transmission VAUXHALL VIVA 2017.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2017.5, Model line: VIVA, Model: VAUXHALL VIVA 2017.5Pages: 201, PDF Size: 5.3 MB

Page 153 of 201

Vehicle care151No.Circuit1Tailgate2–3Heated rear window4Heated exterior mirror5Sunroof6Transmission control module7Engine control module8–9ABS10Body control module, voltage11Rear view camera12–13–14Engine control module/Trans‐

mission control module15Injection system/Starter16Fuel pump17Engine control module1No.Circuit18Engine control module219Injection system/Ignition20Air conditioning system21Battery sensor22Electric steering column lock23Cooling fan low24–25Exterior mirror switch26Engine control module/Manual

transmission automated

module27Fuel system28Brake system29Seat occupancy recognition30Headlight range adjustment31Horn32Front fog light33High beam leftNo.Circuit34High beam right35–36Rear wiper37Cornering light left38Washer system39Cornering light right40–41–42Starter 243Instrument panel44Manual transmission auto‐

mated, DC-DC converter45Starter 146ABS47Cooling fan high48Front wiper49Body control module/Retained

power off

Page 154 of 201

152Vehicle careAfter having changed defective fusesclose the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunction may occur.

Instrument panel fuse box

The fuse box is located on the driver's

side behind a cover in the instrument

panel.

To open the compartment, compress

the locking tabs, fold cover down and

remove.

No.Circuit1Onstar2Air conditioning system3Instrument cluster4Transmission control module5Infotainment6–7Rear parking assist8Data link connection9Electric steering column lock10Sensing and Diagnostic module11DC transformer12–13–14Linear power module15Central locking system/Ignition

system16Ignition system

Page 155 of 201

Vehicle care153No.Circuit17–18Instrument cluster19–20Headlight range adjustment21Power windows, front22Power windows, rear23–24Manual transmission auto‐

mated module25Auxiliary power outlet26Sunroof27–28Body control module 829Body control module 730Body control module 631Body control module 532Body control module 4No.Circuit33Body control module 334Body control module 235Body control module 136–37Steering wheel control LED38–39Logistic/DC transformer40Power window, driver41Blower42Seat heating, front43Air conditioning module44Heated steering wheel45–Vehicle tools

Tools

Vehicles with tyre repair kit

The vehicle tools are in the

compartment under the floor cover in

the load compartment, together with

the tyre repair kit.

Page 160 of 201

158Vehicle careThe Tyre Load menu only appears if

the vehicle is in a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Select:

● Lo for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Hi for full loading.

Tyre pressure sensor matching

process

Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new tyre/wheel position after

rotating the tyres or exchanging the

complete wheel set and if one or more

tyre pressure sensors were replaced. The tyre pressure sensor matching

process should also be performed

after replacing a spare tyre with a

road tyre containing the tyre pressure sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a relearn tool, in the

following order: left side front wheel,

right side front wheel, right side rear

wheel and left side rear wheel. The

turn signal light at the current active

position is illuminated until sensor is

matched.

Consult a workshop for service. There

are two minutes to match the first

wheel position, and five minutes

overall to match all four wheelpositions. If it takes longer, the

matching process stops and must be

restarted.

The tyre pressure sensor matching

process is:

1. Apply the parking brake.

2. Turn the ignition on.

3. On vehicles with manual transmission: select neutral.

4. Use MENU on the turn signal

lever to select the Vehicle

Information Menu in the Driver

Information Centre.

5. Turn the adjuster wheel to scroll to

the tyre pressure menu.

6. Press SET/CLR to begin the

sensor matching process. A

message requesting acceptance

of the process should be

displayed.

7. Press SET/CLR again to confirm

the selection. The horn sounds

twice to indicate that the receiver

is in relearn mode.

8. Start with the left side front wheel.

Page 170 of 201

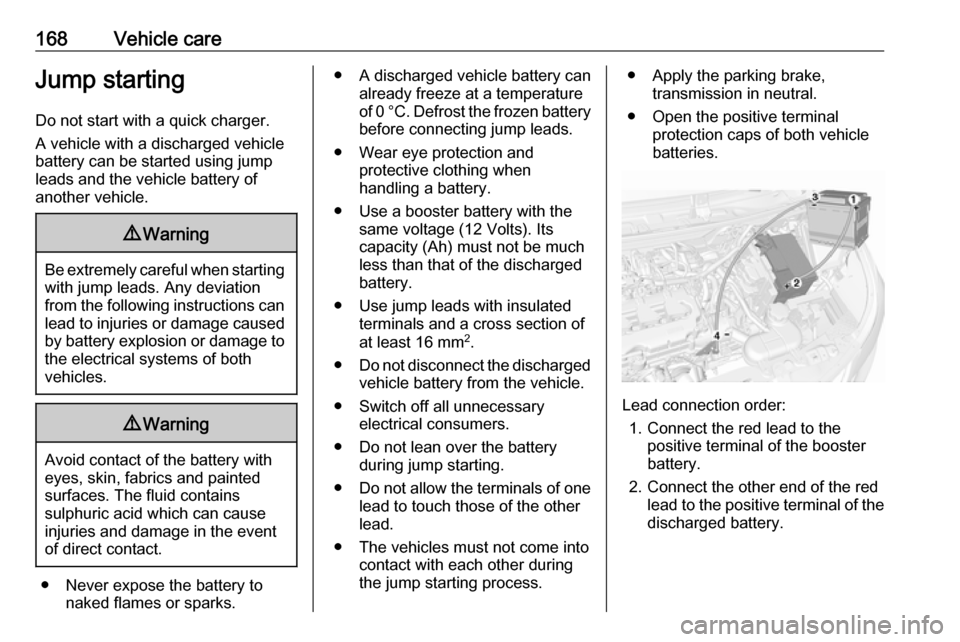

168Vehicle careJump startingDo not start with a quick charger.

A vehicle with a discharged vehicle

battery can be started using jump

leads and the vehicle battery of

another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

.

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral.

● Open the positive terminal protection caps of both vehicle

batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

Page 172 of 201

170Vehicle care

2. Screw in the towing eye as far asit will go until it stops in a

horizontal position.

3. Attach a tow rope – or better still a

tow rod – to the towing eye.

General

The towing eye must only be used for

towing and not for recovering the

vehicle.

Switch on ignition to release steering

wheel lock and to permit operation of

brake lights, horn and windscreen

wiper.

Transmission in neutral.Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

The vehicle must be towed facing

forward, not faster than 88 km/h. In all

other cases and when the

transmission is defective, the front

axle must be raised off the ground.

Seek the assistance of a workshop.

After towing, unscrew the towing eye.

Insert cap and engage in the front

bumper.

Appearance care

Exterior care

Locks The locks are lubricated at the factoryusing a high quality lock cylinder

grease. Use a de-icing agent only

when absolutely necessary, as this

has a degreasing effect and impairs

lock function. After using a de-icing

agent, have the locks regreased by a workshop.

Washing The paintwork of your vehicle is

exposed to environmental influences.

Wash and wax your vehicle regularly. When using automatic vehicle

washes, select a programme that

includes waxing.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned

off immediately, as they contain

aggressive constituents which can

cause paint damage.

Page 185 of 201

![VAUXHALL VIVA 2017.5 Owners Guide Technical data183PerformanceEngineB10XEB10XL LPGMaximum speed [mph]Manual transmission105105Manual transmission automated105–Automatic transmission–– VAUXHALL VIVA 2017.5 Owners Guide Technical data183PerformanceEngineB10XEB10XL LPGMaximum speed [mph]Manual transmission105105Manual transmission automated105–Automatic transmission––](/img/38/19575/w960_19575-184.png)

Technical data183PerformanceEngineB10XEB10XL LPGMaximum speed [mph]Manual transmission105105Manual transmission automated105–Automatic transmission––

Page 186 of 201

![VAUXHALL VIVA 2017.5 Owners Guide 184Technical dataVehicle weight

Kerb weightEngineManual transmissionManual transmission automatedAutomatic transmissionminimum / maximum

[kg]B10XE939 / 1034939/1034–B10XL LPG1025/1091––

Optional VAUXHALL VIVA 2017.5 Owners Guide 184Technical dataVehicle weight

Kerb weightEngineManual transmissionManual transmission automatedAutomatic transmissionminimum / maximum

[kg]B10XE939 / 1034939/1034–B10XL LPG1025/1091––

Optional](/img/38/19575/w960_19575-185.png)

184Technical dataVehicle weight

Kerb weightEngineManual transmissionManual transmission automatedAutomatic transmissionminimum / maximum

[kg]B10XE939 / 1034939/1034–B10XL LPG1025/1091––

Optional accessories increase the kerb weight.

Loading information 3 57.

Page 190 of 201

188Customer informationCustomer

informationCustomer information ................188

Declaration of conformity .........188

Collision damage repair ...........190

Software acknowledgement ....190

Registered trademarks ............192

Vehicle data recording and pri‐

vacy ........................................... 192

Event data recorders ...............192

Radio Frequency Identification (RFID) ..................................... 193Customer information

Declaration of conformity

Transmission systems

This vehicle has systems that

transmit and/or receive radio waves

subject to Directive 1999/5/EC.

These systems are in compliance

with the essential requirements and

other relevant provisions of Directive

1999/5/EC. Copies of the original

Declarations of Conformity can be

obtained on our website.

Page 195 of 201

Customer information193● Vehicle reactions in particulardriving situations ( e.g. inflation of

an airbag, activation of the

stability regulation system).

● Environmental conditions (e.g. temperature).

These data are exclusively technical

and help identifying and correcting

errors as well as optimizing vehicle

functions.

Motion profiles indicating travelled

routes cannot be created with these

data.

If services are used (e.g. repair

works, service processes, warranty

cases, quality assurance),

employees of the service network

(manufacturer included) are able to

read out this technical information

from the event and error data storage

modules applying special diagnostic

devices. If required, you will receive

further information at these

workshops. After an error has been

corrected, the data are deleted from

the error storage module or they are

constantly overwritten.When using the vehicle, situations

may occur in which these technical

data related to other information

(accident report, damages on the

vehicle, witness statements etc.) may

be associated with a specific person - possibly, with the assistance of an

expert.

Additional functions contractually

agreed upon with the client (e.g.

vehicle location in emergency cases)

allow the transmission of particular

vehicle data from the vehicle.

Radio Frequency

Identification (RFID)

RFID technology is used in some

vehicles for functions such as tyre

pressure monitoring and ignition

system security. It is also used in

connection with conveniences such

as radio remote controls for door

locking/unlocking and starting, and in-

vehicle transmitters for garage door

openers. RFID technology in

Vauxhall vehicles does not use or

record personal information or link with any other Vauxhall system

containing personal information.