lock VAUXHALL MOVANO_B 2018.5 Repair Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018.5, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2018.5Pages: 269, PDF Size: 6.41 MB

Page 192 of 269

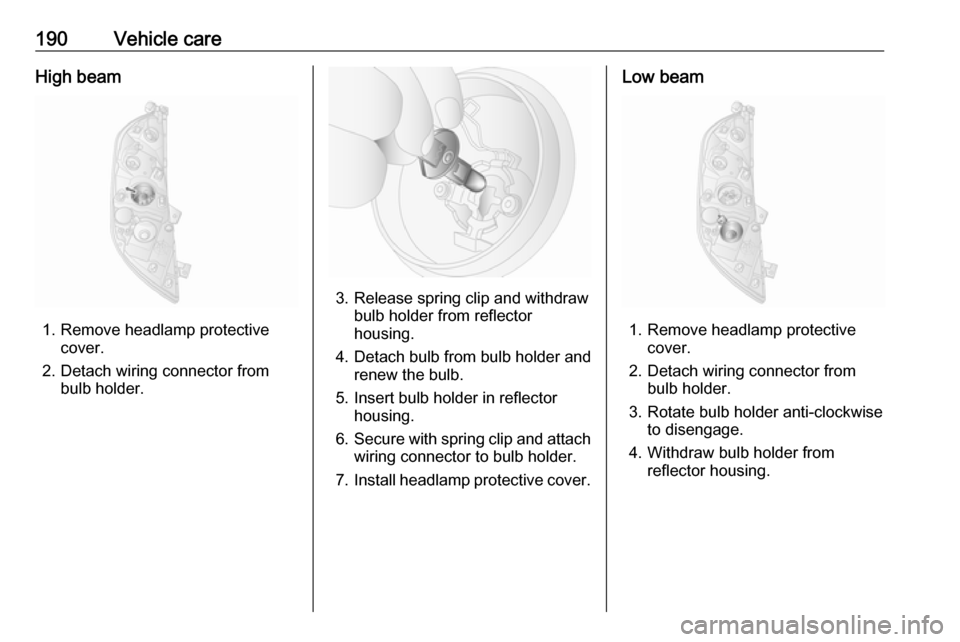

190Vehicle careHigh beam

1. Remove headlamp protectivecover.

2. Detach wiring connector from bulb holder.

3. Release spring clip and withdraw bulb holder from reflector

housing.

4. Detach bulb from bulb holder and renew the bulb.

5. Insert bulb holder in reflector housing.

6. Secure with spring clip and attach

wiring connector to bulb holder.

7. Install headlamp protective cover.

Low beam

1. Remove headlamp protective

cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 193 of 269

Vehicle care191

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install headlamp protective cover.

Sidelights

1. Remove protective cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install protective cover.

Page 194 of 269

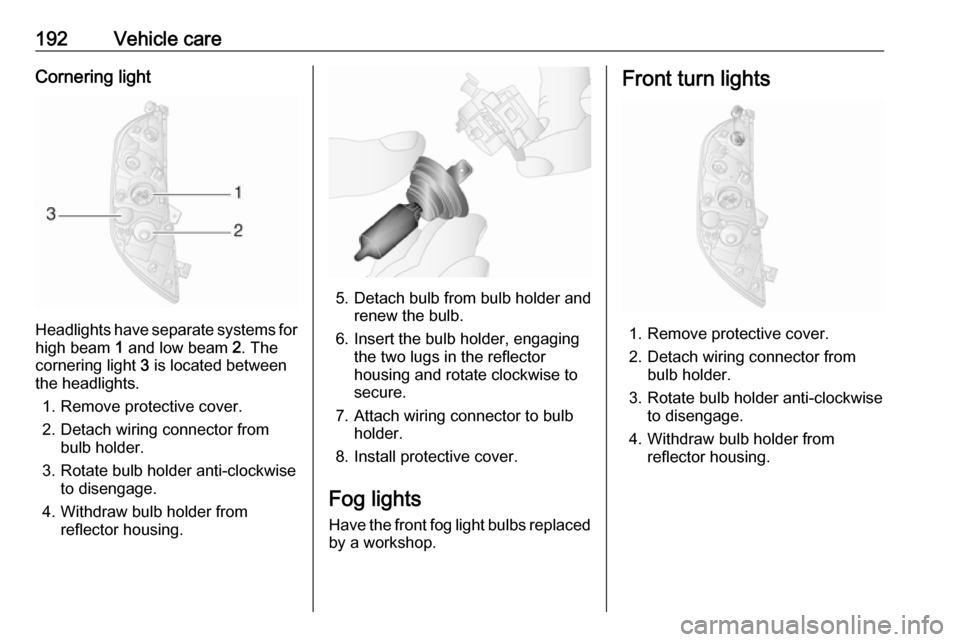

192Vehicle careCornering light

Headlights have separate systems forhigh beam 1 and low beam 2. The

cornering light 3 is located between

the headlights.

1. Remove protective cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install protective cover.

Fog lights

Have the front fog light bulbs replaced

by a workshop.

Front turn lights

1. Remove protective cover.

2. Detach wiring connector from bulb holder.

3. Rotate bulb holder anti-clockwise to disengage.

4. Withdraw bulb holder from reflector housing.

Page 195 of 269

Vehicle care193

5. Detach bulb from bulb holder andrenew the bulb.

6. Insert the bulb holder, engaging the two lugs in the reflectorhousing and rotate clockwise to

secure.

7. Attach wiring connector to bulb holder.

8. Install protective cover.

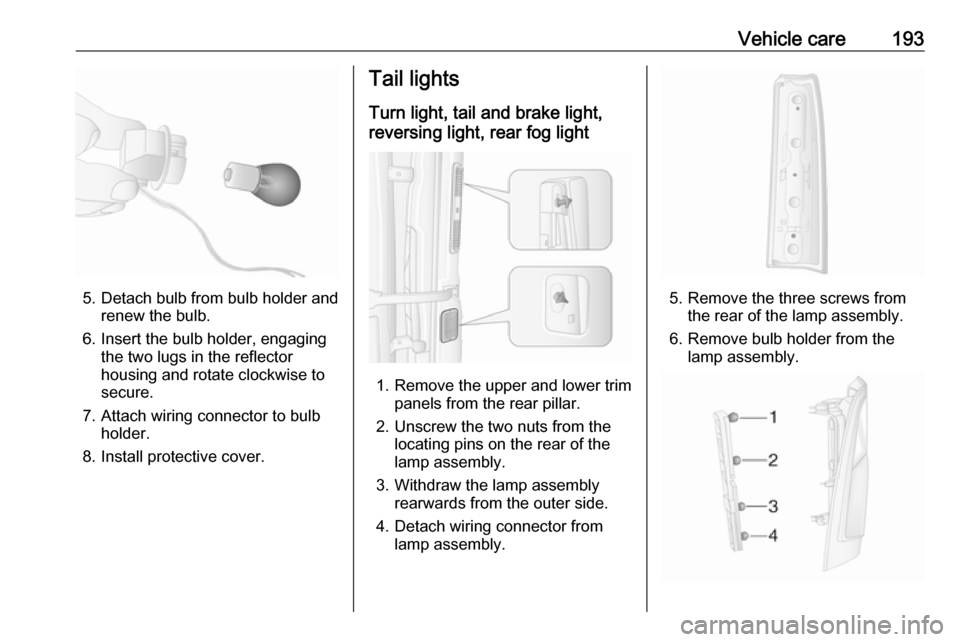

Tail lights

Turn light, tail and brake light,

reversing light, rear fog light

1. Remove the upper and lower trim panels from the rear pillar.

2. Unscrew the two nuts from the locating pins on the rear of the

lamp assembly.

3. Withdraw the lamp assembly rearwards from the outer side.

4. Detach wiring connector from lamp assembly.

5. Remove the three screws from the rear of the lamp assembly.

6. Remove bulb holder from the lamp assembly.

Page 196 of 269

194Vehicle care7. Push bulb into socket slightly,rotate anti-clockwise, remove andrenew bulb.

Turn light ( 1)

Tail and brake light ( 2)

Reversing light ( 3)

Rear fog light, may be on one side

only ( 4)

8. Replace bulb holder in lamp assembly.

9. Replace the three screws on the rear of the lamp assembly.

10. Reattach wiring connector to lamp

assembly.

11. Replace lamp assembly from the outer side into original position,

ensuring that it is seated correctly.

12. Replace the two nuts onto the locating pins on the rear of the

lamp assembly.

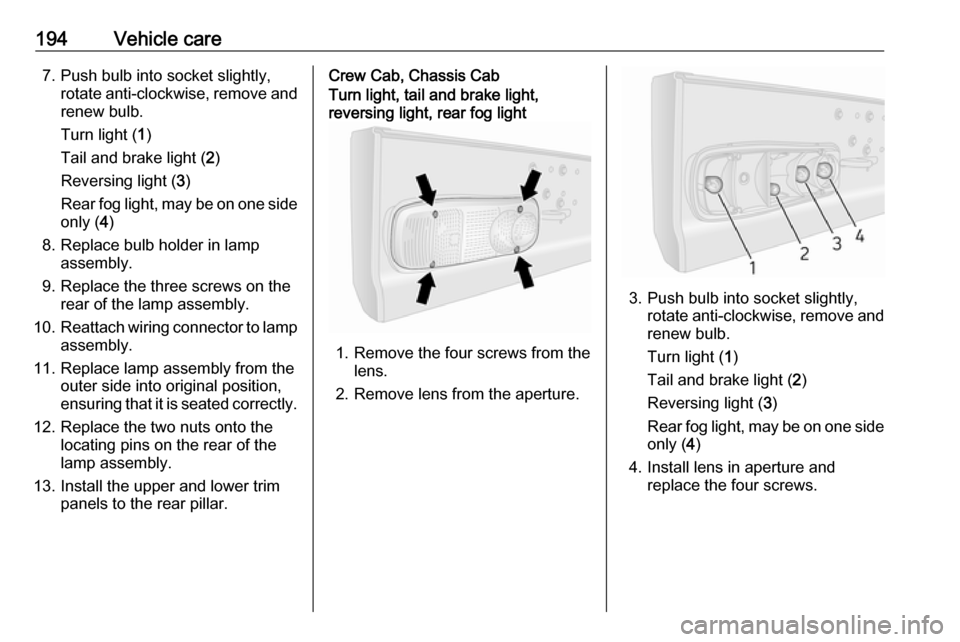

13. Install the upper and lower trim panels to the rear pillar.Crew Cab, Chassis CabTurn light, tail and brake light,

reversing light, rear fog light

1. Remove the four screws from the lens.

2. Remove lens from the aperture.

3. Push bulb into socket slightly, rotate anti-clockwise, remove and

renew bulb.

Turn light ( 1)

Tail and brake light ( 2)

Reversing light ( 3)

Rear fog light, may be on one side only ( 4)

4. Install lens in aperture and replace the four screws.

Page 199 of 269

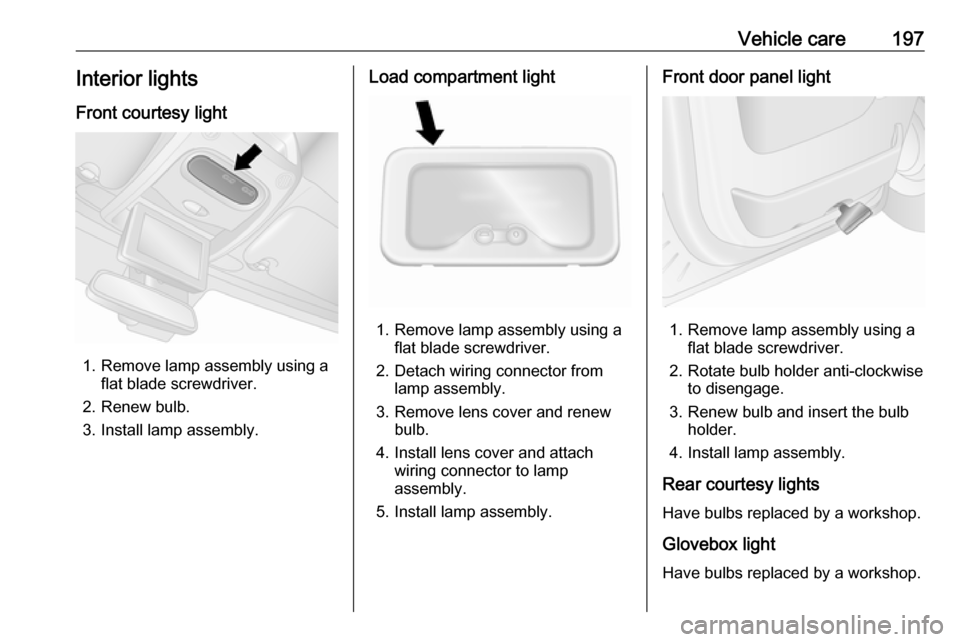

Vehicle care197Interior lights

Front courtesy light

1. Remove lamp assembly using a flat blade screwdriver.

2. Renew bulb.

3. Install lamp assembly.

Load compartment light

1. Remove lamp assembly using a flat blade screwdriver.

2. Detach wiring connector from lamp assembly.

3. Remove lens cover and renew bulb.

4. Install lens cover and attach wiring connector to lamp

assembly.

5. Install lamp assembly.

Front door panel light

1. Remove lamp assembly using a flat blade screwdriver.

2. Rotate bulb holder anti-clockwise to disengage.

3. Renew bulb and insert the bulb holder.

4. Install lamp assembly.

Rear courtesy lights

Have bulbs replaced by a workshop.

Glovebox light

Have bulbs replaced by a workshop.

Page 202 of 269

200Vehicle careSymbolCircuitKWindscreen wipernHeating and ventilation

system / Air conditioningVHeated windscreenQPneumatic suspension

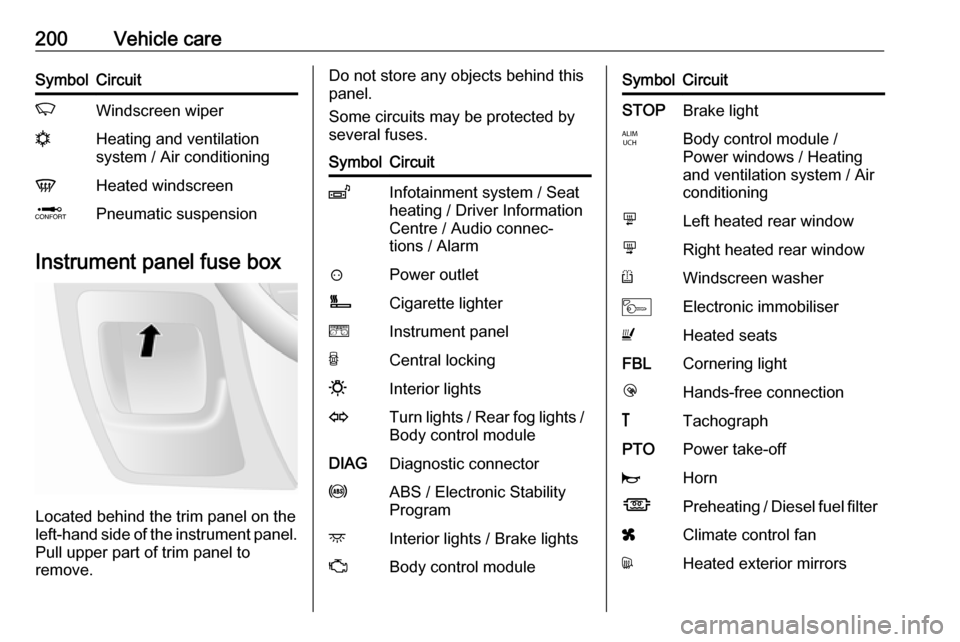

Instrument panel fuse box

Located behind the trim panel on the

left-hand side of the instrument panel. Pull upper part of trim panel to

remove.

Do not store any objects behind this

panel.

Some circuits may be protected by

several fuses.SymbolCircuitZInfotainment system / Seat

heating / Driver Information

Centre / Audio connec‐

tions / Alarm?Power outletÌCigarette lightereInstrument panelUCentral locking0Interior lightsOTurn lights / Rear fog lights /

Body control moduleDIAGDiagnostic connectoruABS / Electronic Stability

ProgramdInterior lights / Brake lightsZBody control moduleSymbolCircuitSTOPBrake lightIBody control module /

Power windows / Heating

and ventilation system / Air

conditioningmLeft heated rear windownRight heated rear windowRWindscreen washerMElectronic immobiliserUHeated seatsFBLCornering lightlHands-free connection&TachographPTOPower take-offjHornÍPreheating / Diesel fuel filterxClimate control fandHeated exterior mirrors

Page 204 of 269

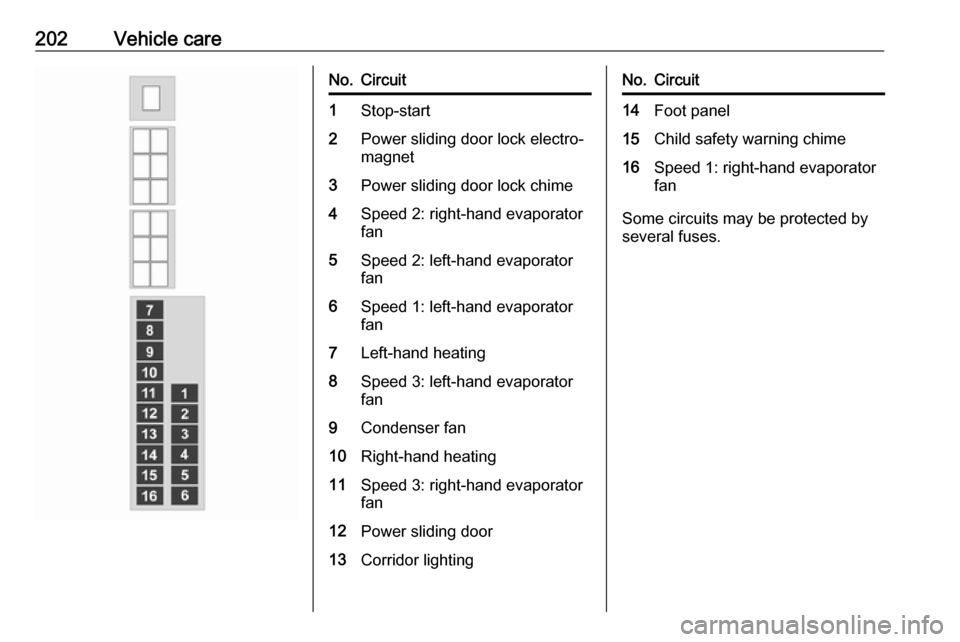

202Vehicle careNo.Circuit1Stop-start2Power sliding door lock electro‐

magnet3Power sliding door lock chime4Speed 2: right-hand evaporator

fan5Speed 2: left-hand evaporator

fan6Speed 1: left-hand evaporator

fan7Left-hand heating8Speed 3: left-hand evaporator

fan9Condenser fan10Right-hand heating11Speed 3: right-hand evaporator

fan12Power sliding door13Corridor lightingNo.Circuit14Foot panel15Child safety warning chime16Speed 1: right-hand evaporator

fan

Some circuits may be protected by

several fuses.

Page 211 of 269

Vehicle care209On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add

no more than 15 mm to the tyre tread

and the inboard sides (including chain

lock).9 Warning

Damage may lead to tyre blowout.

Wheel covers on steel wheels may

come into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 30 mph and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel or on

wheels of a different size than those

fitted at the factory.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding four mm or

that is at the tyre's sidewall near the

rim cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If the vehicle has a flat tyre:

Apply the parking brake and engage

neutral (manual transmission) or N

(manual transmission automated).

The tyre repair kit is located under the

front seat. Slide seat forwards fully

and fold backrest down to access kit.

1. Take the tyre repair kit out from under the front seat.

2. Remove the compressor.

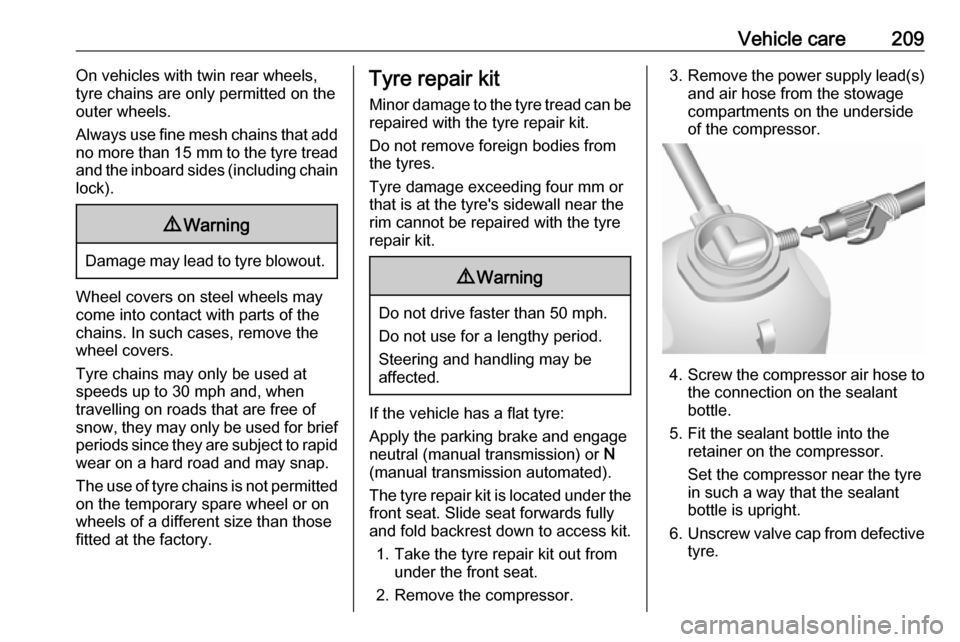

3. Remove the power supply lead(s)

and air hose from the stowage

compartments on the underside

of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

Page 212 of 269

210Vehicle care

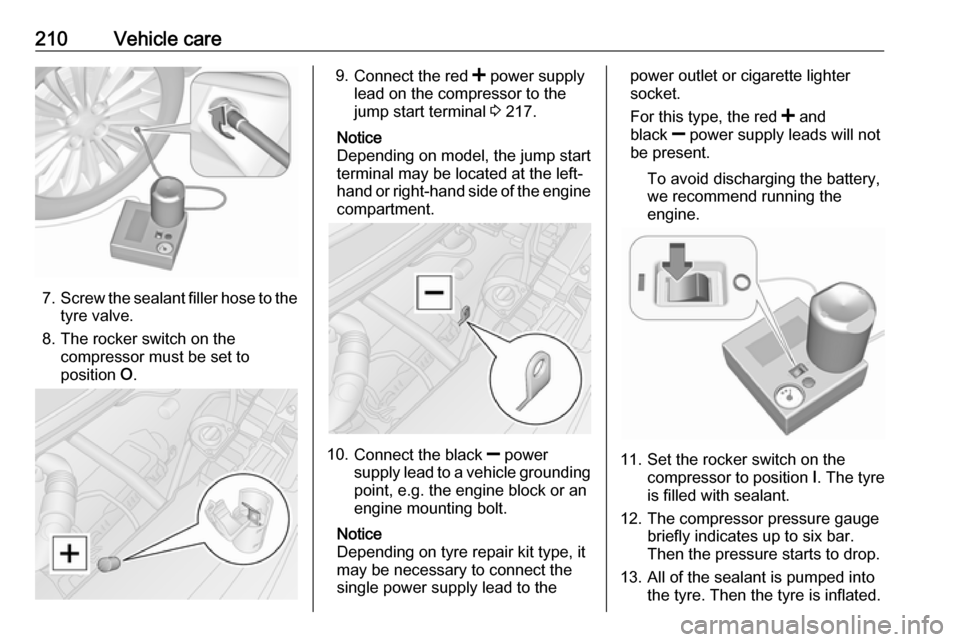

7.Screw the sealant filler hose to the

tyre valve.

8. The rocker switch on the compressor must be set to

position O.

9.

Connect the red < power supply

lead on the compressor to the

jump start terminal 3 217.

Notice

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.

10. Connect the black ] power

supply lead to a vehicle grounding

point, e.g. the engine block or an

engine mounting bolt.

Notice

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

11. Set the rocker switch on the compressor to position I. The tyre

is filled with sealant.

12. The compressor pressure gauge briefly indicates up to six bar.

Then the pressure starts to drop.

13. All of the sealant is pumped into the tyre. Then the tyre is inflated.