warning VAUXHALL ZAFIRA TOURER 2014.5 Owners Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2014.5, Model line: ZAFIRA TOURER, Model: VAUXHALL ZAFIRA TOURER 2014.5Pages: 293, PDF Size: 8.95 MB

Page 211 of 293

Driving and operating209

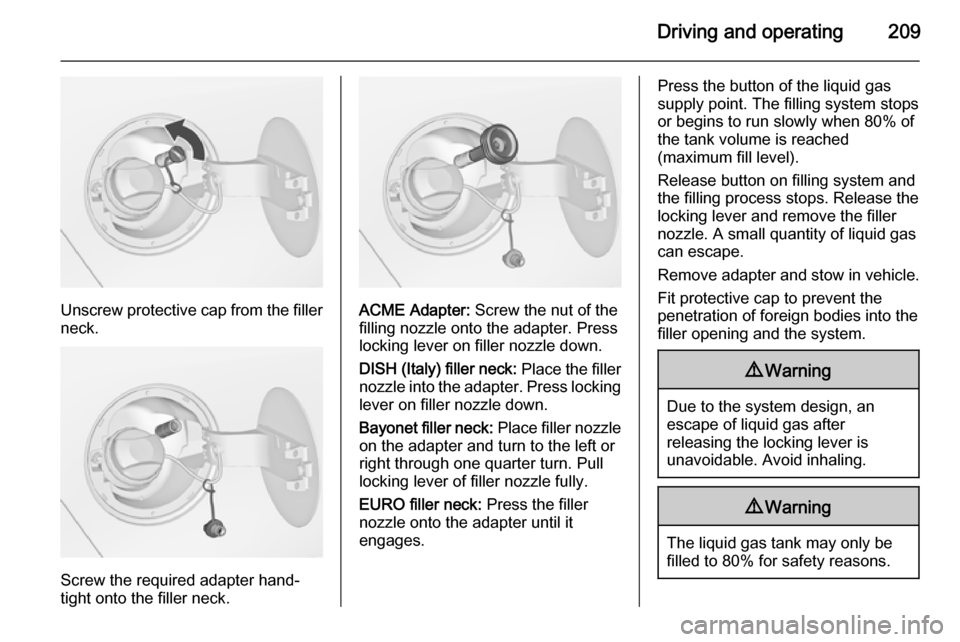

Unscrew protective cap from the filler

neck.

Screw the required adapter hand-

tight onto the filler neck.

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH (Italy) filler neck: Place the filler

nozzle into the adapter. Press locking lever on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system and

the filling process stops. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle.

Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

Page 217 of 293

Driving and operating215

Insert the tensioned coupling ball bar

in the opening and push firmly

upwards until it audibly engages.

The rotary handle snaps back into its

original position resting against the

coupling ball bar without a gap.9 Warning

Do not touch rotary handle during

insertion.

Lock the coupling ball bar by turning

the key to position e. Remove the key

and close the protective flap.

Eye for break-away stopping cable

Attach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

■ Green marking on rotary knob must

point towards green marking on

coupling ball bar.

■ There must be no gap between the

rotary handle and the coupling ball

bar.

■ The coupling ball bar must be firmly

engaged in the opening.

■ The coupling ball bar must be locked and the key removed.9 Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

Dismounting the coupling ball

bar

Page 220 of 293

218Vehicle care

■ Open the bonnet, close all doorsand lock the vehicle.

■ Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems are not functional, e.g. anti-theft alarm

system.

Putting back into operation When the vehicle is to be put back into

operation:

■ Connect the clamp to the negative terminal of the vehicle battery.

Activate the electronics of the

power windows.

■ Check tyre pressure.

■ Fill up the washer fluid reservoir.

■ Check the engine oil level.

■ Check the coolant level.

■ Fit the number plate if necessary.

End-of-life vehicle

recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on ourwebsite, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a

service centre authorised for gas

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

Page 223 of 293

Vehicle care221Engine coolantThe coolant provides freeze

protection down to approx. -28 °C. In

northern countries with very low

temperatures the factory filled coolant

provides frost protection down to

approx. -37°C.Caution

Only use approved antifreeze.

Coolant level

Caution

Too low a coolant level can cause engine damage.

If the cooling system is cold, the

coolant level should be above the

filling line mark. Top up if the level is

low.

9 Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

To top up use a 1:1 mixture of

released coolant concentrate mixed

with clean tap water. If no coolant

concentrate is available, use clean

tap water. Install the cap tightly.

Engine B16DTH: After starting the

engine, set the heating to warmest

temperature and the fan speed to at

least first level for approx. 5 minutes.

This will ensure that the air within the cooling system escapes.

Have the coolant concentration

checked and have the cause of the

coolant loss remedied by a workshop.

Power steering fluidCaution

Extremely small amounts of

contamination can cause steering

system damage and cause it to not work properly. Do not allow

contaminates to contact the fluid

side of the reservoir cap/dipstick or

from entering the reservoir.

Page 224 of 293

222Vehicle care

Power steering fluid level normally

does not have to be checked. If an

unusual noise sounds during steering or the power steering reacts

conspicuous seek the assistance of a

workshop.

Washer fluid

Fill with clean water mixed with a

suitable quantity of windscreen

washer fluid which contains

antifreeze.

Caution

Only washer fluid with a sufficient

antifreeze concentration provides

protection at low temperatures or

a sudden drop in temperature.

Brakes

In the event of minimum thickness ofthe brake lining, a squealing noise

sounds during braking.

Continued driving is possible but

have the brake lining replaced as

soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

Page 226 of 293

224Vehicle care

An AGM battery can be identified by

the label on the battery. We

recommend the use of an original

Vauxhall vehicle battery.

Notice

Using an AGM vehicle battery

different from the original Vauxhall

vehicle battery may result in a lower performance of the stop-start

system.

We recommend that you have the

vehicle battery replaced by a

workshop.

Stop-start system 3 156.

Charging the vehicle battery9 Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 256.

Warning label

Meaning of symbols: ■ No sparks, naked flames or smoking.

■ Always shield eyes. Explosive gases can cause blindness or

injury.

■ Keep the vehicle battery out of reach of children.

■ The vehicle battery contains sulphuric acid which could cause

blindness or serious burn injuries.

■ See the Owner's Manual for further

information.

■ Explosive gas may be present in the vicinity of the vehicle battery.

Page 243 of 293

Vehicle care241

No.Circuit31–32Active damping system, lane

departure warningVehicle tools

Tools

Some tools, the towing eye and (only on vehicles with spare wheel) the

vehicle jacking equipment are placed

in the rear storage in the load

compartment floor.

Open the cover in front of the tailgate.

Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a workshop in the event of damage or

unusual wear.

Winter tyres Winter tyres improve driving safety at

temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Page 245 of 293

Vehicle care2439Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition. After adjusting tyre

pressure, switch on ignition and

select the appropriate setting on the

page Tyre load in the Driver

Information Centre, 3 114.

Tyre pressure monitoring system

The tyre pressure monitoring system

checks the pressure of all four wheels once a minute when vehicle speed

exceeds a certain limit.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information

Centre.

The menu can be selected by the buttons on the turn signal lever.

Press the MENU button to select the

Vehicle Information Menu X .

Page 246 of 293

244Vehicle care

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings are displayed by a message with the

corresponding tyre flashing in the

Driver Information Centre.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 111.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 279.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

If w illuminates up at lower

temperatures and extinguishes after

some driving, this could be an

indicator for getting low pressure.

Check tyre pressure.

Vehicle messages 3 120.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A spare wheel or temporary spare

wheel is not equipped with pressure

sensors. The tyre pressure

monitoring system is not operational

for these wheels. Control indicator w

illuminates. For the further three

wheels the system remains

operational.The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor, replace

valve core and sealing ring. For

clipped sensor, replace complete

valve stem.

Vehicle loading status Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 279, and

select the appropriate setting in the menu Tire Load in the Driver

Information Centre, Vehicle

Information Menu 3 114.

Page 247 of 293

Vehicle care245

Select:■ Light for comfort pressure up to

3 people

■ Eco for Eco pressure up to

3 people

■ Max for full loading

Auto learn function

After changing wheels, the vehicle

must be stationary for approx.

20 minutes, before the system

recalculates. The following relearn process takes up to 10 minutes of

driving with a minimum speed of

12 mph. In this case $ can be

displayed or pressure values can

swap in the Driver Information Centre.

If problems occur during the relearn

process, a warning message is

displayed in the Driver Information

Centre.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).For safety reasons, it is

recommended that the tread depth of

the tyres on one axle should not vary

by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and

rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.