VAUXHALL VIVARO 2015.5 Owner's Manual

Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: VIVARO, Model: VAUXHALL VIVARO 2015.5Pages: 203, PDF Size: 4.54 MB

Page 141 of 203

Vehicle care139

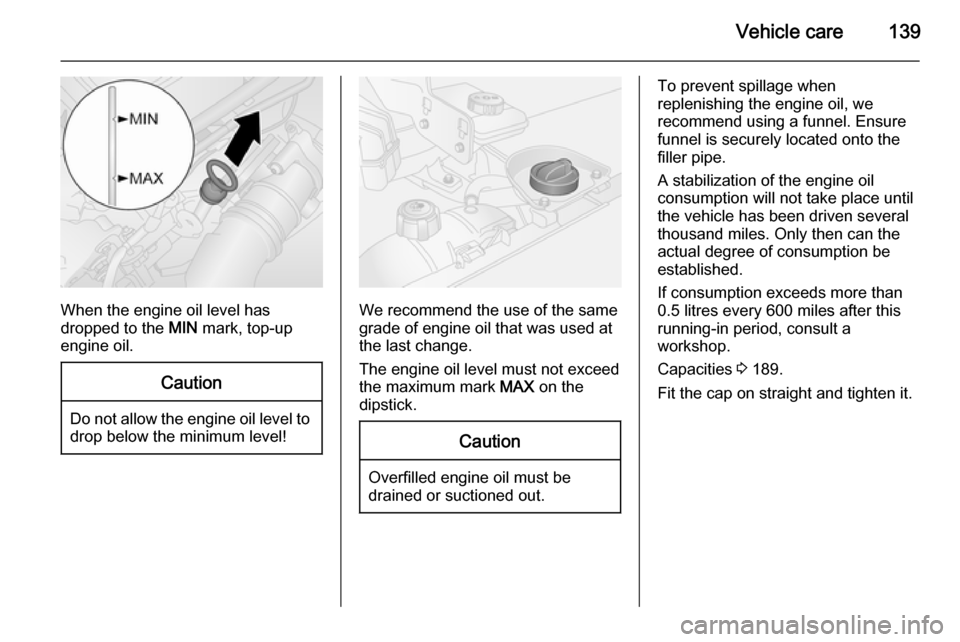

When the engine oil level has

dropped to the MIN mark, top-up

engine oil.

Caution

Do not allow the engine oil level to drop below the minimum level!

We recommend the use of the same

grade of engine oil that was used at

the last change.

The engine oil level must not exceed the maximum mark MAX on the

dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

To prevent spillage when

replenishing the engine oil, we

recommend using a funnel. Ensure funnel is securely located onto the

filler pipe.

A stabilization of the engine oil

consumption will not take place until

the vehicle has been driven several

thousand miles. Only then can the

actual degree of consumption be

established.

If consumption exceeds more than

0.5 litres every 600 miles after this

running-in period, consult a

workshop.

Capacities 3 189.

Fit the cap on straight and tighten it.

Page 142 of 203

140Vehicle careEngine air filterEngine air flow indicator

On certain models, an indicator is

located in the engine induction

system and indicates if the air-intake

to the engine is restricted.

Clear=No restrictionRed tell-tale=Restricted

If the red tell-tale is displayed when

the engine is running, consult a

workshop.

Engine coolant

The coolant provides freeze

protection down to approx. -28 °C.Caution

Only use approved antifreeze.

Coolant level

Caution

Too low a coolant level can cause engine damage.

If the cooling system is cold, the

coolant level should be just above the

MINI mark. Top up if the level is low.9Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

Top up with antifreeze. If no

antifreeze is available, use clean tap

water or distilled water. Install the cap

tightly. Have the antifreeze

concentration checked and have the

cause of the coolant loss remedied by a workshop.

If a substantial amount of coolant is

required, it will be necessary to bleed

any trapped air from the cooling

system. Seek the assistance of a

workshop.

If the coolant temperature is too high, control indicator W 3 86 illuminates

red in the instrument cluster, together

with C 3 84. Consult a workshop if

coolant level is sufficient.

Page 143 of 203

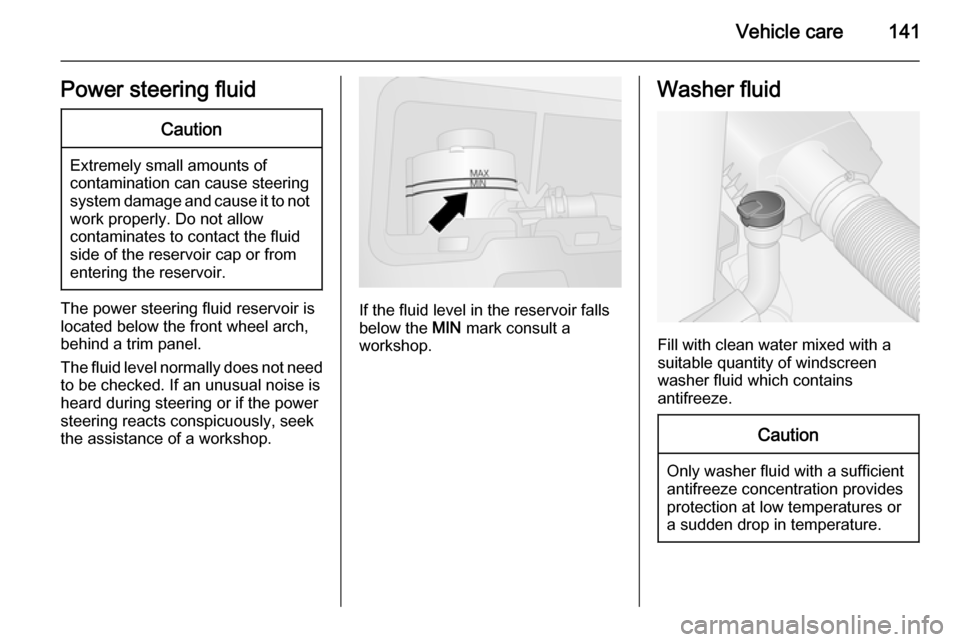

Vehicle care141Power steering fluidCaution

Extremely small amounts of

contamination can cause steering

system damage and cause it to not work properly. Do not allow

contaminates to contact the fluid

side of the reservoir cap or from

entering the reservoir.

The power steering fluid reservoir is located below the front wheel arch,

behind a trim panel.

The fluid level normally does not need

to be checked. If an unusual noise is

heard during steering or if the power

steering reacts conspicuously, seek

the assistance of a workshop.If the fluid level in the reservoir falls

below the MIN mark consult a

workshop.

Washer fluid

Fill with clean water mixed with a

suitable quantity of windscreen

washer fluid which contains

antifreeze.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Page 144 of 203

142Vehicle careBrakesA squealing noise indicates that the

brake lining is at its minimum

thickness. Continued driving is

possible but have the brake lining

replaced as soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

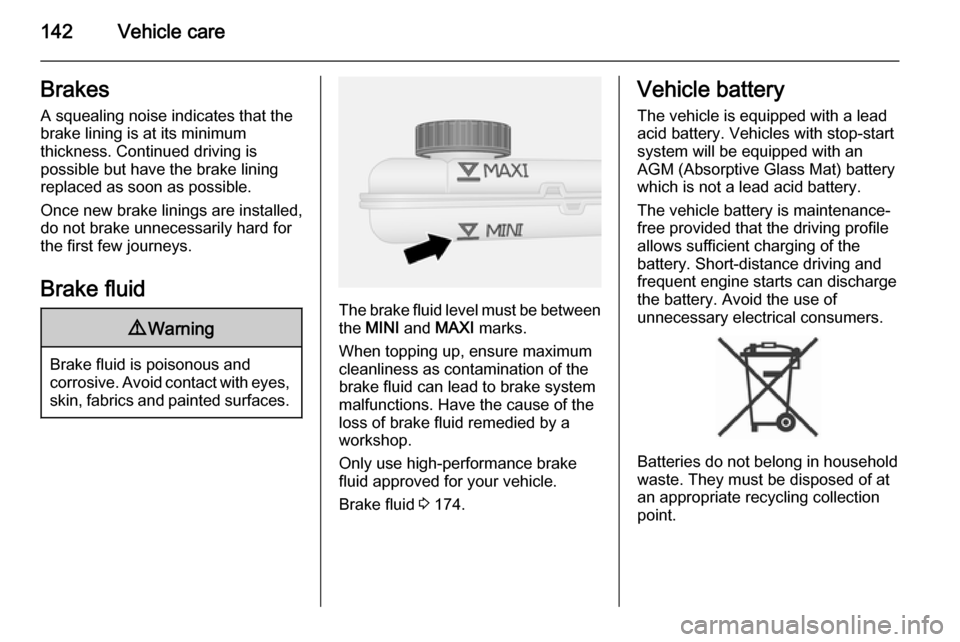

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MINI and MAXI marks.

When topping up, ensure maximum cleanliness as contamination of the

brake fluid can lead to brake system

malfunctions. Have the cause of the

loss of brake fluid remedied by a

workshop.

Only use high-performance brake

fluid approved for your vehicle.

Brake fluid 3 174.

Vehicle battery

The vehicle is equipped with a lead

acid battery. Vehicles with stop-start

system will be equipped with an

AGM (Absorptive Glass Mat) battery

which is not a lead acid battery.

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Page 145 of 203

Vehicle care143

Laying up the vehicle for more than

4 weeks can lead to battery

discharge. Disconnect the clamp from the negative terminal of the vehicle

battery.

Ensure the ignition is switched off

before connecting or disconnecting

the vehicle battery.

Replacing the vehicle battery

In vehicles with stop-start system, be

sure to have the AGM (Absorptive

Glass Mat) battery replaced with

another AGM battery.An AGM battery can be identified by

the label on the battery. We

recommend the use of an original

Vauxhall battery.

Notice

Using an AGM vehicle battery

different from the original Vauxhall

vehicle battery may result in a lower performance of the stop-start

system.

We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 115.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

9 Danger

Ensure adequate ventilation when

charging the battery. There is a

risk of explosion if gases

generated during charging are

allowed to accumulate!

Jump starting 3 167.

Warning label

Page 146 of 203

144Vehicle care

Meaning of symbols:■ No sparks, naked flames or smoking.

■ Always shield eyes. Explosive gases can cause blindness or

injury.

■ Keep the vehicle battery out of reach of children.

■ The vehicle battery contains sulfuric acid which could cause

blindness or serious burn injuries.

■ See the Owner's Manual for further

information.

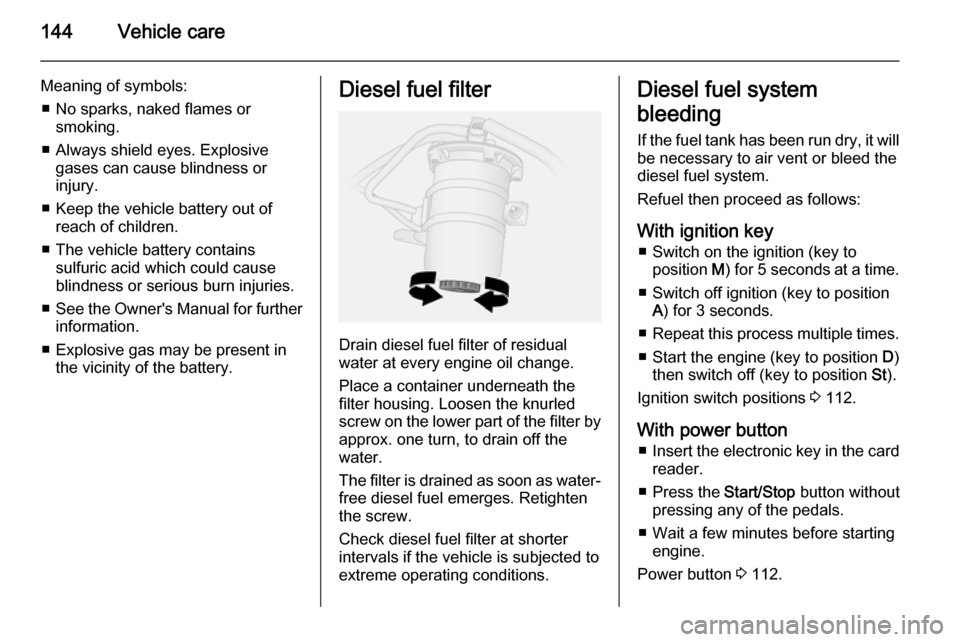

■ Explosive gas may be present in the vicinity of the battery.Diesel fuel filter

Drain diesel fuel filter of residual

water at every engine oil change.

Place a container underneath the

filter housing. Loosen the knurled

screw on the lower part of the filter by approx. one turn, to drain off the

water.

The filter is drained as soon as water-

free diesel fuel emerges. Retighten

the screw.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

Diesel fuel system

bleeding

If the fuel tank has been run dry, it will

be necessary to air vent or bleed the

diesel fuel system.

Refuel then proceed as follows:

With ignition key ■ Switch on the ignition (key to position M) for 5 seconds at a time.

■ Switch off ignition (key to position A) for 3 seconds.

■ Repeat this process multiple times.

■ Start the engine (key to position D)

then switch off (key to position St).

Ignition switch positions 3 112.

With power button ■ Insert the electronic key in the card

reader.

■ Press the Start/Stop button without

pressing any of the pedals.

■ Wait a few minutes before starting engine.

Power button 3 112.

Page 147 of 203

Vehicle care145

If the engine fails to start, seek the

assistance of a workshop.

Starting the engine 3 114.

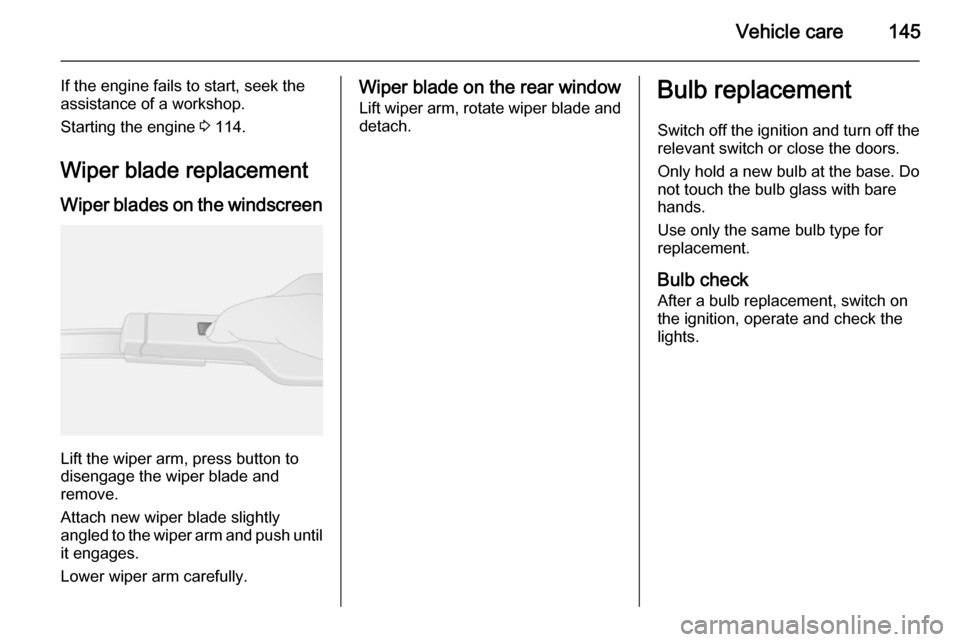

Wiper blade replacement Wiper blades on the windscreen

Lift the wiper arm, press button to

disengage the wiper blade and

remove.

Attach new wiper blade slightly

angled to the wiper arm and push until

it engages.

Lower wiper arm carefully.

Wiper blade on the rear window Lift wiper arm, rotate wiper blade and

detach.Bulb replacement

Switch off the ignition and turn off the

relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Bulb check

After a bulb replacement, switch on

the ignition, operate and check the

lights.

Page 148 of 203

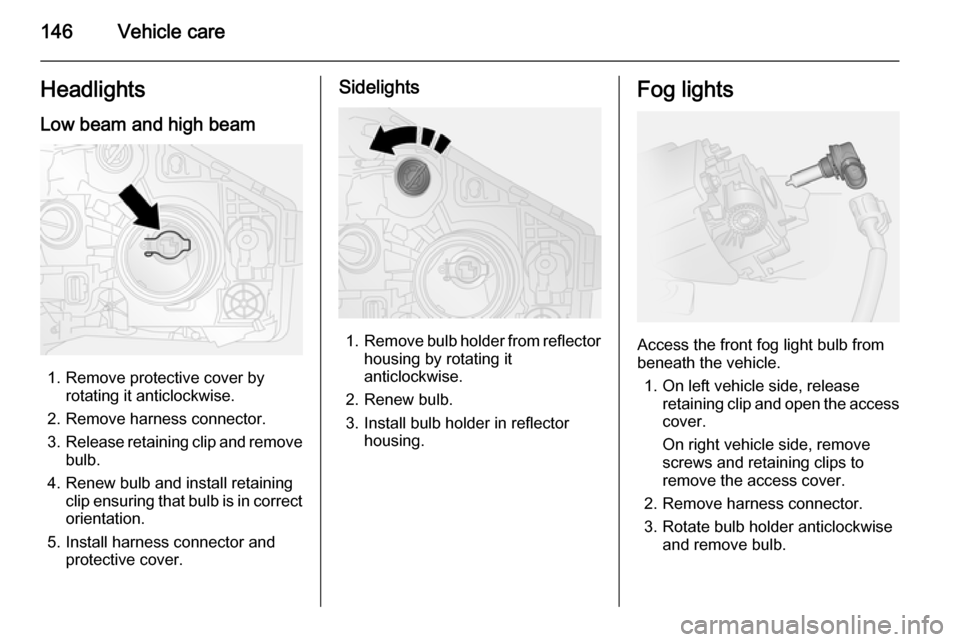

146Vehicle careHeadlights

Low beam and high beam

1. Remove protective cover by rotating it anticlockwise.

2. Remove harness connector.

3. Release retaining clip and remove

bulb.

4. Renew bulb and install retaining clip ensuring that bulb is in correctorientation.

5. Install harness connector and protective cover.

Sidelights

1.Remove bulb holder from reflector

housing by rotating it

anticlockwise.

2. Renew bulb.

3. Install bulb holder in reflector housing.

Fog lights

Access the front fog light bulb from

beneath the vehicle.

1. On left vehicle side, release retaining clip and open the accesscover.

On right vehicle side, remove screws and retaining clips to

remove the access cover.

2. Remove harness connector.

3. Rotate bulb holder anticlockwise and remove bulb.

Page 149 of 203

Vehicle care147

4. Renew bulb and install bulbholder.

5. Install harness connector and access cover.

Front turn signal lights

1. Remove bulb holder from reflector

housing by rotating anticlockwise.

2. Renew bulb.

3. Install bulb holder in reflector housing.

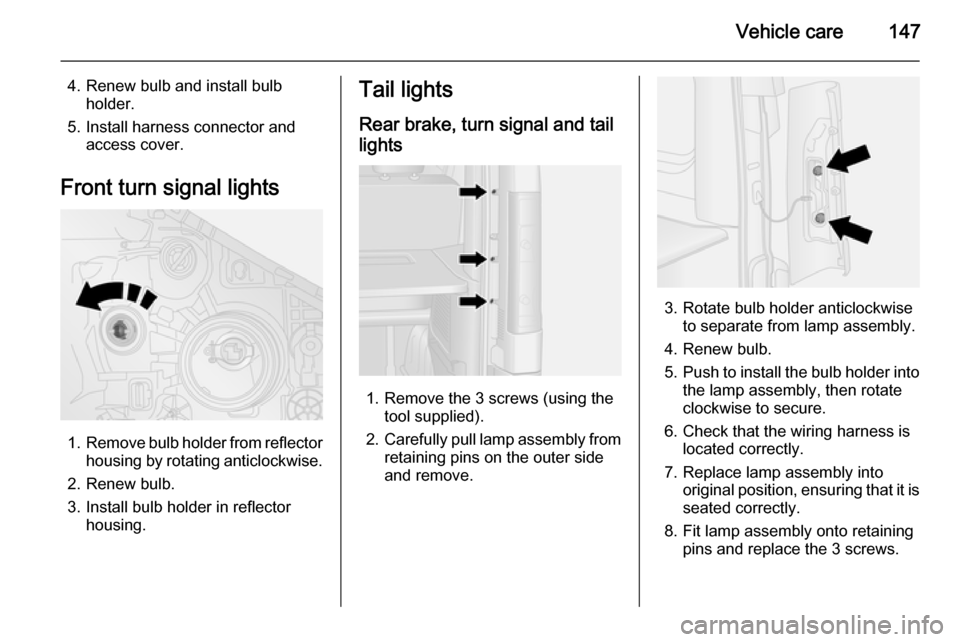

Tail lights

Rear brake, turn signal and tail lights

1. Remove the 3 screws (using the tool supplied).

2. Carefully pull lamp assembly from

retaining pins on the outer side

and remove.

3. Rotate bulb holder anticlockwise to separate from lamp assembly.

4. Renew bulb.

5. Push to install the bulb holder into

the lamp assembly, then rotate

clockwise to secure.

6. Check that the wiring harness is located correctly.

7. Replace lamp assembly into original position, ensuring that it isseated correctly.

8. Fit lamp assembly onto retaining pins and replace the 3 screws.

Page 150 of 203

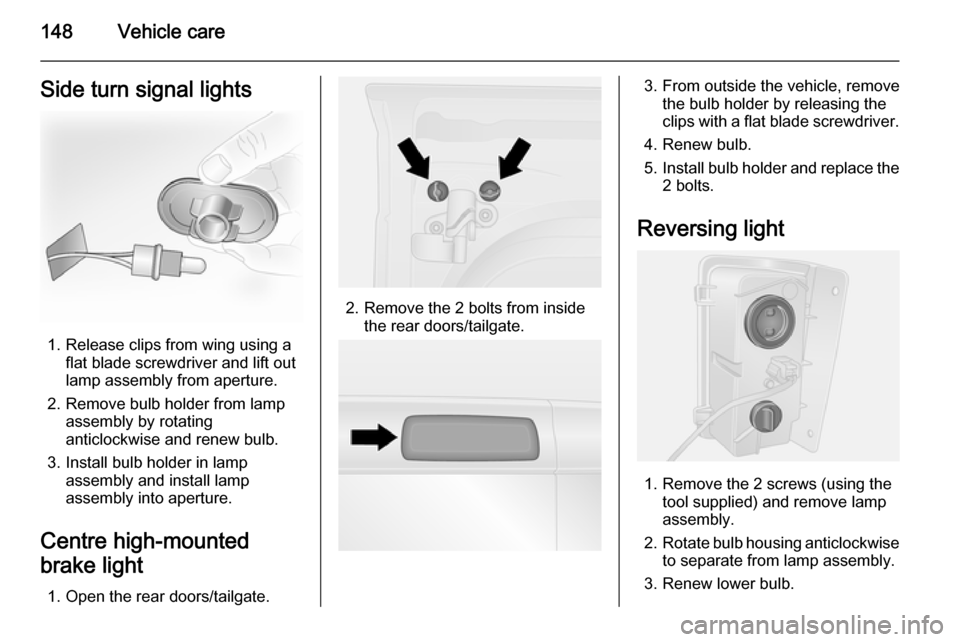

148Vehicle careSide turn signal lights

1. Release clips from wing using aflat blade screwdriver and lift out

lamp assembly from aperture.

2. Remove bulb holder from lamp assembly by rotating

anticlockwise and renew bulb.

3. Install bulb holder in lamp assembly and install lamp

assembly into aperture.

Centre high-mounted

brake light

1. Open the rear doors/tailgate.

2. Remove the 2 bolts from inside the rear doors/tailgate.

3. From outside the vehicle, remove the bulb holder by releasing the

clips with a flat blade screwdriver.

4. Renew bulb.

5. Install bulb holder and replace the

2 bolts.

Reversing light

1. Remove the 2 screws (using the tool supplied) and remove lamp

assembly.

2. Rotate bulb housing anticlockwise

to separate from lamp assembly.

3. Renew lower bulb.