check engine VAUXHALL ZAFIRA TOURER 2016.5 User Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016.5, Model line: ZAFIRA TOURER, Model: VAUXHALL ZAFIRA TOURER 2016.5Pages: 307, PDF Size: 9.2 MB

Page 159 of 307

Climate control157

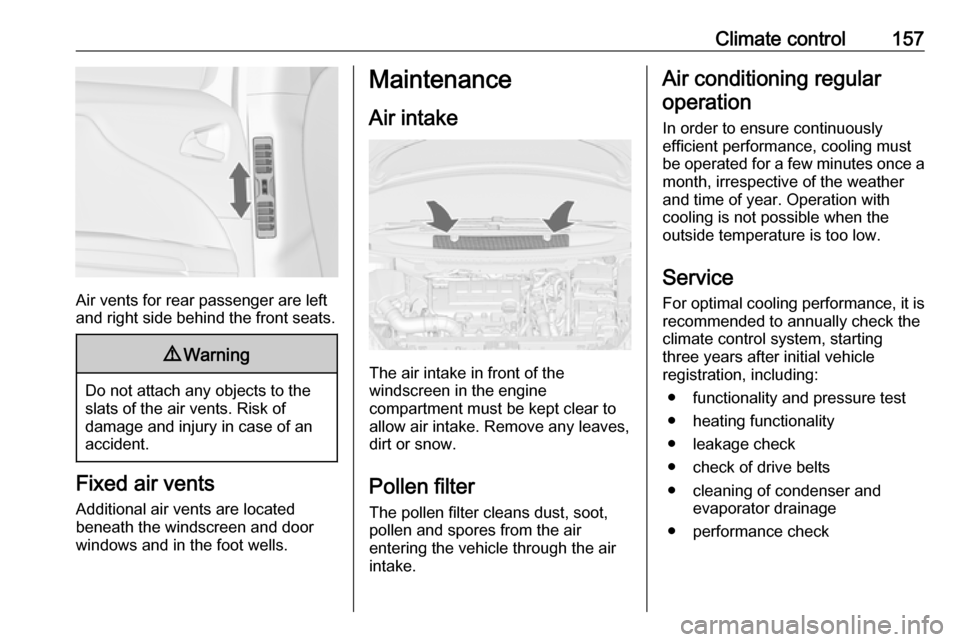

Air vents for rear passenger are left

and right side behind the front seats.

9 Warning

Do not attach any objects to the

slats of the air vents. Risk of

damage and injury in case of an

accident.

Fixed air vents

Additional air vents are located

beneath the windscreen and door windows and in the foot wells.

Maintenance

Air intake

The air intake in front of the

windscreen in the engine

compartment must be kept clear to

allow air intake. Remove any leaves,

dirt or snow.

Pollen filter The pollen filter cleans dust, soot,

pollen and spores from the air

entering the vehicle through the air

intake.

Air conditioning regular

operation

In order to ensure continuously

efficient performance, cooling must

be operated for a few minutes once a

month, irrespective of the weather

and time of year. Operation with

cooling is not possible when the

outside temperature is too low.

Service For optimal cooling performance, it is recommended to annually check the

climate control system, starting

three years after initial vehicle

registration, including:

● functionality and pressure test

● heating functionality

● leakage check

● check of drive belts

● cleaning of condenser and evaporator drainage

● performance check

Page 163 of 307

Driving and operating161Automatic Starter ControlThis function controls the engine

starting procedure. The driver does

not have to hold the key in position 3.

Once applied, the system will go on

starting automatically until the engine

is running. Because of the checking

procedure, the engine starts running after a brief delay.

Possible reasons for a non-starting engine:

● Clutch pedal not operated (manual transmission).

● Brake pedal not operated or selector lever not in P or N

(automatic transmission).

● Timeout occurred.

Turbo engine warm-up Upon start-up, engine available

torque may be limited for a short time,

especially when the engine

temperature is cold. The limitation is

to allow the lubrication system to fully protect the engine.Overrun cut-off

The fuel supply is automatically cut off

during overrun, i.e. when the vehicle

is driven with a gear engaged but

accelerator is released.

Stop-start system

The stop-start system helps to save

fuel and to reduce the exhaust

emissions. When conditions allow, it

switches off the engine as soon as the

vehicle is at a low speed or at a

standstill, e.g. at a traffic light or in a

traffic jam. It starts the engine

automatically as soon as the clutch is depressed. A vehicle battery sensor

ensures that an Autostop is only

performed if the vehicle battery is

sufficiently charged for a restart.

Activation

The stop-start system is available as soon as the engine is started, the

vehicle starts-off and the conditions

as stated below in this section are

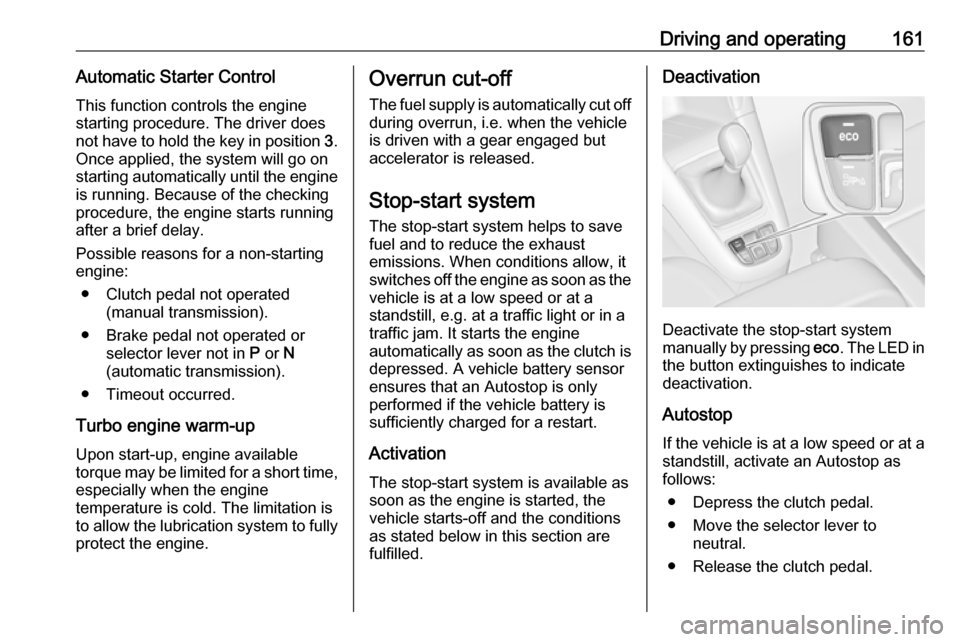

fulfilled.Deactivation

Deactivate the stop-start system

manually by pressing eco. The LED in

the button extinguishes to indicate

deactivation.

Autostop If the vehicle is at a low speed or at a

standstill, activate an Autostop as

follows:

● Depress the clutch pedal.

● Move the selector lever to neutral.

● Release the clutch pedal.

Page 164 of 307

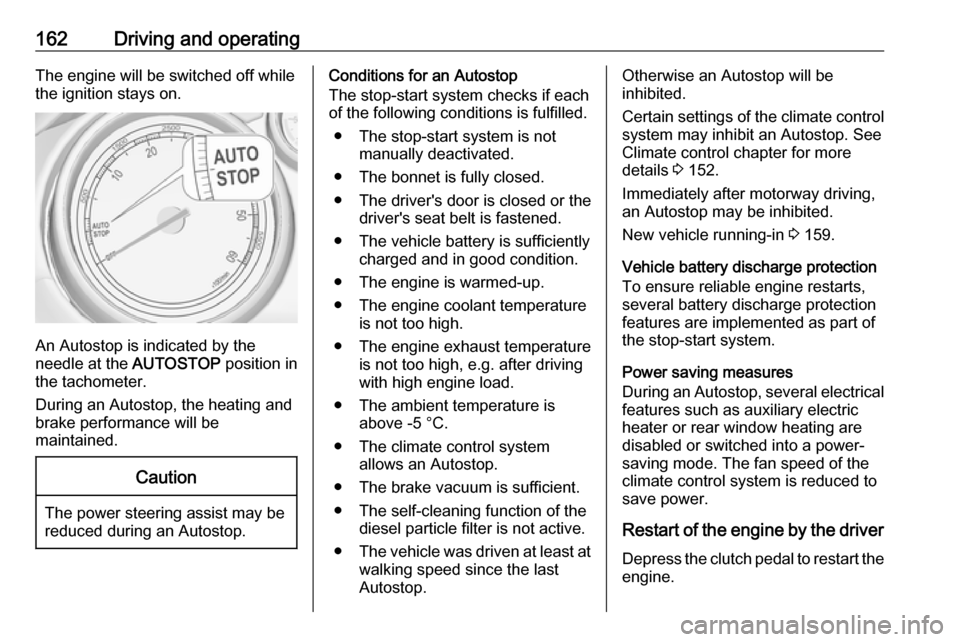

162Driving and operatingThe engine will be switched off while

the ignition stays on.

An Autostop is indicated by the

needle at the AUTOSTOP position in

the tachometer.

During an Autostop, the heating and

brake performance will be

maintained.

Caution

The power steering assist may be

reduced during an Autostop.

Conditions for an Autostop

The stop-start system checks if each

of the following conditions is fulfilled.

● The stop-start system is not manually deactivated.

● The bonnet is fully closed.

● The driver's door is closed or the driver's seat belt is fastened.

● The vehicle battery is sufficiently charged and in good condition.

● The engine is warmed-up.

● The engine coolant temperature is not too high.

● The engine exhaust temperature is not too high, e.g. after driving

with high engine load.

● The ambient temperature is above -5 °C.

● The climate control system allows an Autostop.

● The brake vacuum is sufficient.

● The self-cleaning function of the diesel particle filter is not active.

● The vehicle was driven at least at

walking speed since the last

Autostop.Otherwise an Autostop will be

inhibited.

Certain settings of the climate control

system may inhibit an Autostop. See

Climate control chapter for more

details 3 152.

Immediately after motorway driving,

an Autostop may be inhibited.

New vehicle running-in 3 159.

Vehicle battery discharge protection

To ensure reliable engine restarts, several battery discharge protection

features are implemented as part of

the stop-start system.

Power saving measures

During an Autostop, several electrical

features such as auxiliary electric

heater or rear window heating are

disabled or switched into a power-

saving mode. The fan speed of the

climate control system is reduced to

save power.

Restart of the engine by the driver Depress the clutch pedal to restart the

engine.

Page 169 of 307

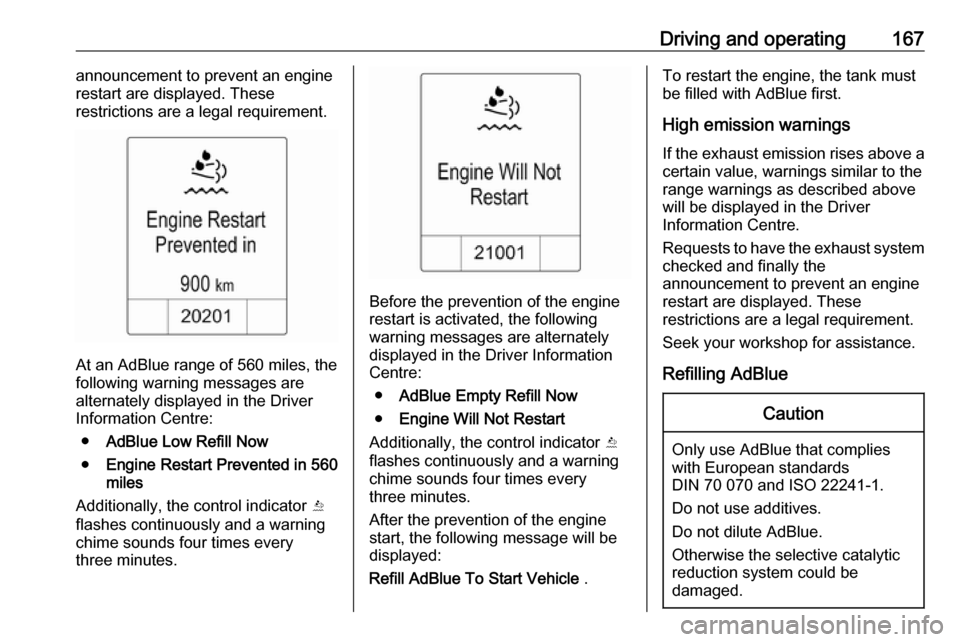

Driving and operating167announcement to prevent an engine

restart are displayed. These

restrictions are a legal requirement.

At an AdBlue range of 560 miles, the following warning messages are

alternately displayed in the Driver

Information Centre:

● AdBlue Low Refill Now

● Engine Restart Prevented in 560

miles

Additionally, the control indicator Y

flashes continuously and a warning

chime sounds four times every

three minutes.

Before the prevention of the engine

restart is activated, the following

warning messages are alternately

displayed in the Driver Information

Centre:

● AdBlue Empty Refill Now

● Engine Will Not Restart

Additionally, the control indicator Y

flashes continuously and a warning

chime sounds four times every

three minutes.

After the prevention of the engine

start, the following message will be

displayed:

Refill AdBlue To Start Vehicle .

To restart the engine, the tank must

be filled with AdBlue first.

High emission warnings If the exhaust emission rises above a

certain value, warnings similar to the

range warnings as described above

will be displayed in the Driver

Information Centre.

Requests to have the exhaust system checked and finally the

announcement to prevent an engine

restart are displayed. These

restrictions are a legal requirement.

Seek your workshop for assistance.

Refilling AdBlueCaution

Only use AdBlue that complies

with European standards

DIN 70 070 and ISO 22241-1.

Do not use additives.

Do not dilute AdBlue.

Otherwise the selective catalytic

reduction system could be

damaged.

Page 176 of 307

174Driving and operatingParking brake

Manual parking brake9 Warning

Always apply parking brake firmly

without operating the release

button, and apply as firmly as

possible on a downhill or uphill

slope.

To release the parking brake, pull

the lever up slightly, press the

release button and fully lower the

lever.

To reduce the operating forces of

the parking brake, depress the

foot brake at the same time.

Control indicator R 3 111.

Electric parking brake

Applying when vehicle is stationary

9 Warning

Pull switch m for approx.

one second, the electric parking

brake operates automatically with

adequate force. For maximum

force, e.g. parking with trailer or on

inclines, pull switch m twice.

The electric parking brake is

applied when control indicator m

illuminates 3 112.

The electric parking brake can always

be activated, even if the ignition is off.

Do not operate electric parking brake

system too often with engine not

running, as this will discharge the

vehicle battery.

Before leaving the vehicle, check the electric parking brake status. Control

indicator m 3 112.

Releasing

Switch on ignition. Keep brake pedal

depressed and then press switch m.

Drive away function

Vehicles with manual transmission:

Depressing the clutch pedal and then

slightly releasing the clutch pedal and

slightly depressing the accelerator

pedal releases the electric parking

Page 213 of 307

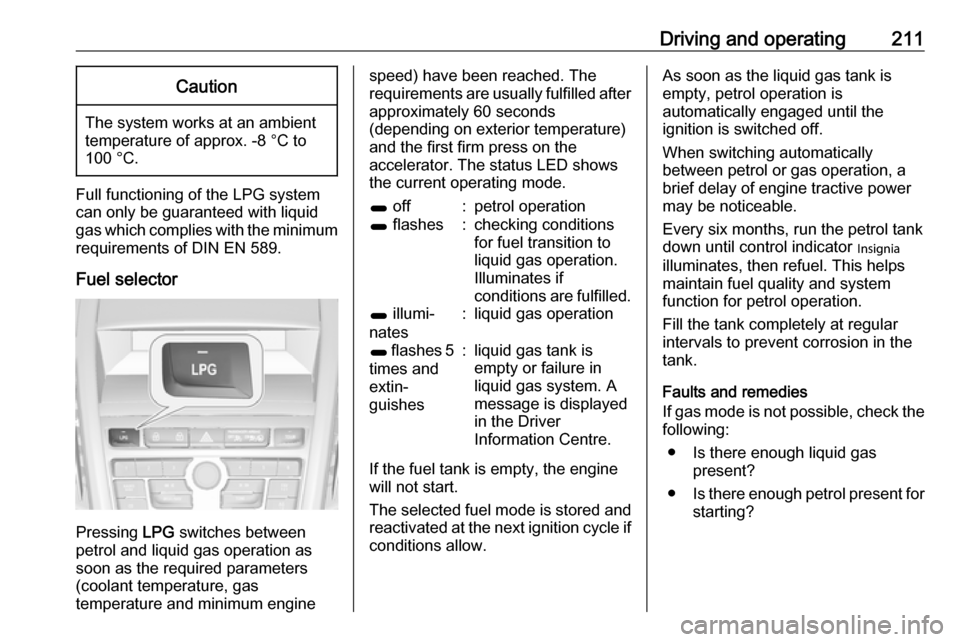

Driving and operating211Caution

The system works at an ambient

temperature of approx. -8 °C to

100 °C.

Full functioning of the LPG system can only be guaranteed with liquid

gas which complies with the minimum

requirements of DIN EN 589.

Fuel selector

Pressing LPG switches between

petrol and liquid gas operation as

soon as the required parameters (coolant temperature, gas

temperature and minimum engine

speed) have been reached. The

requirements are usually fulfilled after

approximately 60 seconds

(depending on exterior temperature)

and the first firm press on the

accelerator. The status LED shows

the current operating mode.1 off:petrol operation1 flashes:checking conditions

for fuel transition to

liquid gas operation.

Illuminates if

conditions are fulfilled.1 illumi‐

nates:liquid gas operation1 flashes 5

times and

extin‐

guishes:liquid gas tank is

empty or failure in

liquid gas system. A

message is displayed

in the Driver

Information Centre.

If the fuel tank is empty, the engine

will not start.

The selected fuel mode is stored and

reactivated at the next ignition cycle if

conditions allow.

As soon as the liquid gas tank is

empty, petrol operation is

automatically engaged until the

ignition is switched off.

When switching automatically

between petrol or gas operation, a

brief delay of engine tractive power

may be noticeable.

Every six months, run the petrol tank down until control indicator I

illuminates, then refuel. This helps

maintain fuel quality and system

function for petrol operation.

Fill the tank completely at regular intervals to prevent corrosion in the

tank.

Faults and remedies

If gas mode is not possible, check the following:

● Is there enough liquid gas present?

● Is there enough petrol present for

starting?

Page 224 of 307

222Driving and operatingAttach breakaway stopping cable to

eye.

Check that the coupling ball bar is correctly installed

● Green marking on rotary knob must point towards green

marking on coupling ball bar.

● There must be no gap between the rotary handle and the

coupling ball bar.

● The coupling ball bar must be firmly engaged in the opening.

● The coupling ball bar must be locked and the key removed.9Warning

Towing a trailer is permitted only

when a coupling ball bar is fitted correctly. If the coupling ball bardoes not engage correctly, seekthe assistance of a workshop.

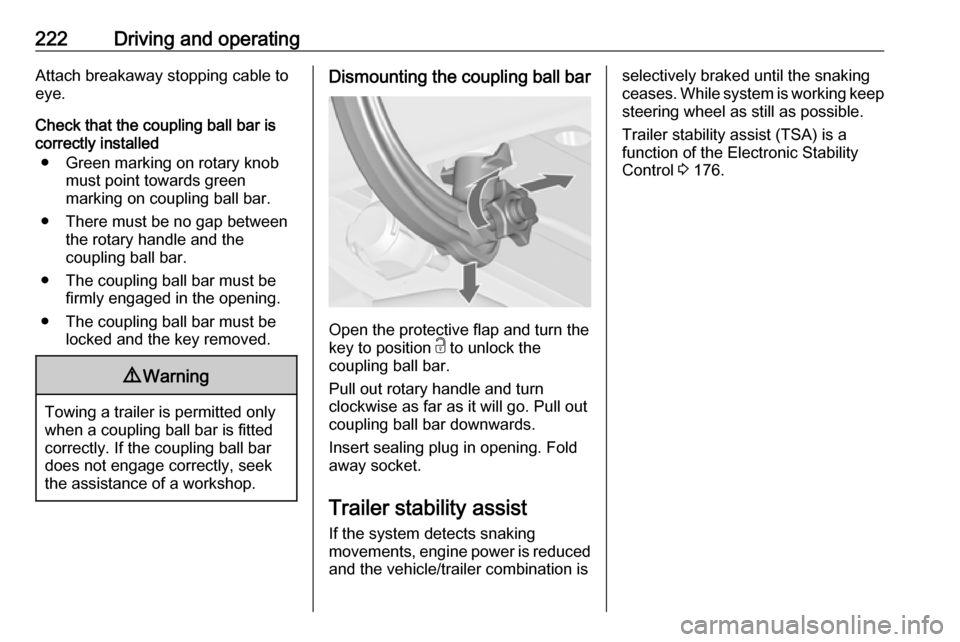

Dismounting the coupling ball bar

Open the protective flap and turn the

key to position c to unlock the

coupling ball bar.

Pull out rotary handle and turn

clockwise as far as it will go. Pull out coupling ball bar downwards.

Insert sealing plug in opening. Fold away socket.

Trailer stability assist

If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep steering wheel as still as possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Control 3 176.

Page 225 of 307

Vehicle care223Vehicle careGeneral Information...................224

Accessories and vehicle modifications .......................... 224

Vehicle storage ........................224

End-of-life vehicle recovery .....224

Vehicle checks ........................... 225

Performing work ......................225

Bonnet ..................................... 225

Engine oil ................................. 226

Engine coolant ......................... 227

Power steering fluid .................228

Washer fluid ............................ 229

Brakes ..................................... 229

Brake fluid ............................... 229

Vehicle battery ......................... 229

Diesel fuel system bleeding .....231

Wiper blade replacement ........231

Bulb replacement .......................232

Halogen headlights ..................232

Adaptive forward lighting .........234

Fog lights ................................. 235

Tail lights ................................. 236

Side turn signal lights ..............238

Number plate light ...................239Interior lights ............................ 239

Instrument panel illumination ...240

Electrical system ........................240

Fuses ....................................... 240

Engine compartment fuse box . 241

Instrument panel fuse box .......243

Load compartment fuse box ....244

Vehicle tools .............................. 246

Tools ........................................ 246

Wheels and tyres .......................247

Winter tyres ............................. 247

Tyre designations ....................247

Tyre pressure .......................... 247

Tyre pressure monitoring system .................................... 248

Tread depth ............................. 251

Changing tyre and wheel size . 252

Wheel covers ........................... 252

Tyre chains .............................. 253

Tyre repair kit .......................... 253

Wheel changing .......................256

Spare wheel ............................ 258

Jump starting ............................. 262

Towing ....................................... 263

Towing the vehicle ...................263

Towing another vehicle ...........264Appearance care .......................265

Exterior care ............................ 265

Interior care ............................. 267

Page 226 of 307

224Vehicle careGeneral Information

Accessories and vehicle modifications

We recommend the use of genuine

parts and accessories and factory

approved parts specific for your

vehicle type. We cannot assess or guarantee reliability of other products

- even if they have a regulatory or

otherwise granted approval.

Do not make any modifications to the electrical system, e.g. changes of

electronic control units (chip tuning).Caution

When transporting the vehicle on

a train or on a recovery vehicle, the

mud flaps might be damaged.

Vehicle storage

Storage for a long period of time

If the vehicle is to be stored for several months:

● Wash and wax the vehicle.

● Have the wax in the engine compartment and underbody

checked.

● Clean and preserve the rubber seals.

● Fill up fuel tank completely.

● Change the engine oil.

● Drain the washer fluid reservoir.

● Check the coolant antifreeze and

corrosion protection.

● Adjust tyre pressure to the value specified for full load.

● Park the vehicle in a dry, well ventilated place. Engage first or

reverse gear or set selector lever

to P. Prevent the vehicle from

rolling.

● Do not apply the parking brake.● Open the bonnet, close all doors and lock the vehicle.

● Disconnect the clamp from the negative terminal of the vehicle

battery. Beware that all systems

are not functional, e.g. anti-theft

alarm system.

Putting back into operation

When the vehicle is to be put back into

operation:

● Connect the clamp to the negative terminal of the vehicle

battery. Activate the electronics

of the power windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the engine oil level.

● Check the coolant level.

● Fit the number plate if necessary.

End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our

Page 227 of 307

Vehicle care225website, where legally required. Only

entrust this work to an authorised

recycling centre.

Gas vehicles must be recycled by a service centre authorised for gas

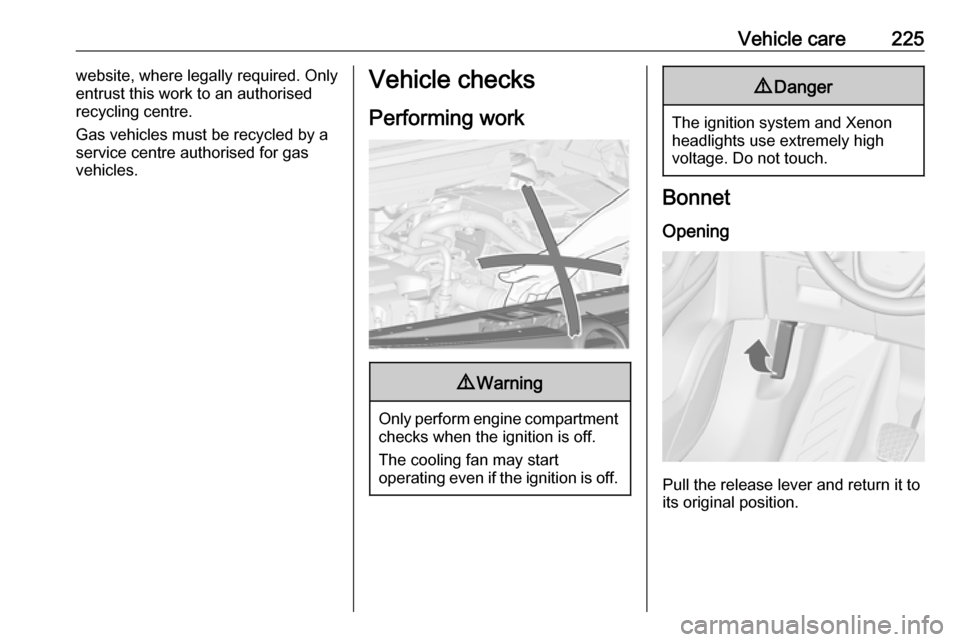

vehicles.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

Bonnet

Opening

Pull the release lever and return it to

its original position.