turn signal VAUXHALL ZAFIRA TOURER 2015 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: ZAFIRA TOURER, Model: VAUXHALL ZAFIRA TOURER 2015Pages: 297, PDF Size: 8.99 MB

Page 202 of 297

200Driving and operating

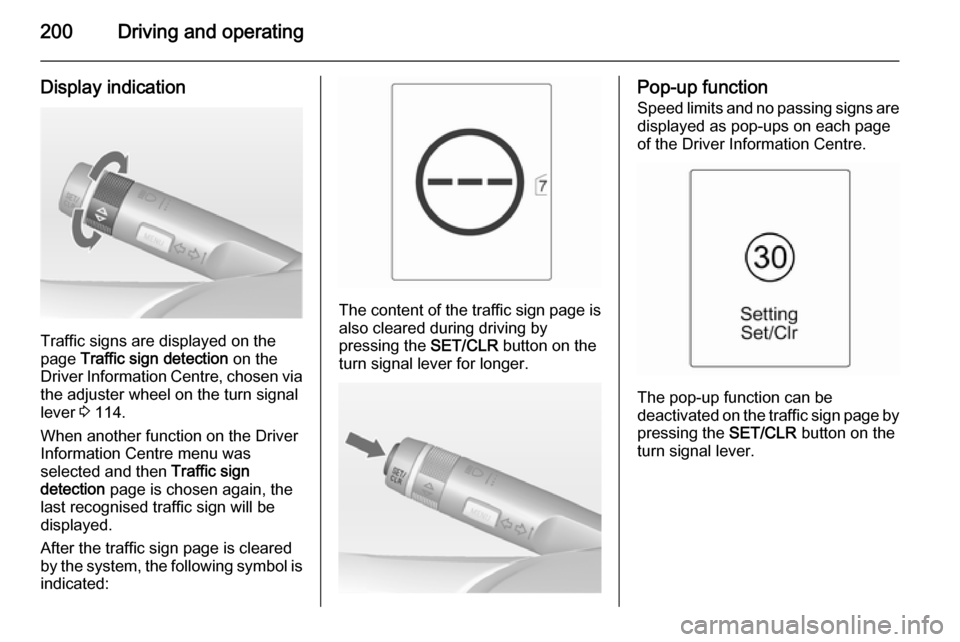

Display indication

Traffic signs are displayed on the

page Traffic sign detection on the

Driver Information Centre, chosen via the adjuster wheel on the turn signal

lever 3 114.

When another function on the Driver

Information Centre menu was

selected and then Traffic sign

detection page is chosen again, the

last recognised traffic sign will be displayed.

After the traffic sign page is cleared

by the system, the following symbol is

indicated:

The content of the traffic sign page is

also cleared during driving by

pressing the SET/CLR button on the

turn signal lever for longer.

Pop-up function

Speed limits and no passing signs are

displayed as pop-ups on each page

of the Driver Information Centre.

The pop-up function can be

deactivated on the traffic sign page by

pressing the SET/CLR button on the

turn signal lever.

Page 204 of 297

202Driving and operating

Criteria for the detection of an

unintended lane change are:

■ no operation of turn signals

■ no brake pedal operation

■ no active accelerator operation or speeding-up

■ no active steering

If the driver is active, no warning will

be issued.

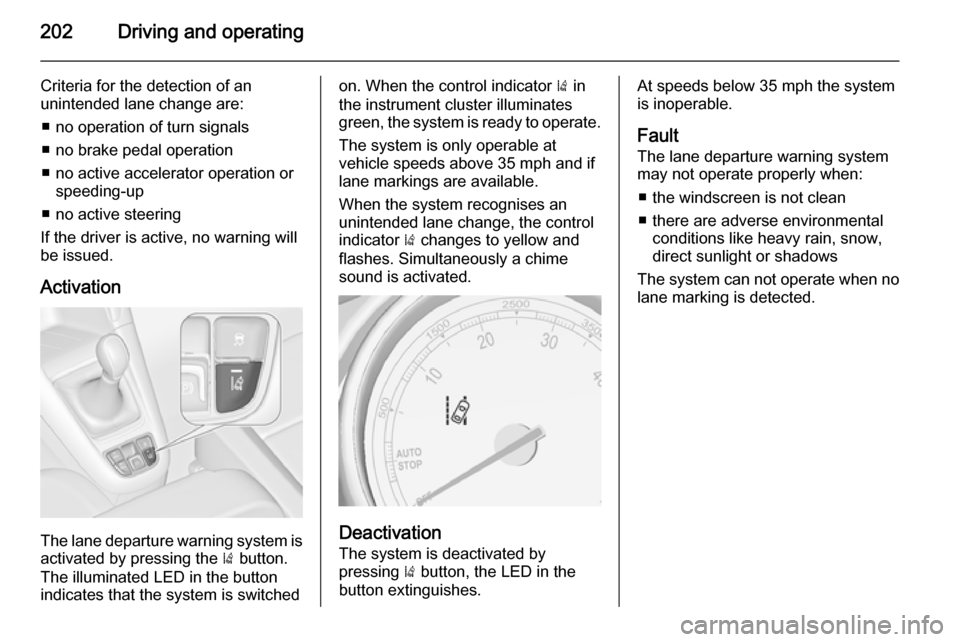

Activation

The lane departure warning system is activated by pressing the ) button.

The illuminated LED in the button

indicates that the system is switched

on. When the control indicator ) in

the instrument cluster illuminates

green, the system is ready to operate.

The system is only operable at

vehicle speeds above 35 mph and if

lane markings are available.

When the system recognises an

unintended lane change, the control

indicator ) changes to yellow and

flashes. Simultaneously a chime

sound is activated.

Deactivation

The system is deactivated by

pressing ) button, the LED in the

button extinguishes.

At speeds below 35 mph the system

is inoperable.

Fault

The lane departure warning system

may not operate properly when:

■ the windscreen is not clean

■ there are adverse environmental conditions like heavy rain, snow,

direct sunlight or shadows

The system can not operate when no

lane marking is detected.

Page 228 of 297

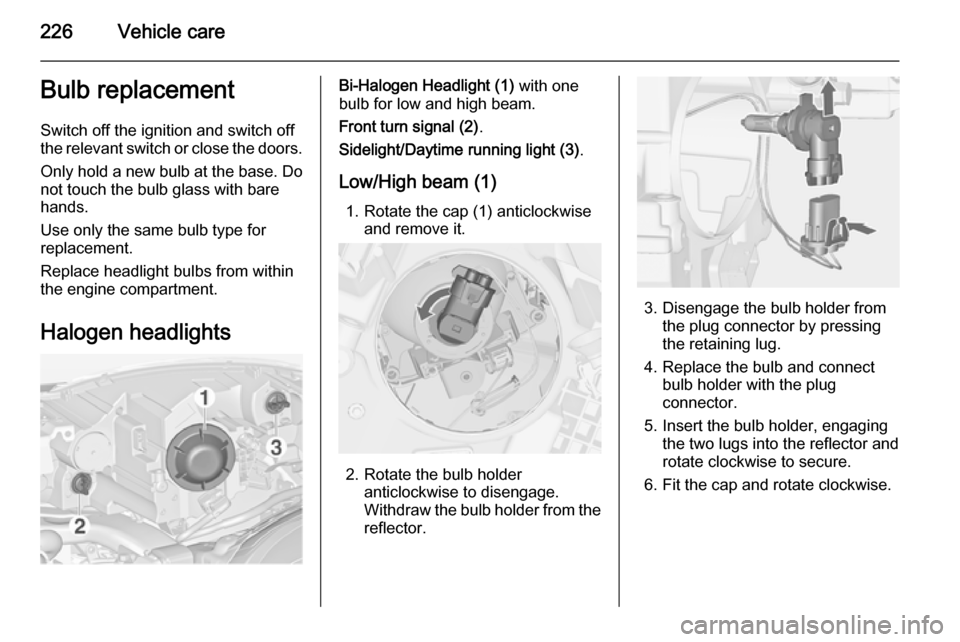

226Vehicle careBulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Halogen headlightsBi-Halogen Headlight (1) with one

bulb for low and high beam.

Front turn signal (2) .

Sidelight/Daytime running light (3) .

Low/High beam (1) 1. Rotate the cap (1) anticlockwise and remove it.

2. Rotate the bulb holder anticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

3. Disengage the bulb holder from the plug connector by pressing

the retaining lug.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

Page 229 of 297

Vehicle care227

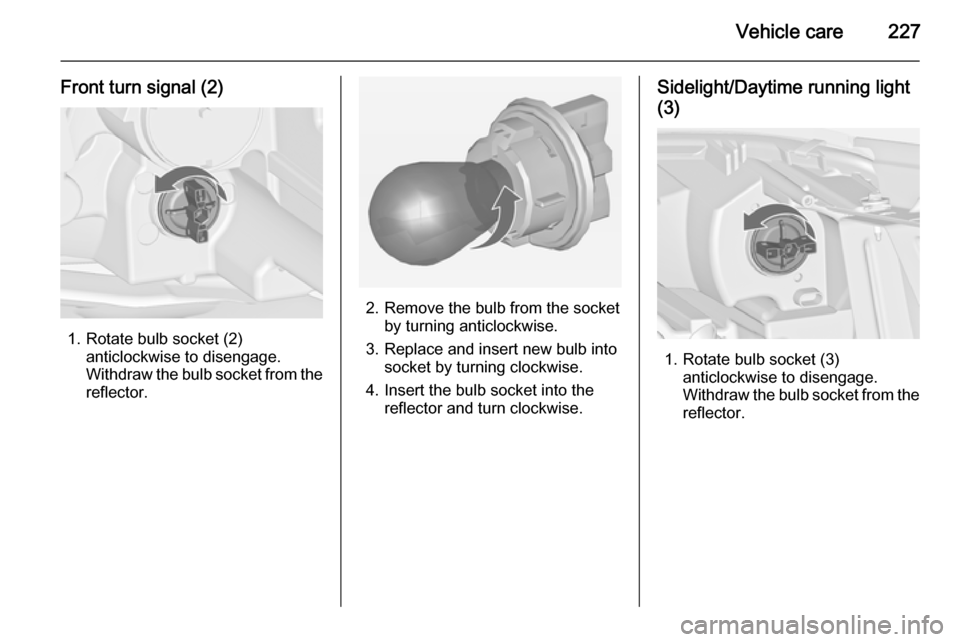

Front turn signal (2)

1. Rotate bulb socket (2)anticlockwise to disengage.

Withdraw the bulb socket from the

reflector.

2. Remove the bulb from the socket by turning anticlockwise.

3. Replace and insert new bulb into socket by turning clockwise.

4. Insert the bulb socket into the reflector and turn clockwise.

Sidelight/Daytime running light

(3)

1. Rotate bulb socket (3) anticlockwise to disengage.

Withdraw the bulb socket from the

reflector.

Page 230 of 297

228Vehicle care

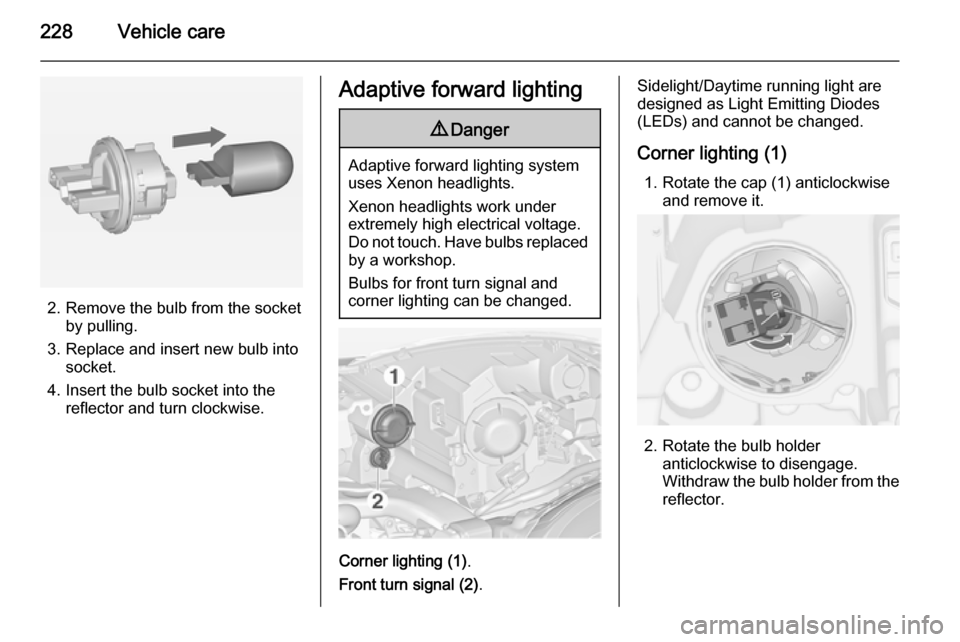

2. Remove the bulb from the socketby pulling.

3. Replace and insert new bulb into socket.

4. Insert the bulb socket into the reflector and turn clockwise.

Adaptive forward lighting9 Danger

Adaptive forward lighting system

uses Xenon headlights.

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Bulbs for front turn signal and

corner lighting can be changed.

Corner lighting (1) .

Front turn signal (2) .

Sidelight/Daytime running light are

designed as Light Emitting Diodes

(LEDs) and cannot be changed.

Corner lighting (1) 1. Rotate the cap (1) anticlockwise and remove it.

2. Rotate the bulb holder anticlockwise to disengage.

Withdraw the bulb holder from the

reflector.

Page 231 of 297

Vehicle care229

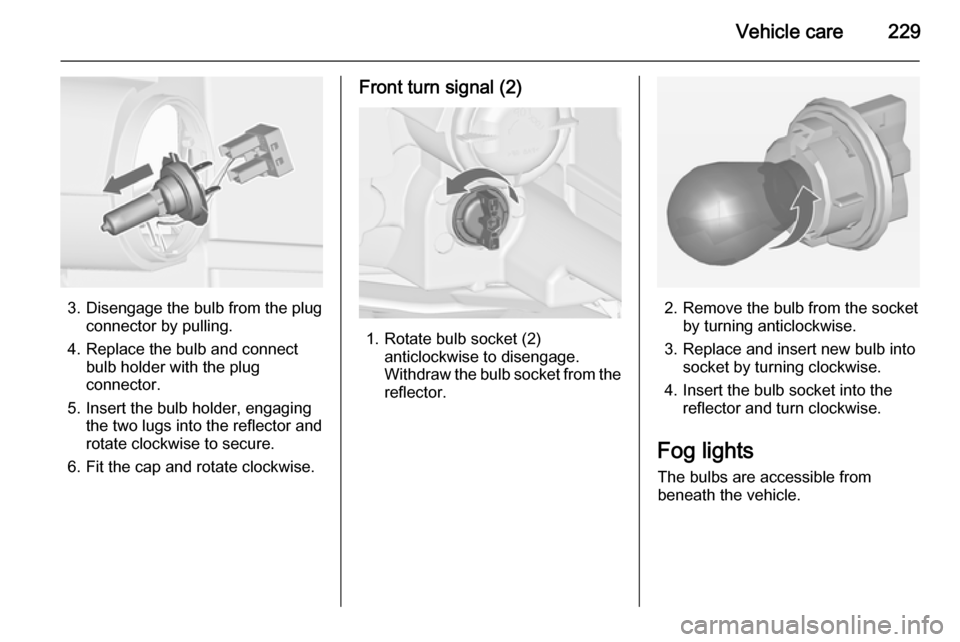

3. Disengage the bulb from the plugconnector by pulling.

4. Replace the bulb and connect bulb holder with the plug

connector.

5. Insert the bulb holder, engaging the two lugs into the reflector and

rotate clockwise to secure.

6. Fit the cap and rotate clockwise.

Front turn signal (2)

1. Rotate bulb socket (2) anticlockwise to disengage.

Withdraw the bulb socket from the

reflector.

2. Remove the bulb from the socket by turning anticlockwise.

3. Replace and insert new bulb into socket by turning clockwise.

4. Insert the bulb socket into the reflector and turn clockwise.

Fog lights The bulbs are accessible from

beneath the vehicle.

Page 233 of 297

Vehicle care231

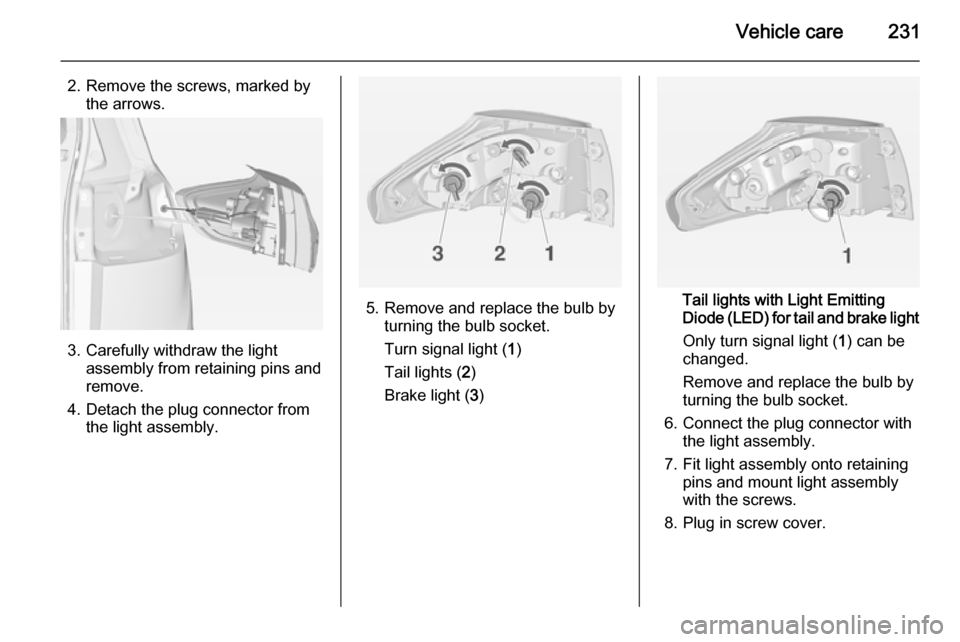

2. Remove the screws, marked bythe arrows.

3. Carefully withdraw the light assembly from retaining pins and

remove.

4. Detach the plug connector from the light assembly.

5. Remove and replace the bulb byturning the bulb socket.

Turn signal light ( 1)

Tail lights ( 2)

Brake light ( 3)Tail lights with Light Emitting

Diode (LED) for tail and brake light

Only turn signal light ( 1) can be

changed.

Remove and replace the bulb by

turning the bulb socket.

6. Connect the plug connector with the light assembly.

7. Fit light assembly onto retaining pins and mount light assembly

with the screws.

8. Plug in screw cover.

Page 235 of 297

Vehicle care233

2. Remove the bulb from the socketby turning anticlockwise.

3. Replace and insert new bulb into the socket by turning clockwise.

4. Insert the bulb socket into the reflector, turn clockwise andengage.

Bulb check Switch on the ignition, operate and

check all lights.

Side turn signal lights

To replace bulb, remove lamp

housing:1. Slide lamp to its left side and remove with its right end.

2. Turn bulb holder anticlockwiseand remove from housing.

3. Pull bulb from bulb holder andreplace it.

4. Insert bulb holder and turn clockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring. Remove cover.

Page 245 of 297

Vehicle care243

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition. After adjusting tyre

pressure, switch on ignition and

select the appropriate setting on the

page Tyre load in the Driver

Information Centre, 3 114.

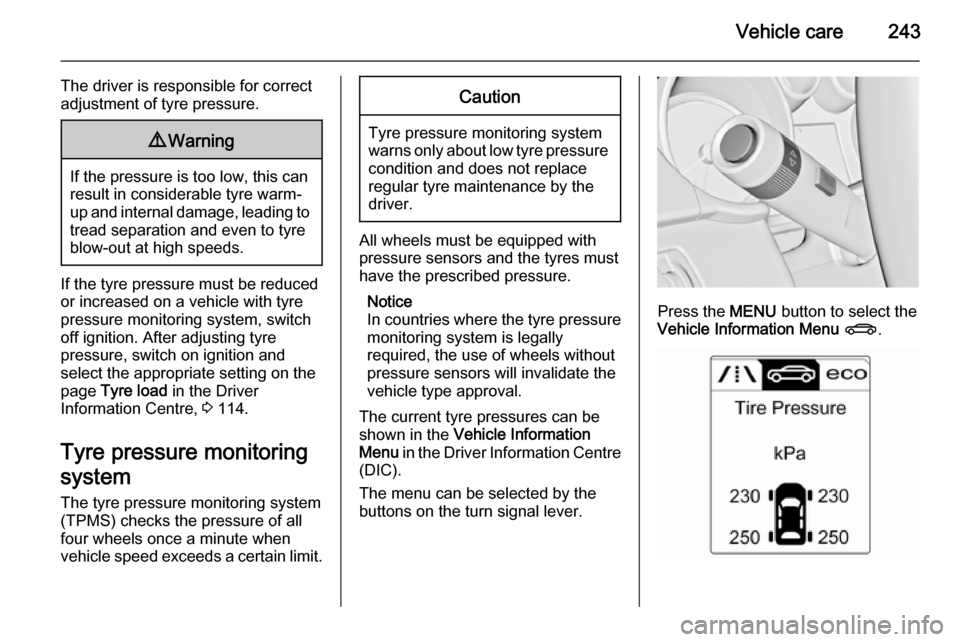

Tyre pressure monitoring system

The tyre pressure monitoring system

(TPMS) checks the pressure of all

four wheels once a minute when

vehicle speed exceeds a certain limit.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The current tyre pressures can be

shown in the Vehicle Information

Menu in the Driver Information Centre

(DIC).

The menu can be selected by the

buttons on the turn signal lever.

Press the MENU button to select the

Vehicle Information Menu X .

Page 247 of 297

Vehicle care245

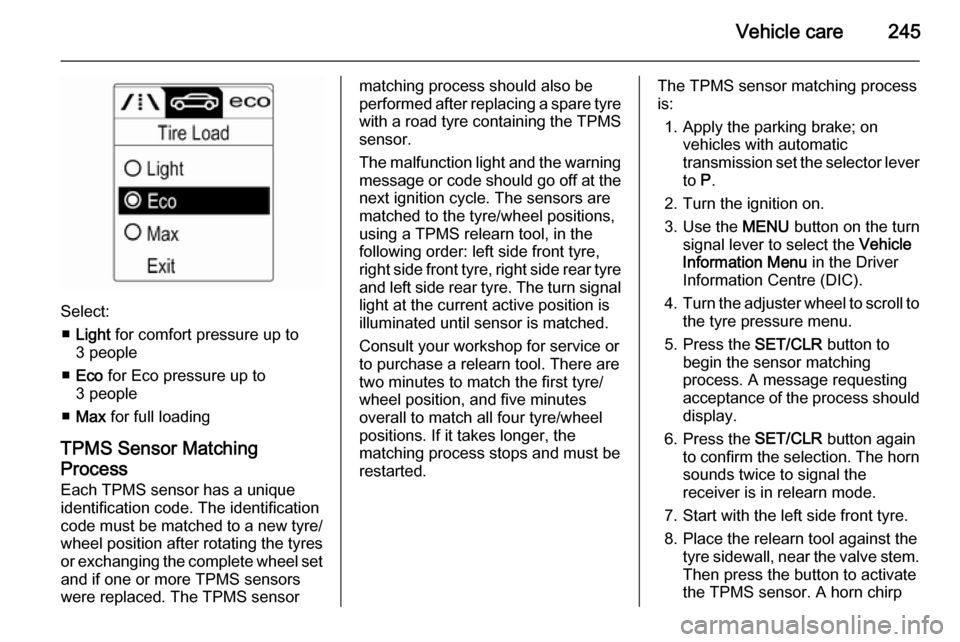

Select:■ Light for comfort pressure up to

3 people

■ Eco for Eco pressure up to

3 people

■ Max for full loading

TPMS Sensor Matching

Process

Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new tyre/

wheel position after rotating the tyres

or exchanging the complete wheel set and if one or more TPMS sensors

were replaced. The TPMS sensor

matching process should also be

performed after replacing a spare tyre

with a road tyre containing the TPMS

sensor.

The malfunction light and the warning

message or code should go off at the

next ignition cycle. The sensors are

matched to the tyre/wheel positions,

using a TPMS relearn tool, in the

following order: left side front tyre,

right side front tyre, right side rear tyre and left side rear tyre. The turn signal

light at the current active position is

illuminated until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

two minutes to match the first tyre/

wheel position, and five minutes

overall to match all four tyre/wheel

positions. If it takes longer, the

matching process stops and must be

restarted.The TPMS sensor matching process

is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

3. Use the MENU button on the turn

signal lever to select the Vehicle

Information Menu in the Driver

Information Centre (DIC).

4. Turn the adjuster wheel to scroll to

the tyre pressure menu.

5. Press the SET/CLR button to

begin the sensor matching

process. A message requesting

acceptance of the process should

display.

6. Press the SET/CLR button again

to confirm the selection. The horn sounds twice to signal the

receiver is in relearn mode.

7. Start with the left side front tyre.

8. Place the relearn tool against the tyre sidewall, near the valve stem.Then press the button to activate

the TPMS sensor. A horn chirp