Automat VAUXHALL ZAFIRA TOURER 2016 Manual Online

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2016, Model line: ZAFIRA TOURER, Model: VAUXHALL ZAFIRA TOURER 2016Pages: 305, PDF Size: 9.15 MB

Page 198 of 305

196Driving and operating

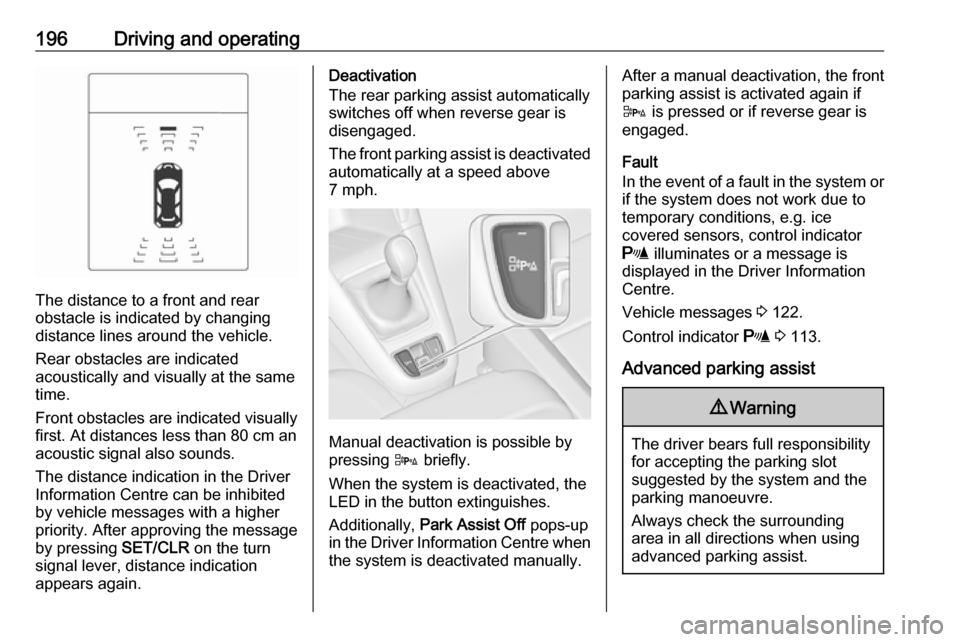

The distance to a front and rear

obstacle is indicated by changing

distance lines around the vehicle.

Rear obstacles are indicated

acoustically and visually at the same

time.

Front obstacles are indicated visually

first. At distances less than 80 cm an

acoustic signal also sounds.

The distance indication in the Driver

Information Centre can be inhibited

by vehicle messages with a higher

priority. After approving the message

by pressing SET/CLR on the turn

signal lever, distance indication

appears again.

Deactivation

The rear parking assist automatically

switches off when reverse gear is

disengaged.

The front parking assist is deactivated

automatically at a speed above

7 mph.

Manual deactivation is possible by

pressing D briefly.

When the system is deactivated, the

LED in the button extinguishes.

Additionally, Park Assist Off pops-up

in the Driver Information Centre when the system is deactivated manually.

After a manual deactivation, the front

parking assist is activated again if

D is pressed or if reverse gear is

engaged.

Fault

In the event of a fault in the system or if the system does not work due to

temporary conditions, e.g. ice

covered sensors, control indicator

r illuminates or a message is

displayed in the Driver Information

Centre.

Vehicle messages 3 122.

Control indicator r 3 113.

Advanced parking assist9 Warning

The driver bears full responsibility

for accepting the parking slot

suggested by the system and the

parking manoeuvre.

Always check the surrounding

area in all directions when using

advanced parking assist.

Page 202 of 305

200Driving and operatingBasic notes on parking assist

systems9 Warning

Under certain circumstances,

various reflective surfaces on

objects or clothing as well as

external noise sources may cause the system to fail to detect

obstacles.

Special attention must be paid to

low obstacles which can damage

the lower part of the bumper.

Caution

Performance of the system can be reduced when sensors are

covered, e.g. by ice or snow.

Performance of the parking assist

system can be reduced due to

heavy loading.

Special conditions apply if there

are taller vehicles in the vicinity

(e.g. off-road vehicles, mini vans,

vans). Object identification and

correct distance indication in the

upper part of these vehicles

cannot be guaranteed.

Objects with a very small reflection

cross-section, e.g. objects of

narrow size or soft materials, may

not be detected by the system.

Parking assist systems do not

detect objects outside the

detection range.

Notice

The parking assist system can be

activated and deactivated by

changing the settings in the

Info-Display. If a trailer coupling is

attached, it must be selected in the

menu.

Vehicle personalisation 3 129.

Notice

The parking assist system

automatically detects factory-fitted

towing equipment. It is deactivated

when the connector is plugged in.

It is possible that the sensor detects

a non-existing object (echo

disturbance) caused by external acoustical or mechanic

disturbances.

Advanced parking assist system

may not respond to changes in the

parking space after initiating a

parallel parking manoeuvre.

Notice

If engaging a forward gear and

exceeding a certain speed, the rear

parking assist will be deactivated

when the rear carrier system is

extended.

If engaging reverse gear first, the

parking assist will detect the rear

carrier system and provide a buzzing sound. Press D briefly to

deactivate the parking assist.

Notice

After production, the advanced

parking assist requires a calibration.

For optimal parking guidance, a

driving distance of at least 22 miles,

including a number of bends, is

required.

Page 204 of 305

202Driving and operatingby approx. 3 metres. The height of thezone is approx. between 0.5 metres

and 2 metres off the ground.

The system is deactivated if the

vehicle is towing a trailer.

Side blind spot alert is designed to ignore stationary objects such as

guardrails, posts, curbs, walls and

beams. Parked vehicles or oncoming

vehicles are not detected.

Fault

Occasional missed alerts can occur under normal circumstances and will

increase in wet conditions.

Side blind spot alert does not operate when the left or right corners of the

rear bumper are covered with mud,

dirt, snow, ice, slush, or in heavy

rainstorms. Cleaning instructions

3 264.

In the event of a fault in the system or if the system does not work due to

temporary conditions, a message is

displayed in the Driver Information

Centre. Seek the assistance of a

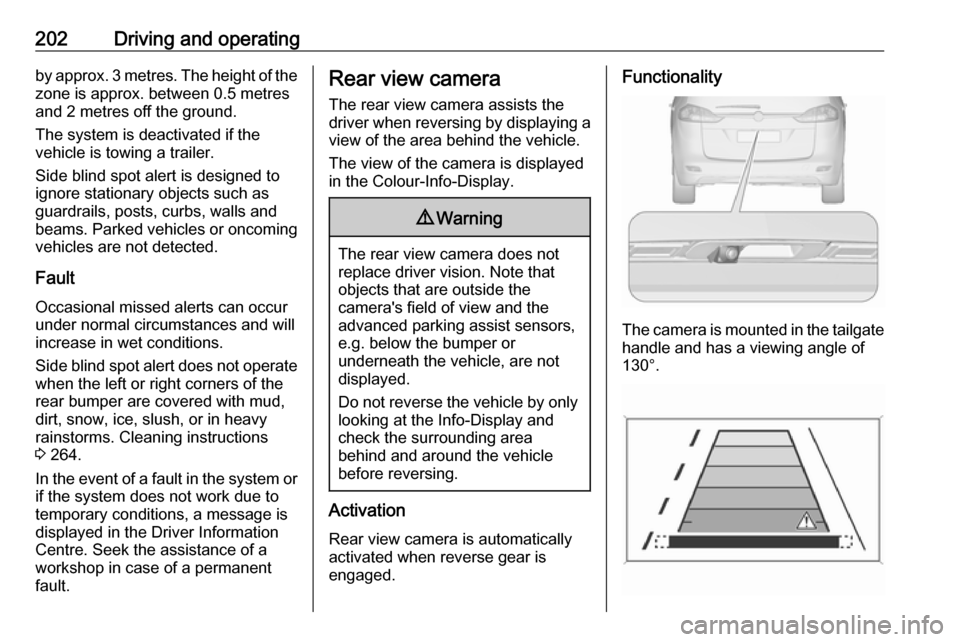

workshop in case of a permanent fault.Rear view camera

The rear view camera assists the

driver when reversing by displaying a view of the area behind the vehicle.

The view of the camera is displayed

in the Colour-Info-Display.9 Warning

The rear view camera does not

replace driver vision. Note that

objects that are outside the

camera's field of view and the

advanced parking assist sensors,

e.g. below the bumper or

underneath the vehicle, are not

displayed.

Do not reverse the vehicle by only looking at the Info-Display and

check the surrounding area

behind and around the vehicle

before reversing.

Activation

Rear view camera is automatically

activated when reverse gear is

engaged.

Functionality

The camera is mounted in the tailgate handle and has a viewing angle of

130°.

Page 211 of 305

Driving and operating209Fuel for natural gasoperation

Use natural gas with a methane

content of approx. 78 - 99%. L-gas

(low) has approx. 78 - 87% and H-gas (high) has approx. 87 - 99%. Biogas

with the same methane content can

also be used if it has been chemically

prepared and desulphurised.

Only use natural gas or biogas that

complies with DIN 51624.

Liquid gas or LPG must not be used.

Fuel selectorPressing Y switches between petrol

and natural gas operation. Switching

is not possible at high loads (e.g.

powerful acceleration, driving at full

throttle). The LED status shows the

current operating mode.1 off:natural gas

operation1 illumi‐

nates:petrol operation1 flashes:no switching is

possible, one type of

fuel is empty

As soon as the natural gas tank is empty, petrol operation is

automatically engaged until the

ignition is switched off.

If the natural gas tank is not refuelled, the system must be manually

switched to petrol operation before

the engine is restarted. This will

prevent damage to the catalytic

converter (overheating caused by

irregular fuel supply).

If the selector switch is operated

several times within a short time, a

switchover inhibitor is activated. The

engine remains in the current

operating mode. The inhibitor

remains active until the ignition is

switched off.

A slight loss of power and torque can

be expected during petrol operation.

You must therefore adapt your driving style (e.g. during overtaking

manoeuvres) and high vehicle loads

(e.g. towing loads) accordingly.

Every six months run the petrol tank

down until control indicator Y

illuminates, then refuel. This is

necessary to maintain fuel quality as

well as system function necessary for

petrol operation.

Fill the tank completely at regular

intervals to prevent corrosion in the

tank.

Fuel for liquid gas operation

Liquid gas is known as LPG

(Liquefied Petroleum Gas) or under

its French name GPL (Gaz de Pétrole Liquéfié). LPG is also known as

Autogas.

Page 212 of 305

210Driving and operatingLPG consists mainly of propane and

butane. The octane rating is between 105 and 115, depending on the

butane proportion. LPG is stored

liquid at around 5 - 10 bar pressure.

The boiling point depends on the

pressure and mixing ratio. At ambient

pressure, it is between -42 °C (pure

propane) and -0.5 °C (pure butane).Caution

The system works at an ambient

temperature of approx. -8 °C to

100 °C.

Full function of the LPG system can only be guaranteed with liquid gas

which complies with the minimum

requirements of DIN EN 589.

Fuel selector

Pressing LPG switches between

petrol and liquid gas operation as

soon as the required parameters (coolant temperature, gas

temperature and minimum engine

speed) have been reached. The

requirements are usually fulfilled after

around 60 seconds (depending on

exterior temperature) and the first firm press on the accelerator. The LED

status shows the current operating

mode.

1 off:petrol operation1 flashes:checking conditions

for fuel transition to

liquid gas operation.

Illuminates if

conditions are fulfilled.1 illumi‐

nates:liquid gas operation1 flashes 5

times and

extin‐

guishes:liquid gas tank is

empty or failure in

liquid gas system. A

message is displayed

in the Driver

Information Centre.

The selected fuel mode is stored and

reactivated at the next ignition cycle if

conditions allow.

As soon as the liquid gas tank is

empty, petrol operation is

automatically engaged until the

ignition is switched off.

Every six months, run the petrol tank down until control indicator i

illuminates, then refuel. This helps

maintain fuel quality and system

function for petrol operation.

Page 214 of 305

212Driving and operating9Danger

Fuel is flammable and explosive.

No smoking. No naked flames or

sparks.

If you can smell fuel in your

vehicle, have the cause of this

remedied immediately by a

workshop.

Caution

In case of misfuelling, do not

switch on ignition.

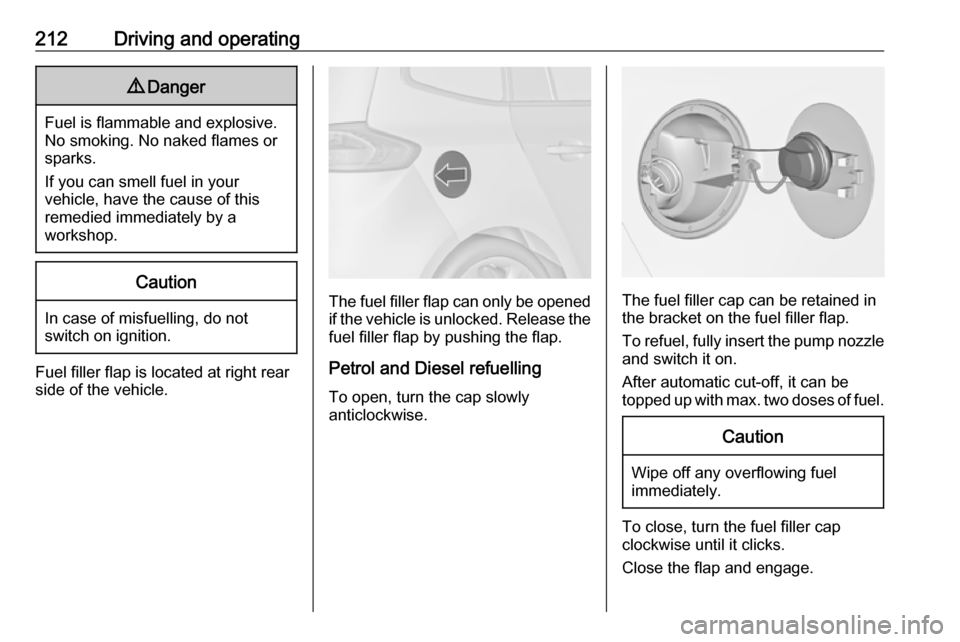

Fuel filler flap is located at right rear

side of the vehicle.

The fuel filler flap can only be opened

if the vehicle is unlocked. Release the

fuel filler flap by pushing the flap.

Petrol and Diesel refuelling To open, turn the cap slowly

anticlockwise.The fuel filler cap can be retained in

the bracket on the fuel filler flap.

To refuel, fully insert the pump nozzle

and switch it on.

After automatic cut-off, it can be

topped up with max. two doses of fuel.

Caution

Wipe off any overflowing fuel

immediately.

To close, turn the fuel filler cap

clockwise until it clicks.

Close the flap and engage.

Page 217 of 305

Driving and operating215

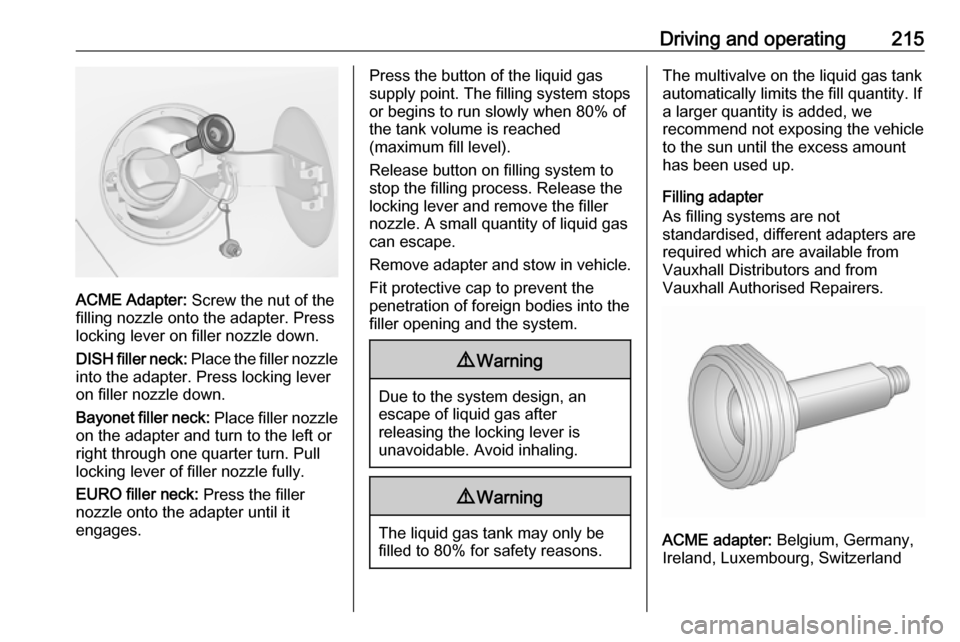

ACME Adapter: Screw the nut of the

filling nozzle onto the adapter. Press

locking lever on filler nozzle down.

DISH filler neck: Place the filler nozzle

into the adapter. Press locking lever

on filler nozzle down.

Bayonet filler neck: Place filler nozzle

on the adapter and turn to the left or

right through one quarter turn. Pull

locking lever of filler nozzle fully.

EURO filler neck: Press the filler

nozzle onto the adapter until it

engages.

Press the button of the liquid gas supply point. The filling system stops

or begins to run slowly when 80% of

the tank volume is reached

(maximum fill level).

Release button on filling system to

stop the filling process. Release the

locking lever and remove the filler

nozzle. A small quantity of liquid gas

can escape.

Remove adapter and stow in vehicle. Fit protective cap to prevent the

penetration of foreign bodies into the

filler opening and the system.9 Warning

Due to the system design, an

escape of liquid gas after

releasing the locking lever is

unavoidable. Avoid inhaling.

9 Warning

The liquid gas tank may only be

filled to 80% for safety reasons.

The multivalve on the liquid gas tank

automatically limits the fill quantity. If

a larger quantity is added, we

recommend not exposing the vehicle

to the sun until the excess amount

has been used up.

Filling adapter

As filling systems are not

standardised, different adapters are

required which are available from

Vauxhall Distributors and from

Vauxhall Authorised Repairers.

ACME adapter: Belgium, Germany,

Ireland, Luxembourg, Switzerland

Page 227 of 305

Vehicle care225

Move the safety catch sideways to theleft vehicle side and open the bonnet.

The bonnet is held open

automatically by a lifter.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Closing Before closing the bonnet, press the

support into the holder.

Lower the bonnet and allow it to fall

into the latch from a low height

(20-25 cm). Check that the bonnet is

engaged.

Caution

Do not press the bonnet into the

latch, to avoid dents.

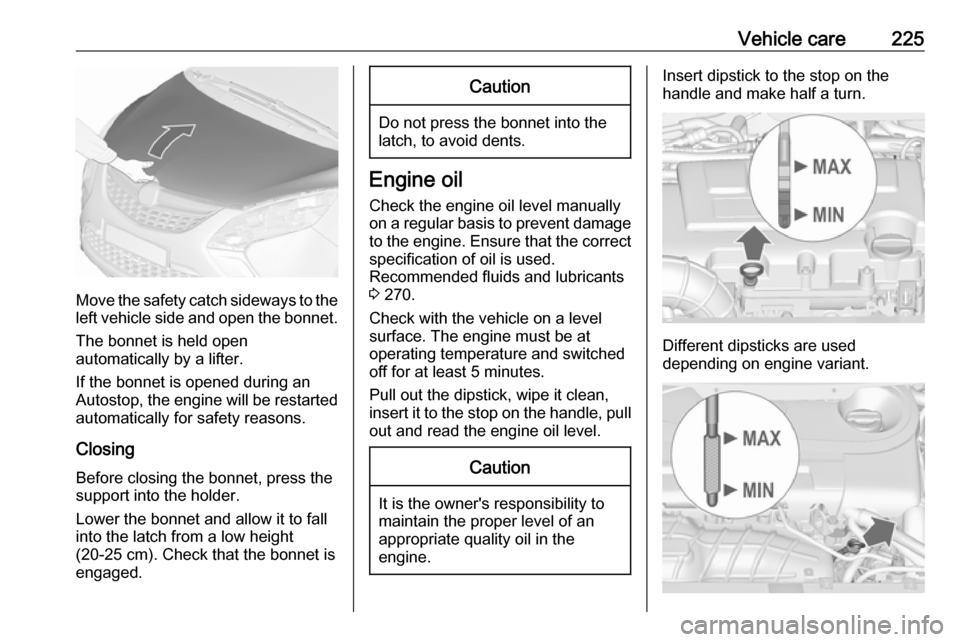

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine. Ensure that the correct specification of oil is used.

Recommended fluids and lubricants

3 270.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 5 minutes.

Pull out the dipstick, wipe it clean, insert it to the stop on the handle, pull

out and read the engine oil level.

Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Insert dipstick to the stop on the

handle and make half a turn.

Different dipsticks are used

depending on engine variant.

Page 251 of 305

Vehicle care249Each time the tyres are replaced, tyre

pressure monitoring system sensors

must be dismounted and serviced. For the screwed sensor, replace

valve core and sealing ring. For

clipped sensor, replace complete

valve stem.

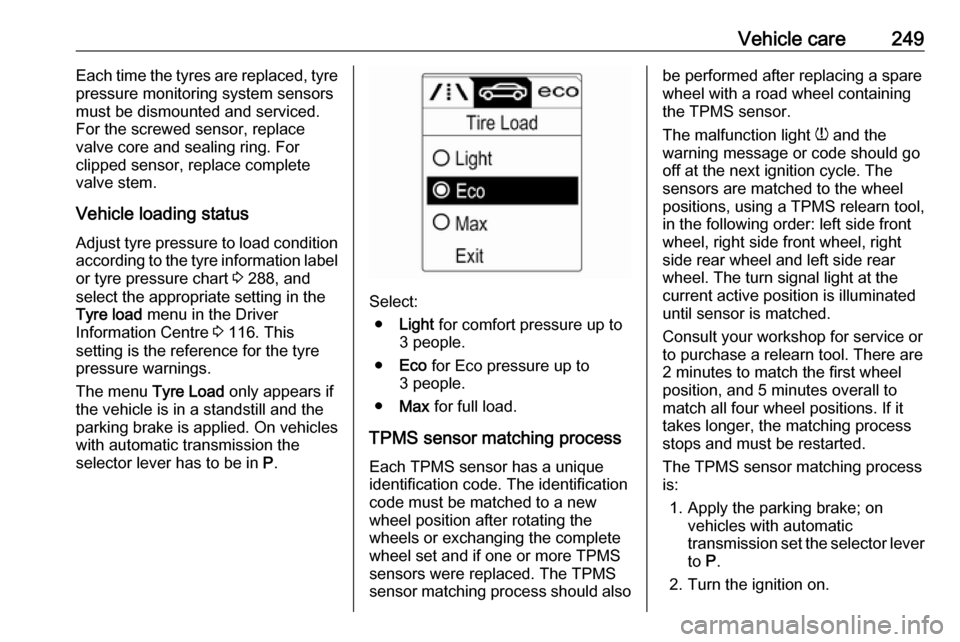

Vehicle loading status

Adjust tyre pressure to load condition according to the tyre information labelor tyre pressure chart 3 288, and

select the appropriate setting in the

Tyre load menu in the Driver

Information Centre 3 116. This

setting is the reference for the tyre

pressure warnings.

The menu Tyre Load only appears if

the vehicle is in a standstill and the

parking brake is applied. On vehicles

with automatic transmission the

selector lever has to be in P.

Select:

● Light for comfort pressure up to

3 people.

● Eco for Eco pressure up to

3 people.

● Max for full load.

TPMS sensor matching process Each TPMS sensor has a unique

identification code. The identification

code must be matched to a new

wheel position after rotating the

wheels or exchanging the complete

wheel set and if one or more TPMS

sensors were replaced. The TPMS sensor matching process should also

be performed after replacing a spare

wheel with a road wheel containing

the TPMS sensor.

The malfunction light w and the

warning message or code should go

off at the next ignition cycle. The

sensors are matched to the wheel

positions, using a TPMS relearn tool,

in the following order: left side front

wheel, right side front wheel, right

side rear wheel and left side rear

wheel. The turn signal light at the

current active position is illuminated

until sensor is matched.

Consult your workshop for service or

to purchase a relearn tool. There are

2 minutes to match the first wheel

position, and 5 minutes overall to

match all four wheel positions. If it

takes longer, the matching process

stops and must be restarted.

The TPMS sensor matching process

is:

1. Apply the parking brake; on vehicles with automatic

transmission set the selector lever

to P.

2. Turn the ignition on.

Page 263 of 305

Vehicle care261●A discharged battery can already

freeze at a temperature of 0 °C.

Defrost the frozen battery before

connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.

● The vehicles must not come into contact with each other during

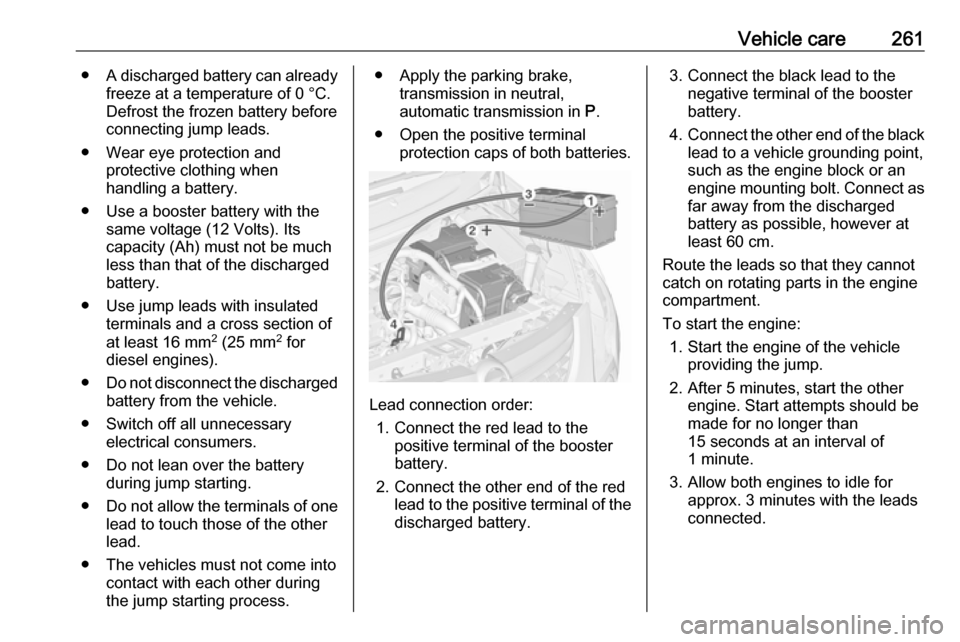

the jump starting process.● Apply the parking brake, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal of the booster

battery.

2. Connect the other end of the red lead to the positive terminal of the

discharged battery.

3. Connect the black lead to the negative terminal of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.