display VAUXHALL MOKKA X 2018.5 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018.5, Model line: MOKKA X, Model: VAUXHALL MOKKA X 2018.5Pages: 255, PDF Size: 7.01 MB

Page 198 of 255

196Vehicle careNo.Circuit29Info Display / Infotainment

system30Transmission control module31Instrument panel cluster32Infotainment system33Trailer socket34Passive entry / Passive start

module

S/B Fuses

No.Circuit01Power seat switch02Spare03Power windows front04Power windows rear05Logistic mode06Power seat switchNo.Circuit07Spare08Spare

Midi Fuse

No.CircuitM01PTC

Load compartment fuse box

Located in the left side of rear

compartment.

To access the fuses, remove the cover.

Page 202 of 255

200Vehicle careThe driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down

tyre will show a decreased value,

which does not indicate an air leak.

Tyre pressure monitoringsystem

The tyre pressure monitoring system

checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The current tyre pressures can be

shown in the Driver Information

Centre.

Midlevel display:

Select the Tyre pressure page under

the Vehicle Information Menu ? in

the Driver Information Centre 3 95.

Page 203 of 255

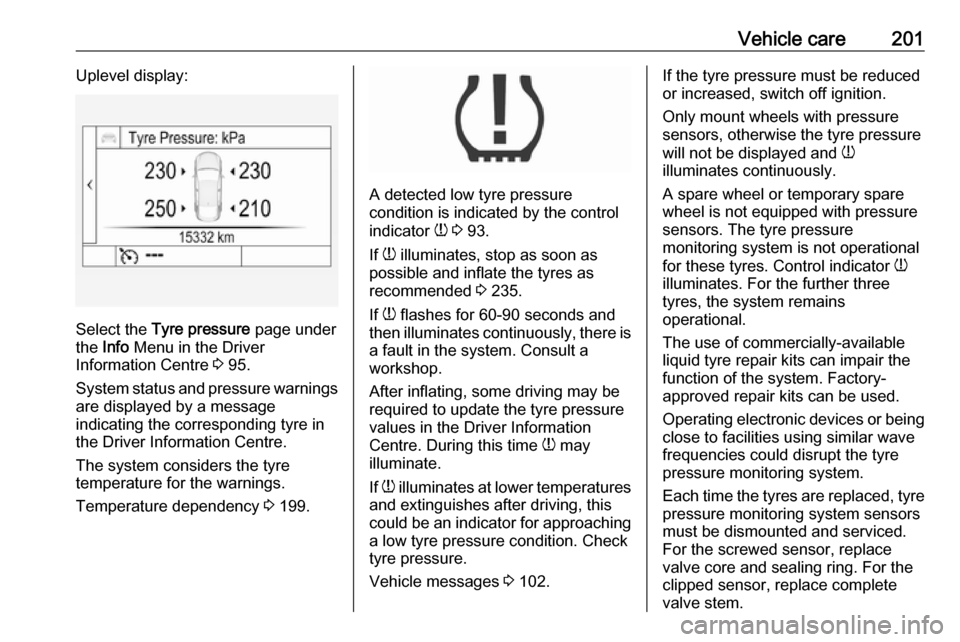

Vehicle care201Uplevel display:

Select the Tyre pressure page under

the Info Menu in the Driver

Information Centre 3 95.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 199.

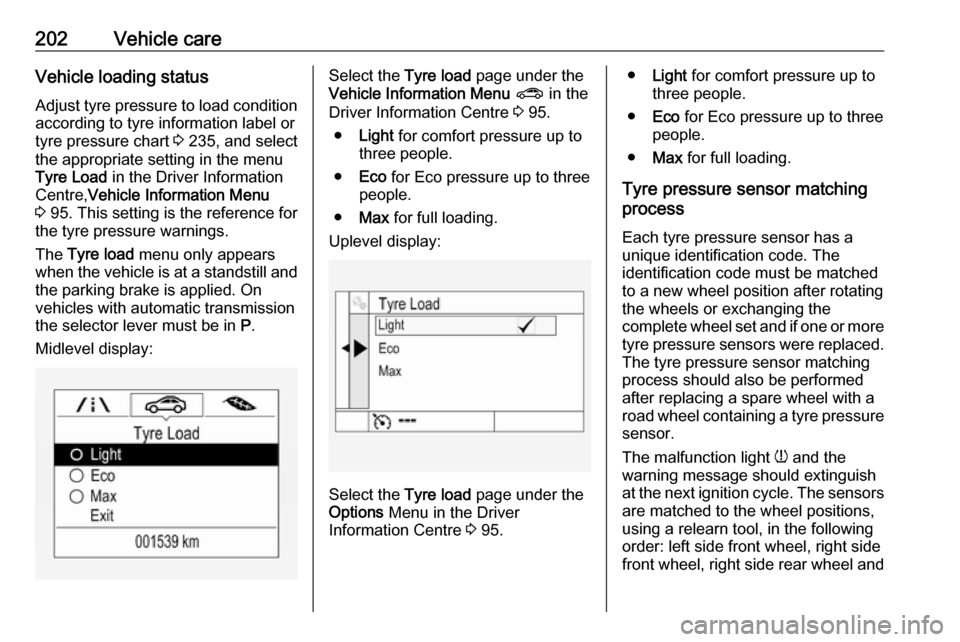

A detected low tyre pressure

condition is indicated by the control

indicator w 3 93.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 235.

If w flashes for 60-90 seconds and

then illuminates continuously, there is a fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching

a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 102.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.

The use of commercially-available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor, replace

valve core and sealing ring. For the

clipped sensor, replace complete

valve stem.

Page 204 of 255

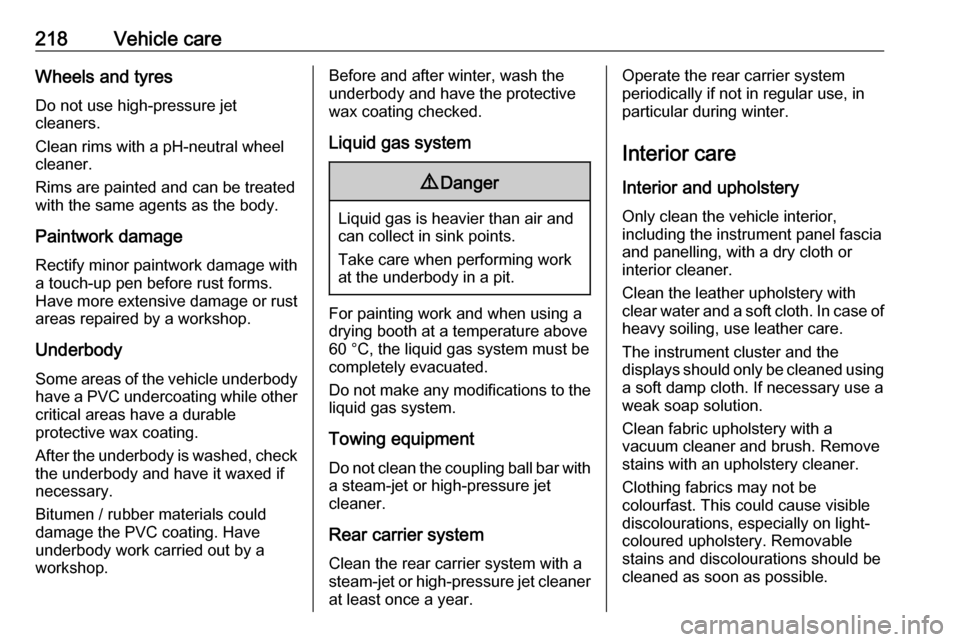

202Vehicle careVehicle loading status

Adjust tyre pressure to load condition according to tyre information label or

tyre pressure chart 3 235, and select

the appropriate setting in the menu

Tyre Load in the Driver Information

Centre, Vehicle Information Menu

3 95. This setting is the reference for

the tyre pressure warnings.

The Tyre load menu only appears

when the vehicle is at a standstill and the parking brake is applied. On

vehicles with automatic transmission

the selector lever must be in P.

Midlevel display:Select the Tyre load page under the

Vehicle Information Menu ? in the

Driver Information Centre 3 95.

● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Uplevel display:

Select the Tyre load page under the

Options Menu in the Driver

Information Centre 3 95.

● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Tyre pressure sensor matching process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating

the wheels or exchanging the

complete wheel set and if one or more tyre pressure sensors were replaced.

The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure sensor.

The malfunction light w and the

warning message should extinguish

at the next ignition cycle. The sensors

are matched to the wheel positions,

using a relearn tool, in the following

order: left side front wheel, right side

front wheel, right side rear wheel and

Page 205 of 255

Vehicle care203left side rear wheel. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult a workshop for service. There

are two minutes to match the first

wheel position, and five minutes

overall to match all four wheel

positions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Press MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Midlevel display:

Uplevel display:

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to signal that the receiver is

in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this tyre and wheel

position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate the sensor

Page 220 of 255

218Vehicle careWheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damageRectify minor paintwork damage witha touch-up pen before rust forms.

Have more extensive damage or rust

areas repaired by a workshop.

Underbody Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check the underbody and have it waxed if

necessary.

Bitumen / rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.Before and after winter, wash the

underbody and have the protective

wax coating checked.

Liquid gas system9 Danger

Liquid gas is heavier than air and

can collect in sink points.

Take care when performing work

at the underbody in a pit.

For painting work and when using a

drying booth at a temperature above

60 °C, the liquid gas system must be

completely evacuated.

Do not make any modifications to the

liquid gas system.

Towing equipment

Do not clean the coupling ball bar with a steam-jet or high-pressure jet

cleaner.

Rear carrier system Clean the rear carrier system with a

steam-jet or high-pressure jet cleaner

at least once a year.

Operate the rear carrier system

periodically if not in regular use, in

particular during winter.

Interior care

Interior and upholstery Only clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean the leather upholstery with

clear water and a soft cloth. In case of

heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.

Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light- coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Page 222 of 255

220Service and maintenanceService and

maintenanceGeneral information ...................220

Service information ..................220

Recommended fluids, lubricants

and parts .................................... 221

Recommended fluids and lubricants ................................ 221General information

Service information In order to ensure economical and

safe vehicle operation and to

maintain the value of your vehicle, it

is of vital importance that all

maintenance work is carried out at the proper intervals as specified.

The detailed, up-to-date service

schedule for your vehicle is available

at the workshop.

Service display 3 85.

European service intervals

Maintenance of your vehicle is

required every 20,000 miles or after

one year, whichever occurs first, unless otherwise indicated in theservice display.

A shorter service interval can be valid for severe driving behaviour, e.g. for

taxis and police vehicles.

The European service intervals are

valid for the following countries:Andorra, Austria, Belgium, Bosnia-

Herzegovina, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany,

Greece, Greenland, Hungary,

Iceland, Ireland, Italy, Latvia,

Liechtenstein, Lithuania,

Luxembourg, Macedonia, Malta,

Monaco, Montenegro, Netherlands,

Norway, Poland, Portugal, Romania, San Marino, Serbia, Slovakia,

Slovenia, Spain, Sweden,

Switzerland, United Kingdom.

Service display 3 85.

International service intervals

Maintenance of your vehicle is

required every 10,000 miles or after

one year, whichever occurs first,

unless otherwise indicated in the

service display.

Severe operating conditions exist if one or more of the following

circumstances occur frequently: Cold starting, stop and go operation, trailer

operation, mountain driving, driving

on poor and sandy road surfaces,

increased air pollution, presence of

airborne sand and high dust content,

Page 223 of 255

Service and maintenance221driving at high altitude and large

variations of temperature. Under

these severe operating conditions, certain service work may be required

more frequently than the regular service interval.

The international service intervals are

valid for the countries which are not

listed in the European service

intervals.

Service display 3 85.

Confirmations

Confirmation of service is recorded in the Service and warranty booklet.

The date and mileage is completed

with the stamp and signature of the

servicing workshop.

Make sure that the Service and

warranty booklet is completed

correctly as continuous proof of

service is essential if any warranty or

goodwill claims are to be met, and is

also a benefit when selling the

vehicle.Service interval with remaining

engine oil life duration

The service interval is based on

several parameters depending on

usage.

The service display lets you know when to change the engine oil.

Service display 3 85.Recommended fluids,

lubricants and parts

Recommended fluids andlubricants

Only use products that meet the

recommended specifications.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Page 245 of 255

Customer information243EnGIS Technologies, Inc.

BringGo ®

is a registered trademark of

EnGIS Technologies, Inc.Google Inc.

Android™ and Google Play™ Store

are trademarks of Google Inc.Stitcher Inc.

Stitcher™ is a trademark of Stitcher,

Inc.Verband der Automobilindustrie e.V.

AdBlue ®

is a registered trademark of

the VDA.Vehicle data recording

and privacy

Event data recorders

Electronic control units are installed in

your vehicle. Control units process

data which is received by vehicle

sensors, for example, or which they

generate themselves or exchange

amongst themselves. Some control

units are necessary for the safe

functioning of your vehicle, others

assist you while you drive (driver

assistance systems), while others

provide comfort or infotainment

functions.

Operating data in the vehicle Control units process data for

operation of the vehicle.This data includes, for example:

● Vehicle status information (e.g. wheel rotation rate, speed,

movement delay, lateral

acceleration, "seatbelts

fastened" display),

● Ambient conditions (e.g. temperature, rain sensor,

distance sensor).

Most of this data is volatile and is

processed only in the vehicle itself,

and not beyond the operating time.

Moreover, many control units include

data storage device (amongst others the vehicle key). This is used to allow

information to be documented

temporarily or permanently on vehicle

condition, component stress,

maintenance requirements and

technical events and errors.

The following information, for

example, is stored:

● System component operating states (e.g. fill level, tyre

pressure, battery status),

● State of charge of the high voltage battery, estimated range(in the case of electric vehicles),

Page 252 of 255

250Head restraint adjustment .............8

Head restraints ............................ 37

Heated mirrors ............................. 32

Heated rear window ..................... 35

Heated steering wheel .................75

Heating ........................................ 41

Heating and ventilation system . 125

High beam ........................... 94, 115

High beam assist ..................94, 116

Hill start assist ........................... 151

Horn ....................................... 13, 76

I

Identification plate .....................224

Ignition switch positions .............134

Immobiliser ............................ 30, 94

Indicators ...................................... 82

Info Display ................................... 99

Information displays...................... 95

Initial drive information.................... 6

Instrument panel fuse box .........194

Instrument panel illumination control .................................... 122

Instrument panel overview ........... 10

Interior care ............................... 218

Interior lighting ............................ 122

Interior lights .............................. 122

Interior mirrors .............................. 32

Interruption of power supply ......147

Introduction .................................... 3J

Jump starting ............................. 212

K Key, memorised settings ..............22

Keys ............................................. 19

Keys, locks ................................... 19

L Lane departure warning .......92, 167

Lashing eyes ............................... 71

Lighting features .........................123

Light switch ................................ 114

Load compartment ................28, 69

Load compartment cover .............70

Load compartment fuse box ......196

Loading information .....................72

Low fuel ....................................... 93

LPG .............................. 84, 170, 226

M Malfunction indicator light ............91

Manual anti-dazzle ......................32

Manual mode ............................. 146

Manual transmission .................. 148

Manual windows ..........................33

Memorised settings ......................22

Midlevel display ............................ 95

Mirror adjustment ........................... 8 Misted light covers .....................122N

New vehicle running-in ..............133

Number plate light .....................191

O Object detection systems ...........160

Odometer ..................................... 82

Oil, engine .......................... 221, 226

OnStar ........................................ 108

Outside temperature ....................78

Overrun cut-off ........................... 137

P Parking ................................ 18, 139

Parking assist ............................ 160

Parking brake ............................ 150

Particulate filter ........................... 141

Performance .............................. 231

Performing work ........................181

Pollen filter ................................. 130

Power button .............................. 134

Power outlets ............................... 81

Power steering fluid ....................183

Power windows ............................ 33

Preheating ................................... 93

Puncture ..................................... 208

R Radio Frequency Identification (RFID) ..................................... 246

Radio remote control ...................20