ECU VAUXHALL MOVANO_B 2014 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2014Pages: 201, PDF Size: 4.74 MB

Page 144 of 201

142Vehicle care

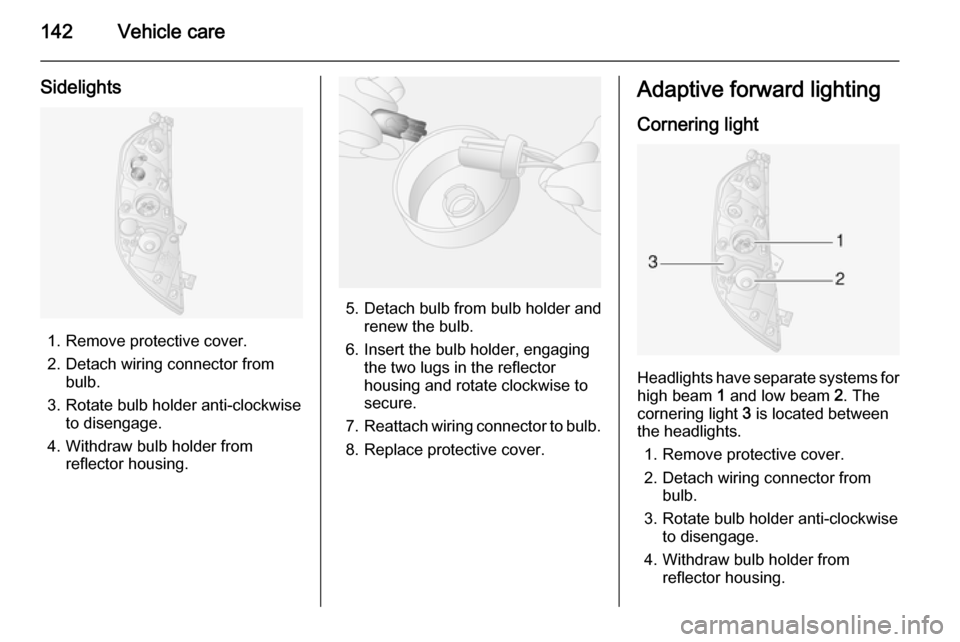

Sidelights

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

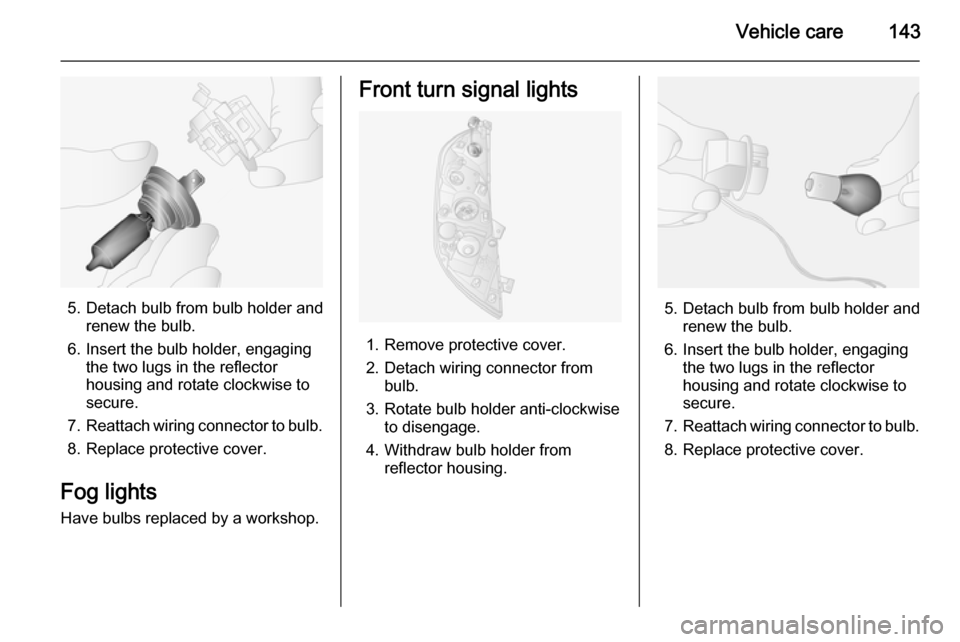

Adaptive forward lighting

Cornering light

Headlights have separate systems forhigh beam 1 and low beam 2. The

cornering light 3 is located between

the headlights.

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 145 of 201

Vehicle care143

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

Fog lights Have bulbs replaced by a workshop.

Front turn signal lights

1. Remove protective cover.

2. Detach wiring connector from bulb.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Reattach wiring connector to bulb.

8. Replace protective cover.

Page 147 of 201

Vehicle care145Side turn signal lights1. Push the lamp assembly to the right and pull at the left-hand sideof the lamp assembly to release

from the aperture.

2. Detach wiring connector from lamp assembly.

3. Remove bulb holder from lamp assembly by rotating 90° and

renew bulb.

4. Install bulb holder in lamp assembly.

5. Reattach wiring connector.

6. Install lamp assembly into aperture and push to the left to

secure.

Mirror turn signal lights 1. Move the lower mirror assembly from the front to access the screw.

2. Remove the screw using a torx screwdriver.

3. Remove bulb holder from the rear

of the lower mirror assembly.

4. Renew bulb.

5. Replace bulb holder.

6. Replace the screw.

Centre high-mounted

brake light

1. Remove cover from the inside of the rear door.

2. Unscrew the nut from the locating

pin at the rear of the lamp

assembly.

Page 159 of 201

Vehicle care157

not be driven. Seek theassistance of a workshop.

20. Stow tyre repair kit under the front

seat.

Notice

The driving characteristics of the repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatabledinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

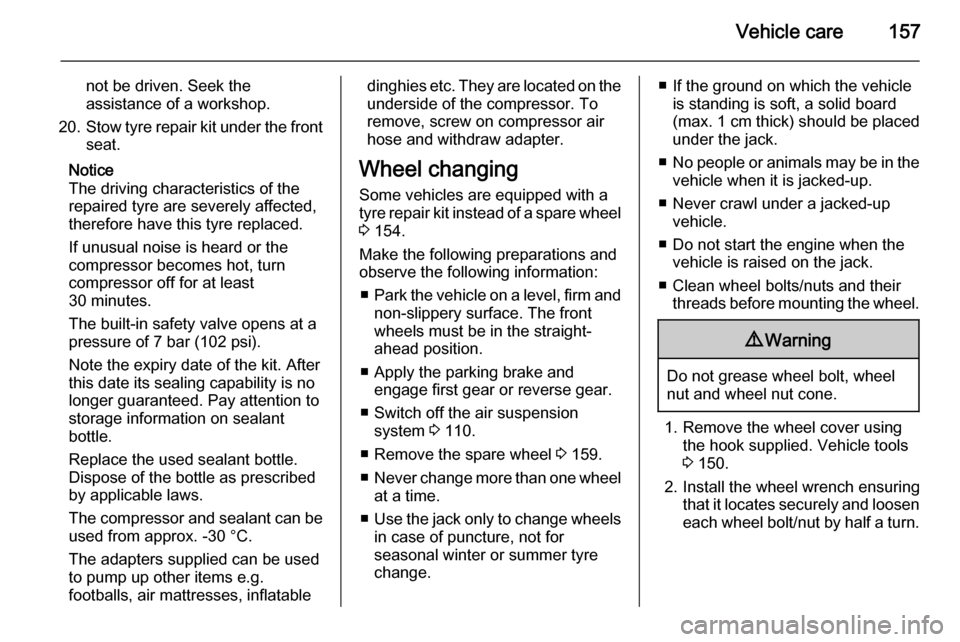

Wheel changing Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 154.

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-slippery surface. The frontwheels must be in the straight-ahead position.

■ Apply the parking brake and engage first gear or reverse gear.

■ Switch off the air suspension system 3 110.

■ Remove the spare wheel 3 159.

■ Never change more than one wheel

at a time.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the engine when the vehicle is raised on the jack.

■ Clean wheel bolts/nuts and their threads before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover using the hook supplied. Vehicle tools

3 150.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt/nut by half a turn.

Page 160 of 201

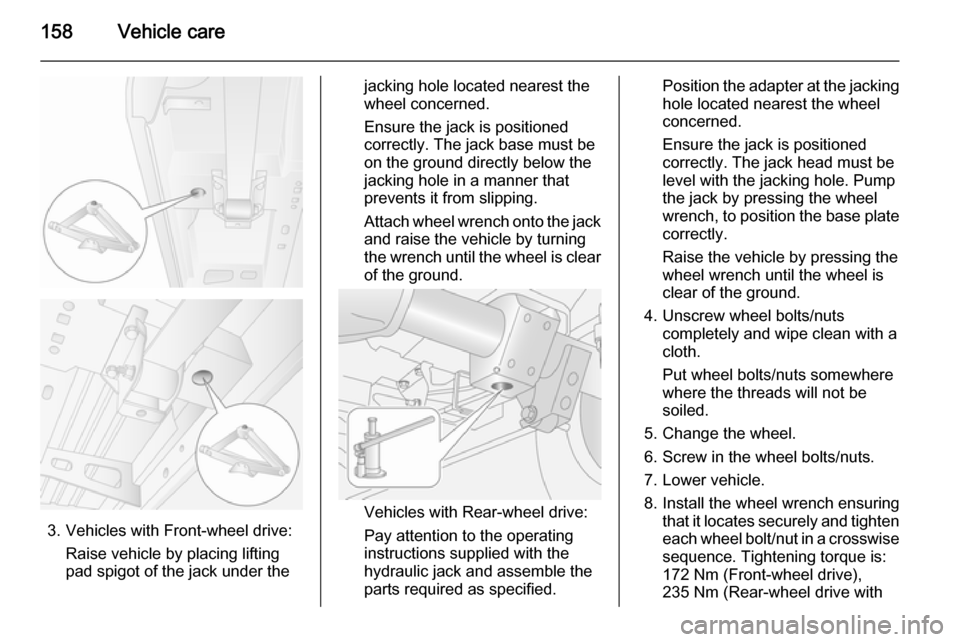

158Vehicle care

3. Vehicles with Front-wheel drive:Raise vehicle by placing lifting

pad spigot of the jack under the

jacking hole located nearest the

wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

Attach wheel wrench onto the jack

and raise the vehicle by turning

the wrench until the wheel is clear of the ground.

Vehicles with Rear-wheel drive:

Pay attention to the operating

instructions supplied with the

hydraulic jack and assemble the

parts required as specified.

Position the adapter at the jacking

hole located nearest the wheel

concerned.

Ensure the jack is positioned

correctly. The jack head must be

level with the jacking hole. Pump

the jack by pressing the wheel

wrench, to position the base plate

correctly.

Raise the vehicle by pressing the wheel wrench until the wheel is

clear of the ground.

4. Unscrew wheel bolts/nuts completely and wipe clean with a

cloth.

Put wheel bolts/nuts somewhere

where the threads will not be

soiled.

5. Change the wheel.

6. Screw in the wheel bolts/nuts.

7. Lower vehicle.

8. Install the wheel wrench ensuring that it locates securely and tighten

each wheel bolt/nut in a crosswise sequence. Tightening torque is:

172 Nm (Front-wheel drive),

235 Nm (Rear-wheel drive with

Page 161 of 201

Vehicle care159

twin rear wheels), 264 Nm (Rear-wheel drive with single rear

wheels).

9. Refit wheel cover.

10. Stow the replaced wheel 3 159

and the vehicle tools 3 150.

11. Have the new wheel balanced on the vehicle. Check the tyre

pressure of the installed tyre

3 189 and also the wheel bolt/nut

torque as soon as possible.

Have the defective tyre renewed or

repaired.

Spare wheel

Some vehicles are equipped with a tyre repair kit instead of a spare wheel 3 154.Caution

The use of a spare wheel that is

smaller than the other wheels or in combination with winter tyres

could affect driveability. Have thedefective tyre replaced as soon as

possible.

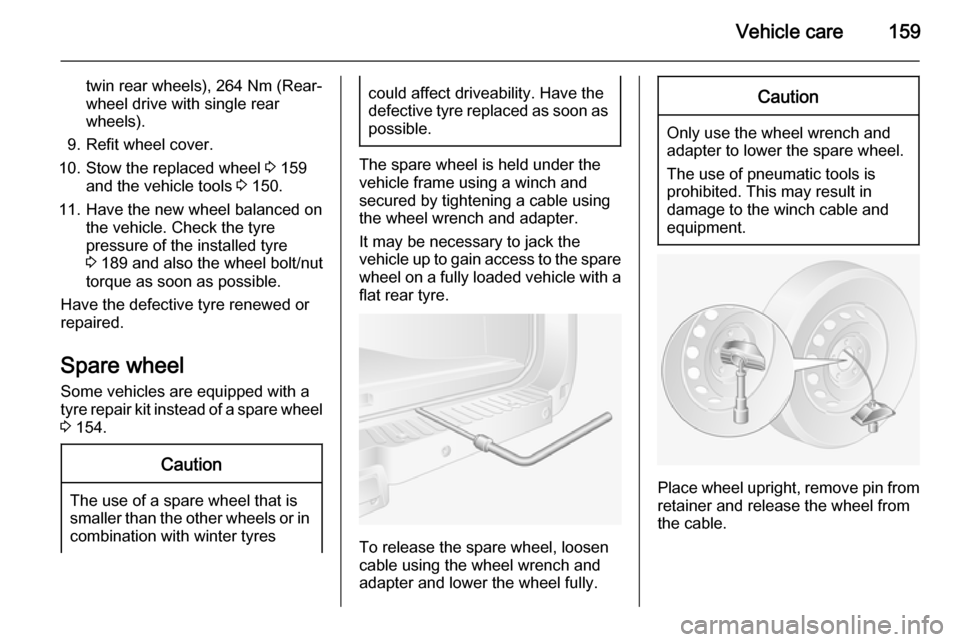

The spare wheel is held under the

vehicle frame using a winch and

secured by tightening a cable using

the wheel wrench and adapter.

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a flat rear tyre.

To release the spare wheel, loosen

cable using the wheel wrench and

adapter and lower the wheel fully.

Caution

Only use the wheel wrench and

adapter to lower the spare wheel.

The use of pneumatic tools is

prohibited. This may result in

damage to the winch cable and

equipment.

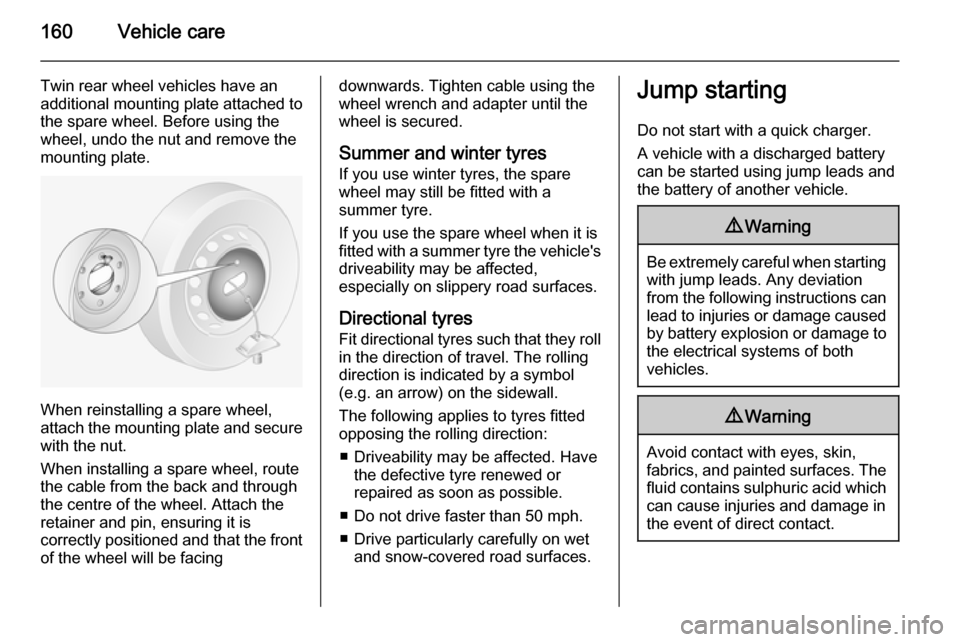

Place wheel upright, remove pin from retainer and release the wheel from

the cable.

Page 162 of 201

160Vehicle care

Twin rear wheel vehicles have an

additional mounting plate attached to

the spare wheel. Before using the

wheel, undo the nut and remove the

mounting plate.

When reinstalling a spare wheel,

attach the mounting plate and secure with the nut.

When installing a spare wheel, route

the cable from the back and through

the centre of the wheel. Attach the

retainer and pin, ensuring it is

correctly positioned and that the front

of the wheel will be facing

downwards. Tighten cable using the

wheel wrench and adapter until the wheel is secured.

Summer and winter tyres If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Do not drive faster than 50 mph.

■ Drive particularly carefully on wet and snow-covered road surfaces.Jump starting

Do not start with a quick charger.

A vehicle with a discharged battery

can be started using jump leads and

the battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact with eyes, skin,

fabrics, and painted surfaces. The fluid contains sulphuric acid which can cause injuries and damage in

the event of direct contact.

Page 194 of 201

192Customer information

■ Vehicle reactions in particulardriving situations (e.g. inflation of

an airbag, activation of the stability

regulation system)

■ Environmental conditions (e.g. temperature)

These data are exclusively technical

and help identifying and correcting

errors as well as optimizing vehicle

functions.

Motion profiles indicating travelled

routes cannot be created with these

data.

If services are used (e.g. repair

works, service processes, warranty

cases, quality assurance),

employees of the service network

(manufacturer included) are able to

read out this technical information

from the event and error data storage

modules applying special diagnostic

devices. If required, you will receive

further information at these

workshops. After an error has been

corrected, the data are deleted from

the error storage module or they are

constantly overwritten.When using the vehicle, situations

may occur in which these technical

data related to other information

(accident report, damages on the

vehicle, witness statements etc.) may be associated with a specific person -

possibly, with the assistance of an

expert.

Additional functions contractually

agreed upon with the client (e.g.

vehicle location in emergency cases)

allow the transmission of particular vehicle data from the vehicle.

Radio Frequency

Identification (RFID) RFID technology is used in somevehicles for functions such as ignition system security. It is also used inconnection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in

Vauxhall vehicles does not use or

record personal information or link

with any other Vauxhall system

containing personal information.

Page 200 of 201

198

Tread depth ............................... 152

Trip computer .............................. 85

Triple-Info-Display .......................83

Trip odometer .............................. 73

Turn and lane-change signals .....89

Turn signal ................................... 78

Tyre chains ................................ 153

Tyre changing ............................. 157

Tyre designations ......................152

Tyre pressure ............................ 152

Tyre pressures ........................... 189

Tyre repair kit ............................. 154

Tyres .......................................... 151

Tyres and wheel size, changing. 153

U Ultrasonic parking assist............. 124

Underseat storage .......................62

Upholstery .................................. 165

Upshift .......................................... 80

Using this manual ..........................3

V Vehicle battery ........................... 137

Vehicle checks............................ 133

Vehicle data ................................ 173

Vehicle data recording and privacy ..................................... 191

Vehicle dimensions .................... 180

Vehicle Identification Number ....170Vehicle jack ................................ 150

Vehicle messages .......................83

Vehicle security ............................ 27

Vehicle specific data ......................3

Vehicle storage .......................... 132

Vehicle tools ............................... 150

Vehicle unlocking ........................... 6

Vehicle weight ........................... 175

Ventilation ..................................... 94

W Warning chimes ........................... 84

Warning lights ............................... 73

Warning triangle .......................... 65

Washer and wiper systems .........14

Washer fluid ............................... 136

Washing the vehicle ...................164

Wheel changing .........................157

Wheel covers ............................. 153

Wheels and tyres .......................151

Windows ....................................... 32

Windscreen wiper/washer ...........69

Winter tyres ............................... 151

Wiper blade replacement ..........139