wiring diagram VOLKSWAGEN CORRADO 1990 User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 376 of 906

AA - USING THIS SECTION (GENERAL HELP INFORMATION)

Article Text (p. 5)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

sensor is out of calibration. A sensor that is out of calibration may

not set a trouble code, but it will cause driveability problems.

L - WIRING DIAGRAMS

Use these WIRING DIAGRAMS to identify and trace component

circuits, locate shorts and opens in circuits, and understand how

individual circuits function as part of a system. The diagrams in this

article are only for fuel, ignition and emission systems

M - VACUUM DIAGRAMS

The VACUUM DIAGRAMS will assist you in finding incorrectly

routed vacuum hoses which may cause driveability problems or computer

indicated malfunctions.

N - REMOVE/INSTALL/OHAUL

N - REMOVE/INSTALL/OHAUL contains information found in the

sub-headings of REMOVAL, OVERHAUL & INSTALLATION. These are procedures

and specifications required to remove, overhaul (if possible) and

install components related to engine performance.

WHERE TO START

PERFORM BASIC INSPECTION

1) Verify customer complaint.

2) Perform visual inspection. See F - BASIC TESTING.

3) Test engine sub-system to determine that the following

systems are functioning properly. See F- BASIC TESTING.

* Mechanical conditions (compression)

* Ignition output

* Fuel Delivery

4) Check air induction system for leaks.

5) Check & adjust basic engine settings listed below to

ensure they are to specification. See D - ADJUSTMENTS.

* Ignition timing

* Idle speed

CHECK FOR TROUBLE CODES

1) If equipped with self-diagnostics, check for trouble

codes. Refer to G - TESTS W/ CODES.

2) Repair causes of trouble code(s).

3) Clear control unit memory.

SYMPTOM DIAGNOSIS

Page 419 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 11)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:42PM

REMOVAL & INSTALLATION

HYDRAULIC MODULATOR/PUMP

Removal & Installation

1) Depressurize brake system. See DEPRESSURIZING BRAKE

SYSTEM. Disconnect negative battery cable. Unplug all electrical

connectors from hydraulic modulator/pump. Identify and disconnect all

hydraulic lines from hydraulic modulator/pump. Plug all line openings.

2) From inside passenger compartment, remove push rod clevis

pin. Remove hydraulic modulator/pump retaining nuts. Remove hydraulic

modulator/pump. To install, reverse removal procedure. Tighten all

fittings to specification. See TORQUE SPECIFICATIONS TABLE at end of

article. Bleed brake system. See BLEEDING BRAKE SYSTEM.

WHEEL SPEED SENSORS

NOTE: To protect magnetic part of sensor, always leave new wheel

speed sensor in special packaging until ready for

installation.

Removal & Installation

Remove bolt retaining wheel speed sensor. Unplug connector.

Remove wheel speed sensor. To install, apply Lubricant (G-000-650) to

sensor. Install sensor, and tighten retaining bolt to 84 INCH lbs. (10

N.m).

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplications Ft. Lbs. (N.m)

Brake Lines-To-Hydraulic Modulator/Pump ............... 11 (15)

Hydraulic Modulator/Pump Retaining Nuts ............... 18 (25)

INCH Lbs. (N.m)

Wheel Sensor Retaining Bolt .......................... 84 (9.5)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ WIRING DIAGRAMS

Page 420 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 12)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

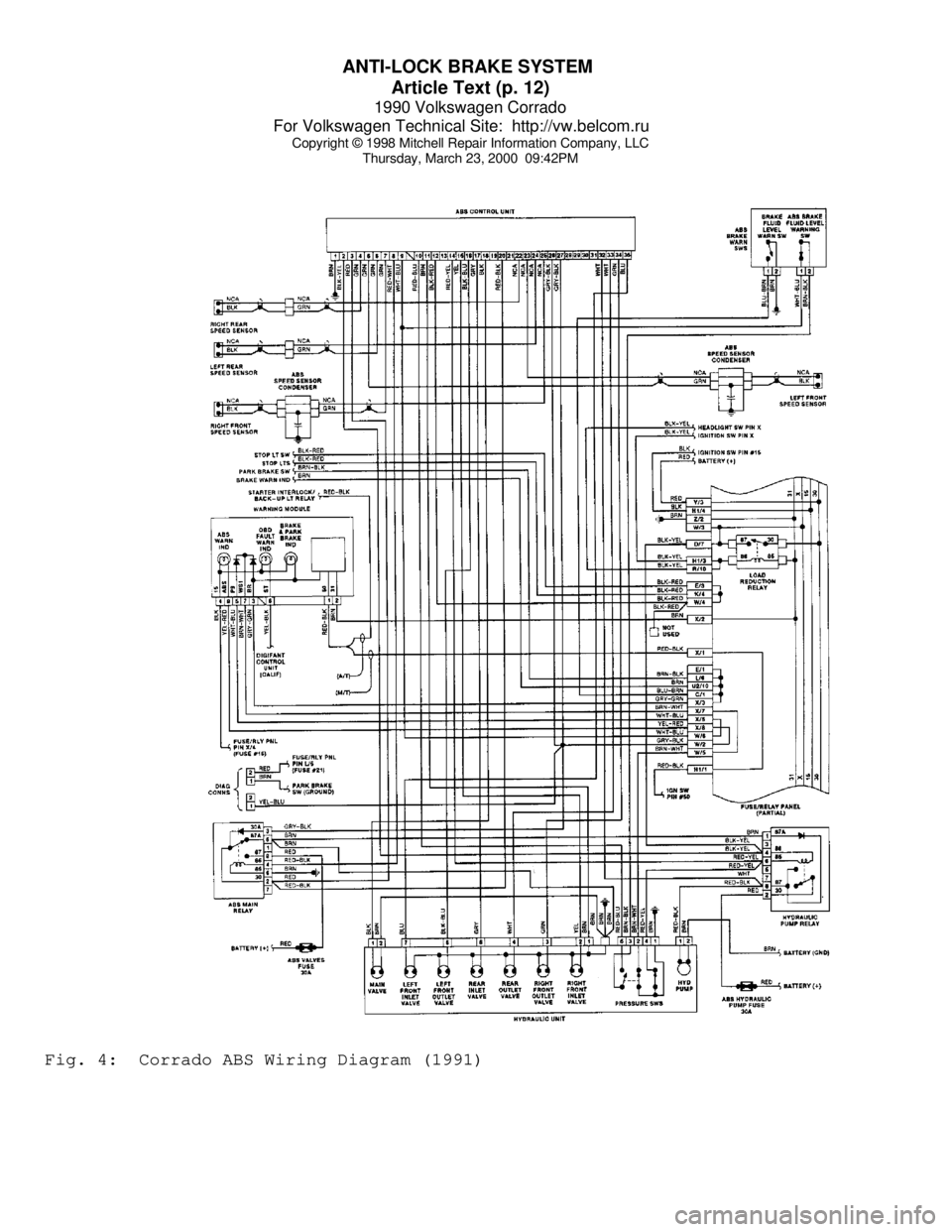

Thursday, March 23, 2000 09:42PMFig. 4: Corrado ABS Wiring Diagram (1991)

Page 421 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 13)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

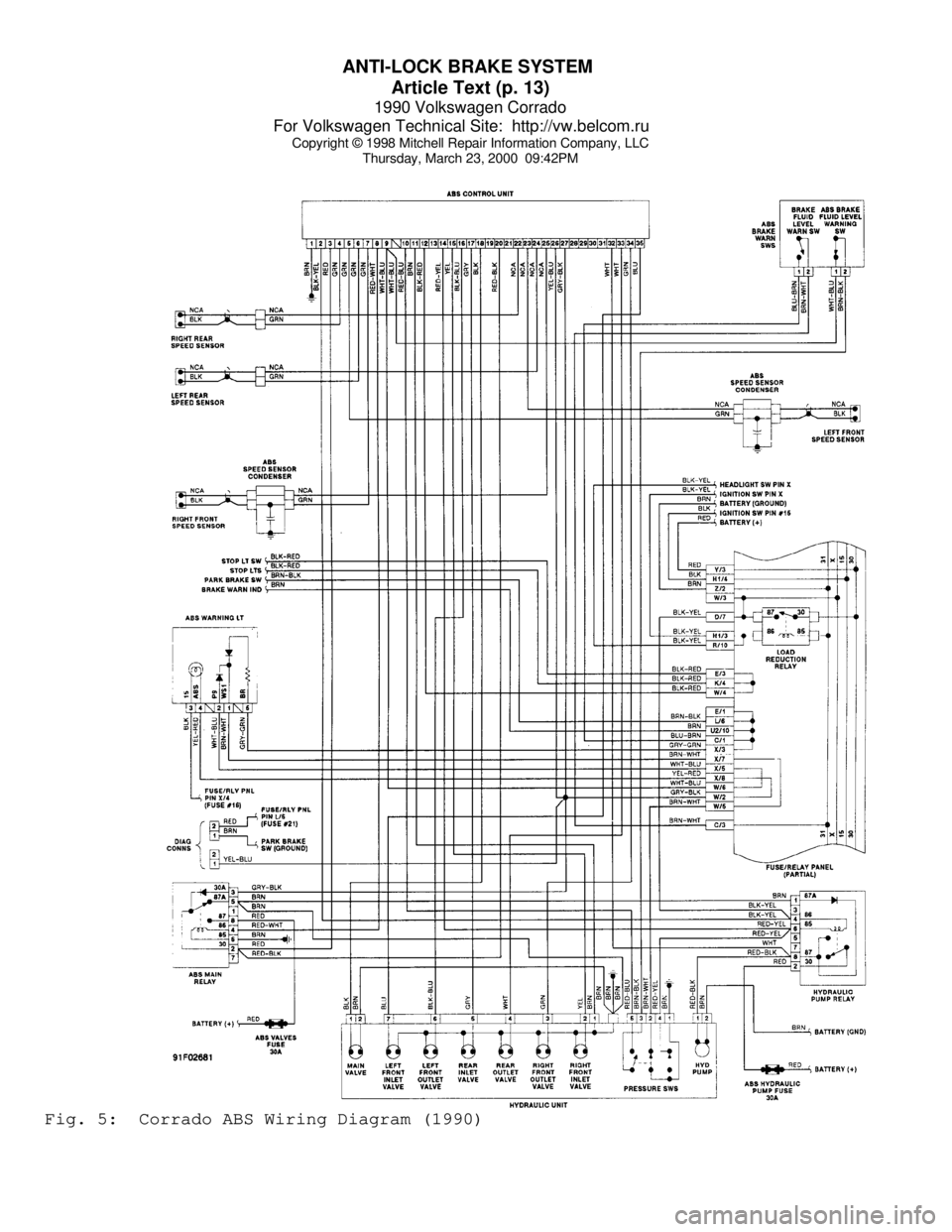

Thursday, March 23, 2000 09:42PMFig. 5: Corrado ABS Wiring Diagram (1990)

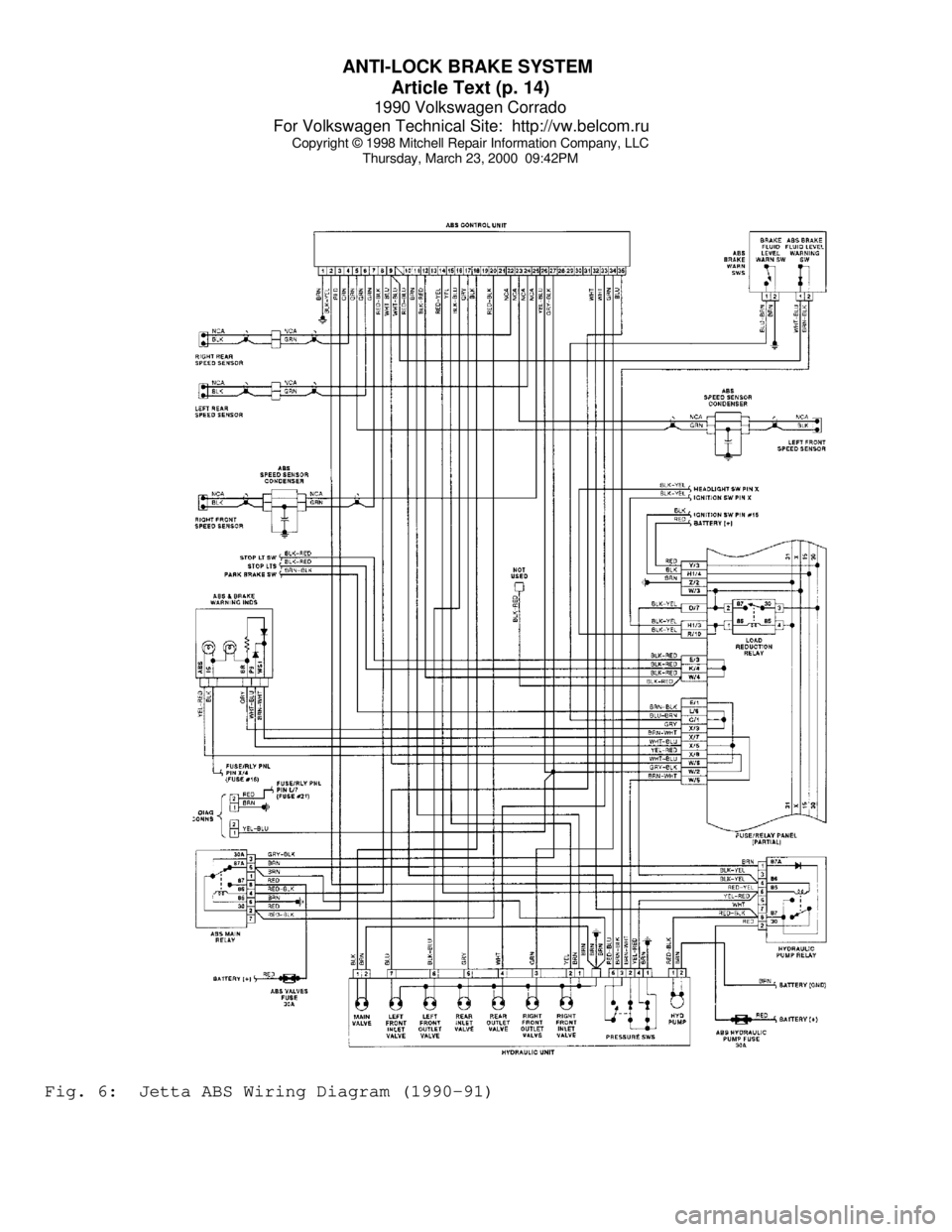

Page 422 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 14)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:42PMFig. 6: Jetta ABS Wiring Diagram (1990-91)

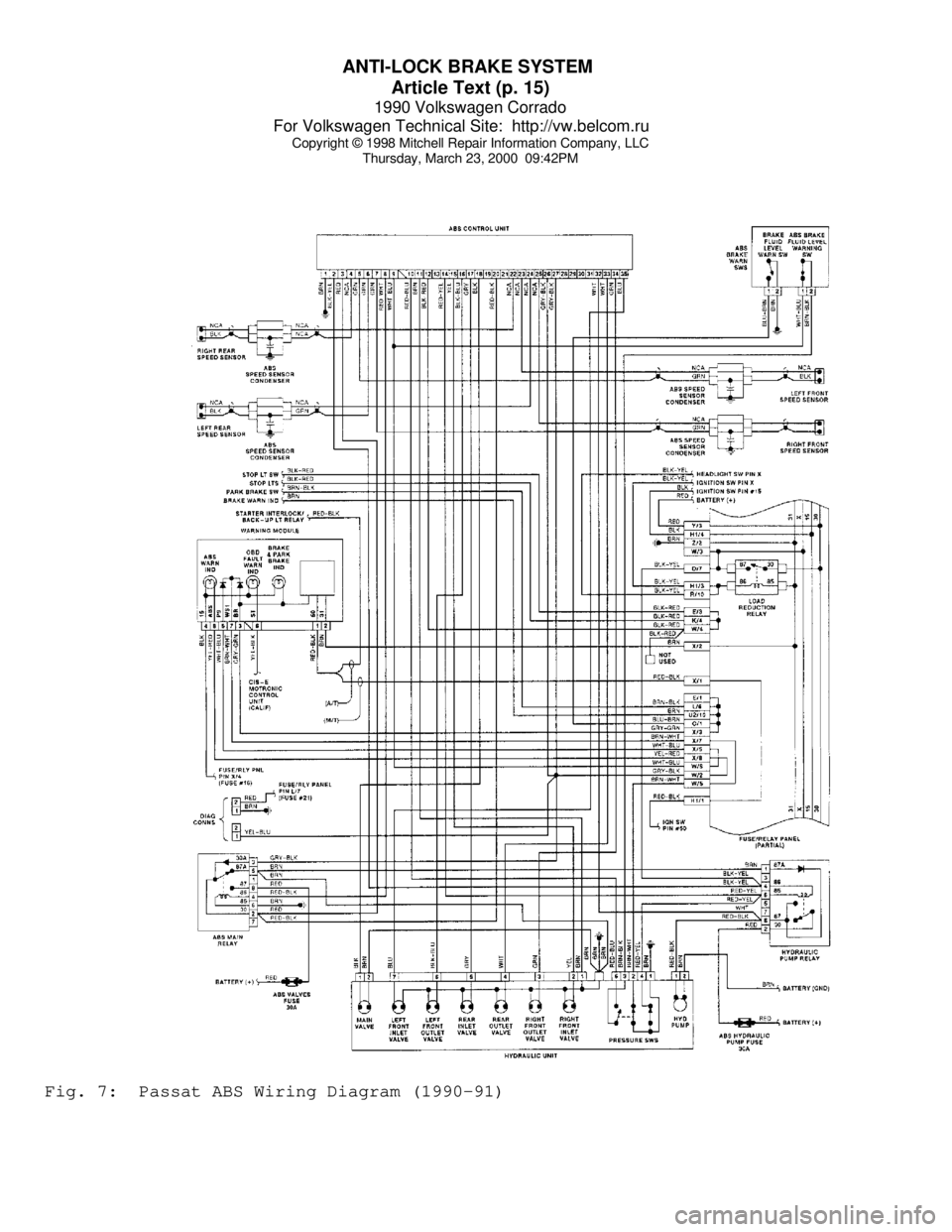

Page 423 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 15)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:42PMFig. 7: Passat ABS Wiring Diagram (1990-91)

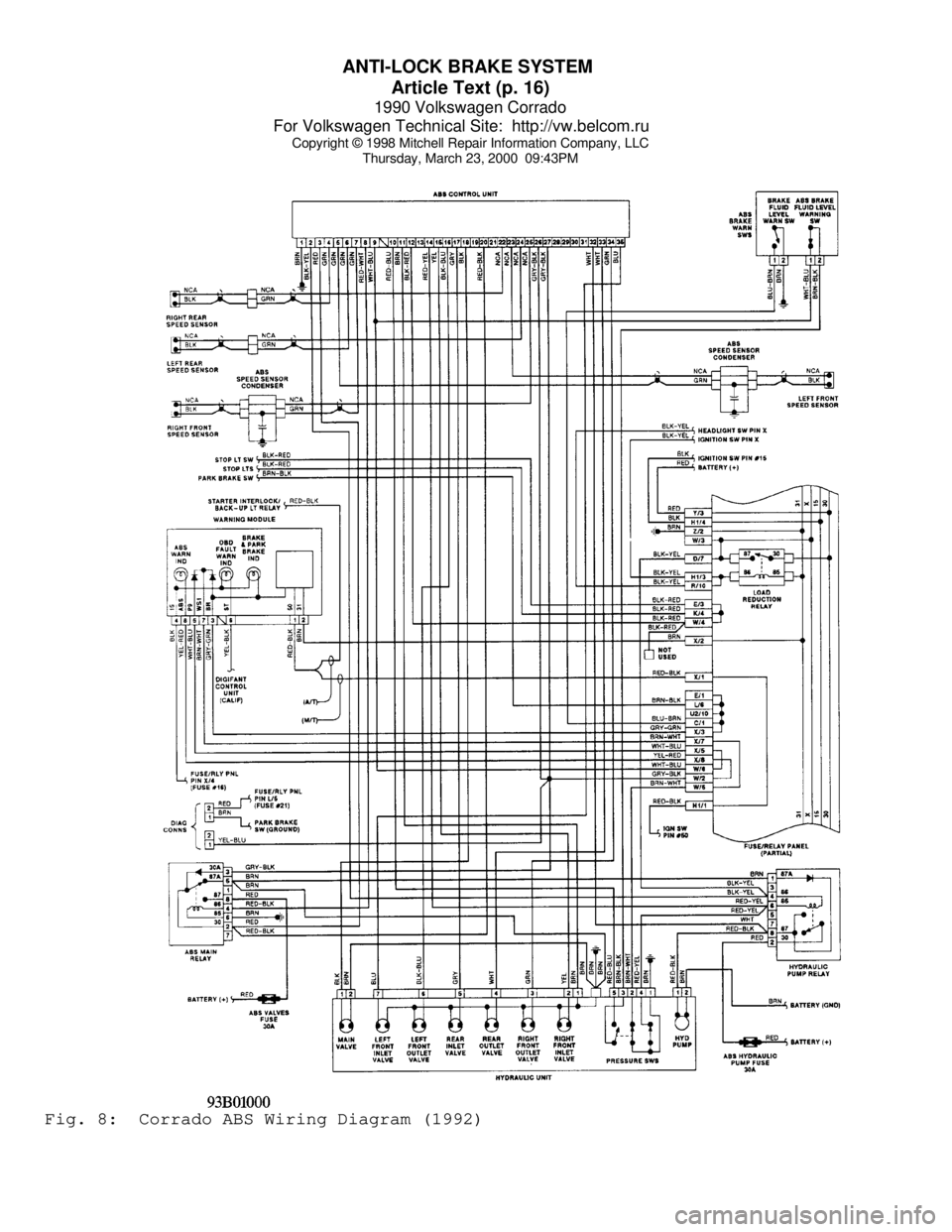

Page 424 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 16)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PMFig. 8: Corrado ABS Wiring Diagram (1992)

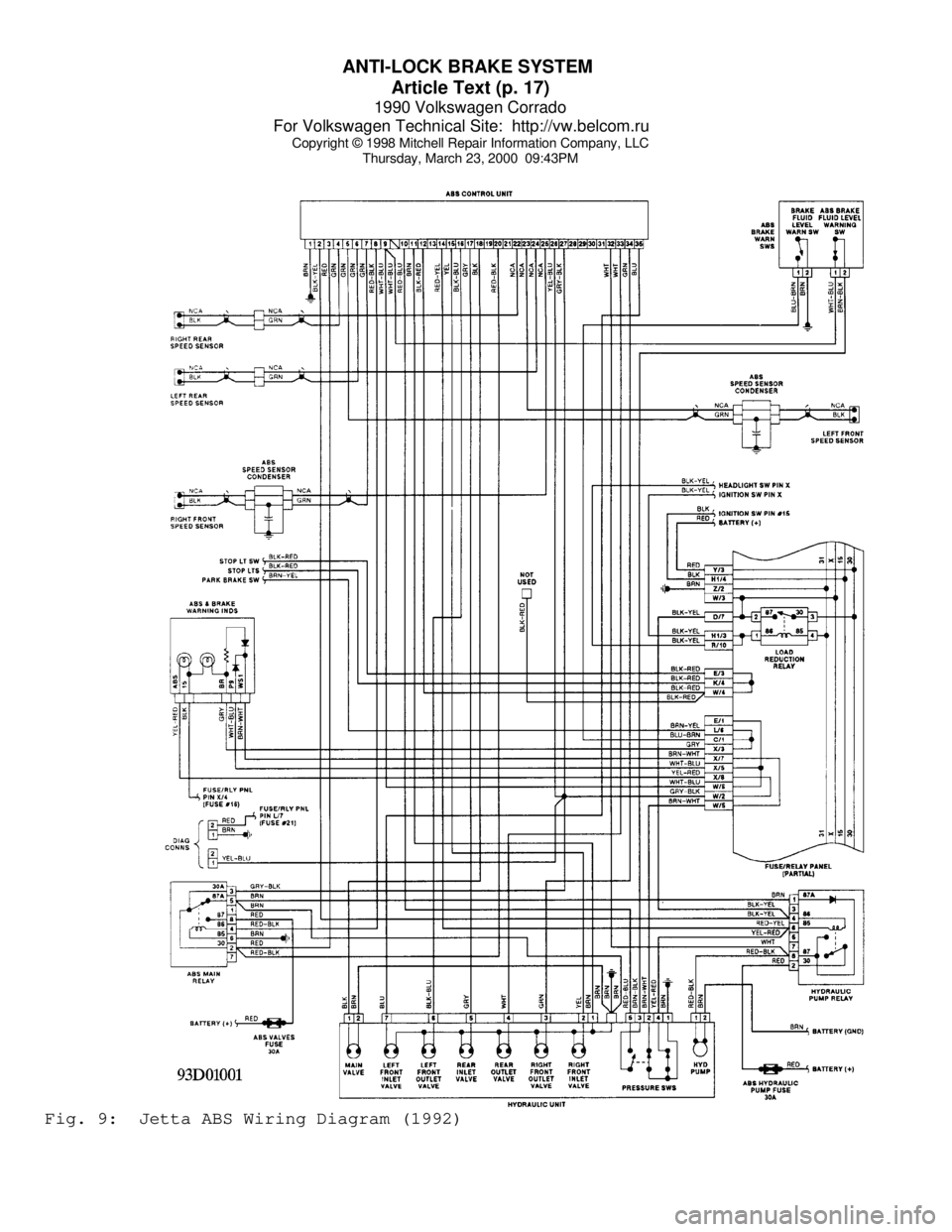

Page 425 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 17)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PMFig. 9: Jetta ABS Wiring Diagram (1992)

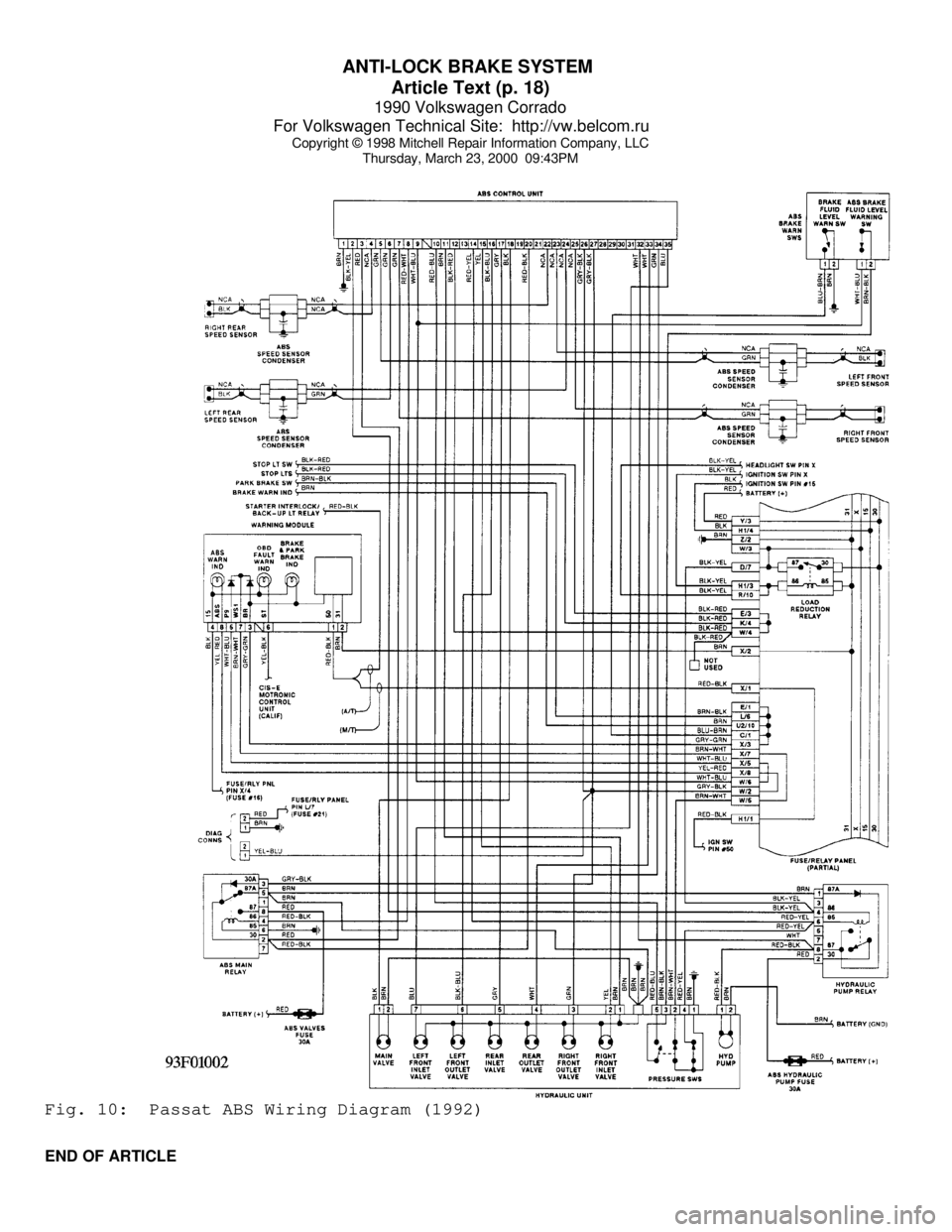

Page 426 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 18)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PMFig. 10: Passat ABS Wiring Diagram (1992)

END OF ARTICLE

Page 546 of 906

F - BASIC TESTING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

ARTICLE BEGINNING

1990 ENGINE PERFORMANCE

Volkswagen Basic Diagnostic Procedures

Cabriolet, Corrado, Fox, Golf GL/GTI, Jetta, Vanagon

INTRODUCTION

The following diagnostic steps will help prevent overlooking

a simple problem. This is also where to begin diagnosis for a no start

condition.

The first step in diagnosing any driveability problem is

verifying the customer's complaint with a test drive under the

conditions the problem reportedly occurred.

Perform a careful and complete visual inspection. Most engine

control problems result from mechanical breakdowns, poor electrical

connections or damaged/misrouted vacuum hoses. Before condemning the

computerized system, perform each test listed in this article.

NOTE: Perform all voltage tests with a Digital Volt-Ohmmeter

(DVOM) with a minimum 10-megohm input impedance, unless

stated otherwise in test procedure.

VISUAL INSPECTION

Visually inspect all electrical wiring, looking for chafed,

stretched, cut or pinched wiring. Ensure electrical connectors fit

tightly and are not corroded. Ensure vacuum hoses are properly routed

and are not pinched or cut. See M - VACUUM DIAGRAMS article to verify

routing and connections (if necessary). Inspect air induction system

for possible vacuum leaks.

MECHANICAL INSPECTION

COMPRESSION

Check engine mechanical condition with a compression gauge,

vacuum gauge, or an engine analyzer. See engine analyzer manual for

specific instructions.

DO NOT use ignition switch during compression tests on fuel

injected vehicles. Use a remote starter to crank engine. Fuel

injectors on many models are triggered by ignition switch during

cranking mode, which can create a fire hazard or contaminate the

engine's oiling system.

EXHAUST SYSTEM BACKPRESSURE

The exhaust system can be checked with a vacuum or pressure

gauge. Remove O2 sensor or air injection check valve (if equipped).

Connect a 1-10 psi pressure gauge and run engine at 2500 RPM. If