ESP VAUXHALL VIVARO 2018 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2018, Model line: VIVARO, Model: VAUXHALL VIVARO 2018Pages: 233, PDF Size: 5.73 MB

Page 155 of 233

Driving and operating153Information Centre 3 100 during this

period, accompanied by a warning

chime.

Release the accelerator pedal and

the speed limiter function is

reactivated once a speed lower than

the limit speed is obtained.

Notice

In vehicles fitted with a Speed

limiter, fully depressing the

accelerator pedal will not allow you

to exceed the set maximum vehicle

speed.

Speed limiter 3 153.

Deactivation

Press §; Speed limiter is deactivated

and the vehicle can be driven normally.

The limit speed is stored and a

corresponding message appears in

the Driver Information Centre.

Reactivation

Press R; The speed limiter function is

reactivated.Pressing < will also reactivate the

speed limiter function, but at the

current vehicle speed only, not the stored speed.

Deleting the limit speed

Press U; Yellow control indicator U

extinguishes in the instrument cluster.

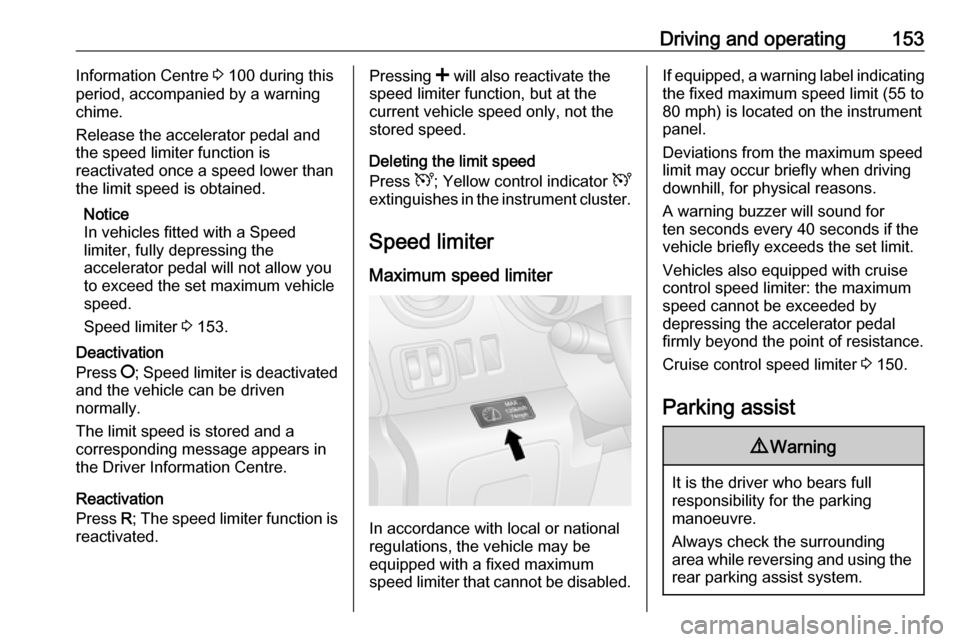

Speed limiter

Maximum speed limiter

In accordance with local or national

regulations, the vehicle may be

equipped with a fixed maximum

speed limiter that cannot be disabled.

If equipped, a warning label indicating the fixed maximum speed limit (55 to

80 mph) is located on the instrument

panel.

Deviations from the maximum speed

limit may occur briefly when driving

downhill, for physical reasons.

A warning buzzer will sound for

ten seconds every 40 seconds if the vehicle briefly exceeds the set limit.

Vehicles also equipped with cruise

control speed limiter: the maximum

speed cannot be exceeded by

depressing the accelerator pedal

firmly beyond the point of resistance.

Cruise control speed limiter 3 150.

Parking assist9 Warning

It is the driver who bears full

responsibility for the parking

manoeuvre.

Always check the surrounding

area while reversing and using the rear parking assist system.

Page 157 of 233

Driving and operating155The system is deactivated and will not

operate. When reverse gear is

selected, no acoustic signal will

sound, indicating deactivation.

The function is reactivated by

pressing and holding r for approx.

three seconds.

Fault

If the system detects an operating

fault, when selecting reverse gear a continuous acoustic alarm will sound

for approx. five seconds, a

corresponding message appears in

the Driver Information Centre 3 100

and F illuminates in the instrument

cluster 3 96. Consult a workshop to

have the cause of the fault remedied.Caution

When reversing, the area should

be free from obstacles which could impact on the underside of the

vehicle.

Impact to the rear axle, which may

not be visible, could lead to

uncharacteristic changes in the

vehicle handling. In the event of

such an impact, consult a

workshop.

Vehicle messages 3 101.

Basic notes on parking assist

system

9 Warning

Under certain circumstances,

various reflective surfaces on

objects or clothing as well as

external noise sources may cause the system to fail to detect

obstacles.

Special attention must be paid to

low obstacles which can damage

the lower part of the bumper.

Caution

Performance of the sensors can

be reduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

system can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles involved (e.g.

off-road vehicles, mini vans,

vans). Object identification in the

upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross-section, e.g. objects of

narrow size or soft materials, may

not be detected by the system.

The parking assist system will not

detect objects which are out of the detection range of the sensors.

Rear view camera

The rear view camera assists the

driver when reversing by displaying a view of the area behind the vehicle in

either the interior mirror or the

Infotainment system display screen.

Page 163 of 233

Driving and operating161If the trailer starts snaking, drive more

slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 217.

Trailer towing Trailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.

The permissible trailer loads are

specified in the vehicle documents. In

general, they are valid for gradients

up to max. 12%.

The permitted trailer load applies up

to the specified incline and up to an

altitude of 1000 metres above sealevel. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10% for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than 8%, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 205.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load is specified on the

towing equipment identification plate

and in the vehicle documents. Always aim for the maximum load, especially in the case of heavy trailers. The

vertical coupling load should never

fall below 25 kg.In the case of trailer loads of

1200 kg or more, the vertical coupling load should not be less than 50 kg.

Rear axle load When the trailer is coupled and the

towing vehicle fully loaded (including all occupants), the permissible rear

axle load (see identification plate or

vehicle documents) must not be

exceeded.

Trailer stability assist If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While the system is working,keep steering wheel as still as

possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Program (ESP® Plus

) 3 148.

Page 167 of 233

Vehicle care165

Move the safety catch, located

slightly right of centre, to the left and raise the bonnet.

The bonnet is held open

automatically by a lifter.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Stop-start system 3 134.

Caution

Ensure the windscreen wiper is

switched off before opening the

bonnet 3 84.

Closing

Lower the bonnet and allow it to fall

into the latch from a low height

(approx. 30 cm). Check that the

bonnet is engaged.Caution

Do not press the bonnet into the

latch, to avoid dents.

9 Warning

In the event of even a minor head-

on collision, have the bonnet

safety catch checked by a

workshop.

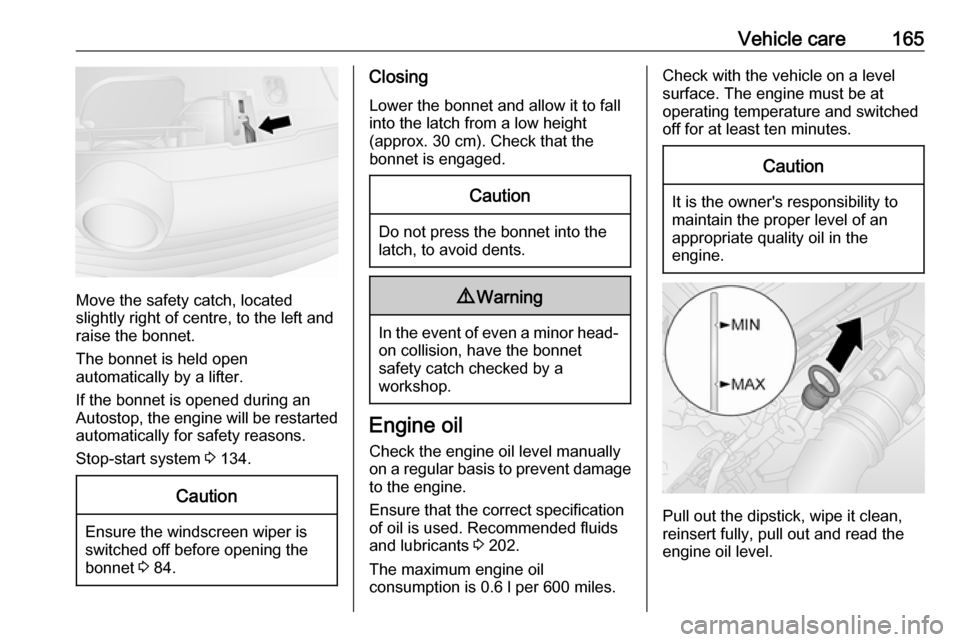

Engine oil

Check the engine oil level manually on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 202.

The maximum engine oil

consumption is 0.6 l per 600 miles.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least ten minutes.Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Pull out the dipstick, wipe it clean,

reinsert fully, pull out and read the

engine oil level.

Page 181 of 233

Vehicle care179Electrical system

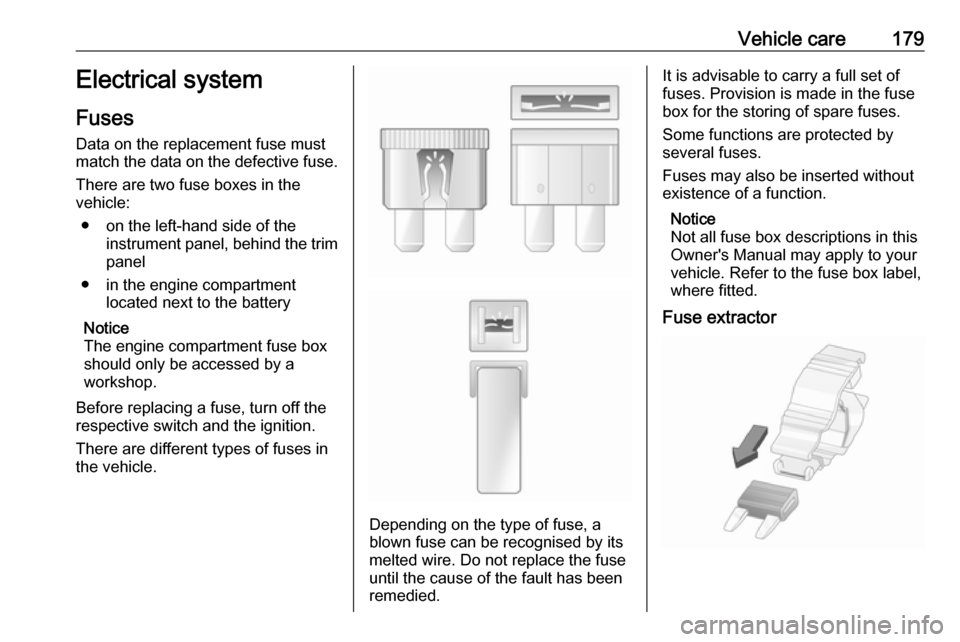

Fuses Data on the replacement fuse must

match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● on the left-hand side of the instrument panel, behind the trim

panel

● in the engine compartment located next to the battery

Notice

The engine compartment fuse box

should only be accessed by a

workshop.

Before replacing a fuse, turn off the

respective switch and the ignition.

There are different types of fuses in

the vehicle.

Depending on the type of fuse, a

blown fuse can be recognised by its

melted wire. Do not replace the fuse until the cause of the fault has been

remedied.

It is advisable to carry a full set of

fuses. Provision is made in the fuse

box for the storing of spare fuses.

Some functions are protected by

several fuses.

Fuses may also be inserted without existence of a function.

Notice

Not all fuse box descriptions in this

Owner's Manual may apply to your

vehicle. Refer to the fuse box label,

where fitted.

Fuse extractor

Page 187 of 233

Vehicle care185

The tyre pressure information label

on the driver's door frame indicates

the original equipment tyres and the

correspondent tyre pressures.

Always inflate tyres to the pressures

shown on the label.

Tyre pressures 3 217.

The tyre pressure data refers to cold tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 207.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 217.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

Tyre pressure values provided on the

tyre information label and tyre

pressure chart are valid for cold tyres, which means at 20 °C. The pressure

increases by nearly 1.5 psi for a

10 °C temperature increase. This

must be considered when warm tyres

are checked.

Page 188 of 233

186Vehicle careTrailer towing

When towing a trailer with a fully

laden vehicle, the tyre pressure must

be increased by 20 kPa/0.2 bar

(3.0 psi) and the maximum speed

limited to 60 mph.

Trailer towing 3 161.

Tyre pressure monitoring

system

The tyre pressure monitoring system

uses radio and sensor technology to

check tyre pressure levels.Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle operating permit.

The tyre pressure monitoring system

sensors monitor the air pressure in

the tyres and transmit tyre pressure

readings to a receiver located in the

vehicle.

Tyre pressure chart 3 217.

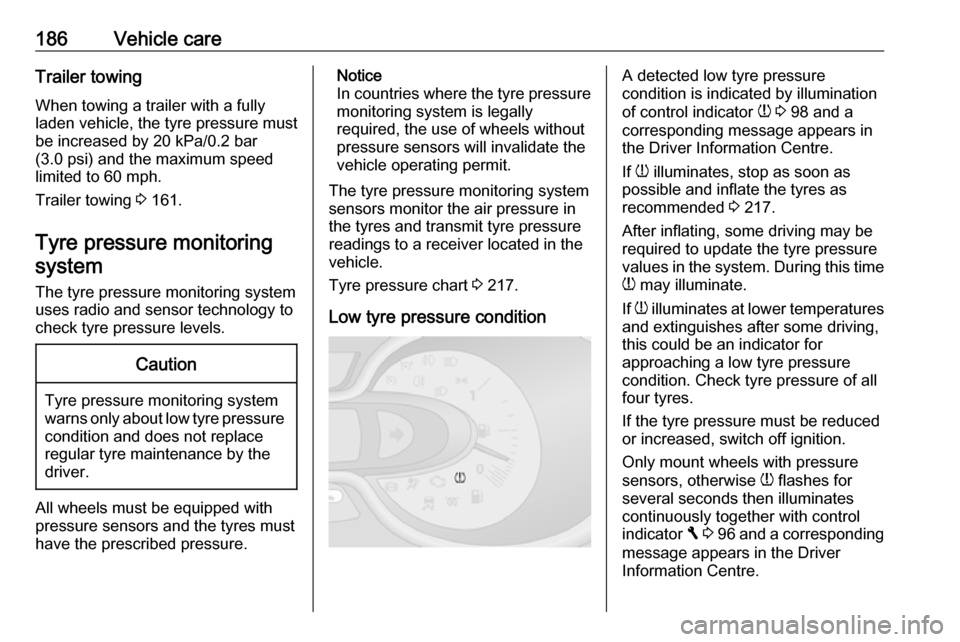

Low tyre pressure conditionA detected low tyre pressure

condition is indicated by illumination

of control indicator w 3 98 and a

corresponding message appears in

the Driver Information Centre.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 217.

After inflating, some driving may be

required to update the tyre pressure

values in the system. During this time

w may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for

approaching a low tyre pressure

condition. Check tyre pressure of all

four tyres.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise w flashes for

several seconds then illuminates

continuously together with control

indicator F 3 96 and a corresponding

message appears in the Driver

Information Centre.

Page 189 of 233

Vehicle care187A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. For the further three

wheels, the tyre pressure monitoring

system remains operational.

Control indicator w and the

corresponding message appears at

each ignition cycle until the tyres are

inflated to the correct tyre pressure.

Driver Information Centre 3 100.

Vehicle messages 3 101.

Puncture

A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 96 and a corresponding message

appears in the Driver Information

Centre. Stop vehicle and switch off

engine.

Tyre pressure 3 217.

Tyre repair kit 3 189.

Spare wheel 3 193.

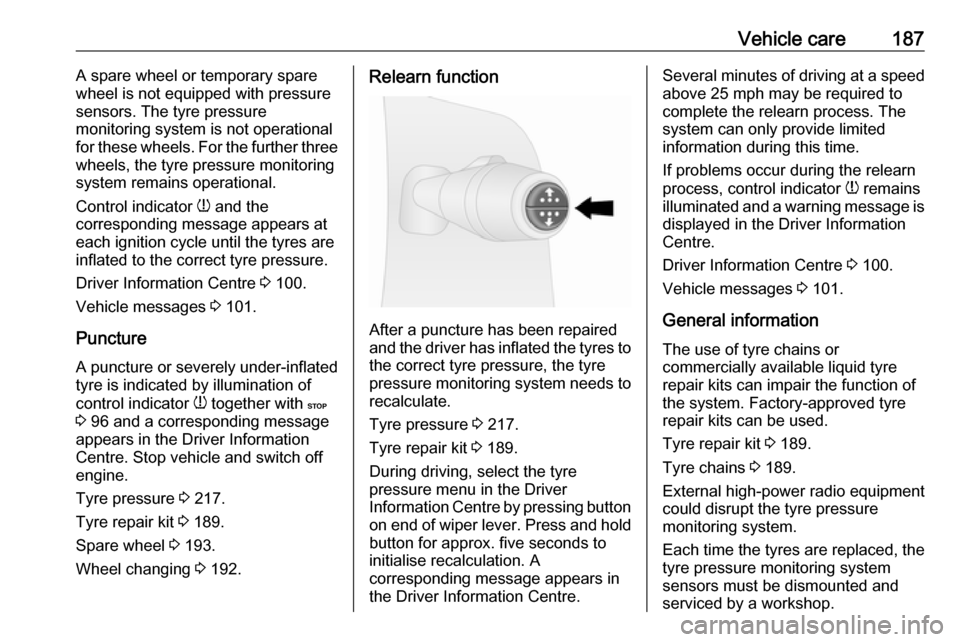

Wheel changing 3 192.Relearn function

After a puncture has been repaired

and the driver has inflated the tyres to

the correct tyre pressure, the tyre

pressure monitoring system needs to recalculate.

Tyre pressure 3 217.

Tyre repair kit 3 189.

During driving, select the tyre

pressure menu in the Driver

Information Centre by pressing button

on end of wiper lever. Press and hold button for approx. five seconds to

initialise recalculation. A

corresponding message appears in

the Driver Information Centre.

Several minutes of driving at a speed above 25 mph may be required to

complete the relearn process. The system can only provide limited

information during this time.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is displayed in the Driver Information

Centre.

Driver Information Centre 3 100.

Vehicle messages 3 101.

General information The use of tyre chains or

commercially available liquid tyre

repair kits can impair the function of

the system. Factory-approved tyre

repair kits can be used.

Tyre repair kit 3 189.

Tyre chains 3 189.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, the

tyre pressure monitoring system

sensors must be dismounted and

serviced by a workshop.

Page 190 of 233

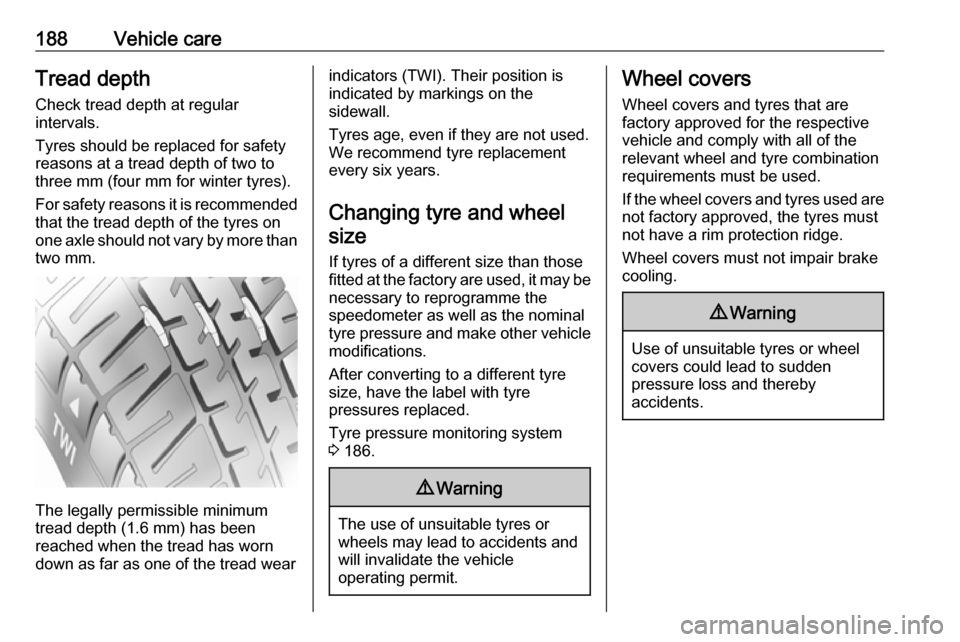

188Vehicle careTread depthCheck tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of two to

three mm (four mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than two mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.

Tyre pressure monitoring system

3 186.9 Warning

The use of unsuitable tyres or

wheels may lead to accidents and will invalidate the vehicle

operating permit.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination

requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Page 195 of 233

Vehicle care193

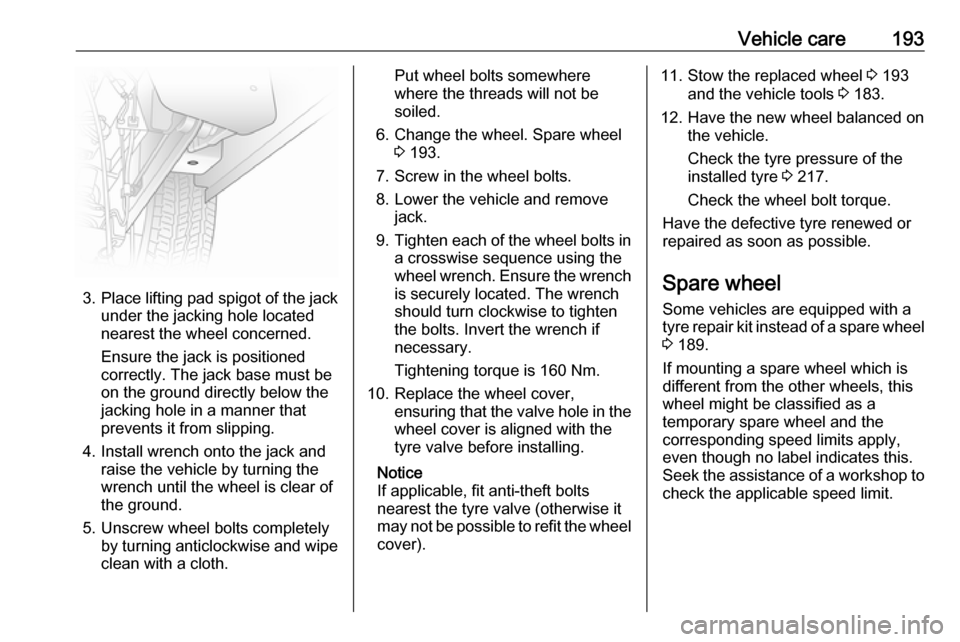

3.Place lifting pad spigot of the jack

under the jacking hole located

nearest the wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

4. Install wrench onto the jack and raise the vehicle by turning the

wrench until the wheel is clear of

the ground.

5. Unscrew wheel bolts completely by turning anticlockwise and wipe

clean with a cloth.

Put wheel bolts somewhere

where the threads will not be

soiled.

6. Change the wheel. Spare wheel 3 193.

7. Screw in the wheel bolts.

8. Lower the vehicle and remove jack.

9. Tighten each of the wheel bolts in

a crosswise sequence using the

wheel wrench. Ensure the wrench is securely located. The wrench

should turn clockwise to tighten

the bolts. Invert the wrench if

necessary.

Tightening torque is 160 Nm.

10. Replace the wheel cover, ensuring that the valve hole in thewheel cover is aligned with the

tyre valve before installing.

Notice

If applicable, fit anti-theft bolts

nearest the tyre valve (otherwise it

may not be possible to refit the wheel

cover).11. Stow the replaced wheel 3 193

and the vehicle tools 3 183.

12. Have the new wheel balanced on the vehicle.

Check the tyre pressure of the

installed tyre 3 217.

Check the wheel bolt torque.

Have the defective tyre renewed or

repaired as soon as possible.

Spare wheel

Some vehicles are equipped with a tyre repair kit instead of a spare wheel

3 189.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.