sensor VAUXHALL MOKKA X 2018 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: MOKKA X, Model: VAUXHALL MOKKA X 2018Pages: 249, PDF Size: 6.83 MB

Page 193 of 249

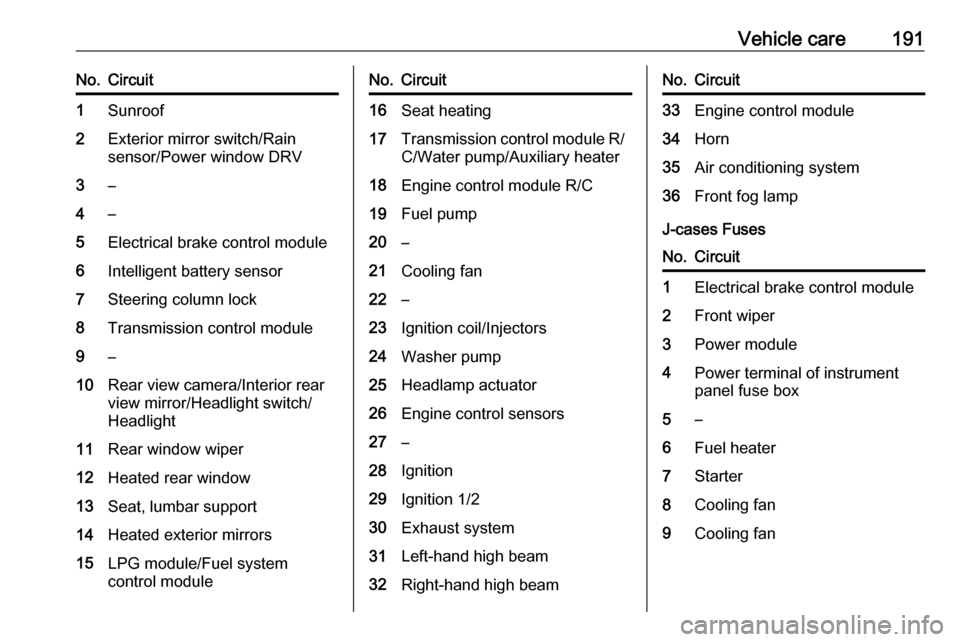

Vehicle care191No.Circuit1Sunroof2Exterior mirror switch/Rain

sensor/Power window DRV3–4–5Electrical brake control module6Intelligent battery sensor7Steering column lock8Transmission control module9–10Rear view camera/Interior rear

view mirror/Headlight switch/

Headlight11Rear window wiper12Heated rear window13Seat, lumbar support14Heated exterior mirrors15LPG module/Fuel system

control moduleNo.Circuit16Seat heating17Transmission control module R/ C/Water pump/Auxiliary heater18Engine control module R/C19Fuel pump20–21Cooling fan22–23Ignition coil/Injectors24Washer pump25Headlamp actuator26Engine control sensors27–28Ignition29Ignition 1/230Exhaust system31Left-hand high beam32Right-hand high beamNo.Circuit33Engine control module34Horn35Air conditioning system36Front fog lamp

J-cases Fuses

No.Circuit1Electrical brake control module2Front wiper3Power module4Power terminal of instrument

panel fuse box5–6Fuel heater7Starter8Cooling fan9Cooling fan

Page 199 of 249

Vehicle care197Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 226.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 232.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down

tyre will show a decreased value,

which does not indicate an air leak.

Tyre pressure monitoringsystem

The tyre pressure monitoring system

checks the pressure of all four tyres

once a minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Page 200 of 249

198Vehicle careNotice

In countries where the tyre pressure monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The current tyre pressures can be

shown in the Driver Information

Centre.

Midlevel display:

Select the Tyre pressure page under

the Vehicle Information Menu ? in

the Driver Information Centre 3 97.

Uplevel display:

Select the Tyre pressure page under

the Info Menu in the Driver

Information Centre 3 97.

System status and pressure warnings

are displayed by a message

indicating the corresponding tyre in

the Driver Information Centre.

The system considers the tyre

temperature for the warnings.

Temperature dependency 3 196.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 95.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 232.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, some driving may be

required to update the tyre pressure

values in the Driver Information

Centre. During this time w may

illuminate.

If w illuminates at lower temperatures

and extinguishes after driving, this

could be an indicator for approaching a low tyre pressure condition. Check

tyre pressure.

Vehicle messages 3 103.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

Page 201 of 249

Vehicle care199A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these tyres. Control indicator w

illuminates. For the further three

tyres, the system remains

operational.

The use of commercially-available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

Operating electronic devices or being

close to facilities using similar wave

frequencies could disrupt the tyre

pressure monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor, replace

valve core and sealing ring. For the

clipped sensor, replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition

according to tyre information label or

tyre pressure chart 3 232, and select

the appropriate setting in themenu Tyre Load in the Driver

Information Centre, Vehicle

Information Menu 3 97 . This setting is

the reference for the tyre pressure

warnings.

The Tyre load menu only appears

when the vehicle is at a standstill and the parking brake is applied. On

vehicles with automatic transmission

the selector lever must be in P.

Midlevel display:

Select the Tyre load page under the

Vehicle Information Menu ? in the

Driver Information Centre 3 97.

● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Uplevel display:

Select the Tyre load page under the

Options Menu in the Driver

Information Centre 3 97.

● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Page 202 of 249

200Vehicle careTyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating the wheels or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced. The tyre pressure sensor matching

process should also be performed

after replacing a spare wheel with a

road wheel containing a tyre pressure sensor.

The malfunction light w and the

warning message should extinguish at the next ignition cycle. The sensors

are matched to the wheel positions,

using a relearn tool, in the following

order: left side front wheel, right side

front wheel, right side rear wheel and

left side rear wheel. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult a workshop for service. There

are two minutes to match the first

wheel position, and five minutes

overall to match all four wheelpositions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with automatic transmission: set the selector

lever to P.

On vehicles with manual

transmission: select neutral.

4. Press MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

Midlevel display:

Uplevel display:

Page 203 of 249

Vehicle care2016. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to signal that the receiver is

in relearn mode.

8. Start with the left side front wheel.

9. Place the relearn tool against the tyre sidewall, near the valve stem.

Then press the button to activate

the tyre pressure sensor. A horn

chirp confirms that the sensor

identification code has been

matched to this tyre and wheel

position.

10. Proceed to the right side front wheel, and repeat the procedure

in Step 9.

11. Proceed to the right side rear wheel, and repeat the procedure

in Step 9.

12. Proceed to the left side rear wheel, and repeat the procedure

in Step 9. The horn sounds twice

to indicate the sensoridentification code has been

matched to the left side rear

wheel, and the tyre pressure

sensor matching process is no

longer active.

13. Turn off the ignition.

14. Set all four tyres to the recommended air pressure level

as indicated on the tyre pressure

information label.

15. Ensure the tyre loading status is set according to the selected tyre

pressure 3 97.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels. Ensure that the direction

of rotation of the wheels is the same

as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Page 237 of 249

Customer information23542367 Wuppertal, GermanyOperation

frequency (MHz)Maximum output

(mW)2400 - 2480102400 - 248020

Antenna module

Laird

8100 Industrial Park Drive, Grand

Blanc, MI, 48439, USA

Operation frequency: N/A

Maximum output: N/A

OnStar module

LG Electronics European Shared

Service Center B.V.

Krijgsman 1, 1186 DM Amstelveen,

The Netherlands

Operation

frequency (MHz)Maximum output

(dBm)2402 - 248042412 - 246218880 - 915331710 - 1785241850 - 1910241920 - 1980242500 - 257023

Electronic key module

Denso Coperation

Waldeckerstraße 11, 64546

Mörfelden-Walldorf, Germany

Operation frequency: 125 kHz

Maximum output: -0.14 dBm

Electronic key

Denso Coperation

Waldeckerstraße 11, 64546

Mörfelden-Walldorf, Germany

Operation frequency: 433.92 MHz

Maximum output: -5.88 dBm

Radio remote control transmitter

Continental Automotive GmbH

Siemensstraße 12, 93055

Regensburg, Germany

Operation frequency: 433.92 MHz

Maximum output: -5.7 dBm

Radio remote control transmitter

Robert Bosch GmbH

Robert Bosch Platz 1, 70839

Gerlingen, Germany

Operation frequency: 433.92 MHz

Maximum output: -4 dbm

Radio remote control receiver

Robert Bosch GmbH

Robert Bosch Platz 1, 70839

Gerlingen, Germany

Operation frequency: 433.92 MHz

Maximum output: N/A

Tyre pressure sensors

Schrader Electronics Ltd.

11 Technology Park, Belfast Road,

Antrim BT41 1QS, Northern Ireland,

United Kingdom

Operation frequency: 433.92 MHz

Maximum output: 10 mW

Parking heater remote control

receiver

Eberspaecher Climate Control

Systemse GmbH & Co. KG