wheel VAUXHALL MOVANO_B 2014 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2014Pages: 201, PDF Size: 4.74 MB

Page 159 of 201

Vehicle care157

not be driven. Seek theassistance of a workshop.

20. Stow tyre repair kit under the front

seat.

Notice

The driving characteristics of the repaired tyre are severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatabledinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air hose and withdraw adapter.

Wheel changing Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 154.

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-slippery surface. The frontwheels must be in the straight-ahead position.

■ Apply the parking brake and engage first gear or reverse gear.

■ Switch off the air suspension system 3 110.

■ Remove the spare wheel 3 159.

■ Never change more than one wheel

at a time.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the engine when the vehicle is raised on the jack.

■ Clean wheel bolts/nuts and their threads before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover using the hook supplied. Vehicle tools

3 150.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt/nut by half a turn.

Page 160 of 201

158Vehicle care

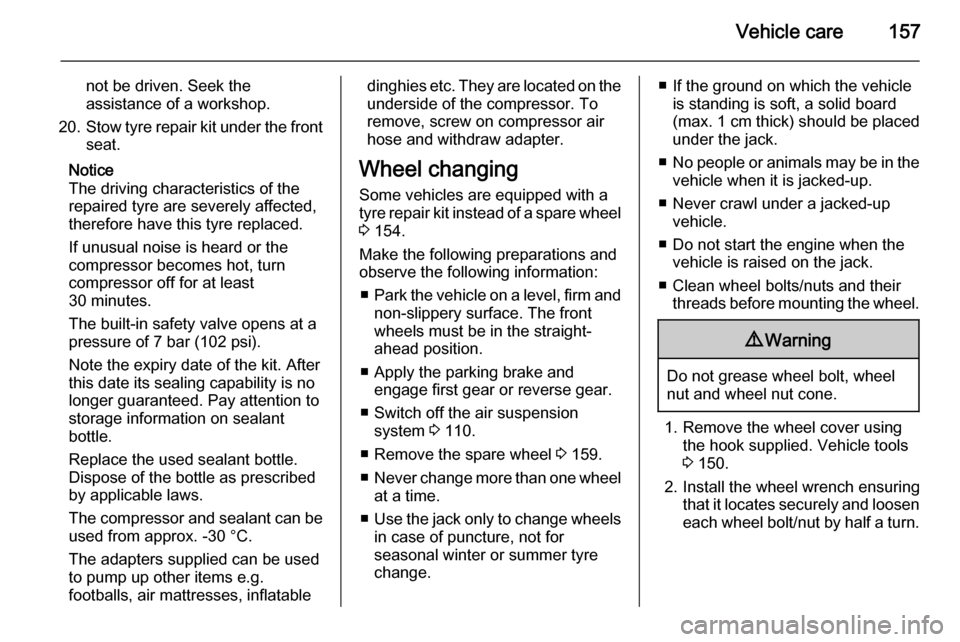

3. Vehicles with Front-wheel drive:Raise vehicle by placing lifting

pad spigot of the jack under the

jacking hole located nearest the

wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

Attach wheel wrench onto the jack

and raise the vehicle by turning

the wrench until the wheel is clear of the ground.

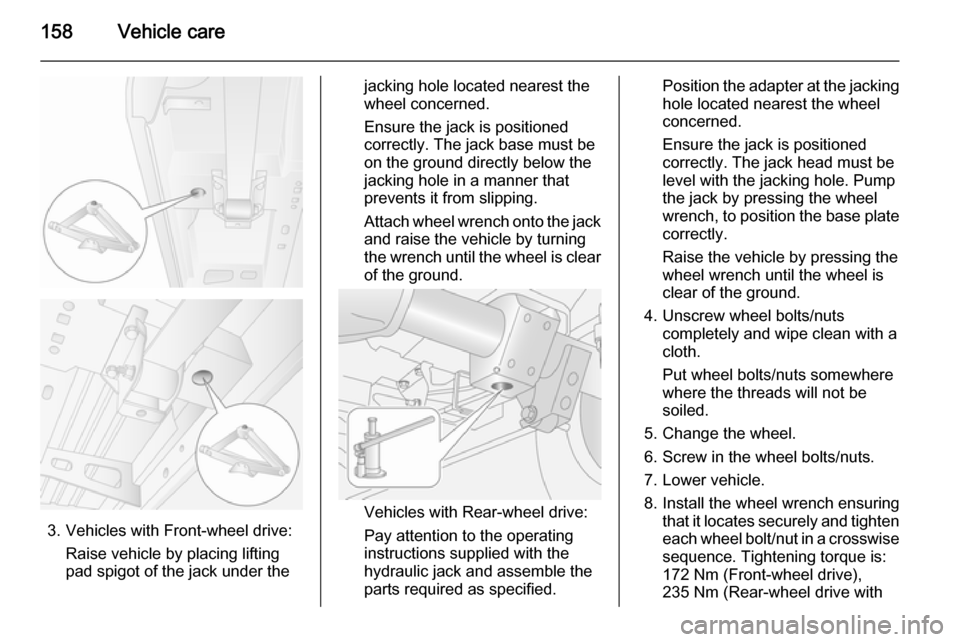

Vehicles with Rear-wheel drive:

Pay attention to the operating

instructions supplied with the

hydraulic jack and assemble the

parts required as specified.

Position the adapter at the jacking

hole located nearest the wheel

concerned.

Ensure the jack is positioned

correctly. The jack head must be

level with the jacking hole. Pump

the jack by pressing the wheel

wrench, to position the base plate

correctly.

Raise the vehicle by pressing the wheel wrench until the wheel is

clear of the ground.

4. Unscrew wheel bolts/nuts completely and wipe clean with a

cloth.

Put wheel bolts/nuts somewhere

where the threads will not be

soiled.

5. Change the wheel.

6. Screw in the wheel bolts/nuts.

7. Lower vehicle.

8. Install the wheel wrench ensuring that it locates securely and tighten

each wheel bolt/nut in a crosswise sequence. Tightening torque is:

172 Nm (Front-wheel drive),

235 Nm (Rear-wheel drive with

Page 161 of 201

Vehicle care159

twin rear wheels), 264 Nm (Rear-wheel drive with single rear

wheels).

9. Refit wheel cover.

10. Stow the replaced wheel 3 159

and the vehicle tools 3 150.

11. Have the new wheel balanced on the vehicle. Check the tyre

pressure of the installed tyre

3 189 and also the wheel bolt/nut

torque as soon as possible.

Have the defective tyre renewed or

repaired.

Spare wheel

Some vehicles are equipped with a tyre repair kit instead of a spare wheel 3 154.Caution

The use of a spare wheel that is

smaller than the other wheels or in combination with winter tyres

could affect driveability. Have thedefective tyre replaced as soon as

possible.

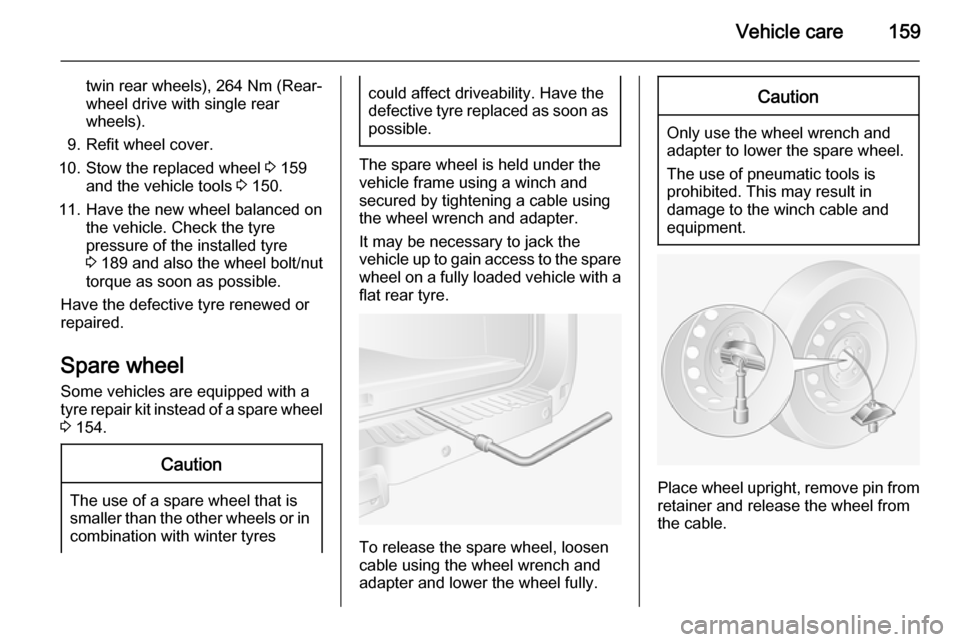

The spare wheel is held under the

vehicle frame using a winch and

secured by tightening a cable using

the wheel wrench and adapter.

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a flat rear tyre.

To release the spare wheel, loosen

cable using the wheel wrench and

adapter and lower the wheel fully.

Caution

Only use the wheel wrench and

adapter to lower the spare wheel.

The use of pneumatic tools is

prohibited. This may result in

damage to the winch cable and

equipment.

Place wheel upright, remove pin from retainer and release the wheel from

the cable.

Page 162 of 201

160Vehicle care

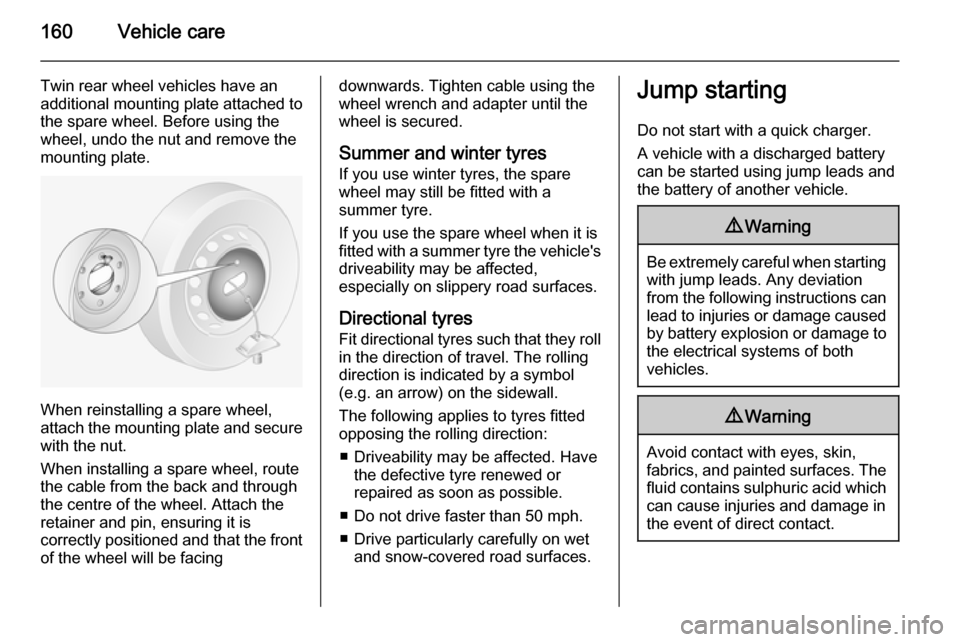

Twin rear wheel vehicles have an

additional mounting plate attached to

the spare wheel. Before using the

wheel, undo the nut and remove the

mounting plate.

When reinstalling a spare wheel,

attach the mounting plate and secure with the nut.

When installing a spare wheel, route

the cable from the back and through

the centre of the wheel. Attach the

retainer and pin, ensuring it is

correctly positioned and that the front

of the wheel will be facing

downwards. Tighten cable using the

wheel wrench and adapter until the wheel is secured.

Summer and winter tyres If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Do not drive faster than 50 mph.

■ Drive particularly carefully on wet and snow-covered road surfaces.Jump starting

Do not start with a quick charger.

A vehicle with a discharged battery

can be started using jump leads and

the battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact with eyes, skin,

fabrics, and painted surfaces. The fluid contains sulphuric acid which can cause injuries and damage in

the event of direct contact.

Page 164 of 201

162Vehicle care

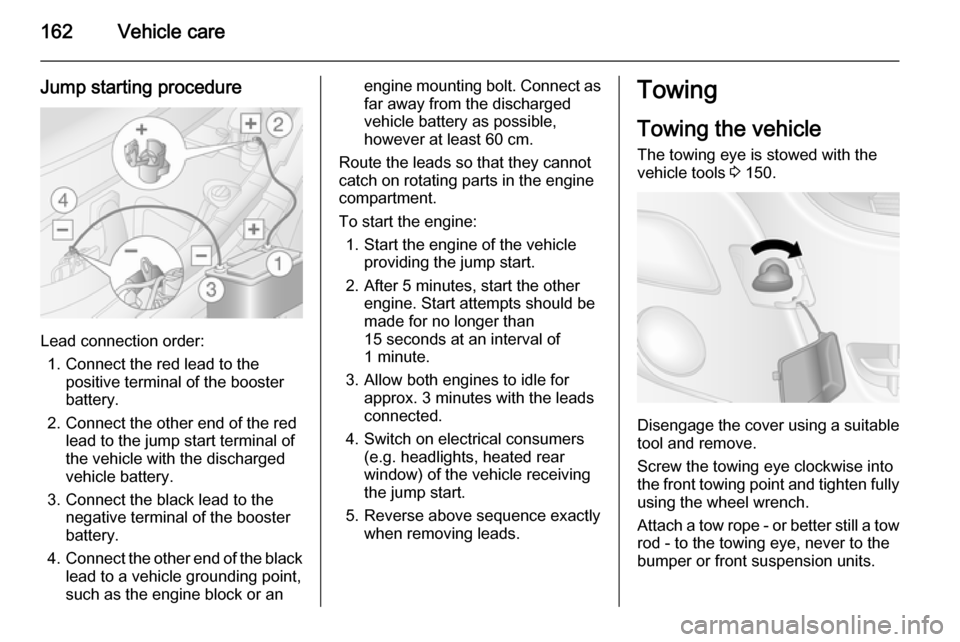

Jump starting procedure

Lead connection order:1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the jump start terminal of

the vehicle with the discharged

vehicle battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

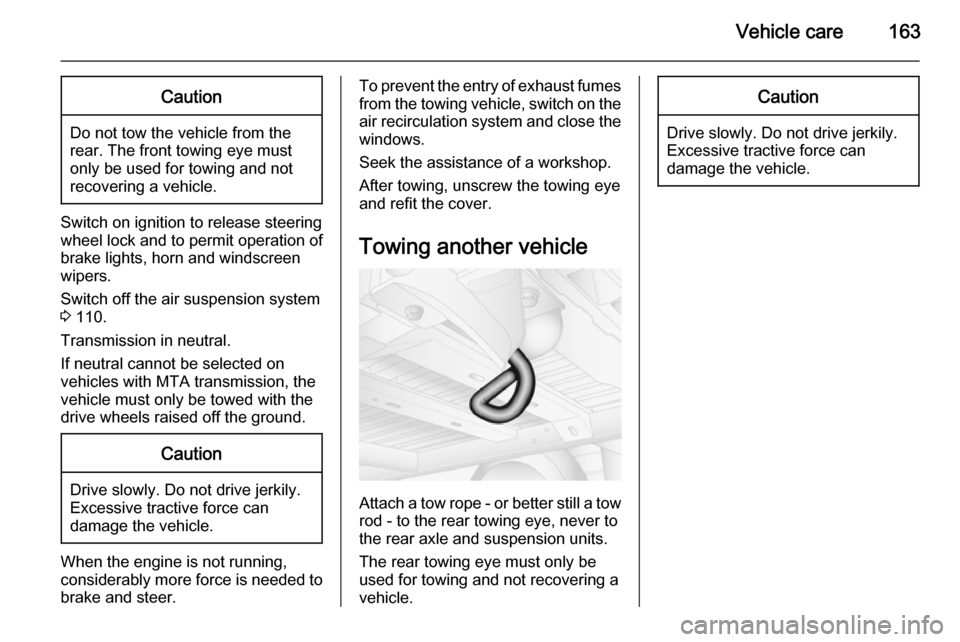

Towing the vehicle The towing eye is stowed with thevehicle tools 3 150.

Disengage the cover using a suitable

tool and remove.

Screw the towing eye clockwise into

the front towing point and tighten fully using the wheel wrench.

Attach a tow rope - or better still a tow

rod - to the towing eye, never to the

bumper or front suspension units.

Page 165 of 201

Vehicle care163Caution

Do not tow the vehicle from the

rear. The front towing eye must

only be used for towing and not

recovering a vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wipers.

Switch off the air suspension system

3 110.

Transmission in neutral.

If neutral cannot be selected on

vehicles with MTA transmission, the vehicle must only be towed with the

drive wheels raised off the ground.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust fumes

from the towing vehicle, switch on the air recirculation system and close the

windows.

Seek the assistance of a workshop.

After towing, unscrew the towing eye

and refit the cover.

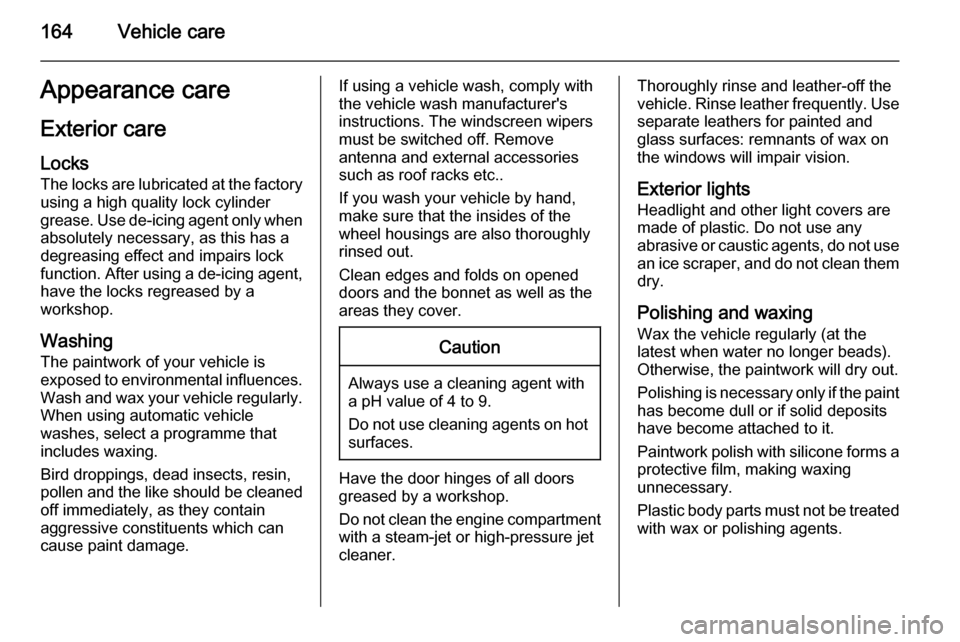

Towing another vehicle

Attach a tow rope - or better still a tow

rod - to the rear towing eye, never to

the rear axle and suspension units.

The rear towing eye must only be

used for towing and not recovering a

vehicle.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

Page 166 of 201

164Vehicle careAppearance care

Exterior care Locks

The locks are lubricated at the factory using a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has adegreasing effect and impairs lockfunction. After using a de-icing agent,

have the locks regreased by a

workshop.

Washing The paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly.

When using automatic vehicle

washes, select a programme that

includes waxing.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.If using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wipers

must be switched off. Remove

antenna and external accessories

such as roof racks etc..

If you wash your vehicle by hand, make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.Caution

Always use a cleaning agent with

a pH value of 4 to 9.

Do not use cleaning agents on hot surfaces.

Have the door hinges of all doors

greased by a workshop.

Do not clean the engine compartment with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use an ice scraper, and do not clean them

dry.

Polishing and waxing Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Plastic body parts must not be treated with wax or polishing agents.

Page 167 of 201

Vehicle care165

Windows and windscreen wiperblades

Use a soft lint-free cloth or chamois

leather together with window cleaner

and insect remover.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Wheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.Paintwork damage

Rectify minor paintwork damage with

a touch-up pen before rust forms.

Have more extensive damage or rust areas repaired by a workshop.

Underbody Some areas of the vehicle underbody

have a PVC undercoating while other

critical areas have a durable

protective wax coating.

After the underbody is washed, check the underbody and have it waxed if

necessary.

Bitumen/rubber materials could

damage the PVC coating. Have

underbody work carried out by a

workshop.

Before and after winter, wash the

underbody and have the protective

wax coating checked.

Towing equipment Do not clean the coupling ball bar with

a steam-jet or high-pressure jet

cleaner.Interior care

Interior and upholsteryOnly clean the vehicle interior,

including the instrument panel fascia

and panelling, with a dry cloth or

interior cleaner.

Clean leather upholstery with clear

water and a soft cloth. In case of

heavy soiling, use leather care.

The instrument cluster and the

displays should only be cleaned using

a soft damp cloth. If necessary use a

weak soap solution.

Clean fabric upholstery with a

vacuum cleaner and brush. Remove

stains with an upholstery cleaner.

Clothing fabrics may not be

colourfast. This could cause visible

discolourations, especially on light- coloured upholstery. Removable

stains and discolourations should be

cleaned as soon as possible.

Clean seat belts with lukewarm water or interior cleaner.

Page 177 of 201

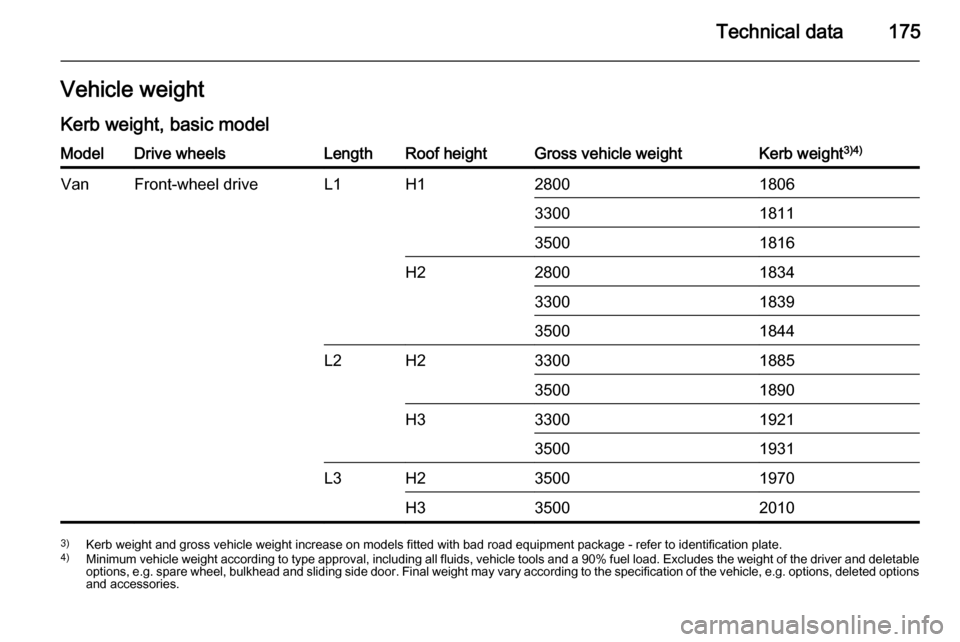

Technical data175Vehicle weight

Kerb weight, basic modelModelDrive wheelsLengthRoof heightGross vehicle weightKerb weight 3)4)VanFront-wheel driveL1H1280018063300181135001816H2280018343300183935001844L2H23300188535001890H33300192135001931L3H235001970H3350020103)

Kerb weight and gross vehicle weight increase on models fitted with bad road equipment package - refer to identification plate.

4) Minimum vehicle weight according to type approval, including all fluids, vehicle tools and a 90% fuel load. Excludes the weight of the driver and deletable

options, e.g. spare wheel, bulkhead and sliding side door. Final weight may vary according to the specification of the vehicle, e.g. options, deleted options

and accessories.

Page 178 of 201

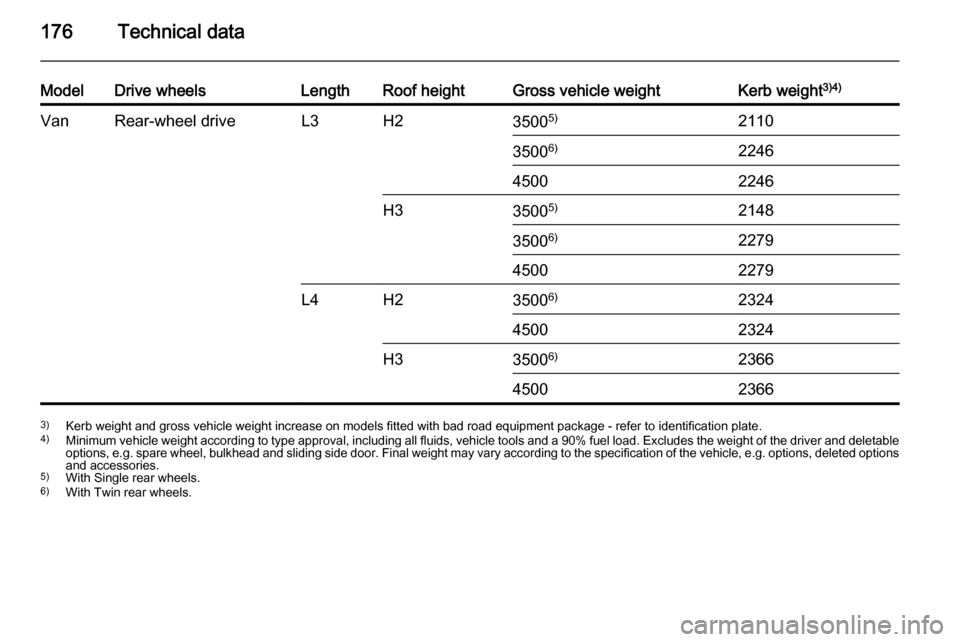

176Technical data

ModelDrive wheelsLengthRoof heightGross vehicle weightKerb weight3)4)VanRear-wheel driveL3H235005)211035006)224645002246H33500 5)214835006)227945002279L4H23500 6)232445002324H335006)2366450023663)

Kerb weight and gross vehicle weight increase on models fitted with bad road equipment package - refer to identification plate.

4) Minimum vehicle weight according to type approval, including all fluids, vehicle tools and a 90% fuel load. Excludes the weight of the driver and deletable

options, e.g. spare wheel, bulkhead and sliding side door. Final weight may vary according to the specification of the vehicle, e.g. options, deleted options

and accessories.

5) With Single rear wheels.

6) With Twin rear wheels.