tow VAUXHALL ZAFIRA 2014.5 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014.5, Model line: ZAFIRA, Model: VAUXHALL ZAFIRA 2014.5Pages: 219, PDF Size: 7.83 MB

Page 149 of 219

Driving and operating147

For the values specific to your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

General information The official fuel consumption and

specific CO 2 emission figures quoted

relate to the EU base model with

standard equipment.

Fuel consumption data and CO 2

emission data are determined

according to regulation

R (EC) No. 715/2007 (in the latest

applicable version), taking into

consideration the vehicle weight in

running order, as specified by the

regulation.

The figures are provided only for the

purpose of comparison between

different vehicle variants and must

not be taken as a guarantee for the

actual fuel consumption of a

particular vehicle. Additional

equipment may result in slightly

higher results than the stated

consumption and CO 2 figures.Furthermore, fuel consumption is

dependent on personal driving style

as well as road and traffic conditions.

Natural gas

The fuel consumption information

was obtained using reference fuel

G20 (methane proportion

99 - 100 mol%) under prescribed

driving conditions. When using

natural gas with a lower proportion of

methane, the fuel consumption can

differ from the specified values.Trailer hitch

General information

Only use towing equipment that has

been approved for your vehicle.

Entrust retrofitting of towing

equipment to a workshop. It may be

necessary to make changes that

affect the cooling system, heat

shields or other equipment.

Fitting of towing equipment could

cover the opening of the towing eye.

If this is the case, use the coupling ball

bar for towing. Always keep the

coupling ball bar in the vehicle.

Installation dimensions of factory-

fitted towing equipment 3 208.

Driving characteristics and towing tips Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the

coupling ball, is being used to reduce snaking movements.

Page 150 of 219

148Driving and operating

For trailers with low driving stability

and trailers with a permitted gross

vehicle weight of more than 1300 kg a speed of 80 km/h must not be

exceeded; the use of a stabiliser is

recommended.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.

When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 206.

Trailer towing Trailer loads

The permissible trailer loads are

vehicle and engine-dependent

maximum values which must not be

exceeded. The actual trailer load is

the difference between the actual

gross weight of the trailer and the

actual coupling socket load with the

trailer coupled.The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12 %

The permitted trailer load applies up to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the air becoming thinner, therefore reducing

climbing ability, the permissible gross

train weight also decreases by 10 %

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than 8 %, e. g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 198.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.The maximum permissible vertical

coupling load (75 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

especially in the case of heavy

trailers. The vertical coupling load

should never fall below 25 kg.

Rear axle load When the trailer is coupled and the

towing vehicle fully loaded, the

permissible rear axle load (see

identification plate or vehicle

documents) may be exceeded by 90 kg and the gross vehicle weight

rating by 75 kg. If the permissible rear

axle load is exceeded, a maximum

speed of 100 km/h applies.

Towing equipmentCaution

When operating without a trailer,

remove the coupling ball bar.

Page 151 of 219

Driving and operating149

Stowage of coupling ball bar

To open the cover, lift the carpeting.

Raise, rotate and lift the ring.

The pouch with the coupling ball bar

is held in place with a rubber strap.

When inserting, ensure that the rotary

handle of the coupling ball bar is

facing upwards.

Fitting the coupling ball bar From underneath at the recesses,

pull the cover in the bumper

rearwards at a slight angle.

Disengage and fold down the socket. Remove the sealing plug from the

opening for the coupling ball bar and

stow it.

Checking the tensioning of the

coupling ball bar

■ Red marking on rotary knob must

point towards white marking on

coupling ball bar.

■ The gap between the rotary knob and the coupling ball bar must beapprox. 6 millimetres.

■ Key must be at position c ( 1).

Otherwise, the coupling ball bar must be tensioned before being inserted:

■ Unlock coupling ball bar by turning key to position c ( 1)

Page 152 of 219

150Driving and operating

■ Pull out rotary knob and turnclockwise as far as it will go.

Inserting the coupling ball bar

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e ( 2). Remove the

key and close the protective flap.

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is

correctly installed

■ Green marking on rotary knob must

point towards white marking on

coupling ball bar.

■ There must be no gap between the

rotary handle and the coupling ball

bar.

■ The coupling ball bar must be firmly

engaged in the opening.

■ The coupling ball bar must be locked and the key removed.9 Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Page 154 of 219

152Vehicle careVehicle careGeneral Information...................152

Vehicle checks ........................... 153

Bulb replacement .......................159

Electrical system ........................166

Vehicle tools .............................. 173

Wheels and tyres .......................173

Jump starting ............................. 186

Towing ....................................... 187

Appearance care .......................189General Information

Accessories and vehicle

modifications

We recommend using genuine parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

Following must be done if the vehicle

should be stored for several months:

■ Wash and wax the vehicle.

■ Have the wax in the engine compartment and underbody

checked.

■ Clean and preserve rubber seals.

■ Fill up fuel tank completely.

■ Change engine oil.

■ Drain washer fluid reservoir.

■ Check coolant antifreeze.

■ Adjust tyre pressure to the value specified for full load.

■ Park vehicle in dry, well ventilated place. Engage first or reverse gear

or set selector lever to P. Prevent

the vehicle from rolling.

■ Do not apply parking brake.

Page 168 of 219

166Vehicle care

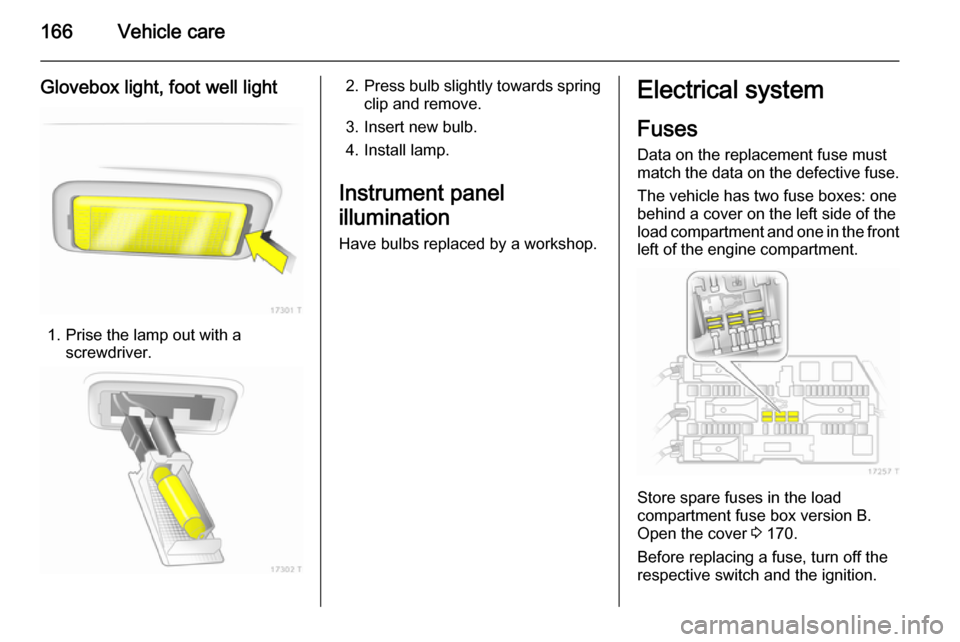

Glovebox light, foot well light

1. Prise the lamp out with ascrewdriver.

2.Press bulb slightly towards spring

clip and remove.

3. Insert new bulb.

4. Install lamp.

Instrument panel

illumination

Have bulbs replaced by a workshop.Electrical system

Fuses

Data on the replacement fuse must

match the data on the defective fuse.

The vehicle has two fuse boxes: one

behind a cover on the left side of the

load compartment and one in the front

left of the engine compartment.

Store spare fuses in the load

compartment fuse box version B.

Open the cover 3 170.

Before replacing a fuse, turn off the

respective switch and the ignition.

Page 174 of 219

172Vehicle care

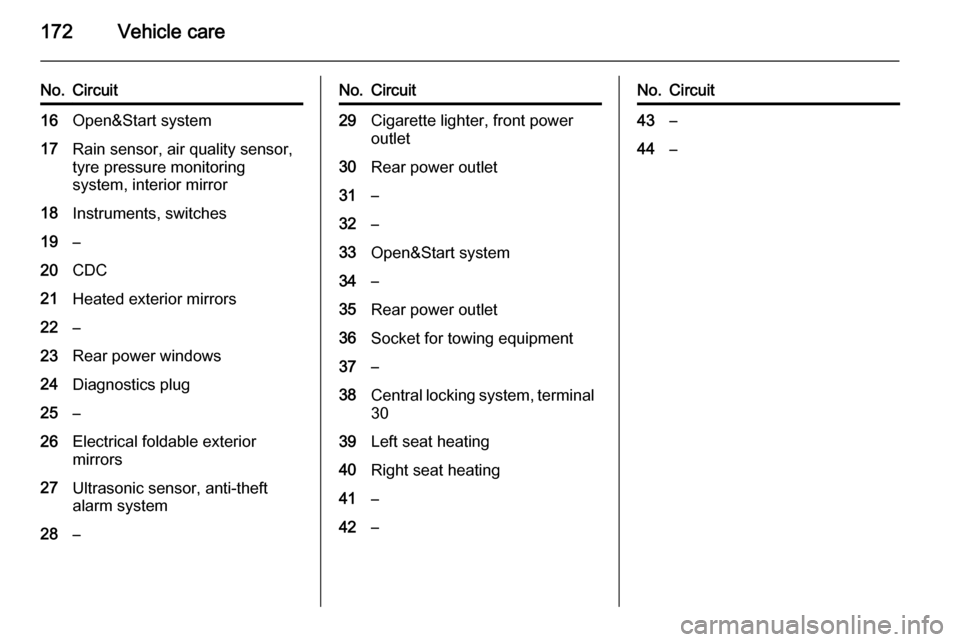

No.Circuit16Open&Start system17Rain sensor, air quality sensor,

tyre pressure monitoring

system, interior mirror18Instruments, switches19–20CDC21Heated exterior mirrors22–23Rear power windows24Diagnostics plug25–26Electrical foldable exterior

mirrors27Ultrasonic sensor, anti-theft

alarm system28–No.Circuit29Cigarette lighter, front power

outlet30Rear power outlet31–32–33Open&Start system34–35Rear power outlet36Socket for towing equipment37–38Central locking system, terminal

3039Left seat heating40Right seat heating41–42–No.Circuit43–44–

Page 175 of 219

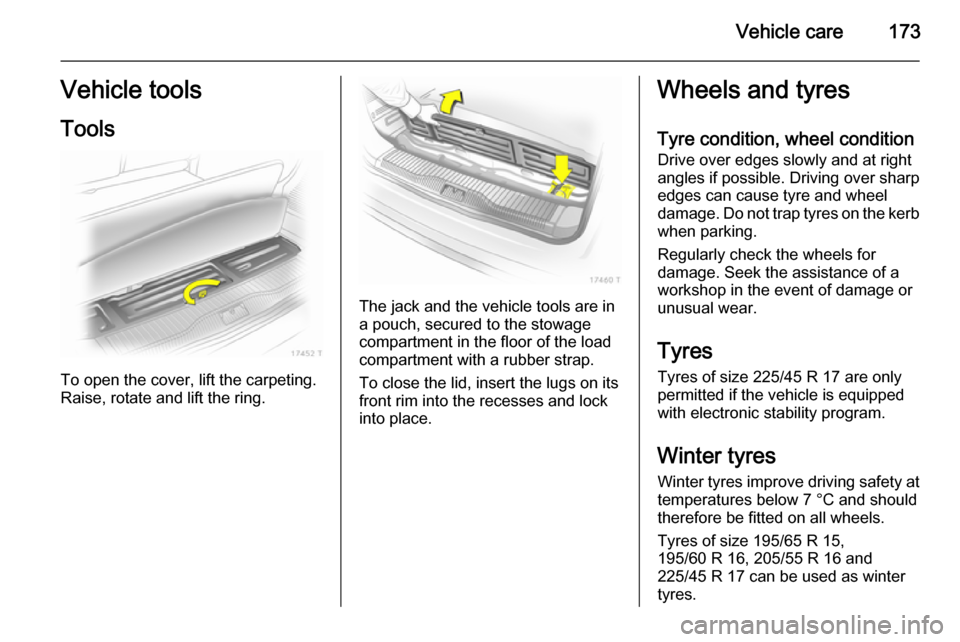

Vehicle care173Vehicle tools

Tools

To open the cover, lift the carpeting.

Raise, rotate and lift the ring.

The jack and the vehicle tools are in

a pouch, secured to the stowage

compartment in the floor of the load

compartment with a rubber strap.

To close the lid, insert the lugs on its

front rim into the recesses and lock

into place.

Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Tyres

Tyres of size 225/45 R 17 are only permitted if the vehicle is equipped

with electronic stability program.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

Tyres of size 195/65 R 15,

195/60 R 16, 205/55 R 16 and

225/45 R 17 can be used as winter

tyres.

Page 181 of 219

Vehicle care179

Always use fine mesh chains that addno more than 10 mm to the tyre tread

and the inboard sides (including chain

lock).9 Warning

Damage may lead to tyre blowout.

Tyre chains are permitted on tyres of

size 195/65 R 15, 195/60 R 16,

205/55 R16, 205/50 R 17 and

225/45 R17.

Tyre chains are not permitted on tyres of size 225/40 R 18, 225/40 ZR 18

and 235/35 R 19.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is near the rim cannot be repaired with the tyre repair kit.

9 Warning

Do not drive faster than 80 km/h.

Do not use for a lengthy period.

Steering and handling may be

affected.

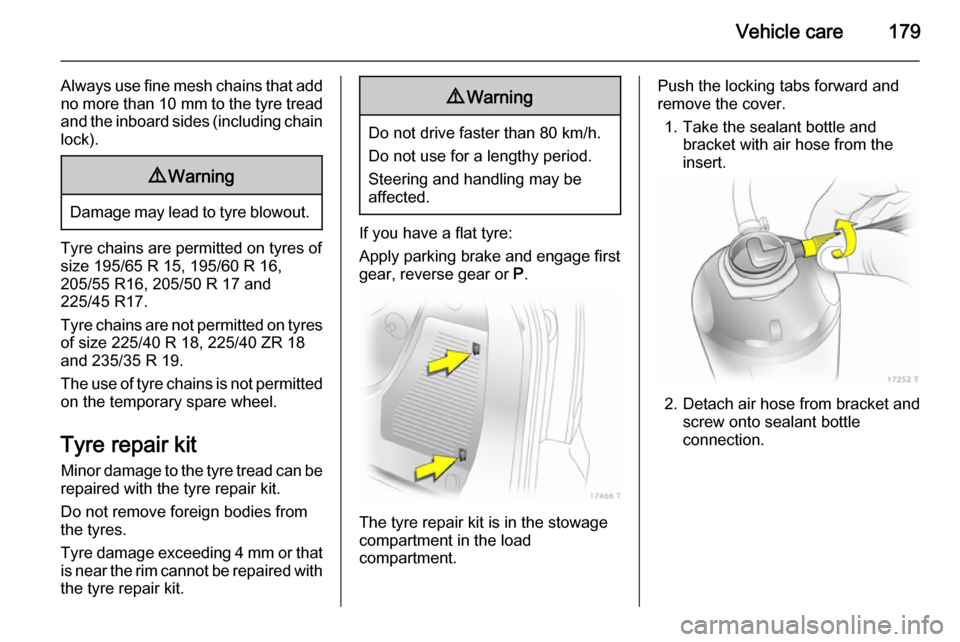

If you have a flat tyre:

Apply parking brake and engage first

gear, reverse gear or P.

The tyre repair kit is in the stowage

compartment in the load

compartment.

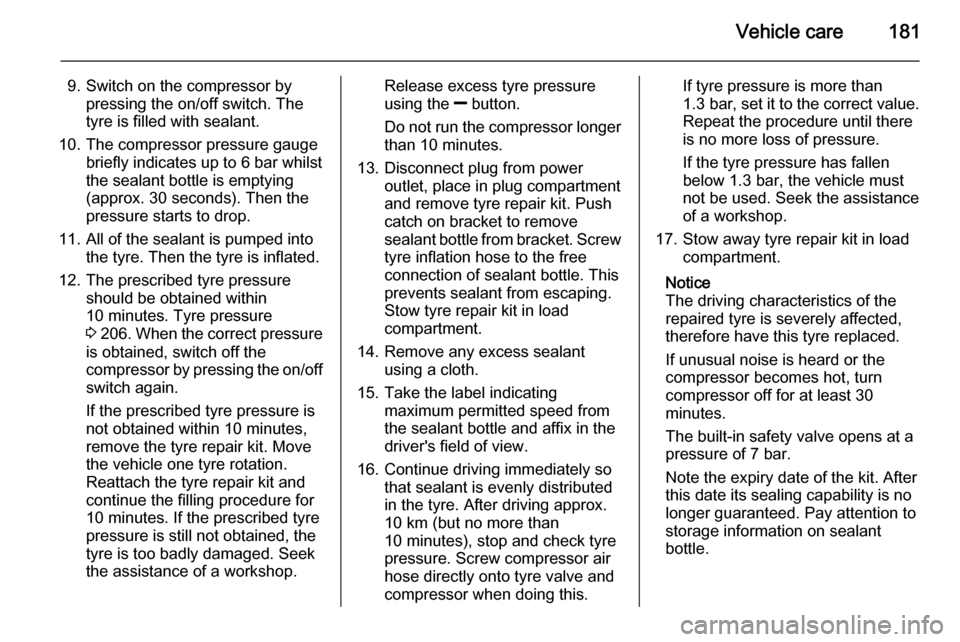

Push the locking tabs forward and

remove the cover.

1. Take the sealant bottle and bracket with air hose from the

insert.

2. Detach air hose from bracket and screw onto sealant bottle

connection.

Page 183 of 219

Vehicle care181

9. Switch on the compressor bypressing the on/off switch. The

tyre is filled with sealant.

10. The compressor pressure gauge briefly indicates up to 6 bar whilstthe sealant bottle is emptying

(approx. 30 seconds). Then the

pressure starts to drop.

11. All of the sealant is pumped into the tyre. Then the tyre is inflated.

12. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 206 . When the correct pressure

is obtained, switch off the

compressor by pressing the on/off switch again.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation.

Reattach the tyre repair kit and

continue the filling procedure for

10 minutes. If the prescribed tyre

pressure is still not obtained, the

tyre is too badly damaged. Seek

the assistance of a workshop.Release excess tyre pressure

using the ] button.

Do not run the compressor longer than 10 minutes.

13. Disconnect plug from power outlet, place in plug compartment

and remove tyre repair kit. Push

catch on bracket to remove

sealant bottle from bracket. Screw

tyre inflation hose to the free

connection of sealant bottle. This

prevents sealant from escaping.

Stow tyre repair kit in load

compartment.

14. Remove any excess sealant using a cloth.

15. Take the label indicating maximum permitted speed from

the sealant bottle and affix in the

driver's field of view.

16. Continue driving immediately so that sealant is evenly distributed

in the tyre. After driving approx.

10 km (but no more than

10 minutes), stop and check tyre

pressure. Screw compressor air

hose directly onto tyre valve and

compressor when doing this.If tyre pressure is more than 1.3 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 1.3 bar, the vehicle must

not be used. Seek the assistance

of a workshop.

17. Stow away tyre repair kit in load compartment.

Notice

The driving characteristics of the

repaired tyre is severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least 30

minutes.

The built-in safety valve opens at a

pressure of 7 bar.

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.