications may show the

engineering code. Check piston

displacement and engine power to identify the respective engine.

Page 215 of 231

![VAUXHALL MOKKA 2016 User Guide Technical data213Engine dataEngine identifier codeA14NETB14NETA16XERA18XERB16DTHSales designation1.41.4 LPG1.61.81.6Engineering codeA14NETB14NETA16XERA18XERB16DTHPiston displacement [cm3

]136413641598 VAUXHALL MOKKA 2016 User Guide Technical data213Engine dataEngine identifier codeA14NETB14NETA16XERA18XERB16DTHSales designation1.41.4 LPG1.61.81.6Engineering codeA14NETB14NETA16XERA18XERB16DTHPiston displacement [cm3

]136413641598](/img/38/19532/w960_19532-214.png)

Technical data213Engine dataEngine identifier codeA14NETB14NETA16XERA18XERB16DTHSales designation1.41.4 LPG1.61.81.6Engineering codeA14NETB14NETA16XERA18XERB16DTHPiston displacement [cm3

]13641364159817961598Engine power [kW]10310385103100at rpm4900-60004900-6000620062003500-4000Torque [Nm]200200155178320at rpm1850-49001850-4900400038002000-2250Fuel typePetrolLiquid Gas/PetrolPetrolPetrolDieselOctane rating RONrecommended95959595possible98989898possible91919191Gas–LPG–––

Page 224 of 231

222Customer informationThis software is provided “as is,”

without warranty of any kind, express

or implied. In no event shall Info-ZIP

or its contributors be held liable for

any direct, indirect, incidental, special

or consequential damages arising out of the use of or inability to use this

software.

Permission is granted to anyone to

use this software for any purpose,

including commercial applications,

and to alter it and redistribute it freely,

subject to the following restrictions:

1. Redistributions of source code must retain the above copyright

notice, definition, disclaimer, and

this list of conditions.

2. Redistributions in binary form (compiled executables) must

reproduce the above copyright

notice, definition, disclaimer, and

this list of conditions in

documentation and/or other

materials provided with the distribution. The sole exception to

this condition is redistribution of a

standard UnZipSFX binary

(including SFXWiz) as part of a

self-extracting archive; that ispermitted without inclusion of this

license, as long as the normal

SFX banner has not been

removed from the binary or

disabled.

3. Altered versions--including, but not limited to, ports to new

operating systems, existing ports

with new graphical interfaces, and dynamic, shared, or static library

versions--must be plainly marked

as such and must not be

misrepresented as being the

original source. Such altered

versions also must not be

misrepresented as being Info-ZIP

releases--including, but not

limited to, labeling of the altered

versions with the names “Info-

ZIP” (or any variation thereof,

including, but not limited to,

different capitalizations), “Pocket

UnZip,” “WiZ” or “MacZip” without

the explicit permission of Info-ZIP. Such altered versions are further

prohibited from misrepresentativeuse of the Zip-Bugs or Info-ZIP e- mail addresses or of the Info-ZIP

URL(s).

4. Info-ZIP retains the right to use the names “Info-ZIP,” “Zip,”

“UnZip,” “UnZipSFX,” “WiZ,”

“Pocket UnZip,” “Pocket Zip,” and

“MacZip” for its own source and

binary releases.

Page 226 of 231

224IndexAAccessories and vehicle modifications .......................... 164

Adaptive forward lighting .....87, 110

Adjustable air vents ...................122

Airbag and belt tensioners ...........83

Airbag deactivation ................47, 83

Airbag label................................... 42 Airbag system .............................. 42

Air conditioning regular operation ................................ 123

Air conditioning system .............. 118

Air intake .................................... 122

Air vents...................................... 122

All-wheel drive ........................... 135

Antilock brake system ................ 136

Antilock brake system (ABS) .......84

Anti-theft alarm system ................25

Anti-theft locking system .............. 25

Appearance care ........................202

Automatic anti-dazzle ..................29

Automatic light control ...............108

Automatic locking ........................23

Automatic transmission .............131

Auxiliary heater ........................... 121

B Battery discharge protection ......116

Battery voltage ............................. 95 Bicycle rack .................................. 56Bonnet ....................................... 165

Bonnet open ................................. 88

Brake and clutch fluid .................206

Brake and clutch system .............84

Brake assist ............................... 137

Brake fluid .................................. 169

Brakes ............................... 136, 169

Breakdown.................................. 200

Bulb replacement ....................... 172

C

Capacities .................................. 217

Catalytic converter .....................131

Central locking system ................21

Centre console storage ...............56

Centre high-mounted brake light 177

Changing tyre and wheel size ...190

Charging system .......................... 84

Child locks ................................... 24

Child restraint installation locations ................................... 49

Child restraints.............................. 48

Child restraint systems ................48

Climate control ............................. 15

Climate control systems .............117

Clock ............................................ 75

Code ............................................. 94

Collision damage repair ..............221

Control indicators.......................... 80

Control of the vehicle .................125