warning VAUXHALL ZAFIRA TOURER 2015 Owner's Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: ZAFIRA TOURER, Model: VAUXHALL ZAFIRA TOURER 2015Pages: 297, PDF Size: 8.99 MB

Page 243 of 297

Vehicle care241

No.Circuit31–32Active damping system, lane

departure warningVehicle tools

Tools

Some tools, the towing eye and (only on vehicles with spare wheel) the

vehicle jacking equipment are placed

in the rear storage in the load

compartment floor.

Open the cover in front of the tailgate.

Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a workshop in the event of damage or

unusual wear.

Winter tyres Winter tyres improve driving safety at

temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

Page 245 of 297

Vehicle care243

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition. After adjusting tyre

pressure, switch on ignition and

select the appropriate setting on the

page Tyre load in the Driver

Information Centre, 3 114.

Tyre pressure monitoring system

The tyre pressure monitoring system

(TPMS) checks the pressure of all

four wheels once a minute when

vehicle speed exceeds a certain limit.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

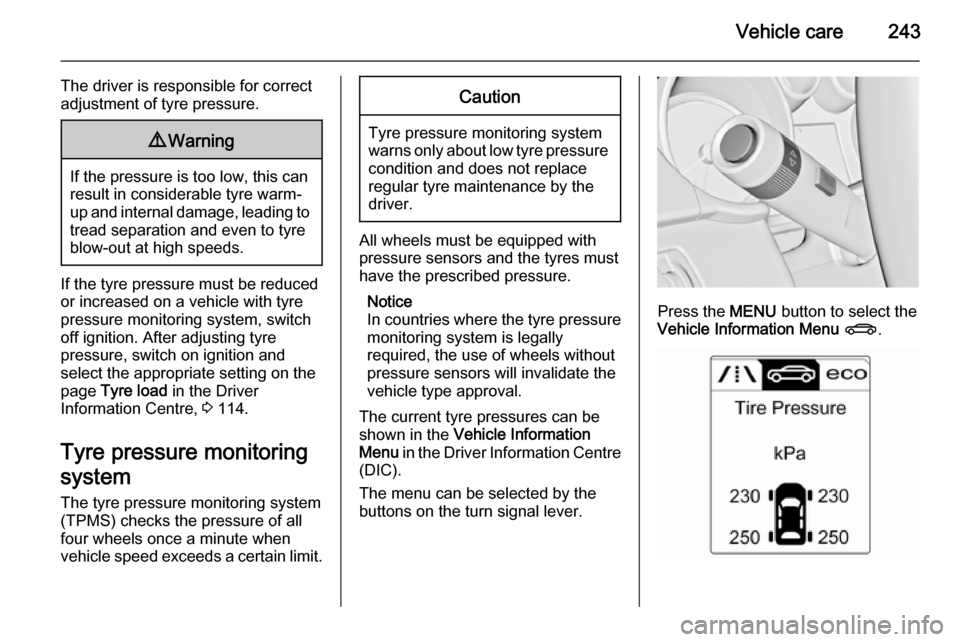

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information Centre

(DIC).

The menu can be selected by the

buttons on the turn signal lever.

Press the MENU button to select the

Vehicle Information Menu X .

Page 246 of 297

244Vehicle care

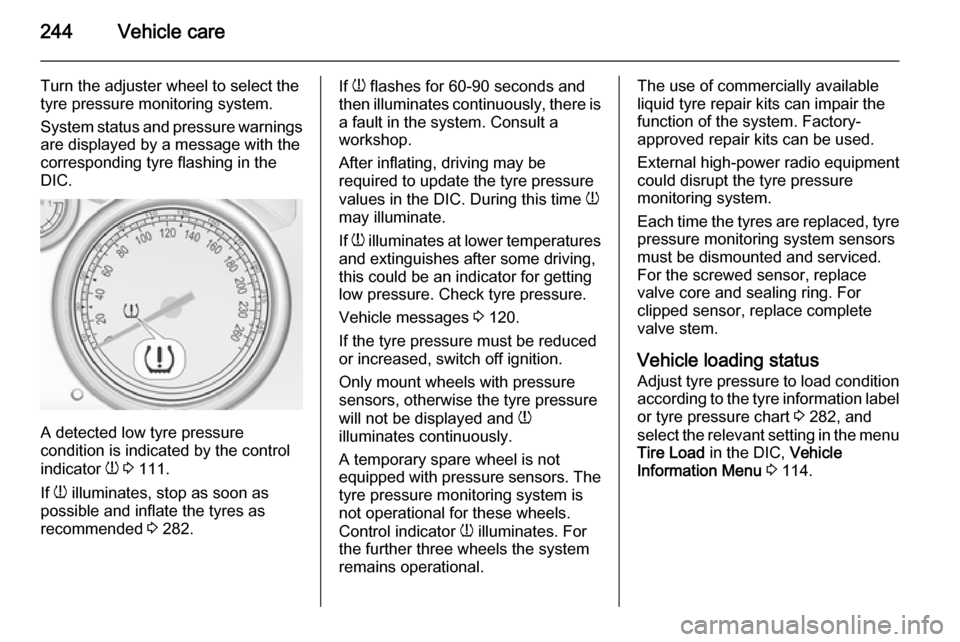

Turn the adjuster wheel to select the

tyre pressure monitoring system.

System status and pressure warnings are displayed by a message with the

corresponding tyre flashing in the

DIC.

A detected low tyre pressure

condition is indicated by the control

indicator w 3 111.

If w illuminates, stop as soon as

possible and inflate the tyres as

recommended 3 282.

If w flashes for 60-90 seconds and

then illuminates continuously, there is

a fault in the system. Consult a

workshop.

After inflating, driving may be

required to update the tyre pressure

values in the DIC. During this time w

may illuminate.

If w illuminates at lower temperatures

and extinguishes after some driving,

this could be an indicator for getting

low pressure. Check tyre pressure.

Vehicle messages 3 120.

If the tyre pressure must be reduced

or increased, switch off ignition.

Only mount wheels with pressure

sensors, otherwise the tyre pressure

will not be displayed and w

illuminates continuously.

A temporary spare wheel is not

equipped with pressure sensors. The

tyre pressure monitoring system is

not operational for these wheels.

Control indicator w illuminates. For

the further three wheels the system

remains operational.The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved repair kits can be used.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced, tyre pressure monitoring system sensors

must be dismounted and serviced.

For the screwed sensor, replace

valve core and sealing ring. For

clipped sensor, replace complete

valve stem.

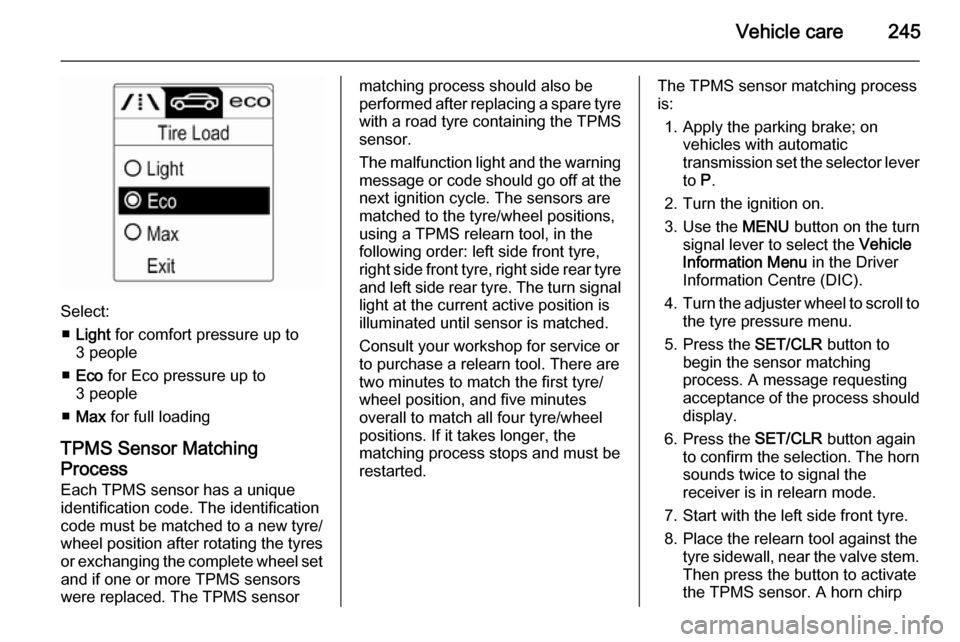

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 282, and

select the relevant setting in the menu

Tire Load in the DIC, Vehicle

Information Menu 3 114.

Page 247 of 297

Vehicle care245

Select:■ Light for comfort pressure up to

3 people

■ Eco for Eco pressure up to

3 people

■ Max for full loading

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/

wheel position after rotating the tyres

or exchanging the complete wheel set and if one or more TPMS sensors

were replaced. The TPMS sensor

matching process should also be

performed after replacing a spare tyre

with a road tyre containing the TPMS

sensor.

The malfunction light and the warning

message or code should go off at the

next ignition cycle. The sensors are

matched to the tyre/wheel positions,

using a TPMS relearn tool, in the

following order: left side front tyre,

right side front tyre, right side rear tyre and left side rear tyre. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

two minutes to match the first tyre/

wheel position, and five minutes

overall to match all four tyre/wheel

positions. If it takes longer, the

matching process stops and must be

restarted.The TPMS sensor matching process

is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

3. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Turn the adjuster wheel to scroll to

the tyre pressure menu.

5. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should

display.

6. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to signal the

receiver is in relearn mode.

7. Start with the left side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp

Page 249 of 297

Vehicle care247Changing tyre and wheel

size If tyres of a different size than those

fitted at the factory are used, it may be

necessary to reprogramme the

speedometer as well as the nominal

tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

Vehicles with steel wheels: When

using locking wheel nuts, the wheel

covers might not be attached to the

steel wheels.

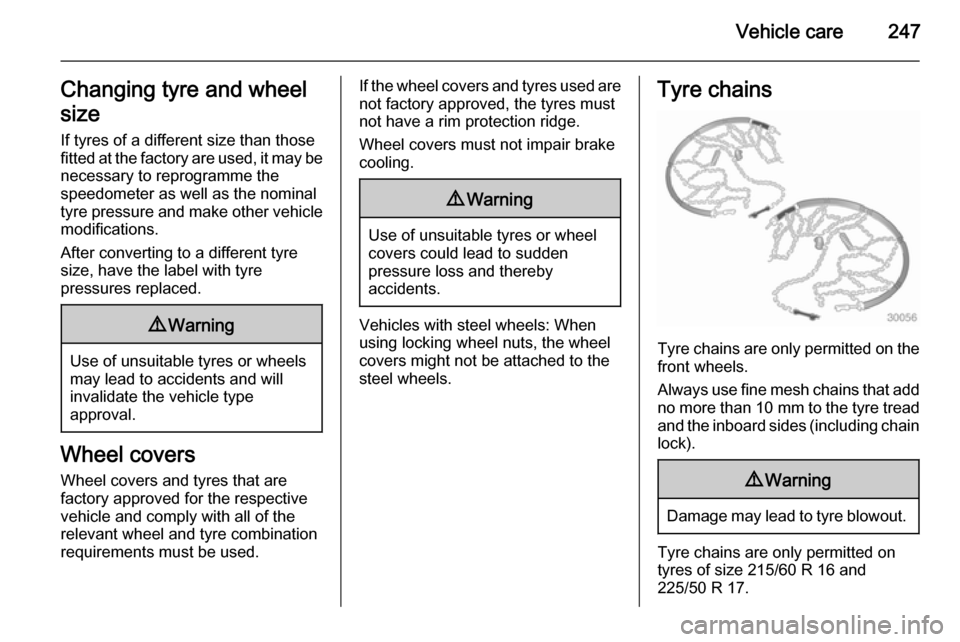

Tyre chains

Tyre chains are only permitted on the

front wheels.

Always use fine mesh chains that add no more than 10 mm to the tyre tread

and the inboard sides (including chain lock).

9 Warning

Damage may lead to tyre blowout.

Tyre chains are only permitted on

tyres of size 215/60 R 16 and

225/50 R 17.

Page 250 of 297

248Vehicle care

The use of tyre chains is not permittedon the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at tyre's sidewall cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If you have a flat tyre:

Apply the parking brake and engage

first gear, reverse gear or P.

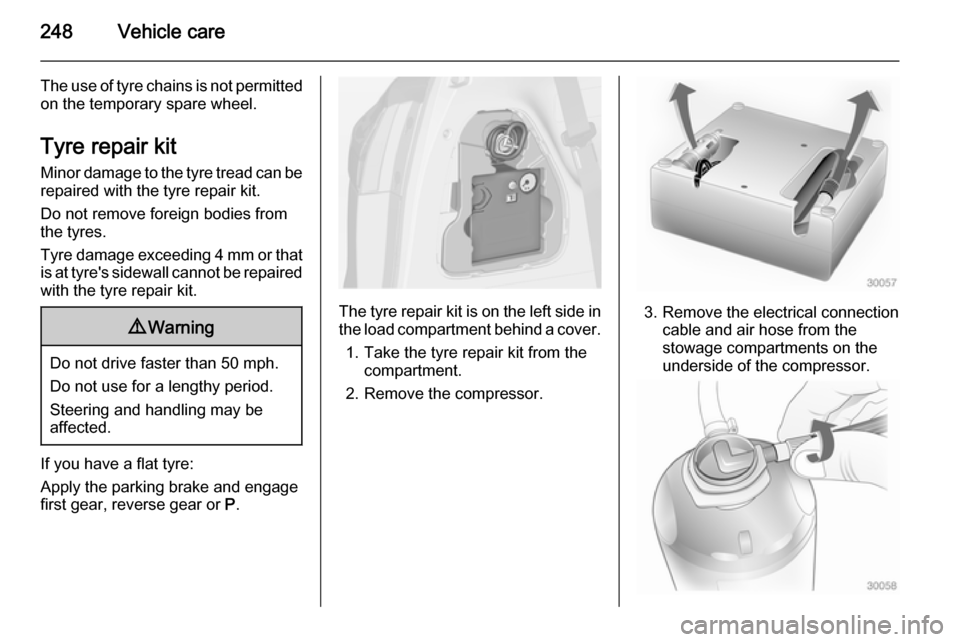

The tyre repair kit is on the left side in

the load compartment behind a cover.

1. Take the tyre repair kit from the compartment.

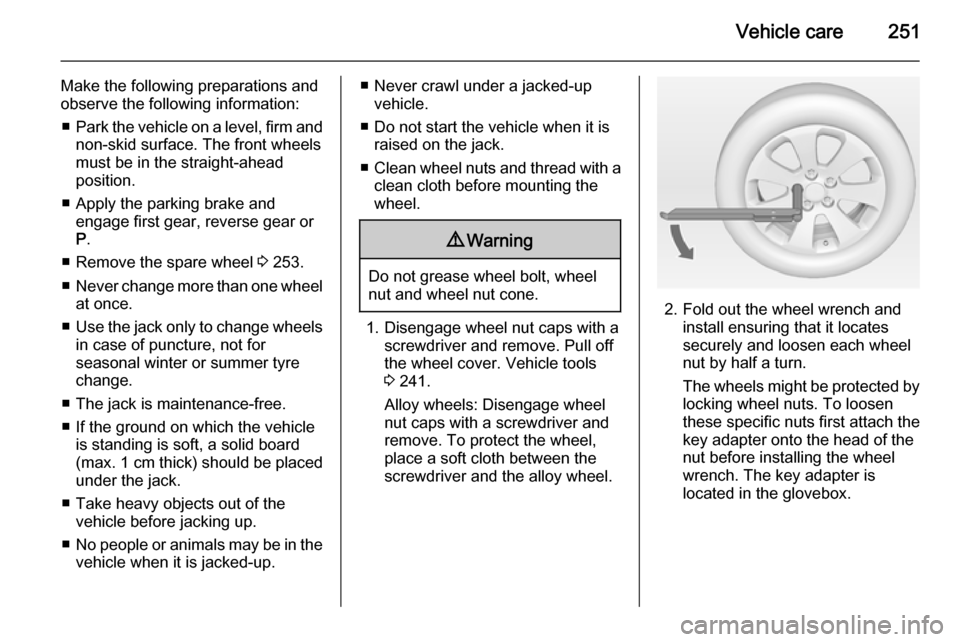

2. Remove the compressor.3. Remove the electrical connection cable and air hose from the

stowage compartments on the

underside of the compressor.

Page 253 of 297

Vehicle care251

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-skid surface. The front wheels

must be in the straight-ahead

position.

■ Apply the parking brake and engage first gear, reverse gear or

P .

■ Remove the spare wheel 3 253.

■ Never change more than one wheel

at once.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ The jack is maintenance-free.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ Take heavy objects out of the vehicle before jacking up.

■ No people or animals may be in the

vehicle when it is jacked-up.■ Never crawl under a jacked-up vehicle.

■ Do not start the vehicle when it is raised on the jack.

■ Clean wheel nuts and thread with a

clean cloth before mounting the

wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Disengage wheel nut caps with a screwdriver and remove. Pull off

the wheel cover. Vehicle tools

3 241.

Alloy wheels: Disengage wheel

nut caps with a screwdriver and

remove. To protect the wheel,

place a soft cloth between the

screwdriver and the alloy wheel.

2. Fold out the wheel wrench and install ensuring that it locates

securely and loosen each wheel

nut by half a turn.

The wheels might be protected by

locking wheel nuts. To loosen

these specific nuts first attach the

key adapter onto the head of the

nut before installing the wheel

wrench. The key adapter is

located in the glovebox.

Page 258 of 297

256Vehicle care

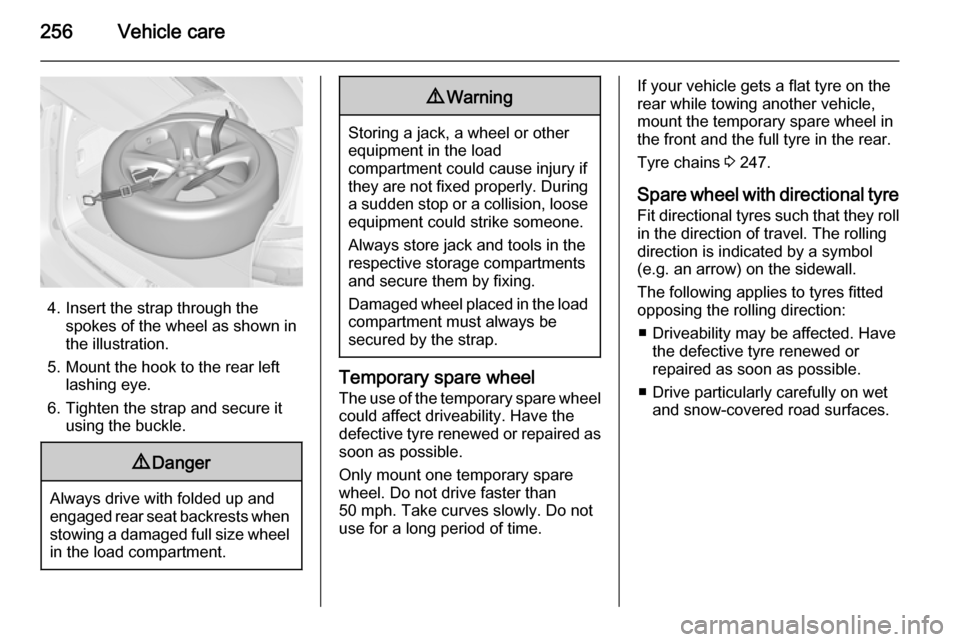

4. Insert the strap through thespokes of the wheel as shown in

the illustration.

5. Mount the hook to the rear left lashing eye.

6. Tighten the strap and secure it using the buckle.

9 Danger

Always drive with folded up and

engaged rear seat backrests when stowing a damaged full size wheel

in the load compartment.

9 Warning

Storing a jack, a wheel or other

equipment in the load

compartment could cause injury if they are not fixed properly. During a sudden stop or a collision, looseequipment could strike someone.

Always store jack and tools in the

respective storage compartments

and secure them by fixing.

Damaged wheel placed in the load

compartment must always be

secured by the strap.

Temporary spare wheel

The use of the temporary spare wheel

could affect driveability. Have the

defective tyre renewed or repaired as soon as possible.

Only mount one temporary spare

wheel. Do not drive faster than

50 mph. Take curves slowly. Do not

use for a long period of time.

If your vehicle gets a flat tyre on the

rear while towing another vehicle,

mount the temporary spare wheel in the front and the full tyre in the rear.

Tyre chains 3 247.

Spare wheel with directional tyre

Fit directional tyres such that they roll in the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Drive particularly carefully on wet and snow-covered road surfaces.

Page 259 of 297

Vehicle care257Jump starting

Do not start with quick charger.

A vehicle with a discharged battery

can be started using jump leads and the battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

■ Never expose the battery to naked flames or sparks.

■ A discharged battery can alreadyfreeze at a temperature of 0 °C.

Defrost the frozen battery before

connecting jump leads.

■ Wear eye protection and protective

clothing when handling a battery.

■ Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

■ Use jump leads with insulated terminals and a cross section of at

least 16 mm 2

(25 mm 2

for diesel

engines).

■ Do not disconnect the discharged battery from the vehicle.

■ Switch off all unnecessary electrical

consumers.

■ Do not lean over the battery during jump starting.

■ Do not allow the terminals of one lead to touch those of the other

lead.

■ The vehicles must not come into contact with each other during the

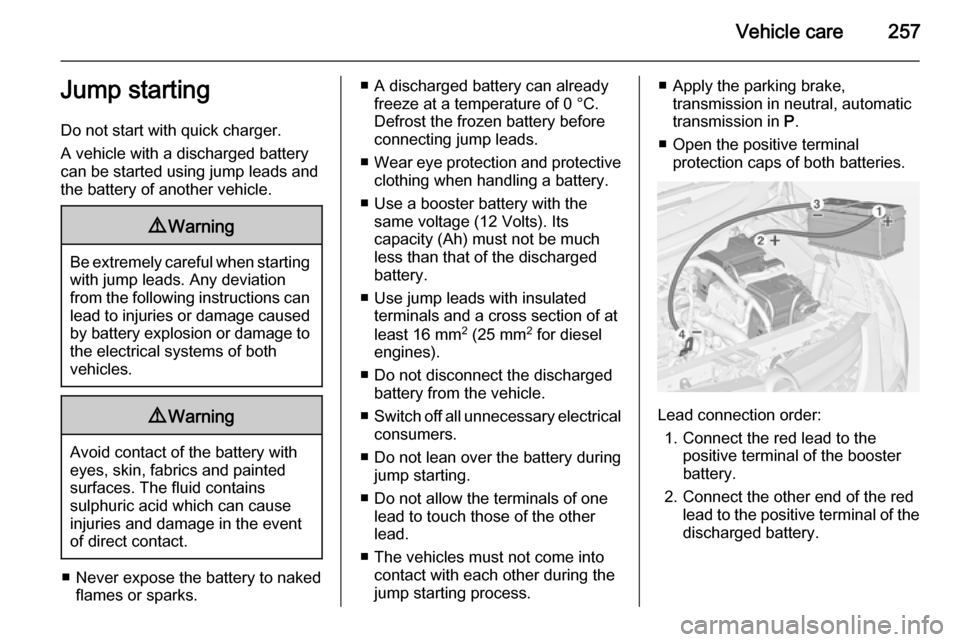

jump starting process.■ Apply the parking brake, transmission in neutral, automatictransmission in P.

■ Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

Page 267 of 297

Service and maintenance265

Confirmations

Confirmation of service is recorded in the Service and Warranty Booklet.

The date and mileage is completed

with the stamp and signature of the

servicing workshop.

Make sure that the Service and

Warranty Booklet is completed

correctly as continuous proof of

service is essential if any warranty or goodwill claims are to be met, and is

also a benefit when selling the

vehicle.

Service interval with remaining engine oil life duration The service interval is based on

several parameters depending on

usage.

The service display lets you know

when to change the engine oil.

Service display 3 104.Recommended fluids,

lubricants and parts

Recommended fluids and

lubricants Only use products that meet the

recommended specifications.

Damage resulting from the use of

products not in line with these

specifications will not be covered by

the warranty.9 Warning

Operating materials are

hazardous and could be

poisonous. Handle with care. Pay

attention to information given on

the containers.

Engine oil

Engine oil is identified by its quality

and its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use. The oil quality ensures e.g. engine

cleanliness, wear protection and oil

ageing control, whereas viscosity

grade gives information on the oil's

thickness over a temperature range.

Dexos is the newest engine oil quality

that provides optimum protection for gasoline and diesel engines. If it is

unavailable, engine oils of other listed qualities have to be used.

Recommendations for gasoline

engines are also valid for

Compressed Natural Gas (CNG),

Liquified Petroleum Gas (LPG) and

Ethanol (E85) fuelled engines.

Select the appropriate engine oil

based on its quality and on the

minimum ambient temperature

3 269.

Topping up engine oil

Engine oils of different manufacturers

and brands can be mixed as long as

they comply with the required engine

oil quality and viscosity.

Use of engine oil with only

ACEA A1/B1 or only A5/B5 quality is

prohibited, since it can cause long-

term engine damage under certain

operating conditions.