engine VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 497 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

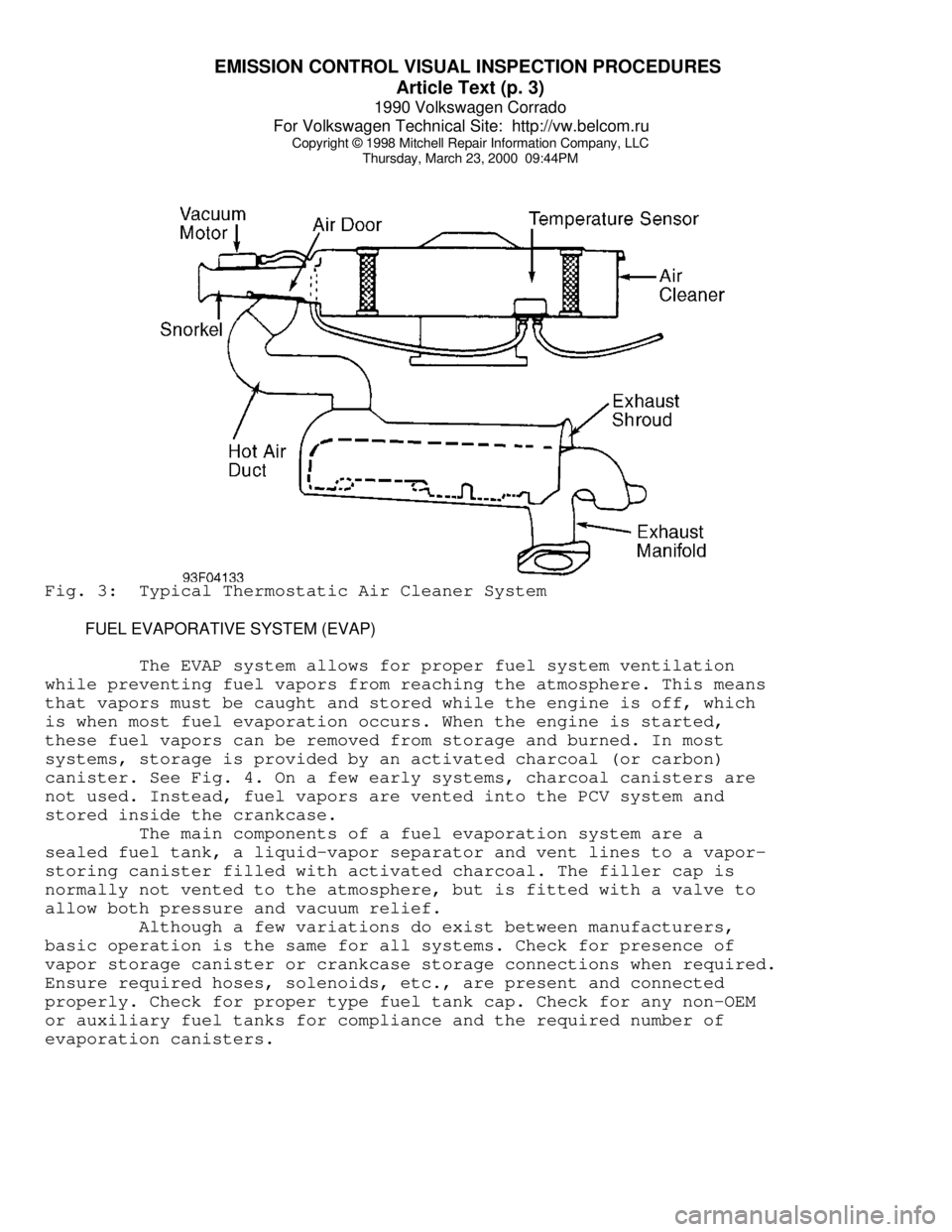

Thursday, March 23, 2000 09:44PMFig. 3: Typical Thermostatic Air Cleaner System

FUEL EVAPORATIVE SYSTEM (EVAP)

The EVAP system allows for proper fuel system ventilation

while preventing fuel vapors from reaching the atmosphere. This means

that vapors must be caught and stored while the engine is off, which

is when most fuel evaporation occurs. When the engine is started,

these fuel vapors can be removed from storage and burned. In most

systems, storage is provided by an activated charcoal (or carbon)

canister. See Fig. 4. On a few early systems, charcoal canisters are

not used. Instead, fuel vapors are vented into the PCV system and

stored inside the crankcase.

The main components of a fuel evaporation system are a

sealed fuel tank, a liquid-vapor separator and vent lines to a vapor-

storing canister filled with activated charcoal. The filler cap is

normally not vented to the atmosphere, but is fitted with a valve to

allow both pressure and vacuum relief.

Although a few variations do exist between manufacturers,

basic operation is the same for all systems. Check for presence of

vapor storage canister or crankcase storage connections when required.

Ensure required hoses, solenoids, etc., are present and connected

properly. Check for proper type fuel tank cap. Check for any non-OEM

or auxiliary fuel tanks for compliance and the required number of

evaporation canisters.

Page 500 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

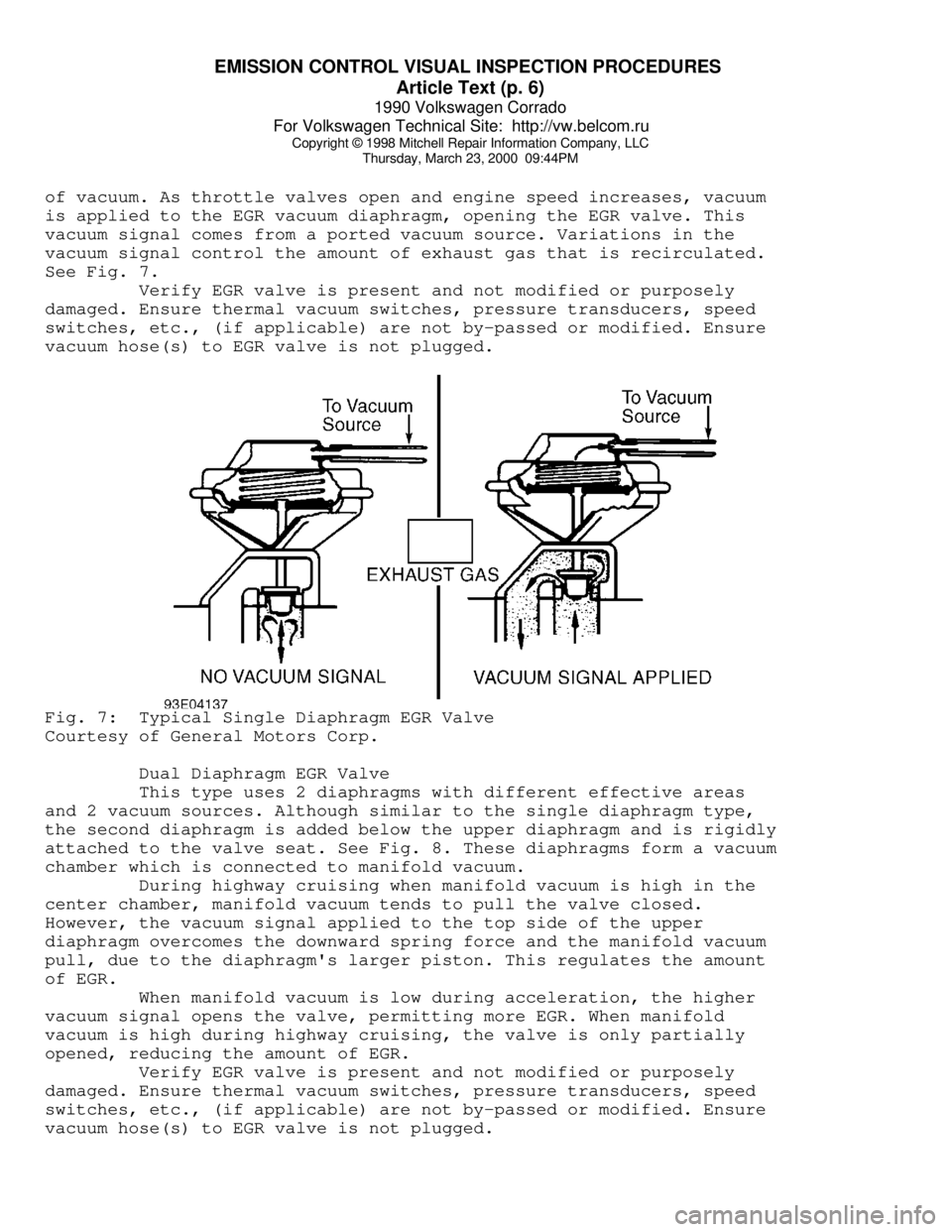

of vacuum. As throttle valves open and engine speed increases, vacuum

is applied to the EGR vacuum diaphragm, opening the EGR valve. This

vacuum signal comes from a ported vacuum source. Variations in the

vacuum signal control the amount of exhaust gas that is recirculated.

See Fig. 7.

Verify EGR valve is present and not modified or purposely

damaged. Ensure thermal vacuum switches, pressure transducers, speed

switches, etc., (if applicable) are not by-passed or modified. Ensure

vacuum hose(s) to EGR valve is not plugged.Fig. 7: Typical Single Diaphragm EGR Valve

Courtesy of General Motors Corp.

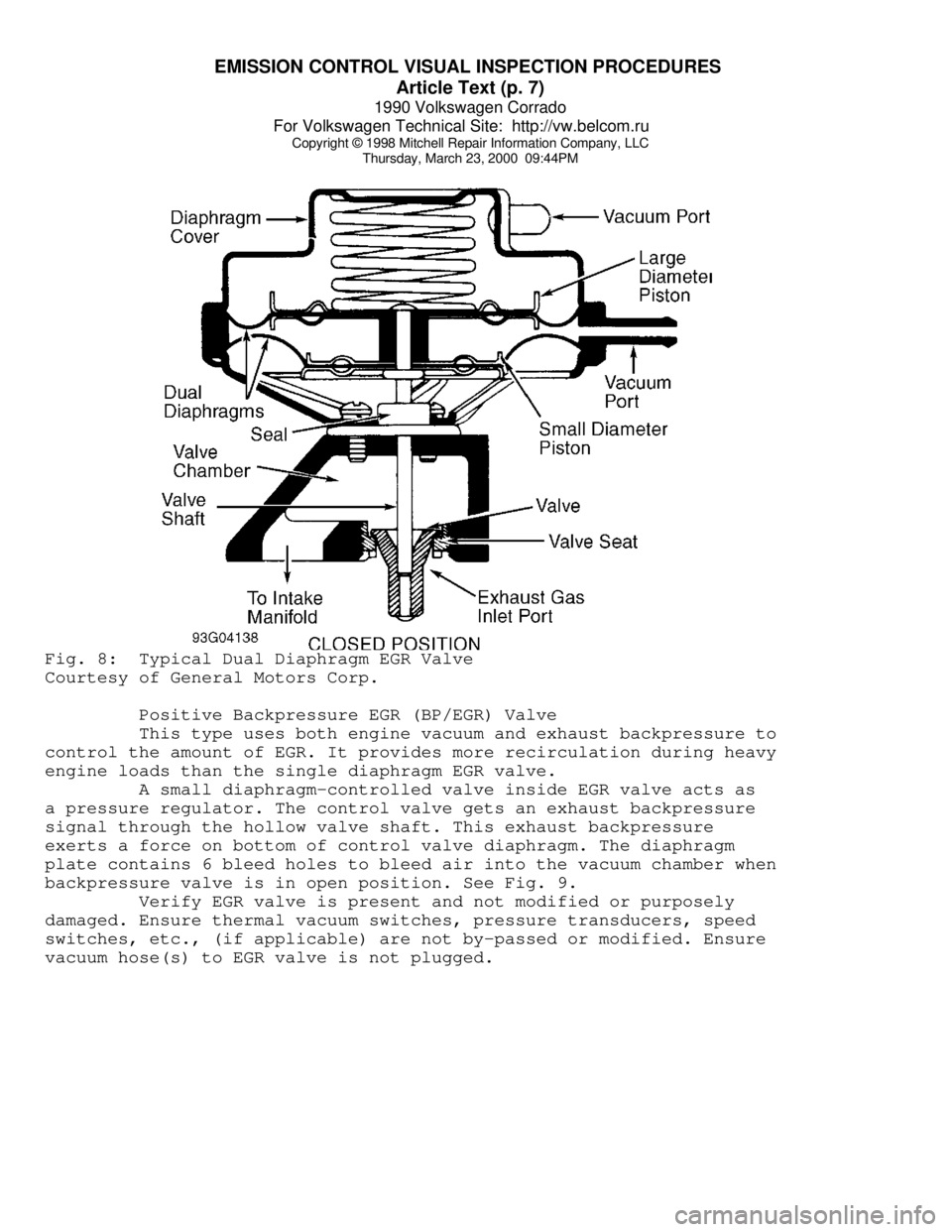

Dual Diaphragm EGR Valve

This type uses 2 diaphragms with different effective areas

and 2 vacuum sources. Although similar to the single diaphragm type,

the second diaphragm is added below the upper diaphragm and is rigidly

attached to the valve seat. See Fig. 8. These diaphragms form a vacuum

chamber which is connected to manifold vacuum.

During highway cruising when manifold vacuum is high in the

center chamber, manifold vacuum tends to pull the valve closed.

However, the vacuum signal applied to the top side of the upper

diaphragm overcomes the downward spring force and the manifold vacuum

pull, due to the diaphragm's larger piston. This regulates the amount

of EGR.

When manifold vacuum is low during acceleration, the higher

vacuum signal opens the valve, permitting more EGR. When manifold

vacuum is high during highway cruising, the valve is only partially

opened, reducing the amount of EGR.

Verify EGR valve is present and not modified or purposely

damaged. Ensure thermal vacuum switches, pressure transducers, speed

switches, etc., (if applicable) are not by-passed or modified. Ensure

vacuum hose(s) to EGR valve is not plugged.

Page 501 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PMFig. 8: Typical Dual Diaphragm EGR Valve

Courtesy of General Motors Corp.

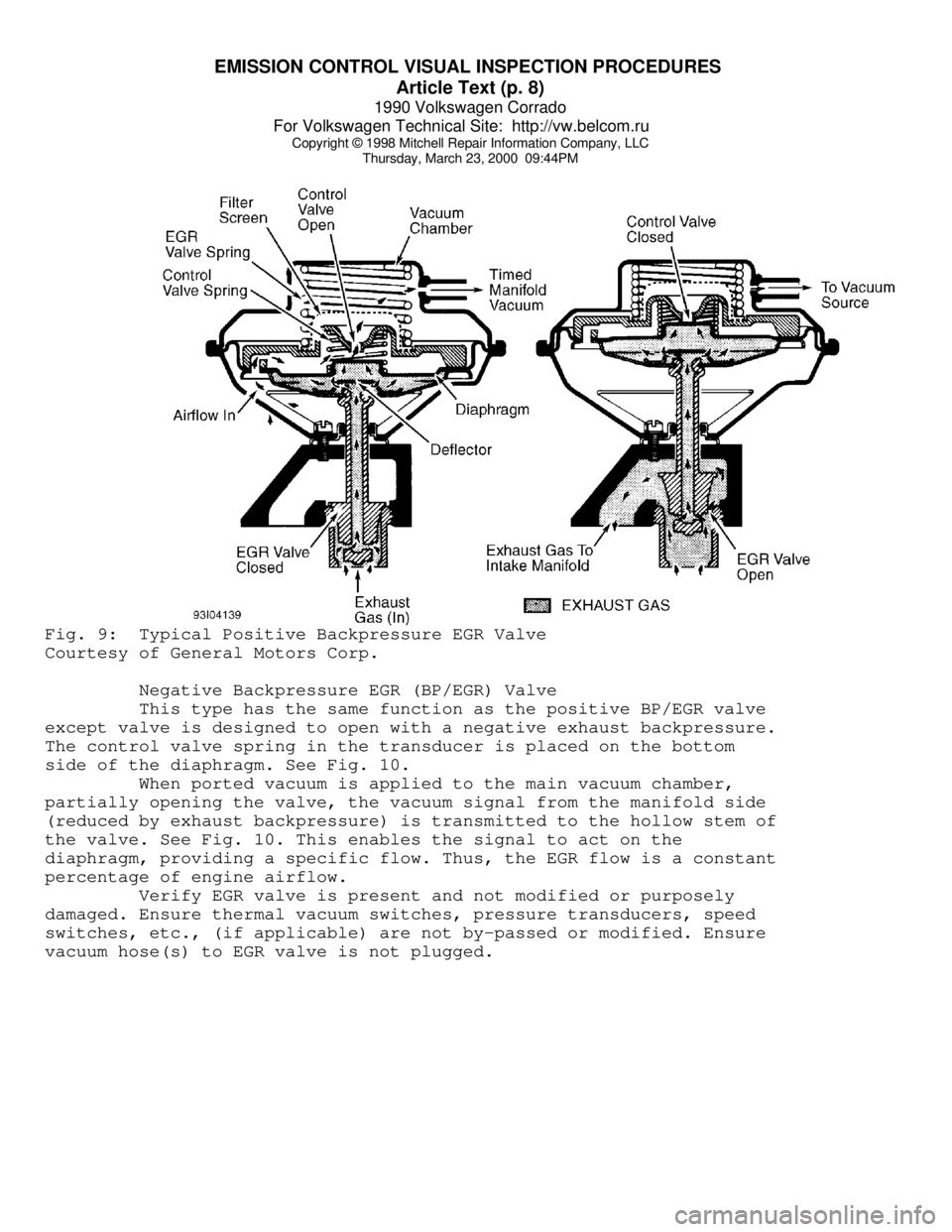

Positive Backpressure EGR (BP/EGR) Valve

This type uses both engine vacuum and exhaust backpressure to

control the amount of EGR. It provides more recirculation during heavy

engine loads than the single diaphragm EGR valve.

A small diaphragm-controlled valve inside EGR valve acts as

a pressure regulator. The control valve gets an exhaust backpressure

signal through the hollow valve shaft. This exhaust backpressure

exerts a force on bottom of control valve diaphragm. The diaphragm

plate contains 6 bleed holes to bleed air into the vacuum chamber when

backpressure valve is in open position. See Fig. 9.

Verify EGR valve is present and not modified or purposely

damaged. Ensure thermal vacuum switches, pressure transducers, speed

switches, etc., (if applicable) are not by-passed or modified. Ensure

vacuum hose(s) to EGR valve is not plugged.

Page 502 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PMFig. 9: Typical Positive Backpressure EGR Valve

Courtesy of General Motors Corp.

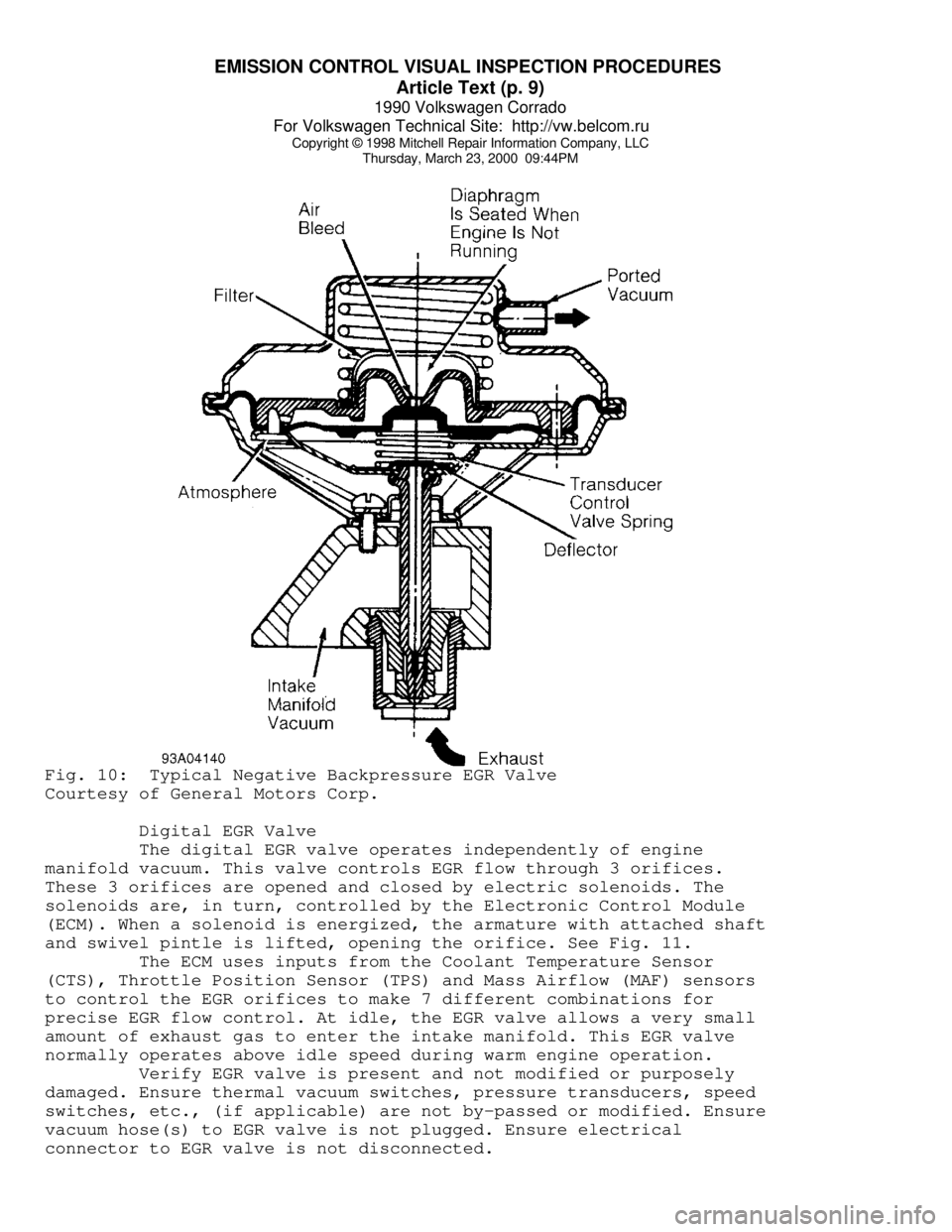

Negative Backpressure EGR (BP/EGR) Valve

This type has the same function as the positive BP/EGR valve

except valve is designed to open with a negative exhaust backpressure.

The control valve spring in the transducer is placed on the bottom

side of the diaphragm. See Fig. 10.

When ported vacuum is applied to the main vacuum chamber,

partially opening the valve, the vacuum signal from the manifold side

(reduced by exhaust backpressure) is transmitted to the hollow stem of

the valve. See Fig. 10. This enables the signal to act on the

diaphragm, providing a specific flow. Thus, the EGR flow is a constant

percentage of engine airflow.

Verify EGR valve is present and not modified or purposely

damaged. Ensure thermal vacuum switches, pressure transducers, speed

switches, etc., (if applicable) are not by-passed or modified. Ensure

vacuum hose(s) to EGR valve is not plugged.

Page 503 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 9)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PMFig. 10: Typical Negative Backpressure EGR Valve

Courtesy of General Motors Corp.

Digital EGR Valve

The digital EGR valve operates independently of engine

manifold vacuum. This valve controls EGR flow through 3 orifices.

These 3 orifices are opened and closed by electric solenoids. The

solenoids are, in turn, controlled by the Electronic Control Module

(ECM). When a solenoid is energized, the armature with attached shaft

and swivel pintle is lifted, opening the orifice. See Fig. 11.

The ECM uses inputs from the Coolant Temperature Sensor

(CTS), Throttle Position Sensor (TPS) and Mass Airflow (MAF) sensors

to control the EGR orifices to make 7 different combinations for

precise EGR flow control. At idle, the EGR valve allows a very small

amount of exhaust gas to enter the intake manifold. This EGR valve

normally operates above idle speed during warm engine operation.

Verify EGR valve is present and not modified or purposely

damaged. Ensure thermal vacuum switches, pressure transducers, speed

switches, etc., (if applicable) are not by-passed or modified. Ensure

vacuum hose(s) to EGR valve is not plugged. Ensure electrical

connector to EGR valve is not disconnected.

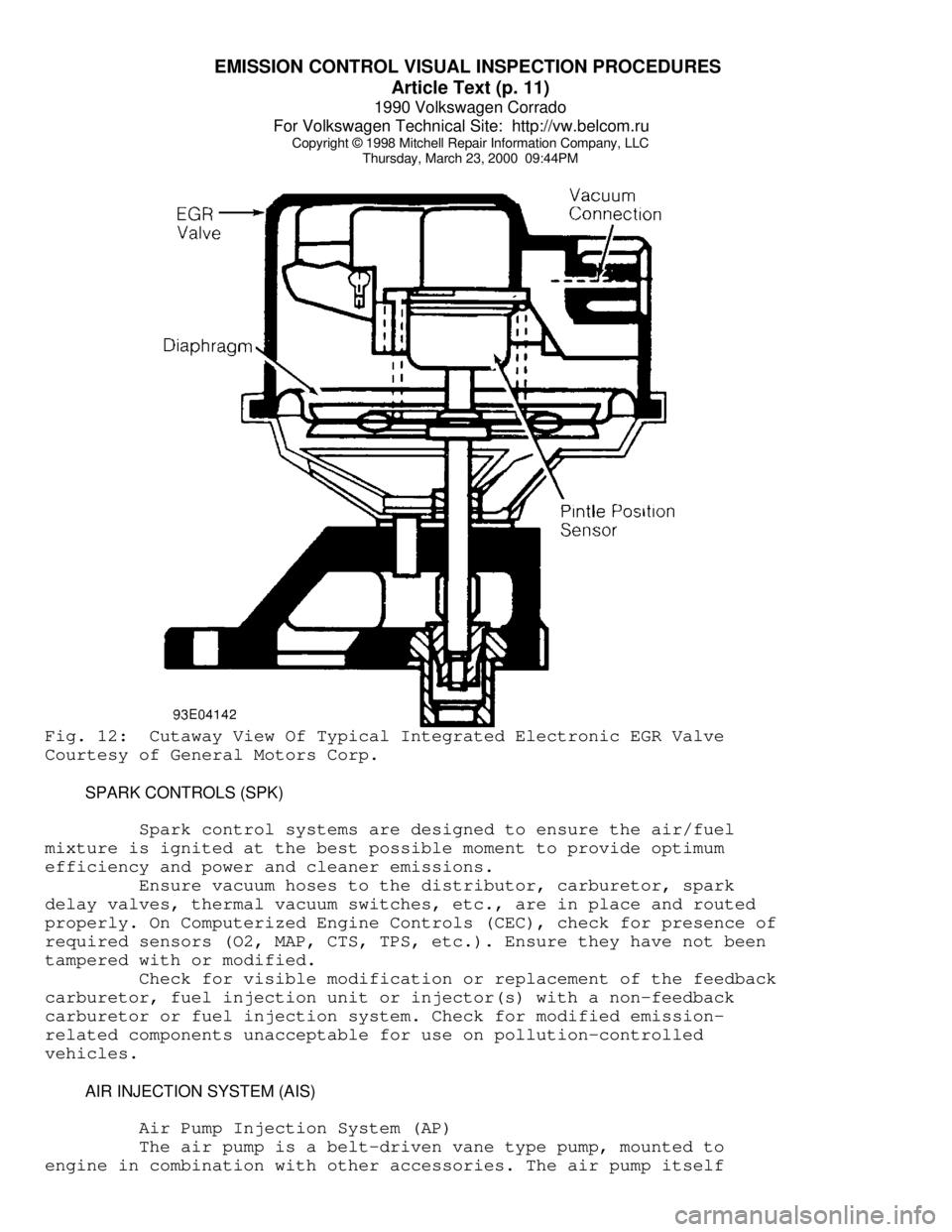

Page 505 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 11)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PMFig. 12: Cutaway View Of Typical Integrated Electronic EGR Valve

Courtesy of General Motors Corp.

SPARK CONTROLS (SPK)

Spark control systems are designed to ensure the air/fuel

mixture is ignited at the best possible moment to provide optimum

efficiency and power and cleaner emissions.

Ensure vacuum hoses to the distributor, carburetor, spark

delay valves, thermal vacuum switches, etc., are in place and routed

properly. On Computerized Engine Controls (CEC), check for presence of

required sensors (O2, MAP, CTS, TPS, etc.). Ensure they have not been

tampered with or modified.

Check for visible modification or replacement of the feedback

carburetor, fuel injection unit or injector(s) with a non-feedback

carburetor or fuel injection system. Check for modified emission-

related components unacceptable for use on pollution-controlled

vehicles.

AIR INJECTION SYSTEM (AIS)

Air Pump Injection System (AP)

The air pump is a belt-driven vane type pump, mounted to

engine in combination with other accessories. The air pump itself

Page 507 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 13)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

OXYGEN SENSOR (O2)

The O2 sensor is mounted in the exhaust system where it

monitors oxygen content of exhaust gases. Some vehicles may use 2 O2

sensors. The O2 sensor produces a voltage signal which is proportional

to exhaust gas oxygen concentration (0-3%) compared to outside oxygen

(20-21%). This voltage signal is low (about .1 volt) when a lean

mixture is present and high (1.0 volt) when a rich mixture is present.

As ECM compensates for a lean or rich condition, this

voltage signal constantly fluctuates between high and low, crossing a

reference voltage supplied by the ECM on the O2 signal line. This is

referred to as cross counts. A problem in the O2 sensor circuit should

set a related trouble code.

COMPUTERIZED ENGINE CONTROLS (CEC)

The CEC system monitors and controls a variety of

engine/vehicle functions. The CEC system is primarily an emission

control system designed to maintain a 14.7:1 air/fuel ratio under most

operating conditions. When the ideal air/fuel ratio is maintained, the

catalytic converter can control oxides of nitrogen (NOx), hydrocarbon

(HC) and carbon monoxide (CO) emissions.

The CEC system consists of the following sub-systems:

Electronic Control Module (ECM), input devices (sensors and switches)

and output signals.

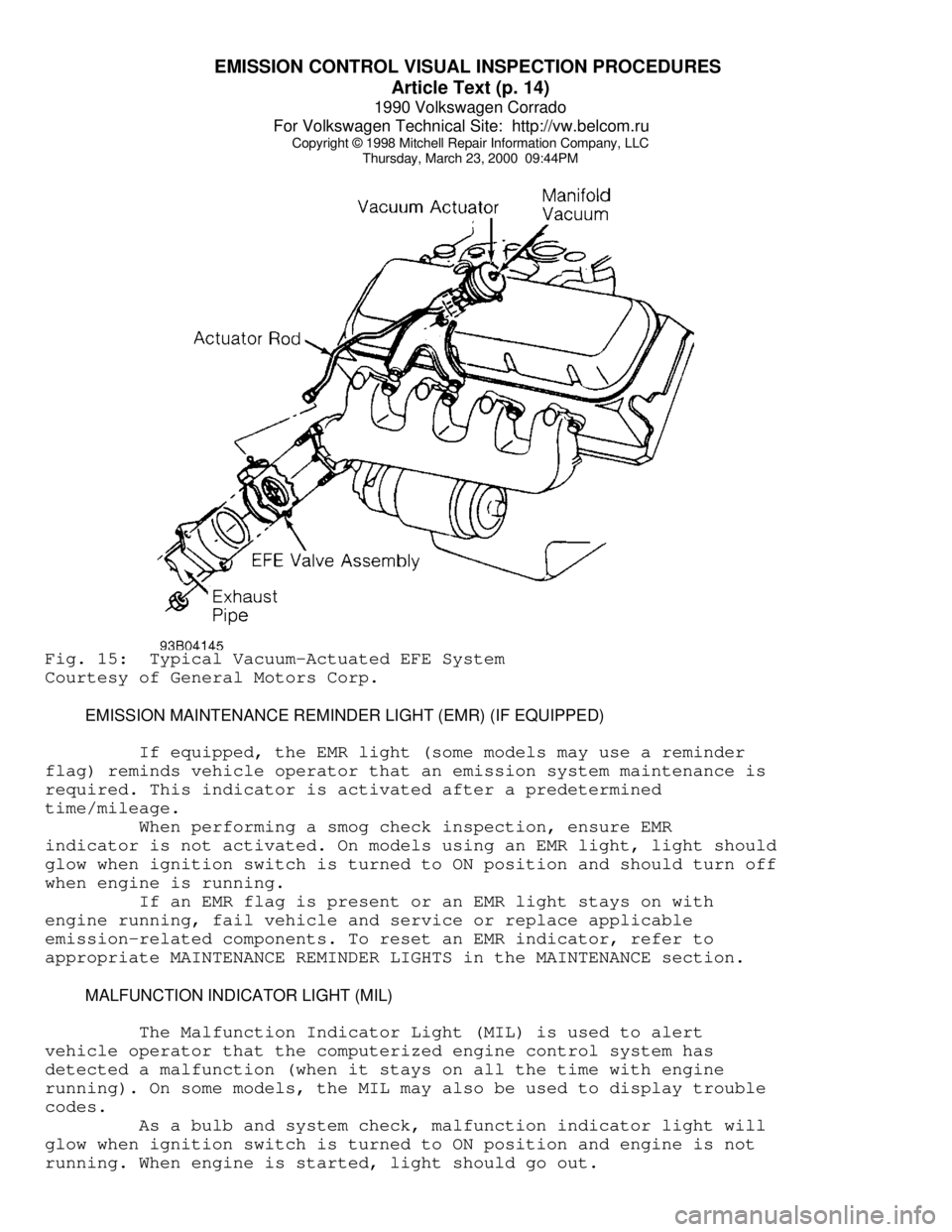

EARLY FUEL EVAPORATION (EFE)

The EFE valve is actuated by either a vacuum actuator or a

bimetal spring (heat-riser type). The EFE valve is closed when engine

is cold. The closed valve restricts exhaust gas flow from the exhaust

manifold. This forces part of the exhaust gas to flow up through a

passage below the carburetor. As the exhaust gas quickly warms the

intake mixture, distribution is improved. This results in better cold

engine driveability, shorter choke periods and lower emissions.

Ensure EFE valve in exhaust manifold is not frozen or rusted

in a fixed position. On vacuum-actuated EFE system, check EFE thermal

vacuum valve and check valve(s). Also check for proper vacuum hose

routing. See Fig. 15.

Page 508 of 906

EMISSION CONTROL VISUAL INSPECTION PROCEDURES

Article Text (p. 14)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PMFig. 15: Typical Vacuum-Actuated EFE System

Courtesy of General Motors Corp.

EMISSION MAINTENANCE REMINDER LIGHT (EMR) (IF EQUIPPED)

If equipped, the EMR light (some models may use a reminder

flag) reminds vehicle operator that an emission system maintenance is

required. This indicator is activated after a predetermined

time/mileage.

When performing a smog check inspection, ensure EMR

indicator is not activated. On models using an EMR light, light should

glow when ignition switch is turned to ON position and should turn off

when engine is running.

If an EMR flag is present or an EMR light stays on with

engine running, fail vehicle and service or replace applicable

emission-related components. To reset an EMR indicator, refer to

appropriate MAINTENANCE REMINDER LIGHTS in the MAINTENANCE section.

MALFUNCTION INDICATOR LIGHT (MIL)

The Malfunction Indicator Light (MIL) is used to alert

vehicle operator that the computerized engine control system has

detected a malfunction (when it stays on all the time with engine

running). On some models, the MIL may also be used to display trouble

codes.

As a bulb and system check, malfunction indicator light will

glow when ignition switch is turned to ON position and engine is not

running. When engine is started, light should go out.

Page 510 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

ARTICLE BEGINNING

Engine Overhaul Procedures - General Information

ALL PISTON ENGINES

* PLEASE READ THIS FIRST *

Examples used in this article are general in nature and do

not necessarily relate to a specific engine or system. Illustrations

and procedures have been chosen to guide mechanic through engine

overhaul process. Descriptions of processes of cleaning, inspection,

assembly and machine shop practice are included.

Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and specifications

for the vehicle being repaired.

ENGINE IDENTIFICATION

The engine may be identified from its Vehicle Identification

Number (VIN) stamped on a metal tab. Metal tab may be located in

different locations depending on manufacturer. Engine identification

number or serial number is located on cylinder block. Location varies

with manufacturer.

INSPECTION PROCEDURES

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

GENERAL

Engine components must be inspected to meet manufacturer's

specifications and tolerances during overhaul. Proper dimensions and

tolerances must be met to obtain proper performance and maximum engine

life.

Micrometers, depth gauges and dial indicator are used for

checking tolerances during engine overhaul. Magnaflux, Magnaglo, dye-

check, ultrasonic and x-ray inspection procedures are used for parts

inspection.

MAGNETIC PARTICLE INSPECTION

Magnaflux & Magnaglo

Magnaflux is an inspection technique used to locate material

flaws and stress cracks. The part in question is subjected to a strong

magnetic field. The entire part, or a localized area, can be

magnetized. The part is coated with either a wet or dry material that

contains fine magnetic particles.

Page 511 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

Cracks which are outlined by the particles cause an

interruption in the magnetic field. The dry powder method of Magnaflux

can be used in normal light. A crack will appear as an obvious bright

line.

Fluorescent liquid is used in conjunction with a blacklight

in a second Magnaflux system called Magnaglo. This type of inspection

demands a darkened room. The crack will appear as a glowing line in

this process. Both systems require complete demagnetizing upon

completion of the inspection. Magnetic particle inspection applies to

ferrous materials only.

PENETRANT INSPECTION

Zyglo

The Zyglo process coats the material with a fluorescent dye

penetrant. The part is often warmed to expand cracks that will be

penetrated by the dye. When the coated part is subjected to inspection

with a blacklight, a crack will glow brightly. Developing solution

is often used to enhance results. Parts made of any material, such as

aluminum cylinder heads or plastics, may be tested using this process.

Dye Check

Penetrating dye is sprayed on the previously cleaned

component. Dye is left on component for 5-45 minutes, depending upon

material density. Component is then wiped clean and sprayed with a

developing solution. Surface cracks will show up as a bright line.

ULTRASONIC INSPECTION

If an expensive part is suspected of internal cracking,

Ultrasonic testing is used. Sound waves are used for component

inspection.

X-RAY INSPECTION

This form of inspection is used on highly stressed

components. X-ray inspection maybe used to detect internal and

external flaws in any material.

PRESSURE TESTING

Cylinder heads can be tested for cracks using a pressure

tester. Pressure testing is performed by plugging all but one of the

holes in the head and injecting air or water into the open passage.

Leaks are indicated by the appearance of wet or damp areas when using

water. When air is used, it is necessary to spray the head surface

with a soap solution. Bubbles will indicate a leak. Cylinder head may

also be submerged in water heated to specified temperature to check

for cracks created during heat expansion.

CLEANING PROCEDURES