oil VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 858 of 906

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 14)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:52PM

injector. A good hot run voltage is usually 13.5 or more volts. This

point, commonly known as open circuit voltage, is critical because the

injector will not get sufficient current saturation if there is a

voltage shortfall. To obtain a good look at this precise point, you

will need to shift your Lab Scope to five volts per division.

You will find that some systems have slight voltage

fluctuations here. This could occur if the injector feed wire is also

used to power up other cycling components, like the ignition coil(s).

Slight voltage fluctuations are normal and are no reason for concern.

Major voltage fluctuations are a different story, however. Major

voltage shifts on the injector feed line will create injector

performance problems. Look for excessive resistance problems in the

feed circuit if you see big shifts and repair as necessary.

Point "B" is where the driver completes the circuit to

ground. This point of the waveform should be a clean square point

straight down with no rounded edges. It is during this period that

current saturation of the injector windings is taking place and the

driver is heavily stressed. Weak drivers will distort this vertical

line.

Point "C" represents the voltage drop across the injector

windings. Point "C" should come very close to the ground reference

point, but not quite touch. This is because the driver has a small

amount of inherent resistance. Any significant offset from ground is

an indication of a resistance problem on the ground circuit that needs

repaired. You might miss this fault if you do not use the negative

battery post for your Lab Scope hook-up, so it is HIGHLY recommended

that you use the battery as your hook-up.

Right after Point "C", something interesting happens. Notice

the trace starts a normal upward bend. This slight inductive rise is

created by the effects of counter voltage and is normal. This is

because the low circuit resistance allowed a fast build-up of the

magnetic field, which in turn created the counter voltage.

Point "D" is the start of the current limiting, also known as

the "Hold" time. Before this point, the driver had allowed the current

to free-flow ("Peak") just to get the injector pintle open. By the

time point "D" occurs, the injector pintle has already opened and the

computer has just significantly throttled the current back. It does

this by only allowing a few volts through to maintain the minimum

current required to keep the pintle open.

The height of the voltage spike seen at the top of Point "D"

represents the electrical condition of the injector windings. The

height of this voltage spike (inductive kick) is proportional to the

number of windings and the current flow through them. The more current

flow and greater number of windings, the more potential for a greater

inductive kick. The opposite is also true. The less current flow or

fewer windings means less inductive kick. Typically you should see a

minimum 35 volts.

If you see approximately 35 volts, it is because a zener

diode is used with the driver to clamp the voltage. Make sure the

beginning top of the spike is squared off, indicating the zener dumped

the remainder of the spike. If it is not squared, that indicates the

spike is not strong enough to make the zener fully dump, meaning there

Page 893 of 906

WIRING DIAGRAM SYMBOLS

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:53PM

Blue ................... BLU ................... BU

Brown .................. BRN ................... BN

Clear .................. CLR ................... CR

Dark Blue ............ DK BLU ............... DK BU

Dark Green ........... DK GRN ............... DK GN

Green .................. GRN ................... GN

Gray ................... GRY ................... GY

Light Blue ........... LT BLU ............... LT BU

Light Green .......... LT GRN ............... LT GN

Orange ................. ORG ................... OG

Pink ................... PNK ................... PK

Purple ................. PPL ................... PL

Red .................... RED ................... RD

Tan .................... TAN ................... TN

Voilet ................. VIO ................... VI

White .................. WHT ................... WT

Yellow ................. YEL ................... YLÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ WIRING DIAGRAM SYMBOL IDENTIFICATION

NOTE: Standard wiring symbols are used on diagrams. The list below

will help clarify any symbols that are not easily understood

at a glance. Most components are labeled "Motor", "Switch" or

"Relay" in addition to being drawn with the standard symbol.

WIRING DIAGRAM SYMBOLS

Views of the symbols used in the WIRING DIAGRAM articles are

in the following graphics. See Figs. 3 through 25.Fig. 3: Circuit BreakerFig. 4: Coil (Internal)Fig. 5: ConnectorFig. 6: Diode (In-Line)Fig. 7: Diode (Internal)Fig. 8: Diode (Light Emitting)

Page 896 of 906

WIRING DIAGRAMS

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:53PM

ARTICLE BEGINNING

1990 WIRING DIAGRAMS

Volkswagen

Corrado

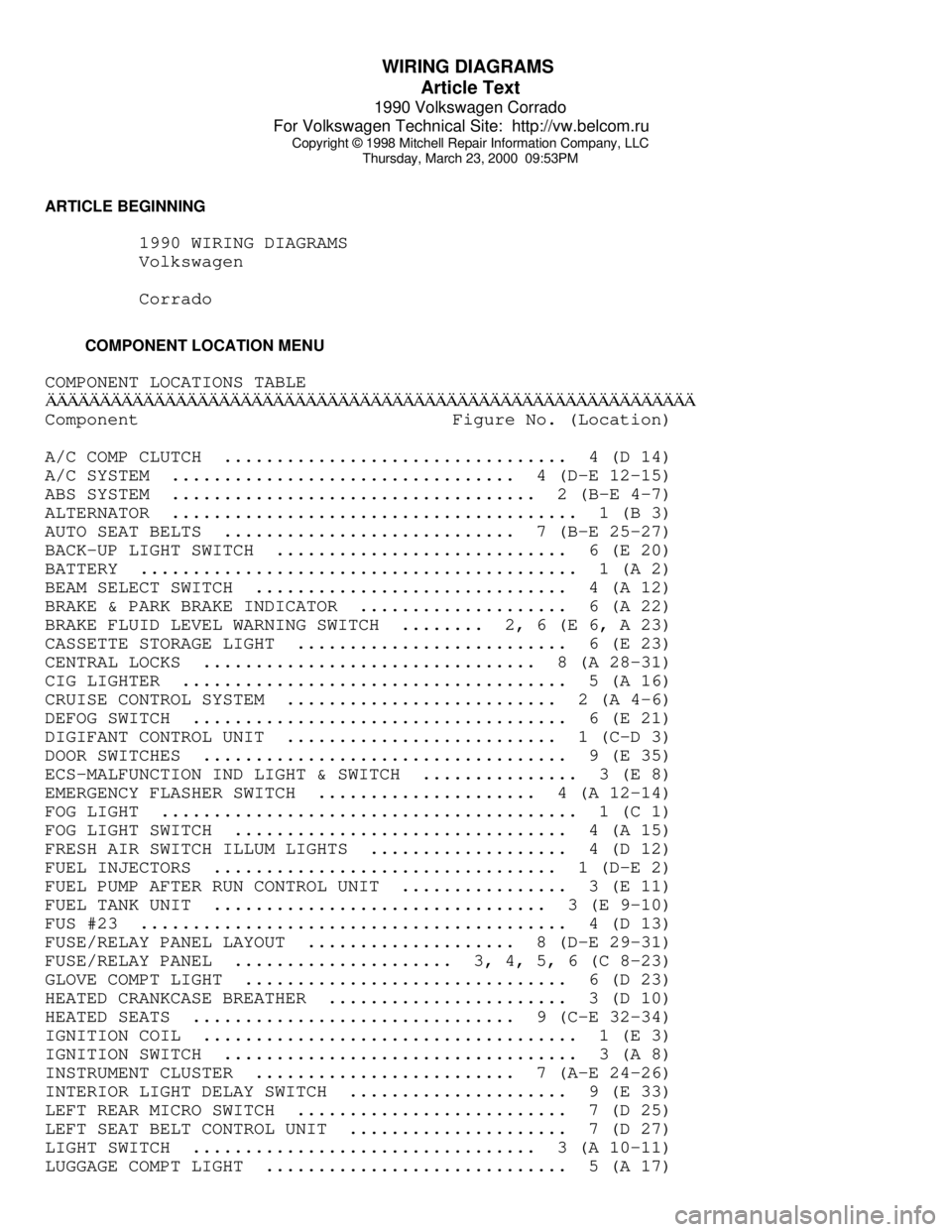

COMPONENT LOCATION MENU

COMPONENT LOCATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Figure No. (Location)

A/C COMP CLUTCH ................................. 4 (D 14)

A/C SYSTEM ................................. 4 (D-E 12-15)

ABS SYSTEM ................................... 2 (B-E 4-7)

ALTERNATOR ....................................... 1 (B 3)

AUTO SEAT BELTS ............................ 7 (B-E 25-27)

BACK-UP LIGHT SWITCH ............................ 6 (E 20)

BATTERY .......................................... 1 (A 2)

BEAM SELECT SWITCH .............................. 4 (A 12)

BRAKE & PARK BRAKE INDICATOR .................... 6 (A 22)

BRAKE FLUID LEVEL WARNING SWITCH ........ 2, 6 (E 6, A 23)

CASSETTE STORAGE LIGHT .......................... 6 (E 23)

CENTRAL LOCKS ................................ 8 (A 28-31)

CIG LIGHTER ..................................... 5 (A 16)

CRUISE CONTROL SYSTEM .......................... 2 (A 4-6)

DEFOG SWITCH .................................... 6 (E 21)

DIGIFANT CONTROL UNIT .......................... 1 (C-D 3)

DOOR SWITCHES ................................... 9 (E 35)

ECS-MALFUNCTION IND LIGHT & SWITCH ............... 3 (E 8)

EMERGENCY FLASHER SWITCH ..................... 4 (A 12-14)

FOG LIGHT ........................................ 1 (C 1)

FOG LIGHT SWITCH ................................ 4 (A 15)

FRESH AIR SWITCH ILLUM LIGHTS ................... 4 (D 12)

FUEL INJECTORS ................................. 1 (D-E 2)

FUEL PUMP AFTER RUN CONTROL UNIT ................ 3 (E 11)

FUEL TANK UNIT ................................ 3 (E 9-10)

FUS #23 ......................................... 4 (D 13)

FUSE/RELAY PANEL LAYOUT .................... 8 (D-E 29-31)

FUSE/RELAY PANEL ..................... 3, 4, 5, 6 (C 8-23)

GLOVE COMPT LIGHT ............................... 6 (D 23)

HEATED CRANKCASE BREATHER ....................... 3 (D 10)

HEATED SEATS ............................... 9 (C-E 32-34)

IGNITION COIL .................................... 1 (E 3)

IGNITION SWITCH .................................. 3 (A 8)

INSTRUMENT CLUSTER ......................... 7 (A-E 24-26)

INTERIOR LIGHT DELAY SWITCH ..................... 9 (E 33)

LEFT REAR MICRO SWITCH .......................... 7 (D 25)

LEFT SEAT BELT CONTROL UNIT ..................... 7 (D 27)

LIGHT SWITCH ................................. 3 (A 10-11)

LUGGAGE COMPT LIGHT ............................. 5 (A 17)

Page 897 of 906

WIRING DIAGRAMS

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:53PM

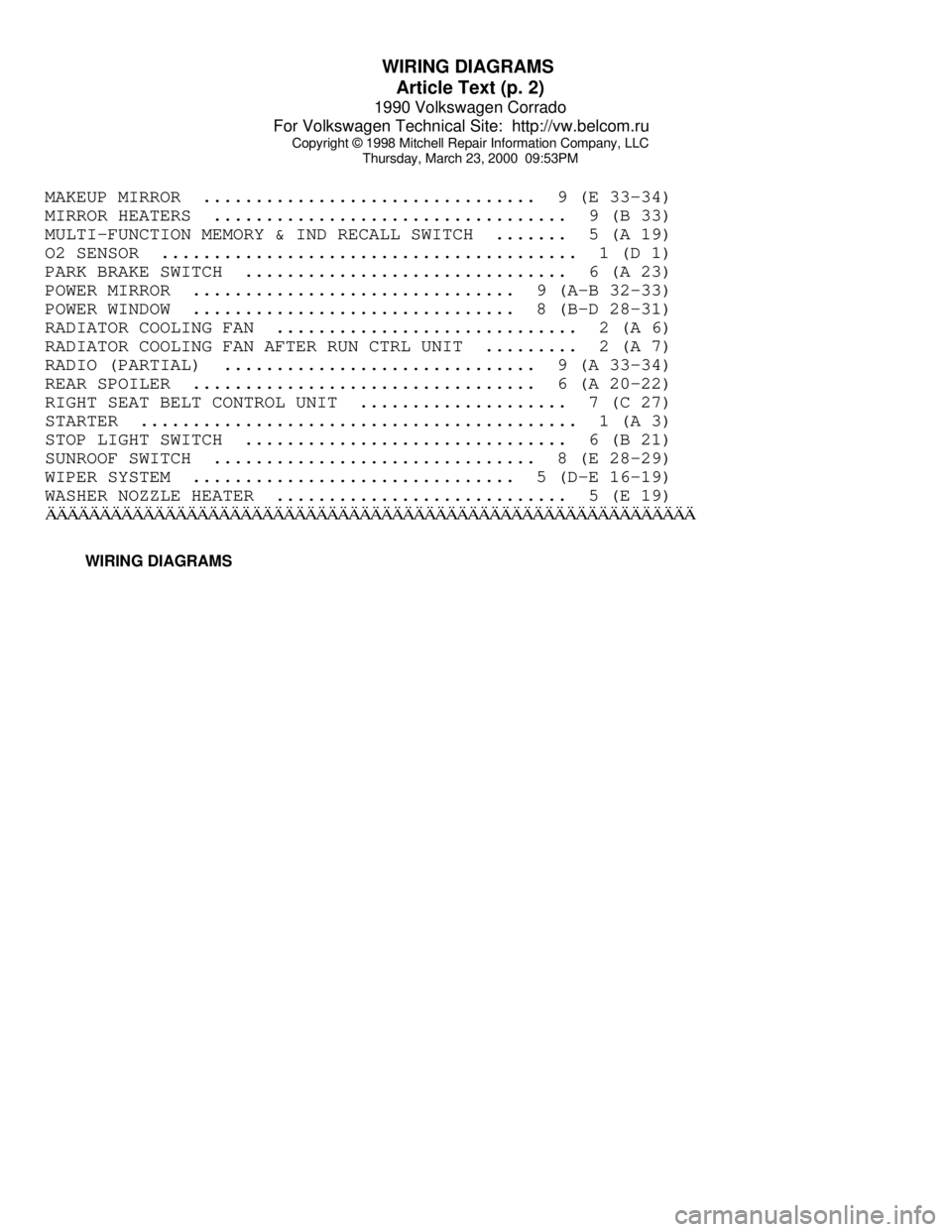

MAKEUP MIRROR ................................ 9 (E 33-34)

MIRROR HEATERS .................................. 9 (B 33)

MULTI-FUNCTION MEMORY & IND RECALL SWITCH ....... 5 (A 19)

O2 SENSOR ........................................ 1 (D 1)

PARK BRAKE SWITCH ............................... 6 (A 23)

POWER MIRROR ............................... 9 (A-B 32-33)

POWER WINDOW ............................... 8 (B-D 28-31)

RADIATOR COOLING FAN ............................. 2 (A 6)

RADIATOR COOLING FAN AFTER RUN CTRL UNIT ......... 2 (A 7)

RADIO (PARTIAL) .............................. 9 (A 33-34)

REAR SPOILER ................................. 6 (A 20-22)

RIGHT SEAT BELT CONTROL UNIT .................... 7 (C 27)

STARTER .......................................... 1 (A 3)

STOP LIGHT SWITCH ............................... 6 (B 21)

SUNROOF SWITCH ............................... 8 (E 28-29)

WIPER SYSTEM ............................... 5 (D-E 16-19)

WASHER NOZZLE HEATER ............................ 5 (E 19)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ WIRING DIAGRAMS