VAUXHALL VIVARO 2017.5 Owner's Manual

Manufacturer: VAUXHALL, Model Year: 2017.5, Model line: VIVARO, Model: VAUXHALL VIVARO 2017.5Pages: 231, PDF Size: 5.52 MB

Page 191 of 231

Vehicle care189

3. Screw the air hose to theconnection on the sealant bottle.

4. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

5. Unscrew valve cap from defective

tyre.6. Screw the filler hose to the tyre valve.

7. The switch on the compressor must be set to O.

8. Connect the electrical connection cable to the power outlet or

cigarette lighter socket.

To avoid discharging the vehicle

battery, we recommend running

the engine.9. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

10. The compressor pressure gauge briefly indicates up to six bar

(600 kPa/87 psi). Then the

pressure starts to drop.

11. All of the sealant is pumped into the tyre. Then the tyre is inflated.

Page 192 of 231

190Vehicle care

12. The prescribed tyre pressureshould be obtained within

15 minutes. Tyre pressure

3 216 . When the correct pressure

is obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 15 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. two metres). Reattach

the tyre repair kit and continue the

filling procedure for 15 minutes. If

the prescribed tyre pressure is still not obtained, the tyre is too badly

damaged. Seek the assistance of

a workshop.

Drain excess tyre pressure with

the button beside the pressure

indicator.

Do not run the compressor for

longer than 15 minutes.

13. Detach the tyre repair kit.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the tyre repair kit and affix in the

driver's field of view.

16. Store the sealant bottle in the plastic bag. Return tyre repair kit

to case and stow under the driver's seat.17. Continue driving immediately so that the sealant is evenlydistributed throughout the tyre.

After driving approx. six miles, but no more than ten minutes, stop

and check tyre pressure using the

compressor. Screw air hose from

compressor directly onto tyre

valve when doing this.

18. If the tyre pressure is more than 2.2 bar (220 kPa/31 psi), set it to

the correct value. Repeat the

procedure until there is no more

loss of pressure.

If the tyre pressure has fallen

below 2.2 bar (220 kPa/31 psi),

the vehicle must not be driven.

Seek the assistance of a

workshop.

19. Detach the tyre repair kit, return to

case and stow under the driver's

seat.9 Warning

Do not allow the sealant to contact

skin, eyes or clothing. If swallowed seek medical assistance

immediately.

Page 193 of 231

Vehicle care191Notice

The driving characteristics of the

repaired tyre is severely affected, therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

Pay attention to storage information

and expiry date on sealant bottle. Its

sealing capability is not guaranteed

after this time.

Replace the used sealant bottle. Dispose of the sealant bottle as

prescribed by applicable laws.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 188.

Make the following preparations and

observe the following information:

● Park the vehicle on a level, firm and non-slippery surface. The

front wheels must be in the

straight-ahead position.

● Apply the parking brake and engage first gear or reverse gear.● Remove the spare wheel 3 192.

● Never change more than one wheel at a time.

● Use the jack only to change wheels in case of puncture, not

for a seasonal winter or summer

tyre change.

● The jack is maintenance-free. ● If the ground on which the vehicle

is standing is soft, a solid board

(max. 1 cm thick) should be

placed under the jack.

● Remove heavy objects out of the

vehicle before jacking up.

● No people or animals may be in the vehicle when it is jacked-up.

● Never crawl under a jacked-up vehicle.

● Do not start the engine when the vehicle is raised on the jack.

● Clean wheel bolts/nuts and thread with a clean cloth before

mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover (using the hook supplied). Vehicle tools

3 182.

2. Loosen each of the wheel bolts by

half a turn using the wheel

wrench. Ensure the wrench

locates securely. The wrench

should turn anticlockwise to

loosen the bolts. Invert the wrench if necessary.

Page 194 of 231

192Vehicle care

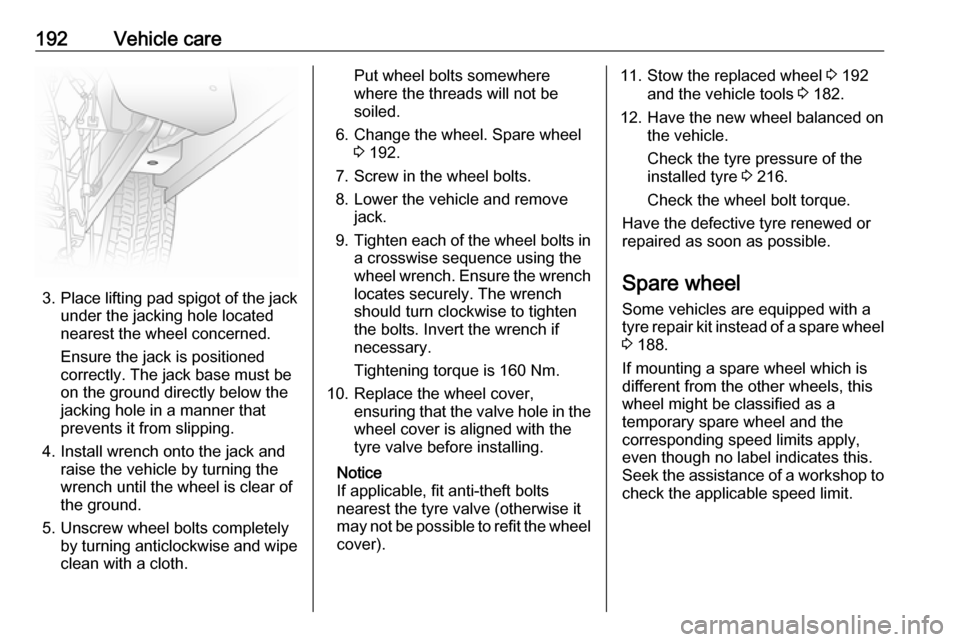

3.Place lifting pad spigot of the jack

under the jacking hole located

nearest the wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

4. Install wrench onto the jack and raise the vehicle by turning the

wrench until the wheel is clear of

the ground.

5. Unscrew wheel bolts completely by turning anticlockwise and wipe

clean with a cloth.

Put wheel bolts somewhere

where the threads will not be

soiled.

6. Change the wheel. Spare wheel 3 192.

7. Screw in the wheel bolts.

8. Lower the vehicle and remove jack.

9. Tighten each of the wheel bolts in

a crosswise sequence using the

wheel wrench. Ensure the wrench locates securely. The wrench

should turn clockwise to tighten

the bolts. Invert the wrench if

necessary.

Tightening torque is 160 Nm.

10. Replace the wheel cover, ensuring that the valve hole in thewheel cover is aligned with the

tyre valve before installing.

Notice

If applicable, fit anti-theft bolts

nearest the tyre valve (otherwise it

may not be possible to refit the wheel

cover).11. Stow the replaced wheel 3 192

and the vehicle tools 3 182.

12. Have the new wheel balanced on the vehicle.

Check the tyre pressure of the

installed tyre 3 216.

Check the wheel bolt torque.

Have the defective tyre renewed or

repaired as soon as possible.

Spare wheel

Some vehicles are equipped with a tyre repair kit instead of a spare wheel

3 188.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.

Page 195 of 231

Vehicle care193Caution

The use of a spare wheel that issmaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a

flat rear tyre.

Wheel changing 3 191.

The spare wheel is mounted under

the rear underbody and may be

secured using a security bolt that can

only be removed using the wheel bolt sleeve supplied. Vehicle tools 3 182.9 Warning

Due to the weight of the tyre

assembly, exercise caution when

releasing the spare wheel carrier.

Do not fully remove bolt 1.

Support the spare wheel with a

suitable object to prevent the

wheel falling suddenly when

loosening the carrier bolts - risk of injury!

To release the spare wheel carrier,fully remove bolt 2 then loosen bolt 1,

ensuring it is not fully removed. Then

move the spare wheel carrier up and

down and from side to side, until it

clears bolt 1, and lower the carrier

assembly.

When installing the wheel ensure that

the spare wheel carrier is correctly

positioned before tightening the bolts.

Summer and winter tyres

If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's driveability may be affected,

especially on slippery road surfaces.

Directional tyres

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

● Driveability may be affected. Have the defective tyre renewed

or repaired as soon as possible

and fit it instead of the spare

wheel.

● Do not drive faster than 50 mph.

● Drive particularly carefully on wet

and snow-covered road

surfaces.

Page 196 of 231

194Vehicle careJump startingDo not start with a quick charger.

A vehicle with a discharged battery

can be started using jump leads and the vehicle battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

● Never expose the battery to naked flames or sparks.

● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery

before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

the jump starting process.● Apply the parking brake, transmission in neutral.

● Open the positive terminal protection caps of both batteries.

The battery is located in the engine

compartment.

Remove cover to access the battery.

Notice

If present, the additional battery is automatically connected to the main vehicle battery only when the engine

is running. It does not need to be manually disconnected before jump

starting the vehicle.

Vehicle battery 3 168.

Page 197 of 231

Vehicle care195

Lead connection order:1. Connect the red lead to the positive terminal (1) of the booster

battery.

2. Connect the other end of the red lead to the positive terminal (2) of

the discharged vehicle battery.

3. Connect the black lead to the negative terminal (3) of the

booster battery.

4. Connect the other end of the black

lead to a vehicle grounding point

(4), such as the engine block or an

engine mounting bolt. Connect as

far away from the discharged

vehicle battery as possible,

however at least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After five minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

one minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.Towing

Towing the vehicle The towing eye is stowed with thevehicle tools 3 182.

Release cap using a suitable tool.

Screw the towing eye clockwise into

the front towing point and tighten fully

using the wheel wrench.

Attach a tow rope - or better still a tow rod - to the towing eye, never to the

bumper or front suspension units.

Page 198 of 231

196Vehicle careCaution

Do not tow the vehicle from the

rear. The front towing eye must

only be used for towing and not

recovering a vehicle.

Caution

Activate the child locks in the rear

doors if the rear seats are

occupied. Child locks 3 30.

Switch on ignition to permit operation

of brake lights, horn and windscreen

wipers, and move the steering wheel

slightly to release the steering wheel

lock.

Notice

Depending on version, it may be

necessary to switch on the engine to

permit operation of brake lights.

Transmission in neutral.

Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

Switch on hazard warning flashers

3 109.

To prevent the entry of exhaust fumes

from the towing vehicle, switch on the air recirculation system 3 115 and

close the windows.

Seek the assistance of a workshop.

After towing, unscrew the towing eye

and replace cap.

Towing another vehicle

The fixed towing eye is located under the rear bumper, on the left vehicle

side.

Attach a tow rope - or better still a tow

rod - to the rear towing eye, never to

the rear axle and suspension units.

The rear towing eye must only be

used for towing and not recovering a

vehicle.

Page 199 of 231

Vehicle care197Caution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

Trailer hitch 3 159.

Appearance care

Exterior care

Locks The locks are lubricated at the factoryusing a high quality lock cylinder

grease. Use de-icing agent only when absolutely necessary, as this has adegreasing effect and impairs lockfunction. After using a de-icing agent,

have the locks regreased by a

workshop.

Washing

The paintwork of your vehicle is

exposed to environmental influences, therefore wash your vehicle regularly.

When using automatic vehicle

washes, we recommend one with

textile brushes and a programme

without wax additives. Restrictions for

filmed or matt painted body parts or

decor tapes, see "Polishing and

waxing".

Never use a steam-jet or high-

pressure jet cleaner for the engine

compartment.Wax painted parts of the vehicle

regularly.

Bird droppings, dead insects, resin,

pollen and the like should be cleaned off immediately, as they contain

aggressive constituents which can

cause paint damage.

If using a vehicle wash, comply with

the vehicle wash manufacturer's

instructions. The windscreen wipers

and rear window wiper must be

switched off and the exterior mirrors

must be folded in. Remove antenna

and external accessories such as roof

racks etc.

If you wash your vehicle by hand,

make sure that the insides of the

wheel housings are also thoroughly

rinsed out.

Clean edges and folds on opened

doors and the bonnet as well as the

areas they cover.

Clean bright metal mouldings with a

cleaning solution approved for

aluminium, to avoid damage.

Page 200 of 231

198Vehicle careCaution

Always use a cleaning agent with

a pH value of four to nine.

Do not use cleaning agents on hot surfaces.

Thoroughly rinse and leather-off the

vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Have the door hinges of all doors

greased by a workshop.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use an ice scraper, and do not clean them

dry.

Polishing and waxing

Wax the vehicle regularly (at the

latest when water no longer beads).

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Unpainted plastic body parts must not be treated with wax or polishing

agents.

Matt filmed body parts or decor tapes must not be polished, to avoid

gleaming. Do not use hot wax

programmes in automatic car washes if the vehicle is equipped with these

parts.

Matt painted decor parts, e.g. mirror

housing cover, must not be polished. Otherwise these parts would become

agleam or the colour would be

dissolved.

Windows and windscreen wiper

blades

Use a soft lint-free cloth or chamois

leather together with window cleaner

and insect remover.When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Remove dirt residues from smearing

wiper blades by using a soft cloth and

window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.

Ice residues, pollution and continuous wiping on dry windows will damage or

even destroy the wiper blades.

Wheels and tyres Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.