check engine VAUXHALL VIVARO 2016.5 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.5, Model line: VIVARO, Model: VAUXHALL VIVARO 2016.5Pages: 211, PDF Size: 5 MB

Page 129 of 211

Driving and operating127AdBlue canisterNotice

Only use the designated AdBlue

canisters for refilling, to prevent a

topping-up of too much AdBlue.

Additionally, the fumes in the tank

are captured in the canister and do

not emerge.

Notice

Since AdBlue has a limited

durability, check the date of expiry

before refilling.

1. Switch off engine and remove key

from ignition switch.

2. Pull fuel filler flap to open.3. Unscrew protective cap anticlockwise from the filler neck.

4. Open AdBlue canister.

5. Mount one end of the hose on the

canister and screw the other end

on the filler neck.

6. Lift the canister until it is empty.

7. Unscrew the hose from the filler neck.

8. Mount the protective cap and turn

clockwise until it engages.

9. Close fuel filler flap and left-hand door.

Notice

Dispose of AdBlue canister and

hose according to environmental requirements.

Notice

Let the vehicle idle for 10 seconds to

allow the system to detect the

AdBlue refill.

Failure to observe this procedure will result in the system only recognising

the AdBlue refill after 20 minutes of

driving.If the AdBlue refill is detected

successfully, AdBlue level warnings

will disappear.

If the AdBlue refill is not detected

some time after running the engine,

seek the assistance of a workshop.

Filler cap

Only use genuine filler caps. Adblue

tank has a special filler cap.

Fault

If the system detects an operating fault, control indicator Y illuminates

together with F and a warning chime.

Seek the assistance of a workshop

immediately.

A corresponding message appears in the Driver Information Centre 3 90.

Page 146 of 211

144Vehicle careVehicle careGeneral Information...................145

Accessories and vehicle modifications .......................... 145

Vehicle storage ........................145

End-of-life vehicle recovery .....145

Vehicle checks ........................... 146

Performing work ......................146

Bonnet ..................................... 146

Engine oil ................................. 147

Engine air filter ........................ 148

Engine coolant ......................... 148

Power steering fluid .................149

Washer fluid ............................ 150

Brakes ..................................... 150

Brake fluid ............................... 150

Vehicle battery ......................... 150

Diesel fuel filter ........................152

Diesel fuel system bleeding .....152

Wiper blade replacement ........153

Bulb replacement .......................154

Headlights ............................... 154

Fog lights ................................. 154

Front turn signal lights .............155

Tail lights ................................. 155

Side turn signal lights ..............156Centre high-mounted brake

light ......................................... 156

Reversing light ......................... 157

Number plate light ...................157

Fog tail light ............................. 157

Interior lights ............................ 158

Instrument panel illumination ...158

Electrical system ........................159

Fuses ....................................... 159

Instrument panel fuse box .......160

Vehicle tools .............................. 163

Tools ........................................ 163

Wheels and tyres .......................164

Tyres ....................................... 164

Winter tyres ............................. 164

Tyre designations ....................164

Tyre pressure .......................... 164

Tyre pressure monitoring system .................................... 166

Tread depth ............................. 167

Changing tyre and wheel size . 168

Wheel covers ........................... 168

Tyre chains .............................. 168

Tyre repair kit .......................... 169

Wheel changing .......................171

Spare wheel ............................ 173

Jump starting ............................. 174Towing....................................... 176

Towing the vehicle ...................176

Towing another vehicle ...........177

Appearance care .......................177

Exterior care ............................ 177

Interior care ............................. 179

Page 147 of 211

Vehicle care145General Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the

electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir. ● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park vehicle in a dry, well ventilated place. Engage first or

reverse gear. Prevent the vehicle from rolling.

● Do not apply the parking brake.

● Open the bonnet, close all doors and lock the vehicle.Putting back into operation

When the vehicle is to be put back into

operation:

● Check tyre pressure.

● Fill up the washer fluid reservoir. ● Check the engine oil level.

● Check the coolant level.

● Fit the number plate, if necessary.

End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website. Only entrust this work to an

authorised recycling centre.

Page 148 of 211

146Vehicle careVehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system generates

extremely high voltages. Do not

touch.

The caps for topping up the engine oil, the coolant, the washer fluid and the

oil dipstick handle are yellow for ease

of identification.

Bonnet

Opening

Pull the release lever and return it to

its original position.

Move the safety catch (located

slightly right of centre) sideways to

the left vehicle side and open the

bonnet.

The bonnet is held open

automatically by a lifter.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Stop-start system 3 119.

Closing

Lower the bonnet and allow it to fall

into the latch from a low height

(approx. 30 cm). Check that the

bonnet is engaged.

Page 149 of 211

Vehicle care147Caution

Do not press the bonnet into the

latch, to avoid dents.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 182.

The maximum engine oil

consumption is 0.6 l per 1000 km.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 10 minutes.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.

Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

When the engine oil level has

dropped to the MIN mark, top-up

engine oil.

Caution

Do not allow the engine oil level to drop below the minimum level!

We recommend the use of the same

grade of engine oil that was used at

the last change.

The engine oil level must not exceed the maximum mark MAX on the

dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

To prevent spillage when

replenishing the engine oil, we

recommend using a funnel to top-up the engine oil. Ensure funnel is

securely located onto the filler pipe.

Page 151 of 211

Vehicle care149If the cooling system is cold, the

coolant level should be just above the

MINI mark. Top-up if the level is low.9Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

Top-up with antifreeze. If no

antifreeze is available, use clean tap

water or distilled water. Install the cap

tightly. Have the antifreeze

concentration checked and have the

cause of the coolant loss remedied by a workshop.

If a substantial amount of coolant is

required, it will be necessary to bleed

any trapped air from the cooling

system. Seek the assistance of a

workshop.

If the coolant temperature is too high, control indicator W 3 87 illuminates

red in the instrument cluster, together

with C 3 86. Consult a workshop if

coolant level is sufficient.

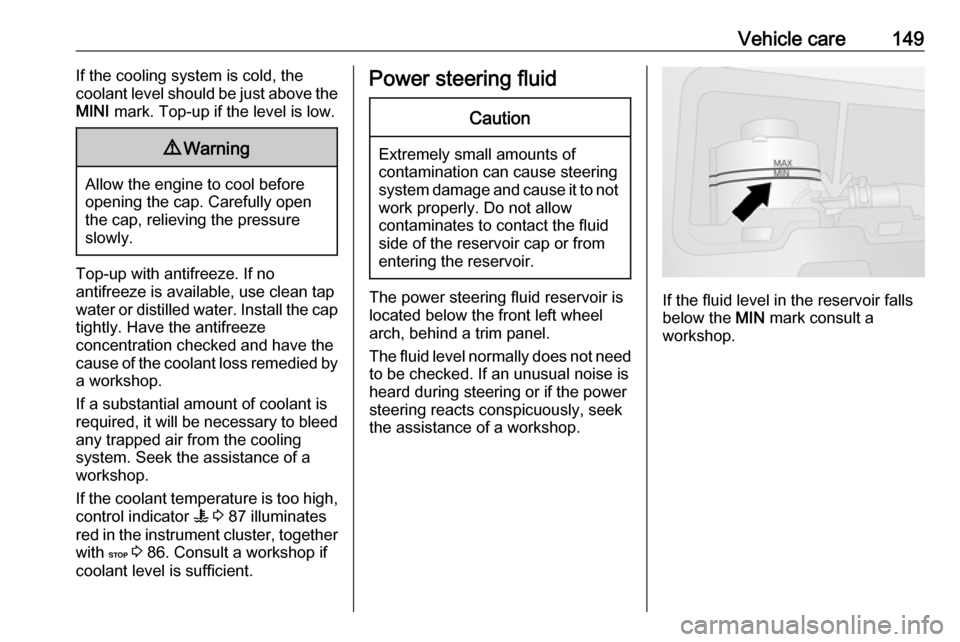

Power steering fluidCaution

Extremely small amounts of

contamination can cause steering

system damage and cause it to not work properly. Do not allow

contaminates to contact the fluid

side of the reservoir cap or from

entering the reservoir.

The power steering fluid reservoir is located below the front left wheel

arch, behind a trim panel.

The fluid level normally does not need

to be checked. If an unusual noise is

heard during steering or if the power

steering reacts conspicuously, seek

the assistance of a workshop.If the fluid level in the reservoir falls

below the MIN mark consult a

workshop.

Page 154 of 211

152Vehicle careWarning label

Meaning of symbols:● No sparks, naked flames or smoking.

● Always shield eyes. Explosive gases can cause blindness or

injury.

● Keep the vehicle battery out of reach of children.

● The vehicle battery contains sulfuric acid which could cause

blindness or serious burn

injuries.

● See the Owner's Manual for further information.

● Explosive gas may be present in the vicinity of the battery.

Diesel fuel filter

The diesel fuel filter is accessible from the underside of the vehicle.

Drain filter of residual water at every

engine oil change.

Place a container underneath the

filter housing. Loosen the knurled

screw on the lower part of the filter by approx. one turn, to drain off the

water.

The filter is drained as soon as water-

free diesel fuel emerges. Retighten

the screw.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

Diesel fuel system bleeding

If the fuel tank has been run dry, it will be necessary to air vent or bleed the

diesel fuel system.

Refuel then proceed as follows:

With ignition key

Page 156 of 211

154Vehicle careBulb replacement

Switch off the ignition and turn off the relevant switch or close the doors.

Only hold a new bulb at the base. Do

not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Bulb check After a bulb replacement, switch on

the ignition, operate and check the

lights.

Headlights

Low beam and high beam Replace headlight bulbs from within

the engine compartment.

1. Remove protective cover by rotating it anticlockwise.

2. Remove harness connector.

3. Release retaining clip and remove

bulb.

4. Renew bulb and install retaining clip ensuring that bulb is in correctorientation.

5. Install harness connector and protective cover.

Sidelights

1.Remove bulb holder from reflector

housing by rotating it

anticlockwise.

2. Renew bulb.

3. Install bulb holder in reflector housing.

Fog lights

Access the front fog light bulb from

beneath the vehicle.

Page 167 of 211

Vehicle care165

The tyre pressure information label

on the driver's door frame indicates

the original equipment tyres and the

correspondent tyre pressures.

Always inflate tyres to the pressures

shown on the label.

Tyre pressures 3 198.

The tyre pressure data refers to cold tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 187.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 198.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

Tyre pressure values provided on the

tyre information label and tyre

pressure chart are valid for cold tyres, which means at 20 °C. The pressure

increases by nearly 1.5 psi for a

10 °C temperature increase. This

must be considered when warm tyres

are checked.

Page 169 of 211

Vehicle care167PunctureA puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 86 and a corresponding message

appears in the DIC. Stop vehicle and

switch off engine.

Tyre pressure 3 198, Tyre repair kit

3 169, Spare wheel 3 173, Wheel

changing 3 171.

Relearn function

After a puncture has been repaired

and the driver has inflated the tyres to

the correct tyre pressure, TPMS

needs to recalculate.

Tyre pressure 3 198, Tyre repair kit

3 169.

During driving, select the tyre

pressure menu in the DIC by pressing button on end of wiper lever. Press

and hold button for approx.

5 seconds to initialise recalculation. A

corresponding message appears in

the DIC.

Several minutes of driving at a speed above 25 mph may be required tocomplete the relearn process. The

system can only provide limited

information during this time.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is

displayed in the DIC.

Driver Information Centre (DIC) 3 90.

Vehicle messages 3 91.

General information The use of tyre chains or

commercially available liquid tyre

repair kits can impair the function of

the system. Factory-approved tyre

repair kits can be used.Tyre repair kit 3 169, Tyre chains

3 168.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced,

TPMS sensors must be dismounted

and serviced by a workshop.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.