lock VAUXHALL MOVANO_B 2019 Manual PDF

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2019, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2019Pages: 249, PDF Size: 6.37 MB

Page 211 of 249

Vehicle care209On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add

no more than 15 mm to the tyre tread

and the inboard sides (including chain

lock).9 Warning

Damage may lead to tyre blowout.

Wheel covers on steel wheels may

come into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 30 mph and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel or on

wheels of a different size than those

fitted at the factory.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at the tyre's sidewall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If the vehicle has a flat tyre:

Apply the parking brake and engage

neutral (manual transmission) or N

(manual transmission automated).

The tyre repair kit is located under the

front seat. Slide seat forwards fully

and fold backrest down to access kit.

1. Take the tyre repair kit out from under the front seat.

2. Remove the compressor.

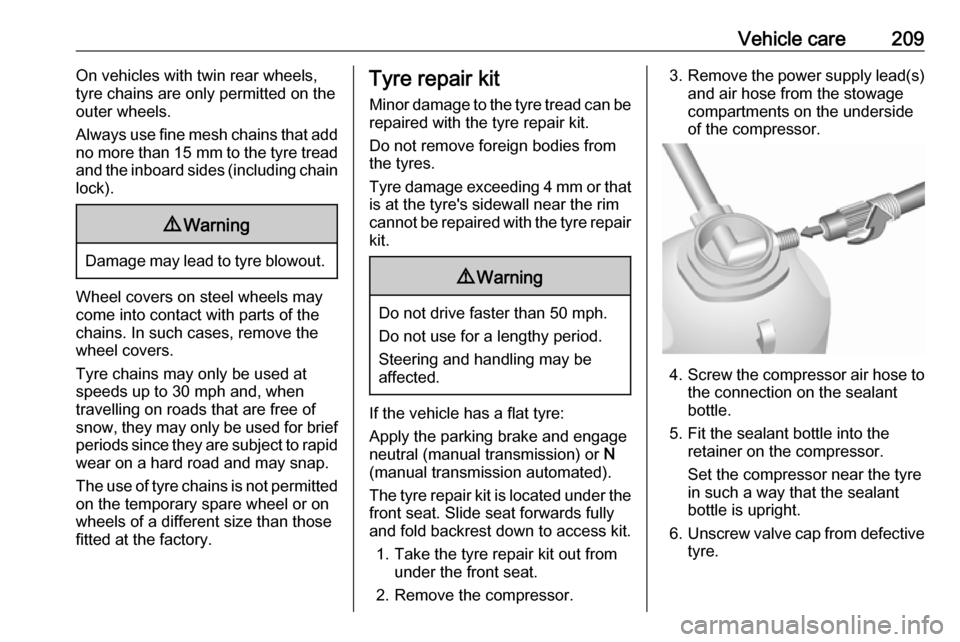

3. Remove the power supply lead(s)

and air hose from the stowage

compartments on the underside

of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

Page 212 of 249

210Vehicle care

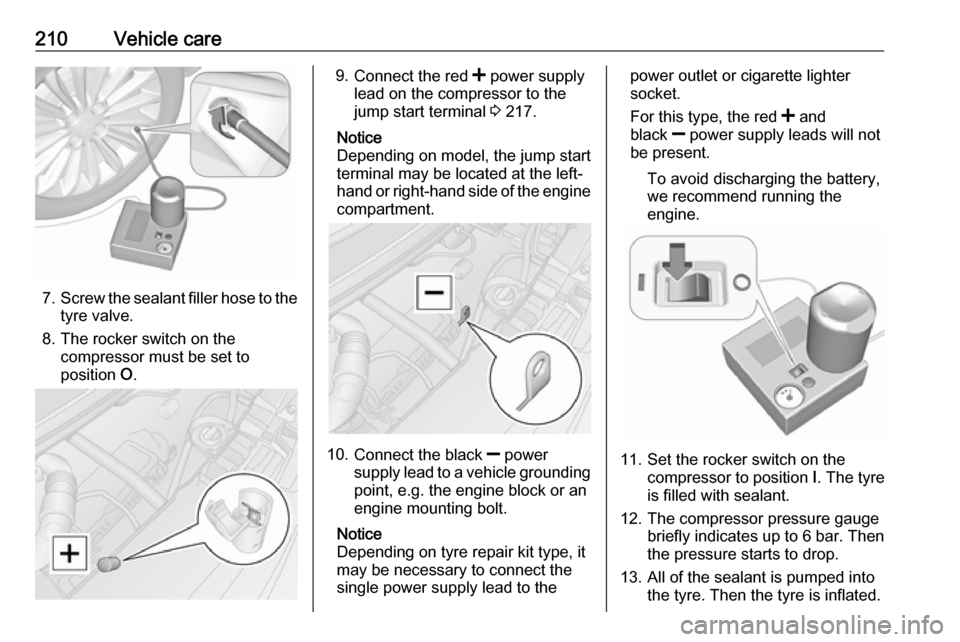

7.Screw the sealant filler hose to the

tyre valve.

8. The rocker switch on the compressor must be set to

position O.

9.

Connect the red < power supply

lead on the compressor to the

jump start terminal 3 217.

Notice

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.

10. Connect the black ] power

supply lead to a vehicle grounding

point, e.g. the engine block or an

engine mounting bolt.

Notice

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

11. Set the rocker switch on the compressor to position I. The tyre

is filled with sealant.

12. The compressor pressure gauge briefly indicates up to 6 bar. Then

the pressure starts to drop.

13. All of the sealant is pumped into the tyre. Then the tyre is inflated.

Page 217 of 249

Vehicle care215

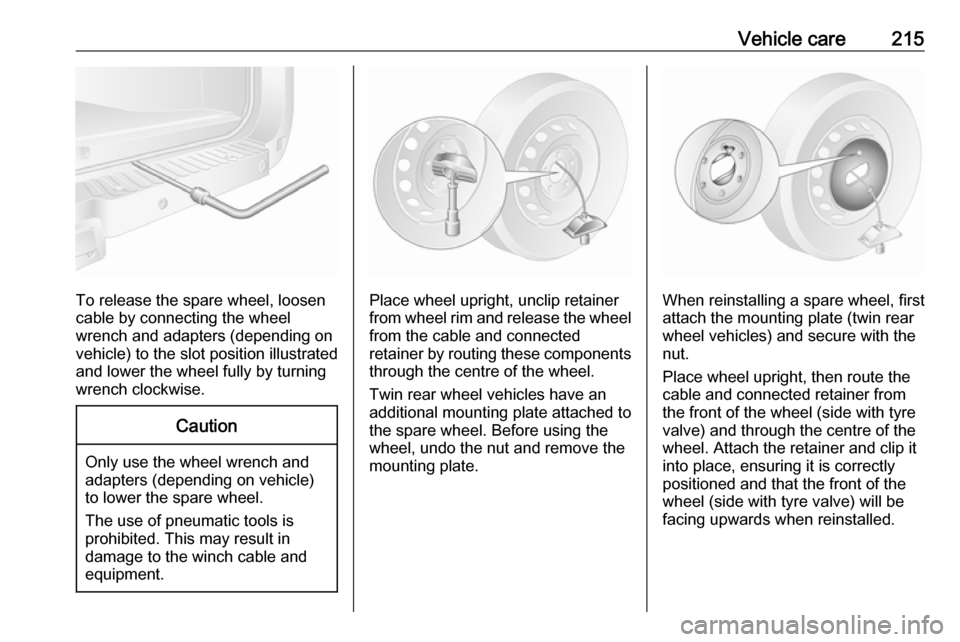

To release the spare wheel, loosen

cable by connecting the wheel

wrench and adapters (depending on

vehicle) to the slot position illustrated

and lower the wheel fully by turning

wrench clockwise.

Caution

Only use the wheel wrench and

adapters (depending on vehicle)

to lower the spare wheel.

The use of pneumatic tools is

prohibited. This may result in

damage to the winch cable and

equipment.

Place wheel upright, unclip retainer

from wheel rim and release the wheel

from the cable and connected

retainer by routing these components through the centre of the wheel.

Twin rear wheel vehicles have an

additional mounting plate attached to

the spare wheel. Before using the

wheel, undo the nut and remove the

mounting plate.When reinstalling a spare wheel, first

attach the mounting plate (twin rear

wheel vehicles) and secure with the

nut.

Place wheel upright, then route the

cable and connected retainer from

the front of the wheel (side with tyre

valve) and through the centre of the

wheel. Attach the retainer and clip it

into place, ensuring it is correctly

positioned and that the front of the

wheel (side with tyre valve) will be

facing upwards when reinstalled.

Page 218 of 249

216Vehicle care

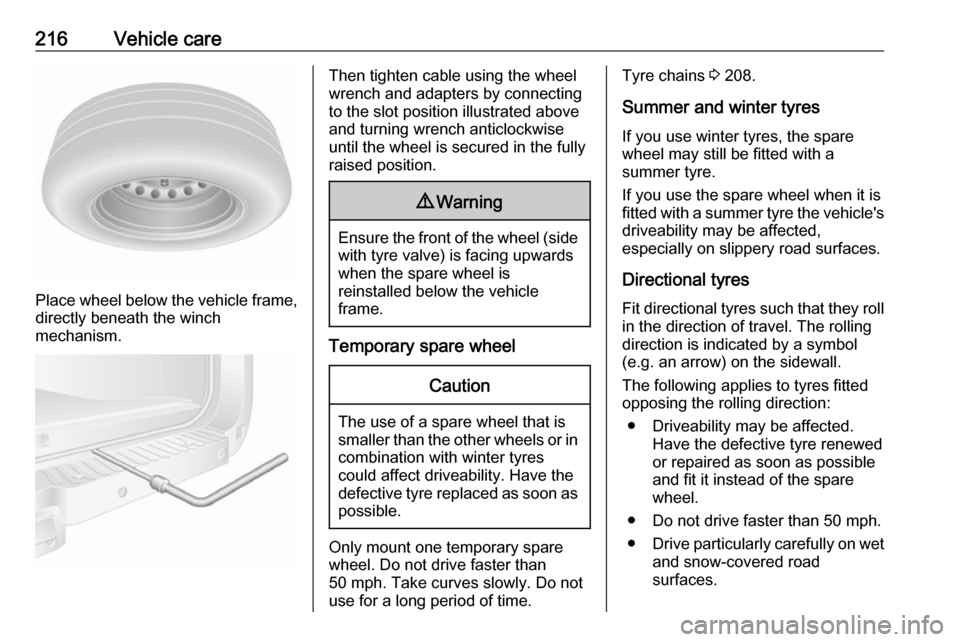

Place wheel below the vehicle frame,

directly beneath the winch

mechanism.

Then tighten cable using the wheel

wrench and adapters by connecting

to the slot position illustrated above

and turning wrench anticlockwise

until the wheel is secured in the fully

raised position.9 Warning

Ensure the front of the wheel (side

with tyre valve) is facing upwards

when the spare wheel is

reinstalled below the vehicle

frame.

Temporary spare wheel

Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Only mount one temporary spare

wheel. Do not drive faster than

50 mph. Take curves slowly. Do not

use for a long period of time.

Tyre chains 3 208.

Summer and winter tyres

If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Do not drive faster than 50 mph.

● Drive particularly carefully on wet

and snow-covered road

surfaces.

Page 220 of 249

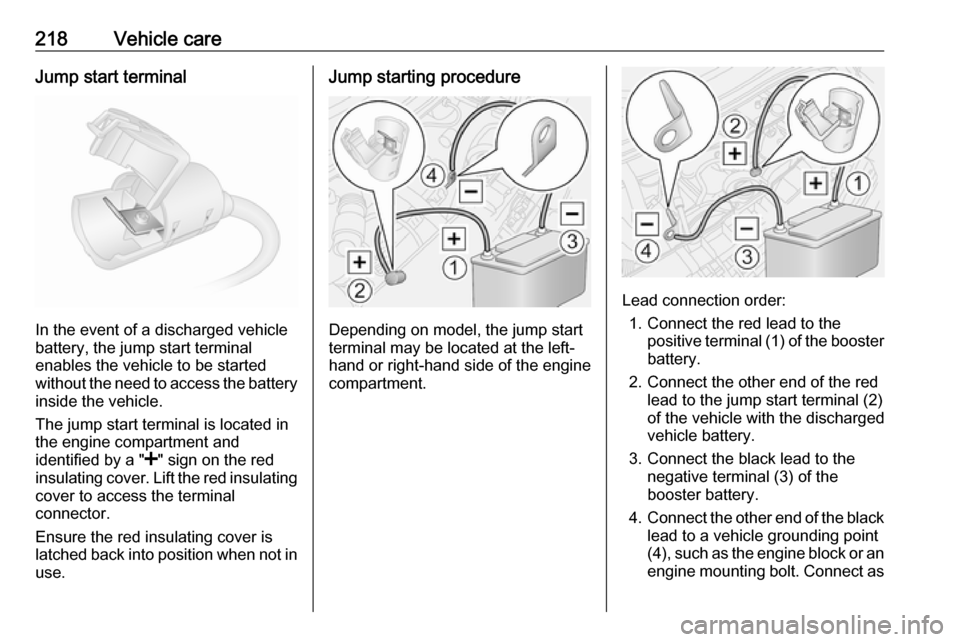

218Vehicle careJump start terminal

In the event of a discharged vehicle

battery, the jump start terminal

enables the vehicle to be started

without the need to access the battery inside the vehicle.

The jump start terminal is located in

the engine compartment and

identified by a " <" sign on the red

insulating cover. Lift the red insulating

cover to access the terminal

connector.

Ensure the red insulating cover is

latched back into position when not in

use.

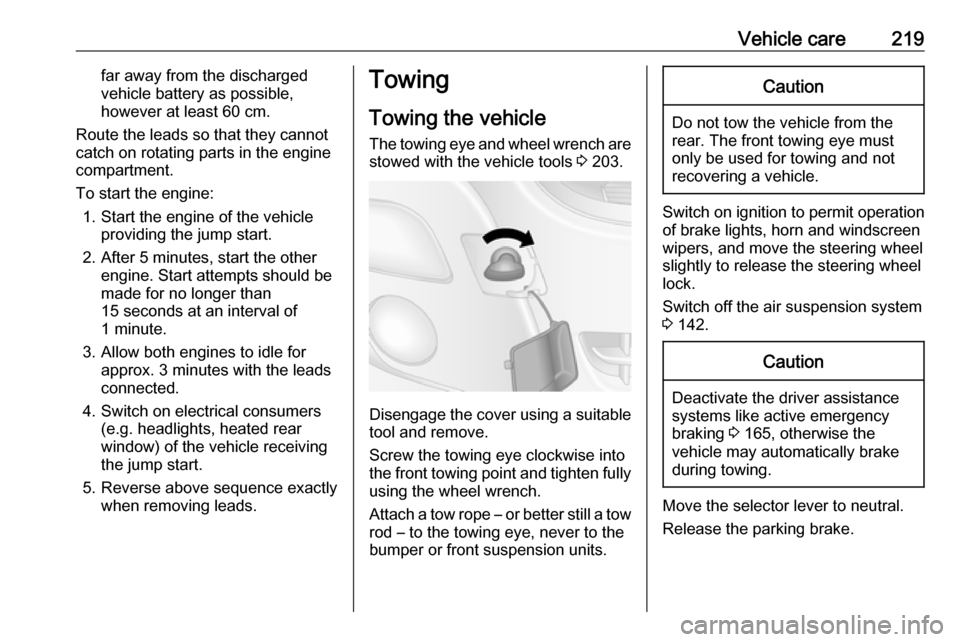

Jump starting procedure

Depending on model, the jump start

terminal may be located at the left-

hand or right-hand side of the engine

compartment.

Lead connection order:

1. Connect the red lead to the positive terminal (1) of the booster

battery.

2. Connect the other end of the red lead to the jump start terminal (2)

of the vehicle with the discharged

vehicle battery.

3. Connect the black lead to the negative terminal (3) of the

booster battery.

4. Connect the other end of the black

lead to a vehicle grounding point

(4), such as the engine block or an

engine mounting bolt. Connect as

Page 221 of 249

Vehicle care219far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

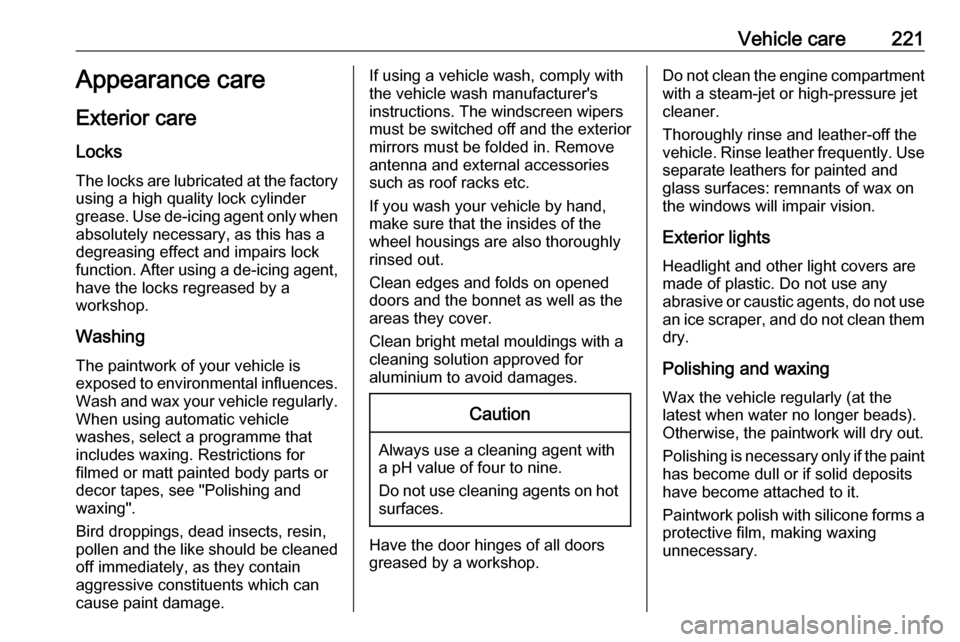

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle The towing eye and wheel wrench are

stowed with the vehicle tools 3 203.

Disengage the cover using a suitable

tool and remove.

Screw the towing eye clockwise into

the front towing point and tighten fully using the wheel wrench.

Attach a tow rope – or better still a tow

rod – to the towing eye, never to the

bumper or front suspension units.

Caution

Do not tow the vehicle from the

rear. The front towing eye must

only be used for towing and not

recovering a vehicle.

Switch on ignition to permit operation

of brake lights, horn and windscreen

wipers, and move the steering wheel

slightly to release the steering wheel

lock.

Switch off the air suspension system 3 142.

Caution

Deactivate the driver assistance

systems like active emergency

braking 3 165, otherwise the

vehicle may automatically brake during towing.

Move the selector lever to neutral.

Release the parking brake.

Page 223 of 249

Vehicle care221Appearance care

Exterior care LocksThe locks are lubricated at the factoryusing a high quality lock cylinder

grease. Use de-icing agent only when

absolutely necessary, as this has a

degreasing effect and impairs lock

function. After using a de-icing agent,

have the locks regreased by a

workshop.

WashingThe paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly.

When using automatic vehicle

washes, select a programme that

includes waxing. Restrictions for

filmed or matt painted body parts or decor tapes, see "Polishing and

waxing".

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can cause paint damage.If using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wipers

must be switched off and the exterior

mirrors must be folded in. Remove

antenna and external accessories

such as roof racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.

Clean bright metal mouldings with a

cleaning solution approved for

aluminium to avoid damages.Caution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Have the door hinges of all doors

greased by a workshop.

Do not clean the engine compartment with a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a protective film, making waxing

unnecessary.

Page 230 of 249

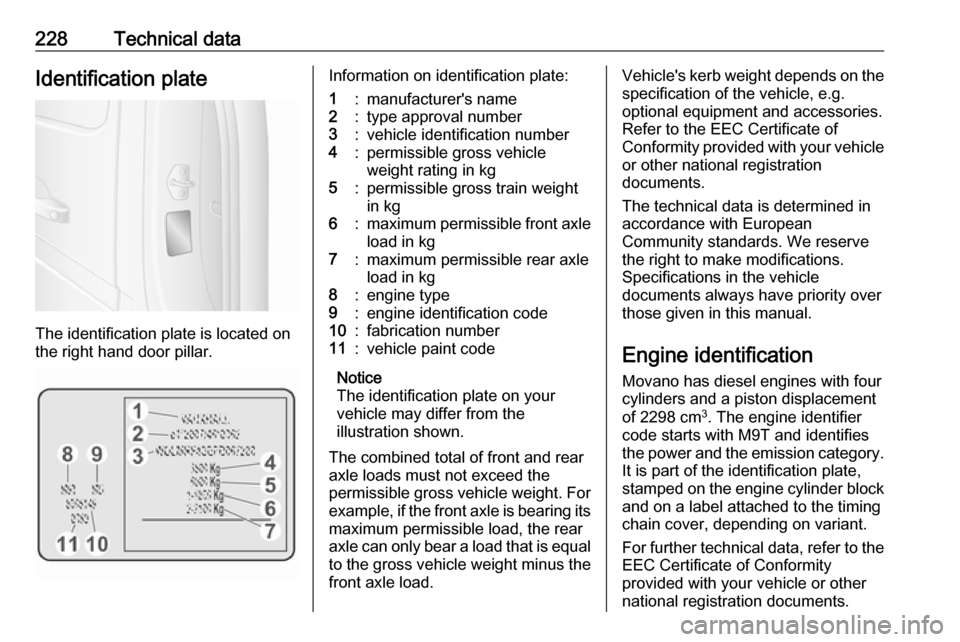

228Technical dataIdentification plate

The identification plate is located on

the right hand door pillar.

Information on identification plate:1:manufacturer's name2:type approval number3:vehicle identification number4:permissible gross vehicle

weight rating in kg5:permissible gross train weight

in kg6:maximum permissible front axle load in kg7:maximum permissible rear axle

load in kg8:engine type9:engine identification code10:fabrication number11:vehicle paint code

Notice

The identification plate on your

vehicle may differ from the

illustration shown.

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

Vehicle's kerb weight depends on the

specification of the vehicle, e.g.

optional equipment and accessories.

Refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

Movano has diesel engines with four

cylinders and a piston displacement

of 2298 cm 3

. The engine identifier

code starts with M9T and identifies

the power and the emission category. It is part of the identification plate,

stamped on the engine cylinder block

and on a label attached to the timing

chain cover, depending on variant.

For further technical data, refer to the EEC Certificate of Conformity

provided with your vehicle or other

national registration documents.

Page 240 of 249

238Customer informationOnline servicesIf your vehicle has a radio networkconnection, this allows data to be

exchanged between your vehicle and other systems. The radio network

connection is made possible by

means of a transmitter device in your

vehicle or a mobile device provided

by you (e.g. a smartphone). Online

functions can be used via this radio

network connection. These include

online services and applications /

apps provided to you by the

manufacturer or other providers.

Proprietary services

In the case of the manufacturer's

online services, the relevant functions are described by the manufacturer in

an appropriate location (e.g. Owner's

Manual, the manufacturer's website) and the associated data protection

information is provided. Personal

data may be used to provide online

services. Data exchange for this

purpose takes place via a protected

connection, e.g. using the

manufacturer's IT systems provided

for the purpose. Collection,processing and use of personal data

for the purposes of preparation of services take place solely on the

basis of legal permission, e.g. in the

case of a legally prescribed

emergency communication system or a contractual agreement, or by virtue

of consent.

You can activate or deactivate the services and functions (which are

subject to charges to some extent)

and, in some cases, the vehicle's

entire radio network connection. This

does not include statutory functions

and services such as an emergency

communication system.

Third party services If you make use of online services

from other providers (third parties),

these services are subject to the

liability and data protection and usage conditions of the provider in question.

The manufacturer frequently has no

influence over the content exchanged

in this regard.Therefore, please note the nature,

scope and purpose of the collection

and use of personal data within the

scope of third party services provided by the service provider in question.

Radio Frequency

Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and immobiliser.

It is also used in connection with

conveniences such as radio remote

controls for door locking / unlocking and starting. RFID technology in

Vauxhall vehicles does not use or

record personal information or link

with any other Vauxhall system

containing personal information.

Page 242 of 249

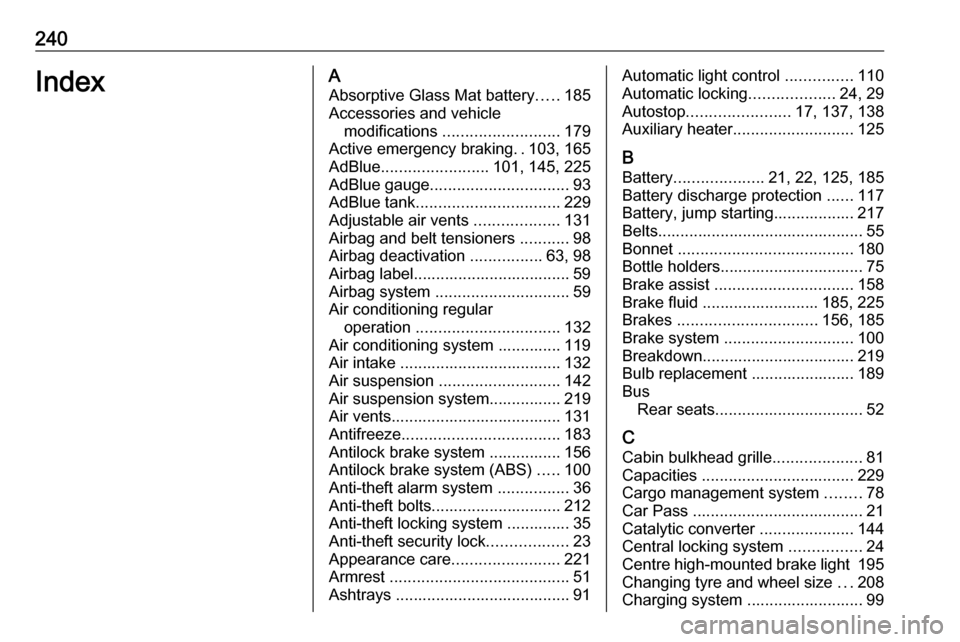

240IndexAAbsorptive Glass Mat battery .....185

Accessories and vehicle modifications .......................... 179

Active emergency braking ..103, 165

AdBlue ........................ 101, 145, 225

AdBlue gauge ............................... 93

AdBlue tank ................................ 229

Adjustable air vents ...................131

Airbag and belt tensioners ...........98

Airbag deactivation ................63, 98

Airbag label................................... 59 Airbag system .............................. 59

Air conditioning regular operation ................................ 132

Air conditioning system .............. 119

Air intake .................................... 132

Air suspension ........................... 142

Air suspension system................ 219

Air vents...................................... 131

Antifreeze ................................... 183

Antilock brake system ................ 156

Antilock brake system (ABS) .....100

Anti-theft alarm system ................36

Anti-theft bolts............................. 212

Anti-theft locking system .............. 35

Anti-theft security lock ..................23

Appearance care ........................221

Armrest ........................................ 51

Ashtrays ....................................... 91Automatic light control ...............110

Automatic locking ...................24, 29

Autostop ....................... 17, 137, 138

Auxiliary heater ........................... 125

B Battery .................... 21, 22, 125, 185

Battery discharge protection ......117

Battery, jump starting.................. 217

Belts.............................................. 55

Bonnet ....................................... 180

Bottle holders................................ 75

Brake assist ............................... 158

Brake fluid .......................... 185, 225

Brakes ............................... 156, 185

Brake system ............................. 100

Breakdown.................................. 219

Bulb replacement ....................... 189

Bus Rear seats ................................. 52

C

Cabin bulkhead grille ....................81

Capacities .................................. 229

Cargo management system ........78

Car Pass ...................................... 21

Catalytic converter .....................144

Central locking system ................24

Centre high-mounted brake light 195

Changing tyre and wheel size ...208

Charging system .......................... 99