Engine VAUXHALL VIVARO C 2020 Manual PDF

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2020, Model line: VIVARO C, Model: VAUXHALL VIVARO C 2020Pages: 289, PDF Size: 10.16 MB

Page 233 of 289

Vehicle care231

Grab the fuse with the fuse extractor

and withdraw the fuse.

Engine compartment fuse

box

The fuse box is in the front left of the

engine compartment.

Disengage the cover and remove it.

No.Circuit12Heated washer jets14Front and rear screenwash

pump15Front radar system, electric

power steering17Built-in systems interfaceNo.Circuit19Front wiper motor20Front and rear screenwash

pump21Headlight wash pump22Horn23Right high beam24Left high beam

After having changed defective fuses,

close the fuse box cover and lock it.

If the fuse box cover is not closed

correctly, malfunction may occur.

Instrument panel fuse boxThe fuse box is located behind a

cover in the instrument panel at the

left side.

Page 239 of 289

Vehicle care237Directional tyresDirectional tyres should be mounted

so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol (e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Tyre pressure 3 271.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 268.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 271.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

Page 243 of 289

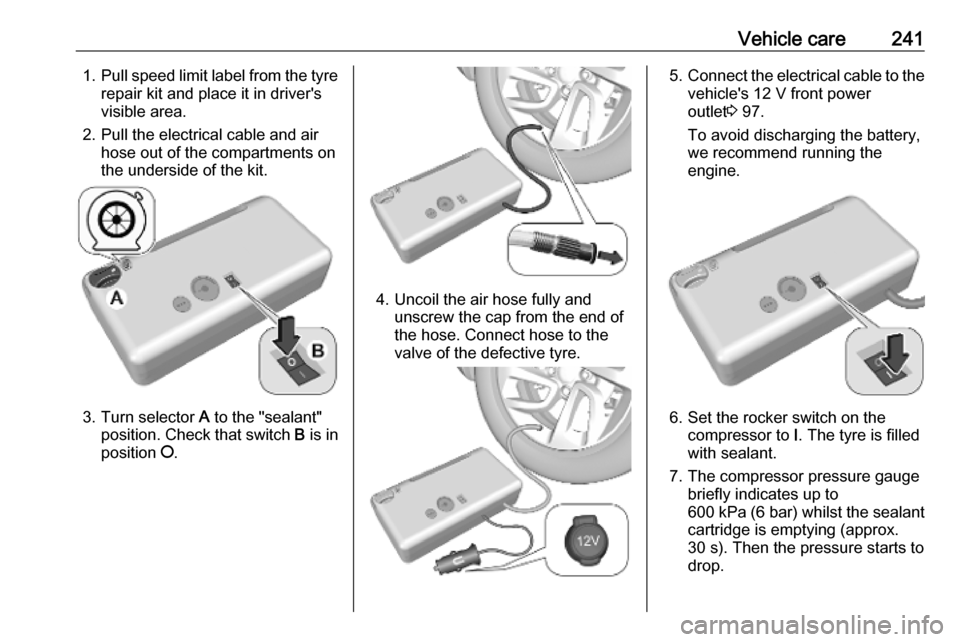

Vehicle care2411.Pull speed limit label from the tyre

repair kit and place it in driver's

visible area.

2. Pull the electrical cable and air hose out of the compartments on

the underside of the kit.

3. Turn selector A to the "sealant"

position. Check that switch B is in

position J.

4. Uncoil the air hose fully and

unscrew the cap from the end of

the hose. Connect hose to the

valve of the defective tyre.

5. Connect the electrical cable to the

vehicle's 12 V front power

outlet 3 97.

To avoid discharging the battery,

we recommend running the

engine.

6. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

7. The compressor pressure gauge briefly indicates up to

600 kPa (6 bar) whilst the sealant

cartridge is emptying (approx.

30 s). Then the pressure starts to

drop.

Page 252 of 289

250Vehicle care● A discharged vehicle battery canalready freeze at a temperature

of 0 °C. Defrost the frozen battery before connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 V). Its capacity

(Ah) must not be much less than

that of the discharged vehicle

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

vehicle battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the vehicle battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the parking brake, transmission in neutral,

automatic transmission in P.

Open the positive terminal protection

caps of both vehicle batteries.

Lead connection order: 1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the boosterbattery.

4. Connect the other end of the black

lead to a vehicle grounding point

of your vehicle in the engine

compartment.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than 15

seconds at an interval of 1 minute.

3. Allow both engines to idle for approx. three minutes with the

leads connected.

4. Switch on electrical consumers e.g. headlights, heated rear

window of the vehicle receiving

the jump start.

5. Reverse above sequence exactly when removing leads.

Page 254 of 289

252Vehicle careCaution

Drive slowly. Do not drive jerkily.

Excessive tractive force can

damage the vehicle.

When the engine is not running,

considerably more force is needed to

brake and steer.

To prevent the entry of exhaust gases from the towing vehicle, switch on the

air recirculation and close the

windows.

Vehicles with automatic transmission: The vehicle must be towed facing

forwards, not faster than 50 mph nor further than 60 miles. In all other

cases and when the transmission is

defective, the front axle must be

raised off the ground.

Seek the assistance of a workshop. After towing, unscrew the towing eye.

Insert cap with the flange into the

recess and fix cap by pushing.

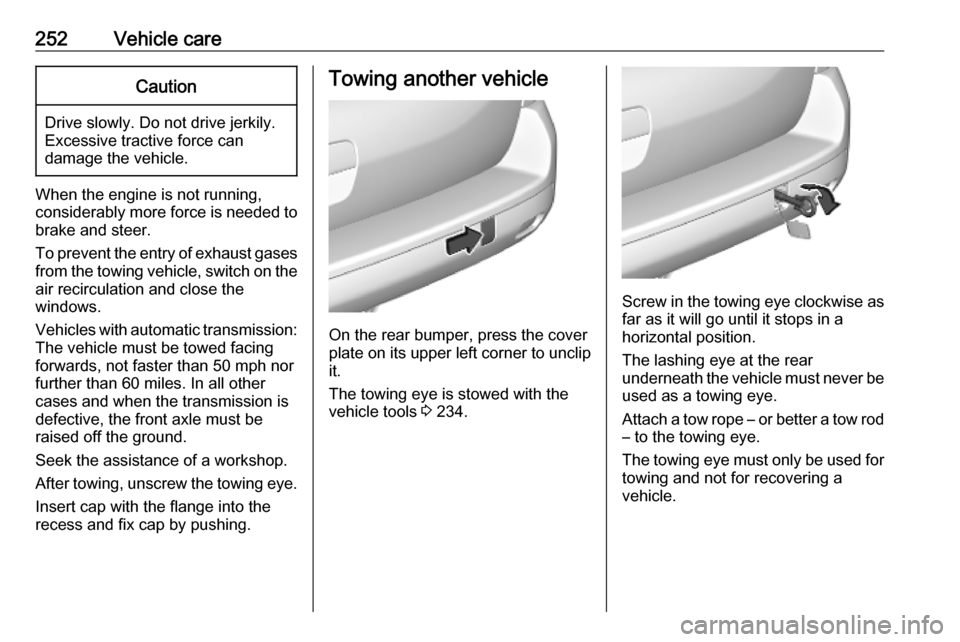

Towing another vehicle

On the rear bumper, press the cover

plate on its upper left corner to unclip it.

The towing eye is stowed with the

vehicle tools 3 234.

Screw in the towing eye clockwise as

far as it will go until it stops in a

horizontal position.

The lashing eye at the rear

underneath the vehicle must never be used as a towing eye.

Attach a tow rope – or better a tow rod

– to the towing eye.

The towing eye must only be used for towing and not for recovering a

vehicle.

Page 256 of 289

254Vehicle careDo not clean the engine compartmentwith a steam-jet or high-pressure jet

cleaner.

Thoroughly rinse and leather-off the

vehicle. Rinse leather frequently. Use

separate leathers for painted and

glass surfaces: remnants of wax on

the windows will impair vision.

Have the door hinges of all doors

greased by a workshop.

Exterior lights

Headlight and other light covers are

made of plastic. Do not use any

abrasive or caustic agents, do not use

an ice scraper, and do not clean them dry.

Polishing and waxing Wax the vehicle regularly at the latest

when water no longer beads.

Otherwise, the paintwork will dry out.

Polishing is necessary only if the paint

has become dull or if solid deposits

have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.Plastic body parts must not be treated with wax or polishing agents.

Windows and wiper blades Switch off wipers before handling in

their areas.

Use a soft lint-free cloth or chamois

leather together with window cleaner

and insect remover.

Use only water-repellent products

approved for the vehicle.

When cleaning the rear window from

inside, always wipe in parallel to the

heating element to prevent damage.

For mechanical removal of ice, use a

sharp-edged ice scraper. Press the

scraper firmly against the glass so

that no dirt can get under it and

scratch the glass.

Clean smearing wiper blades with a

soft cloth and window cleaner.

Remove dirt residues from smearing

wiper blades by using a soft cloth and

window cleaner. Also make sure to

remove any residues such as wax,

insect residues and similar from the

window.Ice residues, pollution and continuous

wiping on dry windows will damage or

even destroy the wiper blades.

Glass panel Never clean with solvents or abrasive

agents, fuels, aggressive media e.g.

paint cleaner, acetone-containing

solutions, acidic or highly alkaline

media or abrasive pads.

Wheels and tyres

Do not use high-pressure jet

cleaners.

Clean rims with a pH-neutral wheel

cleaner.

Rims are painted and can be treated

with the same agents as the body.

Paintwork damageRectify minor paintwork damage witha touch-up pen before rust forms.

Have more extensive damage or rust

areas repaired by a workshop.

Page 262 of 289

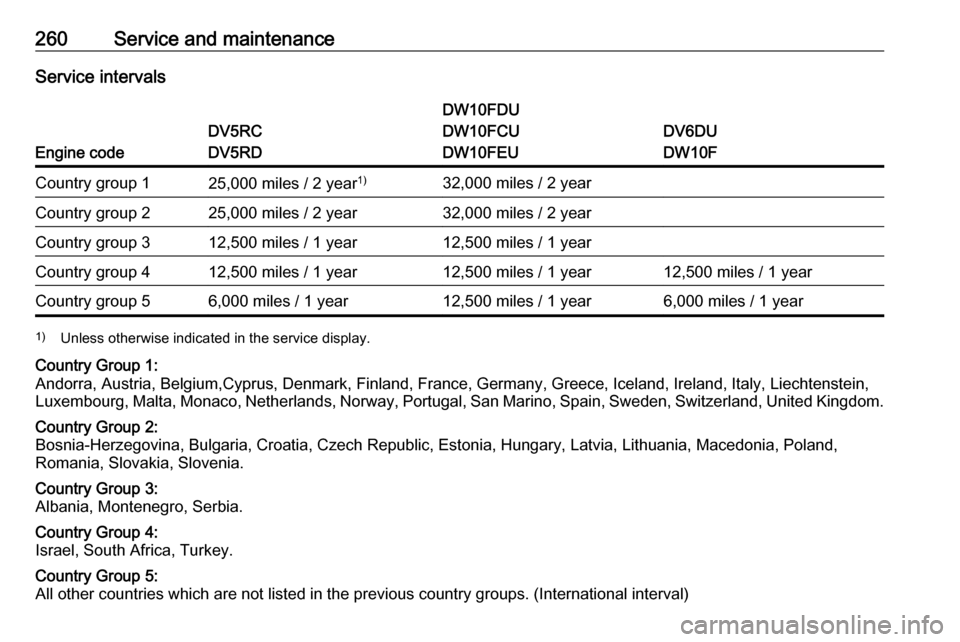

260Service and maintenanceService intervals

Engine code

DV5RC

DV5RD

DW10FDU

DW10FCU

DW10FEU

DV6DU

DW10F

Country group 125,000 miles / 2 year 1)32,000 miles / 2 yearCountry group 225,000 miles / 2 year32,000 miles / 2 yearCountry group 312,500 miles / 1 year12,500 miles / 1 yearCountry group 412,500 miles / 1 year12,500 miles / 1 year12,500 miles / 1 yearCountry group 56,000 miles / 1 year12,500 miles / 1 year6,000 miles / 1 year1)

Unless otherwise indicated in the service display.Country Group 1:

Andorra, Austria, Belgium,Cyprus, Denmark, Finland, France, Germany, Greece, Iceland, Ireland, Italy, Liechtenstein, Luxembourg, Malta, Monaco, Netherlands, Norway, Portugal, San Marino, Spain, Sweden, Switzerland, United Kingdom.Country Group 2:

Bosnia-Herzegovina, Bulgaria, Croatia, Czech Republic, Estonia, Hungary, Latvia, Lithuania, Macedonia, Poland,

Romania, Slovakia, Slovenia.Country Group 3:

Albania, Montenegro, Serbia.Country Group 4:

Israel, South Africa, Turkey.Country Group 5:

All other countries which are not listed in the previous country groups. (International interval)

Page 264 of 289

262Service and maintenanceRecommended fluids,lubricants and parts

Recommended fluids and lubricants

Only use products that meet the

recommended specifications.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

aging control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 266.

Topping up engine oilCaution

In case of any spilled oil, wipe it up and dispose it properly.

Engine oils of different manufacturersand brands can be mixed as long as

they comply with the required engine

oil quality and viscosity.

Use of engine oils for all petrol

engines with only ACEA quality is

prohibited, since it can cause engine

damage under certain operating

conditions.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 266.

Additional engine oil additives

The use of additional engine oil

additives could cause damage and

invalidate the warranty.

Engine oil viscosity grades

The SAE viscosity grade gives

information of the thickness of the oil.

Multigrade oil is indicated by two

figures, e.g. SAE 5W-30. The first

figure, followed by a W, indicates the

low temperature viscosity and the

second figure the high temperature viscosity.

Select the appropriate viscosity grade depending on the minimum ambient

temperature 3 266.

All of the recommended viscosity

grades are suitable for high ambient

temperatures.

Coolant and antifreeze

Use only organic acid type-long life

coolant (LLC) antifreeze approved for

the vehicle. Consult a workshop.

The system is factory filled with

coolant designed for excellent

corrosion protection and frost

protection down to approx. -37 °C.

This concentration should be

maintained all year round. The use of additional coolant additives that

intend to give additional corrosion

Page 266 of 289

264Technical dataTechnical dataVehicle identification..................264

Vehicle Identification Number ..264

Identification plate ...................264

Engine identification ................265

Vehicle data ............................... 266

Recommended fluids and lubricants ................................ 266

Engine data ............................. 268

Vehicle dimensions .................270

Capacities ................................ 270

Tyre pressures ........................ 271Vehicle identification

Vehicle IdentificationNumber

The Vehicle Identification Number

may be embossed on the instrument

panel, visible through the windscreen.

Identification plate

The identification plate is located on

the front left or right door frame.

Page 267 of 289

Technical data265Information on identification label:1:manufacturer2:type approval number3:vehicle identification number4:permissible gross vehicle weightrating in kg5:permissible gross train weight

in kg6:maximum permissible front axle

load in kg7:maximum permissible rear axle

load in kg8:vehicle-specific or country-

specific data

The combined total of front and rear

axle loads must not exceed the

permissible gross vehicle weight.

Vehicle's kerb weight depends on the

specification of the vehicle, e.g.

optional equipment and accessories. Refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

Engine identification

The technical data tables show the

engine identifier code.

Engine data 3 268.

To identify the respective engine,

refer to the engine power in the EEC

Certificate of Conformity provided

with your vehicle or other national

registration documents.