check engine VAUXHALL VIVA 2017 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2017, Model line: VIVA, Model: VAUXHALL VIVA 2017Pages: 201, PDF Size: 5.29 MB

Page 112 of 201

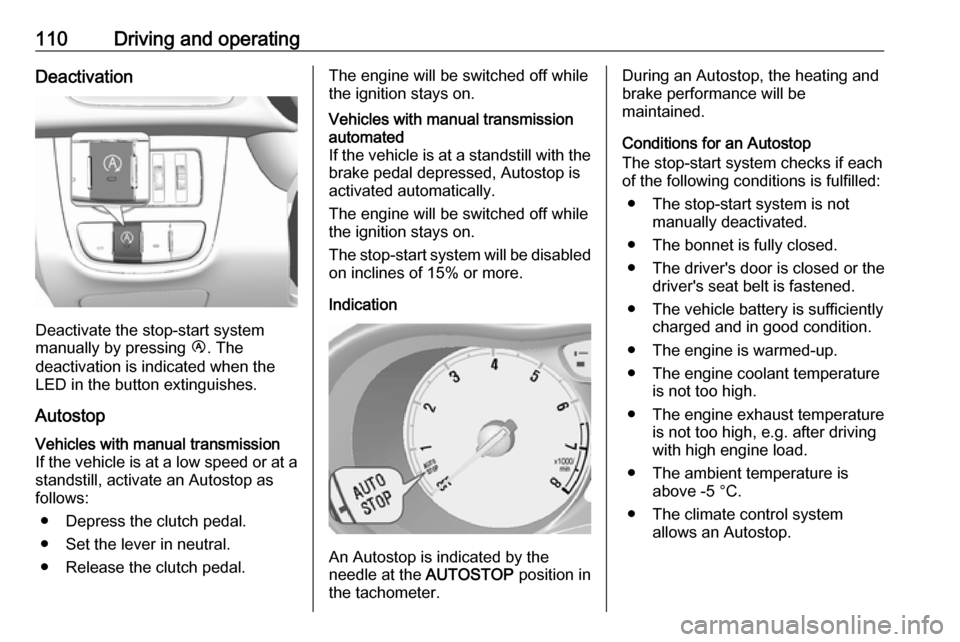

110Driving and operatingDeactivation

Deactivate the stop-start system

manually by pressing Ï. The

deactivation is indicated when the

LED in the button extinguishes.

Autostop

Vehicles with manual transmission

If the vehicle is at a low speed or at a

standstill, activate an Autostop as

follows:

● Depress the clutch pedal.

● Set the lever in neutral.

● Release the clutch pedal.The engine will be switched off while

the ignition stays on.Vehicles with manual transmission

automated

If the vehicle is at a standstill with the brake pedal depressed, Autostop is

activated automatically.

The engine will be switched off while

the ignition stays on.

The stop-start system will be disabled

on inclines of 15% or more.

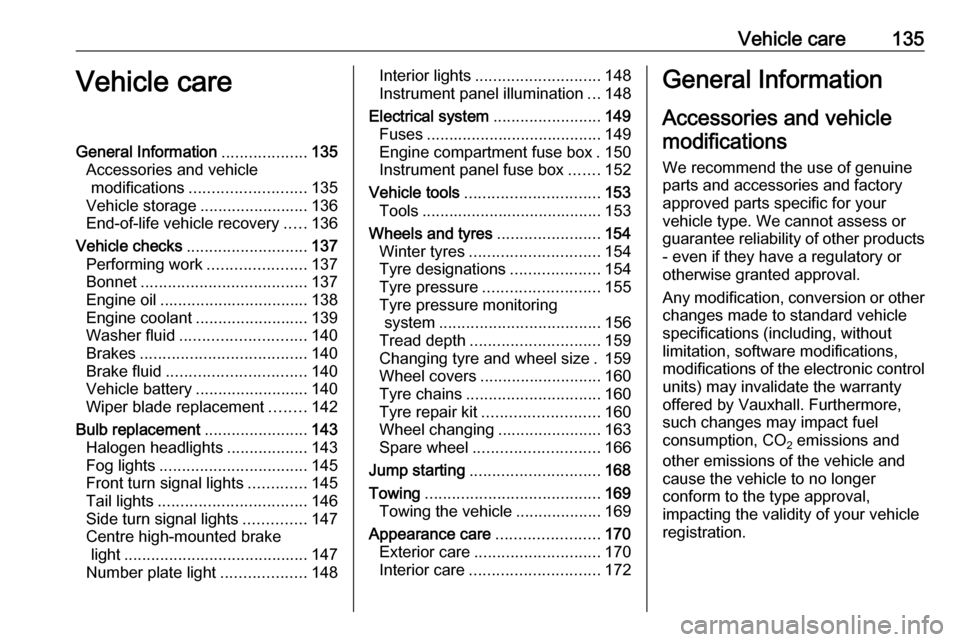

Indication

An Autostop is indicated by the

needle at the AUTOSTOP position in

the tachometer.

During an Autostop, the heating and

brake performance will be

maintained.

Conditions for an Autostop

The stop-start system checks if each

of the following conditions is fulfilled:

● The stop-start system is not manually deactivated.

● The bonnet is fully closed.

● The driver's door is closed or the driver's seat belt is fastened.

● The vehicle battery is sufficiently charged and in good condition.

● The engine is warmed-up.

● The engine coolant temperature is not too high.

● The engine exhaust temperature is not too high, e.g. after driving

with high engine load.

● The ambient temperature is above -5 °C.

● The climate control system allows an Autostop.

Page 131 of 201

Driving and operating129LED off:petrol operationLED

flashes:checking conditions for

fuel transition to liquid

gas operation.

Illuminates if conditions

are fulfilled.LED illu‐

minates:liquid gas operationLED

flashes

five

times

and

extin‐

guishes:liquid gas tank is empty

or failure in liquid gas

system. A message is

displayed in the Driver

Information Centre.

If the fuel tank is empty, the engine

will not start.

The selected fuel mode is stored and

reactivated at the next ignition cycle if

conditions allow.

As soon as the liquid gas tanks are

empty, petrol operation is

automatically engaged until the

ignition is switched off.

When switching automatically

between petrol or gas operation, a

brief delay of engine tractive power

may be noticeable.

Every six months, run the petrol tank

down until control indicator Y

illuminates, then refuel. This helps

maintain fuel quality and system

function for petrol operation.

Fill the tank completely at regular intervals to prevent corrosion in the

tank.

Faults and remedies

If gas mode is not possible, check the following:

● Is there enough liquid gas present?

● Is there enough petrol present for

starting?

Due to extreme temperatures in

combination with the gas

composition, it may take slightly

longer before the system switches

from petrol to gas mode.

In extreme situations, the system may

also switch back to petrol mode if the

minimum requirements are not

fulfilled. If conditions allow, it might be possible to manually switch back to

liquid gas operation.Seek the assistance of a workshop in

the event of all other faults.Caution

Repairs and adjustments may only be made by trained specialists in

order to maintain the safety and

warranty on the LPG system.

Liquid gas is given a particular odour

(odorised) so that any leaks can be

detected easily.

9 Warning

If you smell gas in the vehicle or in

the immediate vicinity, switch to petrol mode immediately. No

smoking. No naked flames or

ignition sources.

If the gas odour persists, do not start

the engine. Have the cause of the

fault remedied by a workshop.

When using underground car parks,

follow the instructions of the operator

and local laws.

Page 137 of 201

Vehicle care135Vehicle careGeneral Information...................135

Accessories and vehicle modifications .......................... 135

Vehicle storage ........................136

End-of-life vehicle recovery .....136

Vehicle checks ........................... 137

Performing work ......................137

Bonnet ..................................... 137

Engine oil ................................. 138

Engine coolant ......................... 139

Washer fluid ............................ 140

Brakes ..................................... 140

Brake fluid ............................... 140

Vehicle battery ......................... 140

Wiper blade replacement ........142

Bulb replacement .......................143

Halogen headlights ..................143

Fog lights ................................. 145

Front turn signal lights .............145

Tail lights ................................. 146

Side turn signal lights ..............147

Centre high-mounted brake light ......................................... 147

Number plate light ...................148Interior lights ............................ 148

Instrument panel illumination ...148

Electrical system ........................149

Fuses ....................................... 149

Engine compartment fuse box . 150

Instrument panel fuse box .......152

Vehicle tools .............................. 153

Tools ........................................ 153

Wheels and tyres .......................154

Winter tyres ............................. 154

Tyre designations ....................154

Tyre pressure .......................... 155

Tyre pressure monitoring

system .................................... 156

Tread depth ............................. 159

Changing tyre and wheel size . 159 Wheel covers ........................... 160

Tyre chains .............................. 160

Tyre repair kit .......................... 160

Wheel changing .......................163

Spare wheel ............................ 166

Jump starting ............................. 168

Towing ....................................... 169

Towing the vehicle ...................169

Appearance care .......................170

Exterior care ............................ 170

Interior care ............................. 172General Information

Accessories and vehiclemodifications

We recommend the use of genuine

parts and accessories and factory approved parts specific for your

vehicle type. We cannot assess or

guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Any modification, conversion or other changes made to standard vehicle

specifications (including, without

limitation, software modifications,

modifications of the electronic control

units) may invalidate the warranty

offered by Vauxhall. Furthermore,

such changes may impact fuel

consumption, CO 2 emissions and

other emissions of the vehicle and

cause the vehicle to no longer

conform to the type approval,

impacting the validity of your vehicle

registration.

Page 138 of 201

136Vehicle careCaution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, wellventilated place. Engage first or

reverse gear. Prevent the vehicle from rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are not functional, e.g. anti-theft

alarm system.

Putting back into operation When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our

website. Only entrust this work to an

authorised recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.

Page 139 of 201

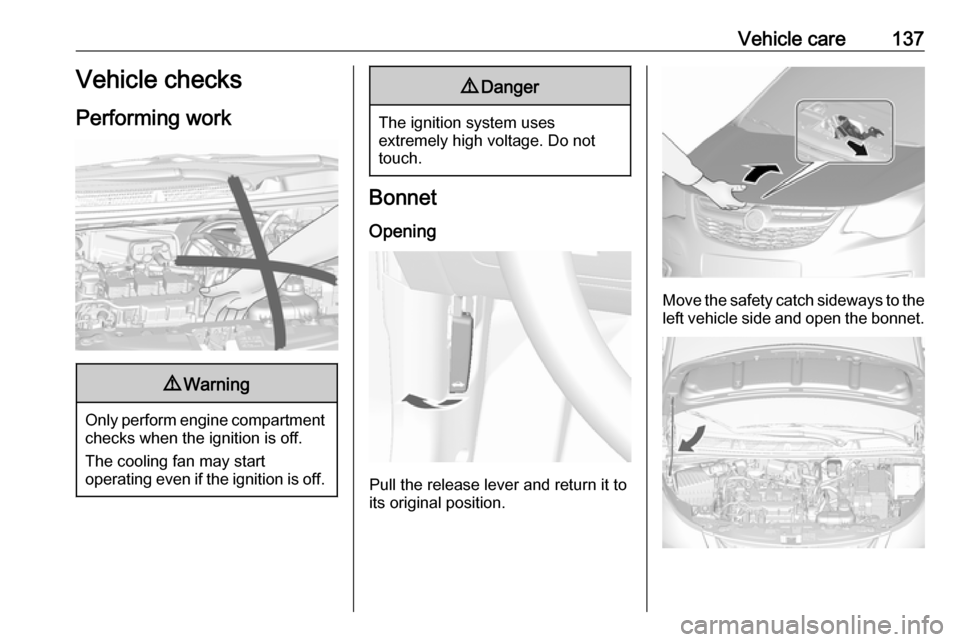

Vehicle care137Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system uses

extremely high voltage. Do not

touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch sideways to the left vehicle side and open the bonnet.

Page 140 of 201

138Vehicle care9Warning

When the engine is hot, touch the

bonnet support rod at the foam

padding only.

Lift the bonnet, remove the bonnet

support rod from the holder and

secure the bonnet support rod

properly.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing

Before closing the bonnet, make sure that all caps are closed properly, then

press the support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is

engaged.

Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 175.

The maximum engine oil

consumption is 0.6 l per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least five minutes.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Insert dipstick to the stop on the

handle and make half a turn.

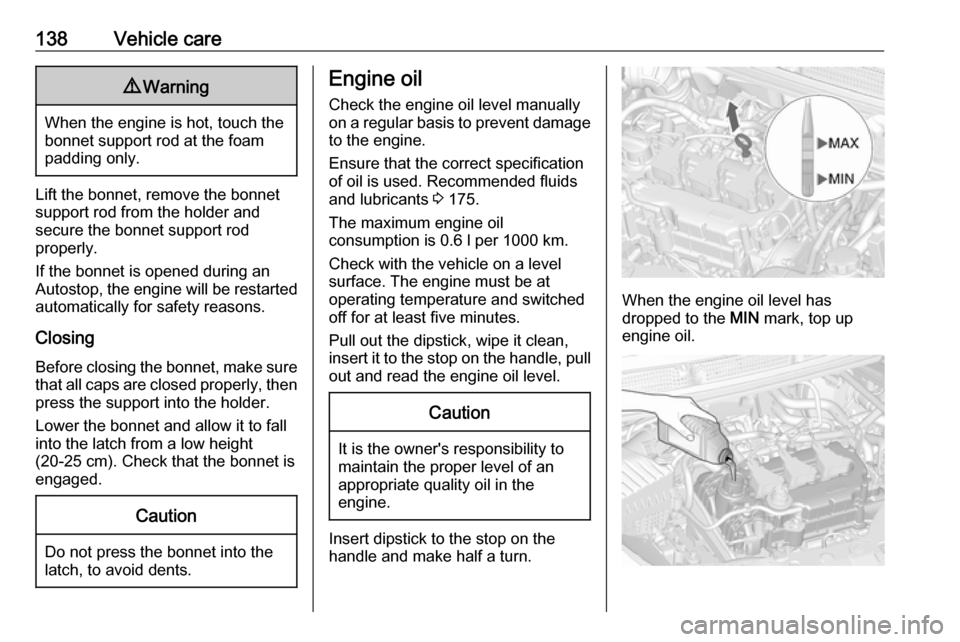

When the engine oil level has

dropped to the MIN mark, top up

engine oil.

Page 141 of 201

Vehicle care139We recommend the use of the same

grade of engine oil that was used at

last change.

The engine oil level must not exceed

the MAX mark on the dipstick.Caution

Overfilled engine oil must be

drained or suctioned out.

Capacities 3 186.

Fit the cap on straight and tighten it.

Engine coolant The coolant provides freeze

protection down to approx. -28 °C. In

northern countries with very low

temperatures the factory filled coolant

provides frost protection down to

approx. -37 °C.

Caution

Only use approved antifreeze.

Coolant and antifreeze 3 175.

Coolant levelCaution

Too low a coolant level can cause

engine damage.

If the cooling system is cold, the

coolant level should be above the

filling line mark. Top up if the level is

low.

9 Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top up use a 1:1 mixture of

released coolant concentrate mixed

with clean tap water. If no coolant

concentrate is available, use clean

tap water. Install the cap tightly. Have

the coolant concentration checked

and have the cause of the coolant

loss remedied by a workshop.

Page 145 of 201

Vehicle care143Bulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base! Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.Halogen headlights

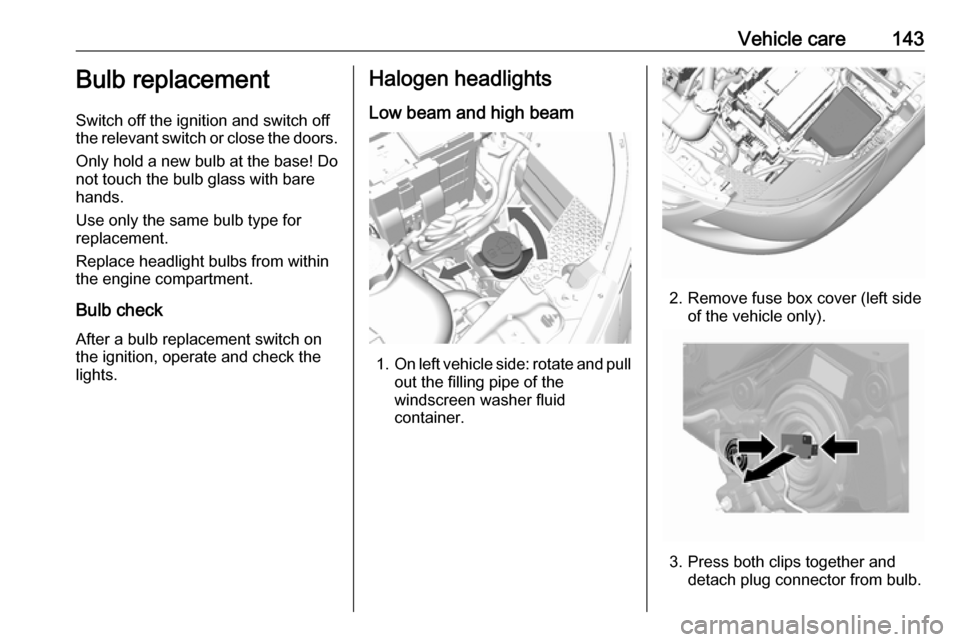

Low beam and high beam

1. On left vehicle side: rotate and pull

out the filling pipe of the

windscreen washer fluid

container.

2. Remove fuse box cover (left side of the vehicle only).

3. Press both clips together anddetach plug connector from bulb.

Page 157 of 201

Vehicle care155Directional tyresDirectional tyres must be mounted so

that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

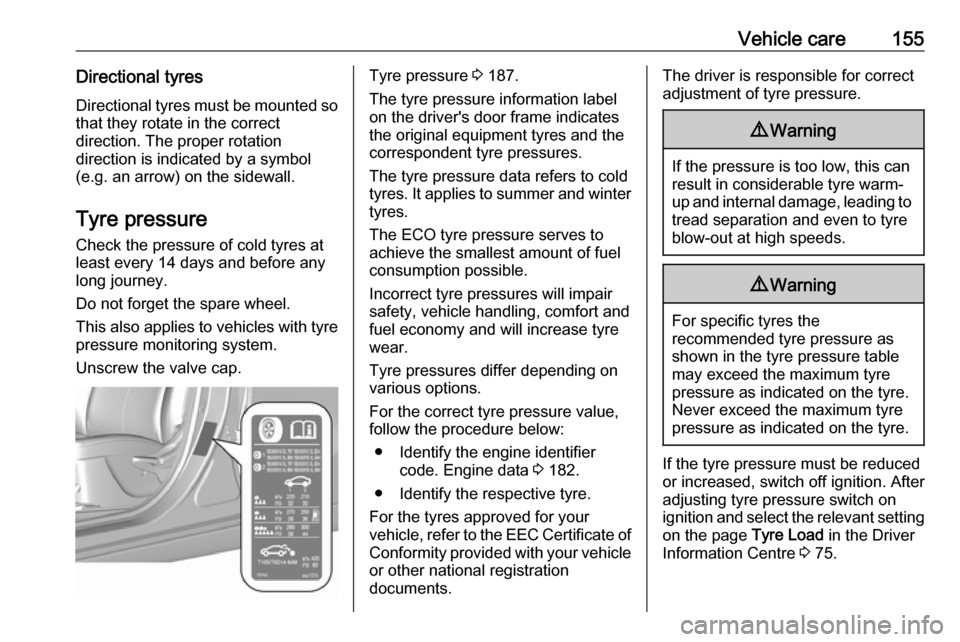

Tyre pressure

Check the pressure of cold tyres at least every 14 days and before any

long journey.

Do not forget the spare wheel.

This also applies to vehicles with tyre pressure monitoring system.

Unscrew the valve cap.Tyre pressure 3 187.

The tyre pressure information label

on the driver's door frame indicates

the original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options.

For the correct tyre pressure value,

follow the procedure below:

● Identify the engine identifier code. Engine data 3 182.

● Identify the respective tyre.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle or other national registration

documents.The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

If the tyre pressure must be reduced

or increased, switch off ignition. After

adjusting tyre pressure switch on

ignition and select the relevant setting on the page Tyre Load in the Driver

Information Centre 3 75.

Page 180 of 201

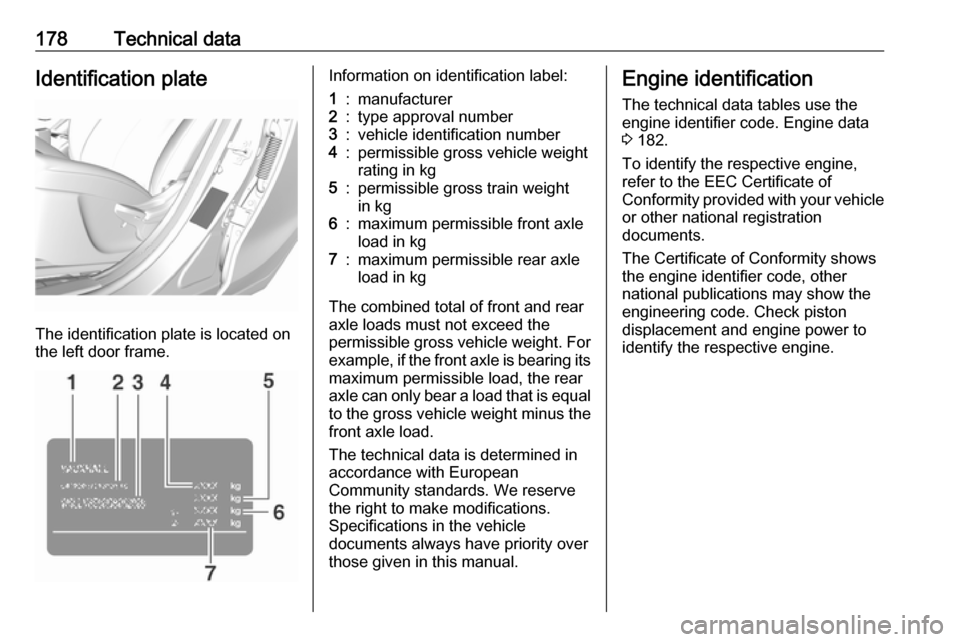

178Technical dataIdentification plate

The identification plate is located on

the left door frame.

Information on identification label:1:manufacturer2:type approval number3:vehicle identification number4:permissible gross vehicle weight rating in kg5:permissible gross train weight

in kg6:maximum permissible front axle

load in kg7:maximum permissible rear axle

load in kg

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight. For

example, if the front axle is bearing its

maximum permissible load, the rear

axle can only bear a load that is equal

to the gross vehicle weight minus the front axle load.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The technical data tables use the

engine identifier code. Engine data

3 182.

To identify the respective engine,

refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The Certificate of Conformity shows

the engine identifier code, other

national publications may show the

engineering code. Check piston

displacement and engine power to

identify the respective engine.