engine VOLKSWAGEN CORRADO 1990 Workshop Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 213 of 906

* SUSPENSION UNIFORM INSPECTION GUIDELINES *

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:38PM

The Motorist Assurance Program continues to work

cooperatively and proactively with government agencies and consumer

groups toward solutions that both benefit the customer and are

mutually acceptable to both regulators and industry. We maintain the

belief that industry must retain control over how we conduct our

business, and we must be viewed as part of the solution and not part

of the problem. Meetings with state and other government officials

concerned with auto repair and/or consumer protection are conducted.

Feedback from these representatives are brought back to members, and

the program adjusted as needed.

To assure auto repair customers recourse if they were not

satisfied with a repair transaction, the Motorist Assurance Program

offers arbitration through MAP/BBB-CARE in cooperation with the

Council of Better Business Bureaus and individual participating

Bureaus. MAP "piloted" in Indianapolis and Pittsburgh during spring,

1996 - and publicized "roll-outs" in New Jersey, Detroit (MI), Chicago

(IL) and Richmond (VA) were conducted. To put some "teeth" in the

program, and accreditation requirement for shops was initiated. The

requirements are stringent and a self-policing method has been

incorporated which includes the "mystery shopping" of outlets. In

addition, a committee of service providers had been working diligently

developing standards for newspaper, television and Internet

advertising.

We welcome you to join us as we continue our outreach ...

with your support, both the automotive repair industry and your

customers will reap the benefits. Please visit MAP at our Internet

site: www.hunter.com/map.htm or contact us at:

808 17th Street, NW Suite 200

Washington, D.C. 20006

Ph. (202) 466-7050 Fax (202) 223-9569

OVERVIEW OF SERVICE REQUIREMENTS & SUGGESTIONS

It is MAP policy that all exhaust, brake, ABS, steering and

suspension, wheel alignment, tires and wheels, driveline, engine

performance and maintenance and heating, ventilation and air

conditioning services be offered and performed under the guidelines

and procedures specified in these sections.

Before any service is performed on a vehicle, an inspection

of the appropriate system must be performed. The results of this

inspection must be explained to the customer and documented on an

inspection form. The condition of the vehicle and its components will

indicate what services/part replacements may be required or suggested.

In addition, suggestions may be made to satisfy the needs expressed by

the customer.

This section lists the various parts and conditions that

indicate required or suggested service or part replacement. Although

this list is extensive, it is not inclusive. In addition to this list,

a technician may make a suggestion. This suggestion must be based on

substantial and informed experience or the vehicle manufacturer's

recommended service interval.

Page 285 of 906

* SYMPTOM CHECK LIST *

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

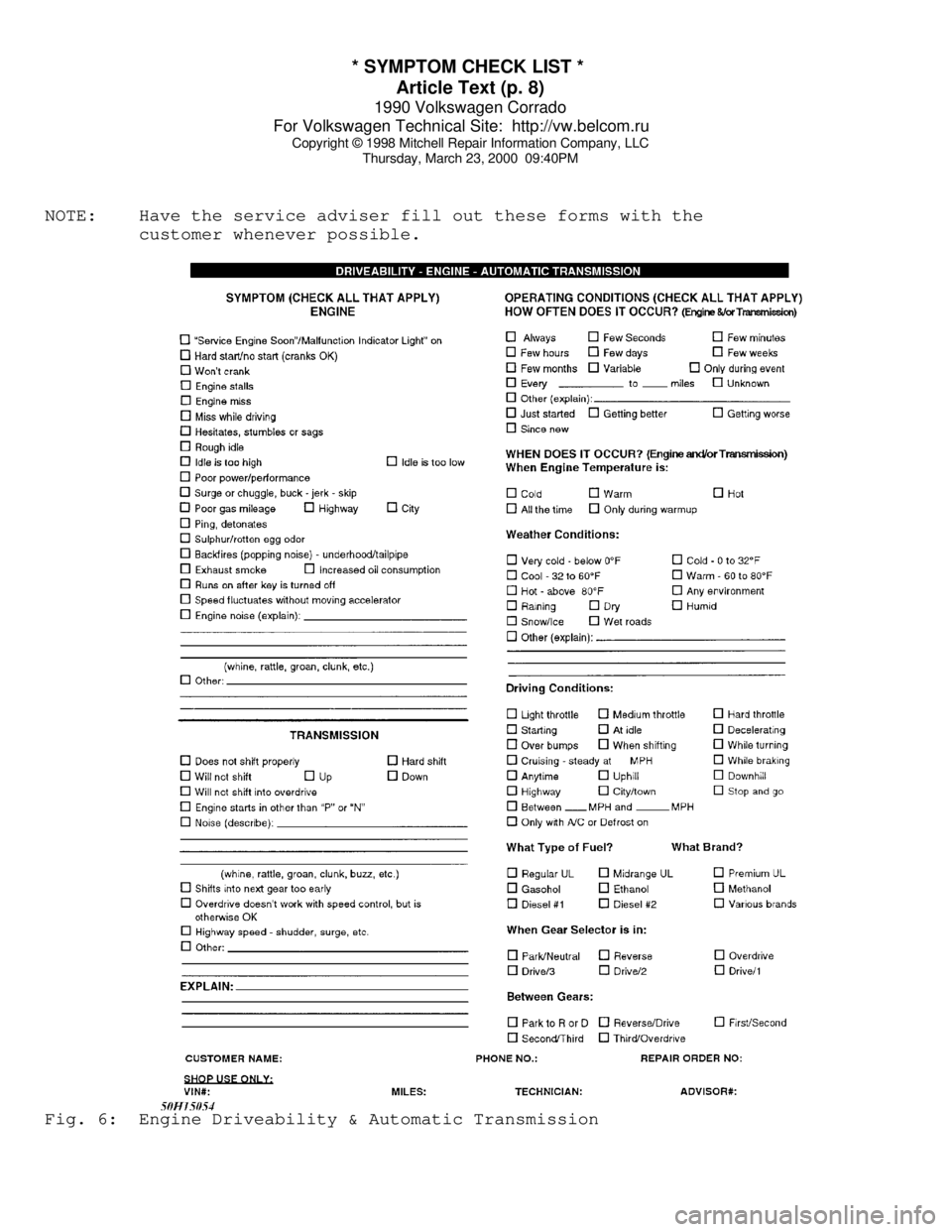

NOTE: Have the service adviser fill out these forms with the

customer whenever possible.Fig. 6: Engine Driveability & Automatic Transmission

Page 292 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

ARTICLE BEGINNING

1989-90 VOLKSWAGEN ENGINES

1.8L 8-Valve & 1.8L 16-Valve 4-Cylinder

1989-90

Cabriolet, Fox, Golf, GTI, Jetta, Jetta GLI

1990

Corrado

* PLEASE READ THIS FIRST *

NOTE: For engine repair procedures not covered in this article,

see ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION article

in the GENERAL INFORMATION section.

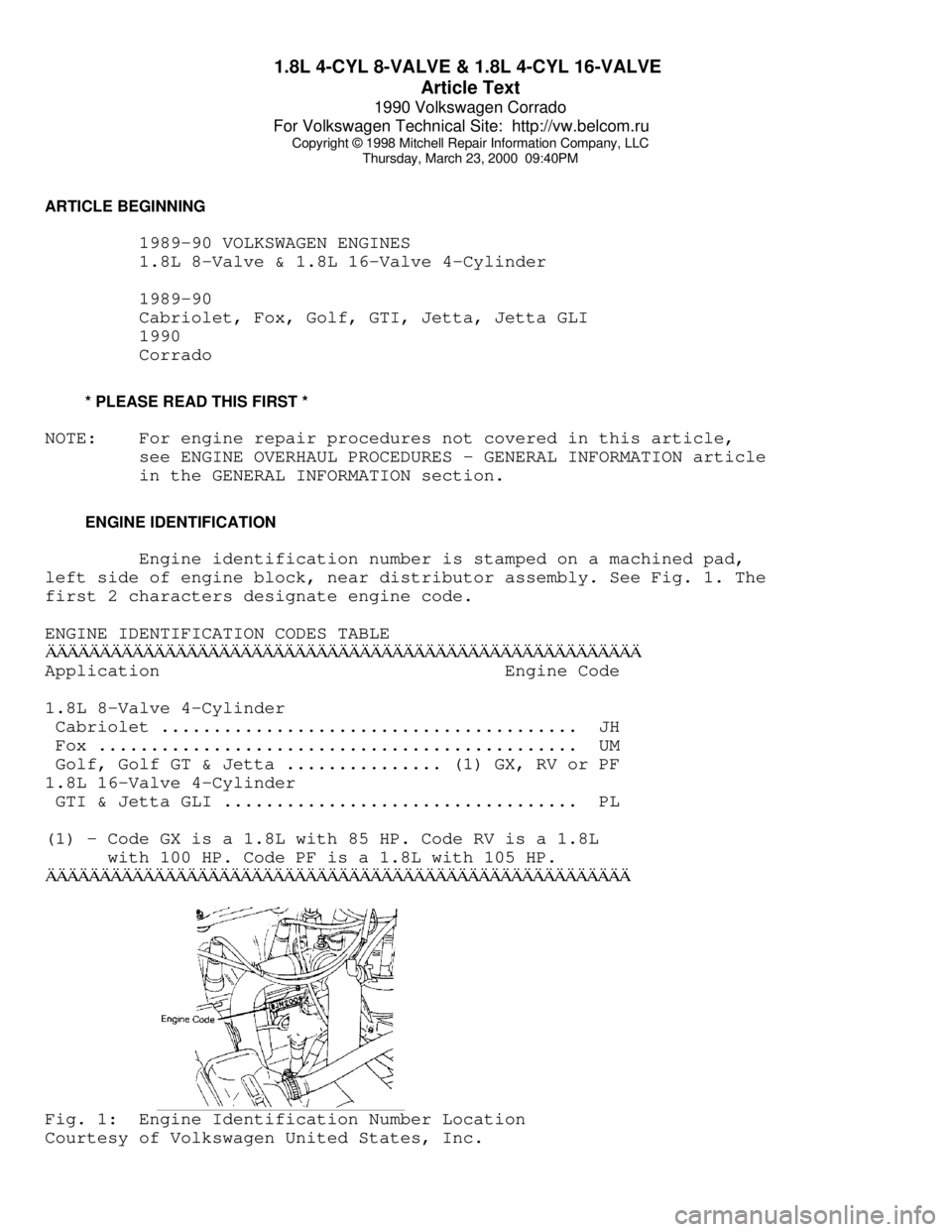

ENGINE IDENTIFICATION

Engine identification number is stamped on a machined pad,

left side of engine block, near distributor assembly. See Fig. 1. The

first 2 characters designate engine code.

ENGINE IDENTIFICATION CODES TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Engine Code

1.8L 8-Valve 4-Cylinder

Cabriolet ........................................ JH

Fox .............................................. UM

Golf, Golf GT & Jetta ............... (1) GX, RV or PF

1.8L 16-Valve 4-Cylinder

GTI & Jetta GLI .................................. PL

(1) - Code GX is a 1.8L with 85 HP. Code RV is a 1.8L

with 100 HP. Code PF is a 1.8L with 105 HP.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFig. 1: Engine Identification Number Location

Courtesy of Volkswagen United States, Inc.

Page 293 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

NOTE: Match mark engine mounts to ensure original alignment is

achieved after installation. On vehicles with A/C and power

steering, remove components with hoses attached and secure

out of way.

ENGINE R & I (EXCEPT FOX)

REMOVAL (EXCEPT FOX)

1) Disconnect and remove battery. Open fuel tank fill cap and

radiator cap. Remove intake air duct. On 16-valve engines, remove

intake manifold assembly. On vehicles with A/C, remove trim panel and

lower apron. Remove condenser from crossmember and radiator. Remove

all duct work. Mark and disconnect A/C and cooling fan electrical

connectors. Remove accessory belts.

2) On Golf, GTI and Jetta models, leave A/C hoses attached

and remove A/C compressor. Pivot A/C condenser and compressor to side

of vehicle and secure.

3) On Cabriolet and Scirocco models, remove alternator and

timing belt cover. Remove 3 A/C bracket Allen head bolts behind timing

belt cover. Remove A/C bracket support brace. Remove A/C compressor

bracket bolts. Leave hoses attached and secure A/C compressor with

bracket out of way.

4) On all models, open heater controls. Remove cooling hose

from thermostat housing flange and drain coolant. Remove flange. Mark

and remove all cooling system hoses (as necessary).

5) On Golf, GTI and Jetta models, remove grille from radiator

support. Disconnect electrical connectors at radiator support. Remove

radiator-to-support bolts. Remove radiator support using care not

damage headlights. Remove radiator, fan and shroud assembly.

6) On all models, remove axle shafts from transaxle. See FWD

AXLE SHAFTS article in the DRIVE AXLES section. Mark and disconnect

shift linkage and speedometer cable. Mark and remove electrical

connectors and vacuum hoses (as necessary). Disconnect throttle,

cruise and kickdown cables (if equipped). Leave fuel lines connected

and remove cold start injector and warm-up regulator.

7) Remove fuel injectors and install protective caps and

plugs. Remove rear engine mount. Remove complete transaxle mount. On

Cabriolet models, remove right front tire assembly. Remove right and

left engine mount through bolts.

8) On all models, install engine sling on engine lift hooks.

Carefully raise engine and transaxle out of vehicle. Separate

transaxle from engine (if necessary).

INSTALLATION

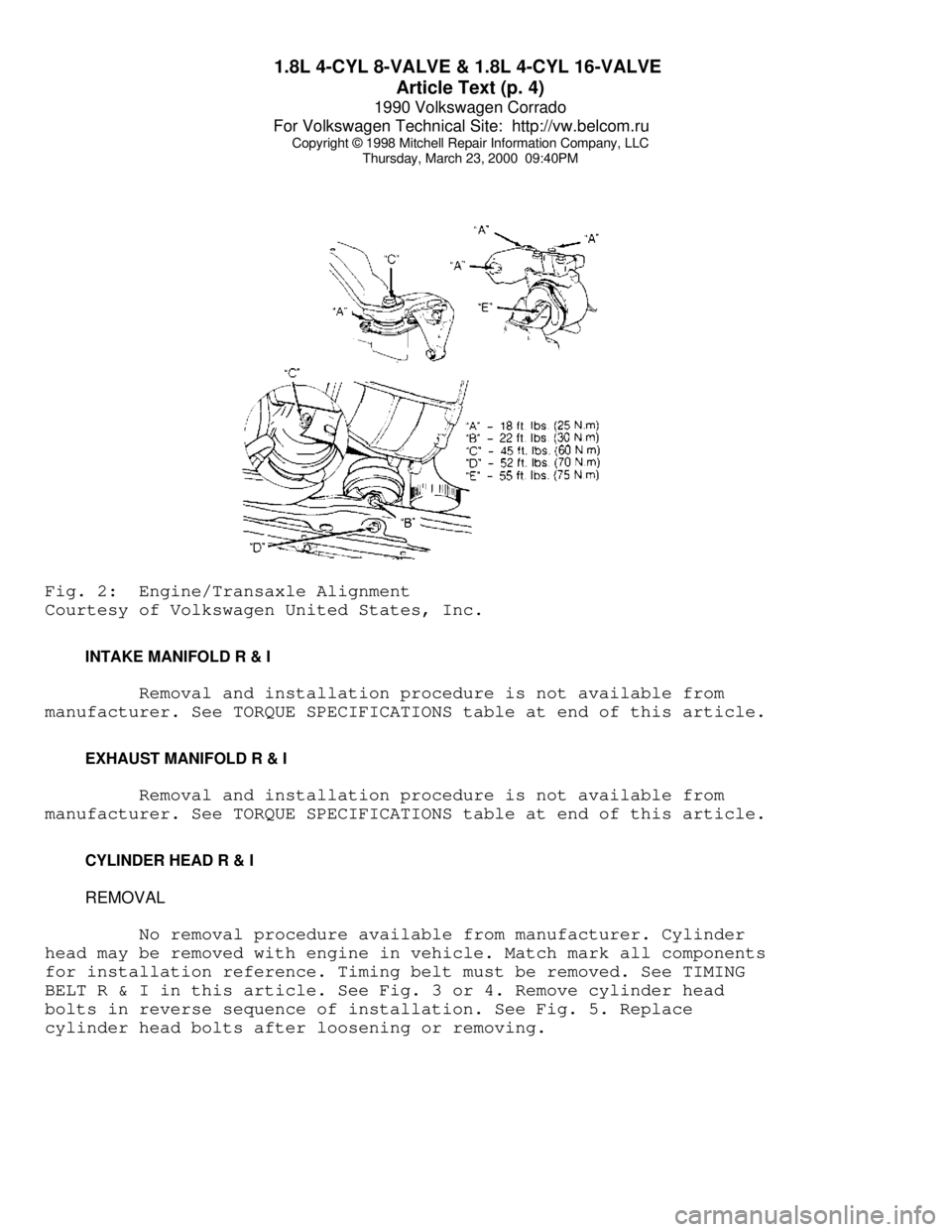

1) To install, reverse removal procedure. Engine alignment

adjustment is necessary whenever engine is removed or mounts are

loosened. To adjust, loosen through bolt on engine mount "A". Loosen

transmission transaxle mount "B" bolts. Loosen front engine mount and

bracket. See Fig. 2.

2) Lightly rock engine and transaxle to allow position to

Page 294 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

shift as necessary. Evenly tighten mount bolts in reverse order of

loosening. Fill fluids to proper level. Adjust clutch pedal (if

equipped). Tighten all bolts and nuts to specifications.

ENGINE R & I (FOX)

REMOVAL (FOX)

1) Disconnect negative battery cable. Open heater valve,

coolant expansion tank and drain radiator through lower radiator hose.

Mark and disconnect all heater hoses. Disconnect electric cooling fan

and thermo switch. Remove lower and side radiator mounting bolts.

Remove fan, shroud and radiator. Remove M/T clutch cable (if

equipped).

2) Mark and disconnect electrical wiring and vacuum hoses (as

necessary). Disconnect throttle, cruise and kickdown linkage (if

equipped). Remove fuel injectors and install protective caps and

plugs. Leave fuel lines attached and remove cold start valve. Remove

charcoal canister and set aside.

3) Remove 3 upper engine-to-transaxle bolts. Remove intake

air duct. Remove left and right engine mount nuts. Disconnect and

remove starter assembly. Remove 2 lower engine-to-transaxle bolts.

Remove transaxle inspection cover plate. Disconnect exhaust inlet pipe

support and separate inlet pipe from exhaust manifold.

4) Support transaxle. Attach engine sling to engine lifting

hooks. Raise engine/transaxle until engine clears engine mounts.

Ensure transaxle is supported. Remove remaining engine-to-transaxle

bolts. Lift and separate engine from vehicle without transaxle.

INSTALLATION

Lubricate transaxle main shaft splines and contact area

between clutch release bearing and clutch pressure plate with MoS2

grease. DO NOT lubricate guide sleeve for clutch release bearing. To

complete installation, reverse removal procedure. DO NOT reuse self-

locking nuts. Ensure engine mounts are installed to original location.

Tighten engine mounts and subframe bolts with engine running at idle.

Page 295 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PMFig. 2: Engine/Transaxle Alignment

Courtesy of Volkswagen United States, Inc.

INTAKE MANIFOLD R & I

Removal and installation procedure is not available from

manufacturer. See TORQUE SPECIFICATIONS table at end of this article.

EXHAUST MANIFOLD R & I

Removal and installation procedure is not available from

manufacturer. See TORQUE SPECIFICATIONS table at end of this article.

CYLINDER HEAD R & I

REMOVAL

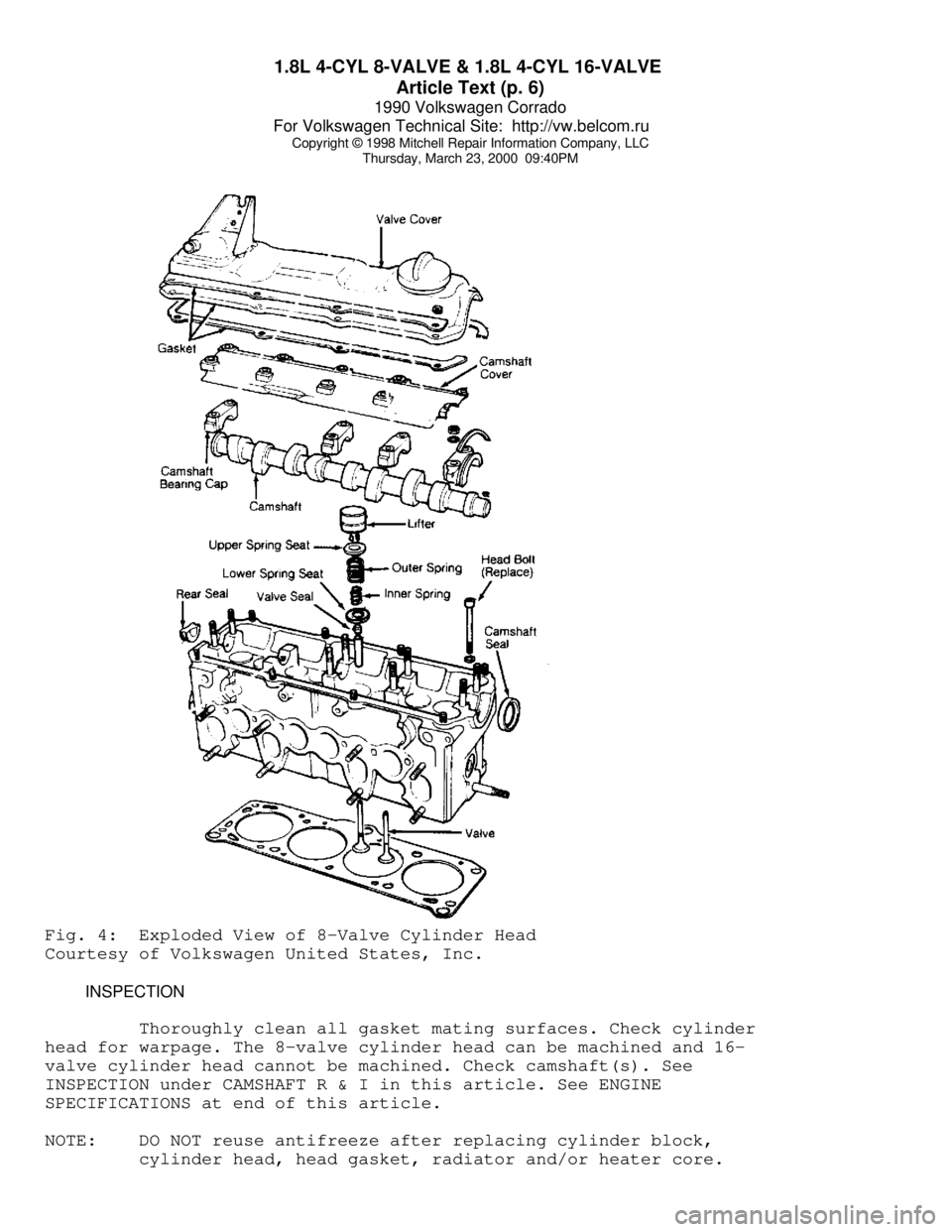

No removal procedure available from manufacturer. Cylinder

head may be removed with engine in vehicle. Match mark all components

for installation reference. Timing belt must be removed. See TIMING

BELT R & I in this article. See Fig. 3 or 4. Remove cylinder head

bolts in reverse sequence of installation. See Fig. 5. Replace

cylinder head bolts after loosening or removing.

Page 297 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 6)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PMFig. 4: Exploded View of 8-Valve Cylinder Head

Courtesy of Volkswagen United States, Inc.

INSPECTION

Thoroughly clean all gasket mating surfaces. Check cylinder

head for warpage. The 8-valve cylinder head can be machined and 16-

valve cylinder head cannot be machined. Check camshaft(s). See

INSPECTION under CAMSHAFT R & I in this article. See ENGINE

SPECIFICATIONS at end of this article.

NOTE: DO NOT reuse antifreeze after replacing cylinder block,

cylinder head, head gasket, radiator and/or heater core.

Page 301 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 10)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

2) Align crankshaft sprocket mark with mark on lower timing

belt cover. See Fig. 10. Install timing belt around camshaft sprocket.

Rotate tensioner clockwise until Timing Belt Tension Scale (VW 210)

reads 13-14. Rotate crankshaft 2 revolutions and check timing mark

alignment. To complete installation, reverse removal procedure.

CAMSHAFT OIL SEAL R & I

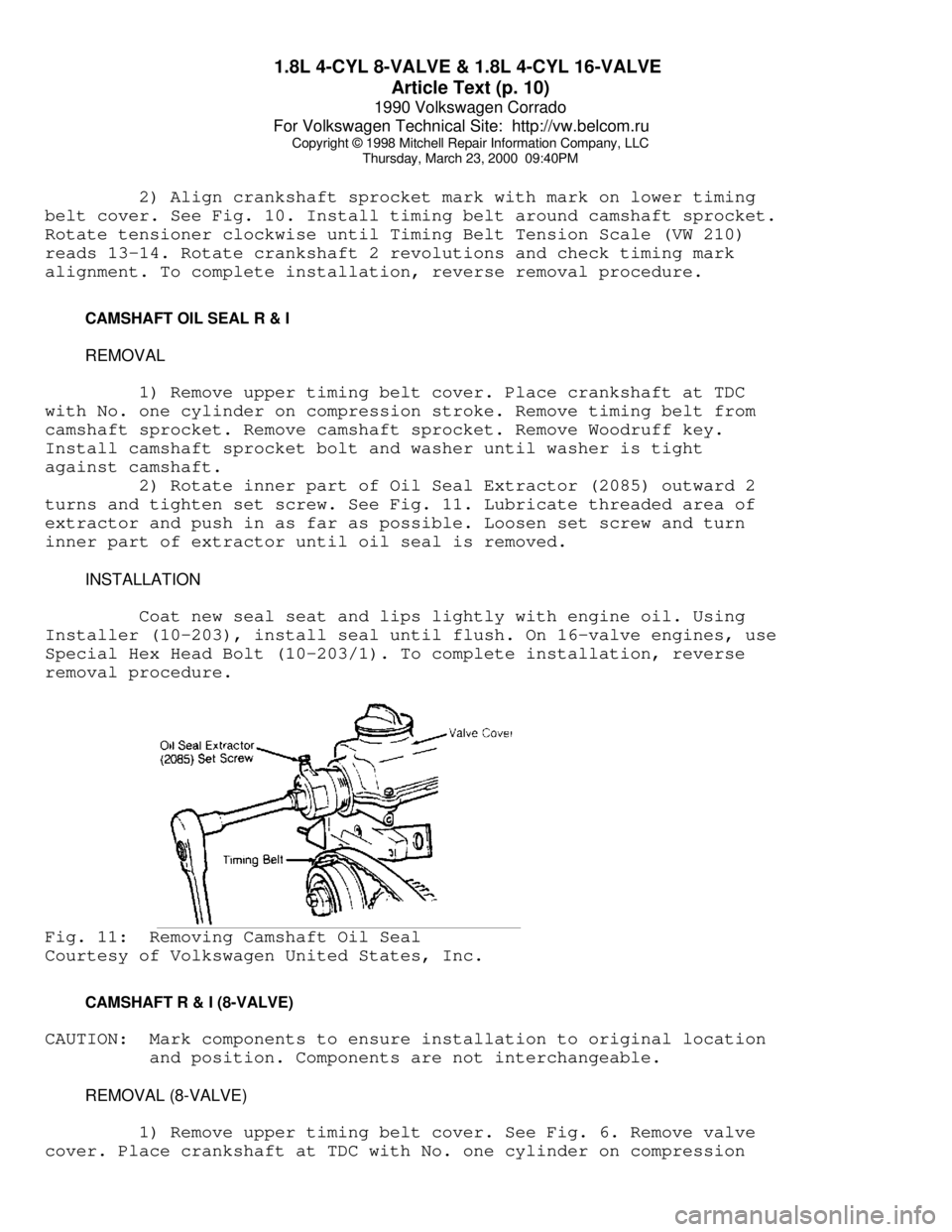

REMOVAL

1) Remove upper timing belt cover. Place crankshaft at TDC

with No. one cylinder on compression stroke. Remove timing belt from

camshaft sprocket. Remove camshaft sprocket. Remove Woodruff key.

Install camshaft sprocket bolt and washer until washer is tight

against camshaft.

2) Rotate inner part of Oil Seal Extractor (2085) outward 2

turns and tighten set screw. See Fig. 11. Lubricate threaded area of

extractor and push in as far as possible. Loosen set screw and turn

inner part of extractor until oil seal is removed.

INSTALLATION

Coat new seal seat and lips lightly with engine oil. Using

Installer (10-203), install seal until flush. On 16-valve engines, use

Special Hex Head Bolt (10-203/1). To complete installation, reverse

removal procedure.Fig. 11: Removing Camshaft Oil Seal

Courtesy of Volkswagen United States, Inc.

CAMSHAFT R & I (8-VALVE)

CAUTION: Mark components to ensure installation to original location

and position. Components are not interchangeable.

REMOVAL (8-VALVE)

1) Remove upper timing belt cover. See Fig. 6. Remove valve

cover. Place crankshaft at TDC with No. one cylinder on compression

Page 302 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 11)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

stroke. Remove timing belt from camshaft sprocket. Remove camshaft

sprocket. Remove Woodruff key. Check camshaft end play with cam

followers removed and bearing cap Nos. 1 and 5 installed. See CAMSHAFT

table at end of this article.

2) Remove bearing cap Nos. 1, 3 and 5 evenly a little at a

time. Repeat for remaining caps. Lift camshaft out of cylinder head.

See INSPECTION below.

INSPECTION

1) Check camshaft bearing oil clearance. See ENGINE

SPECIFICATIONS at end of this article. If oil clearance is greater

than specifications, install new camshaft and recheck clearance.

2) If clearance is still greater than specifications,

replace cylinder head. If replacing camshaft(s), ensure identification

number between lobes of cylinder No. one, are the same.

INSTALLATION (8-VALVE)

1) On engines with oil spray jets, position spray at right

angle to camshaft. Place camshaft in cylinder head with both high

points of lobes, for No. one cylinder facing upward. Install bearing

cap Nos. 1, 3 and 5.

2) Tighten evenly a little at a time. Repeat procedure for

remaining bearing caps. To complete installation, reverse removal

procedure. Ensure timing marks are properly aligned. Allow lifters to

bleed down for 30 minutes before starting engine.

CAMSHAFT R & I (16-VALVE)

REMOVAL (16-VALVE)

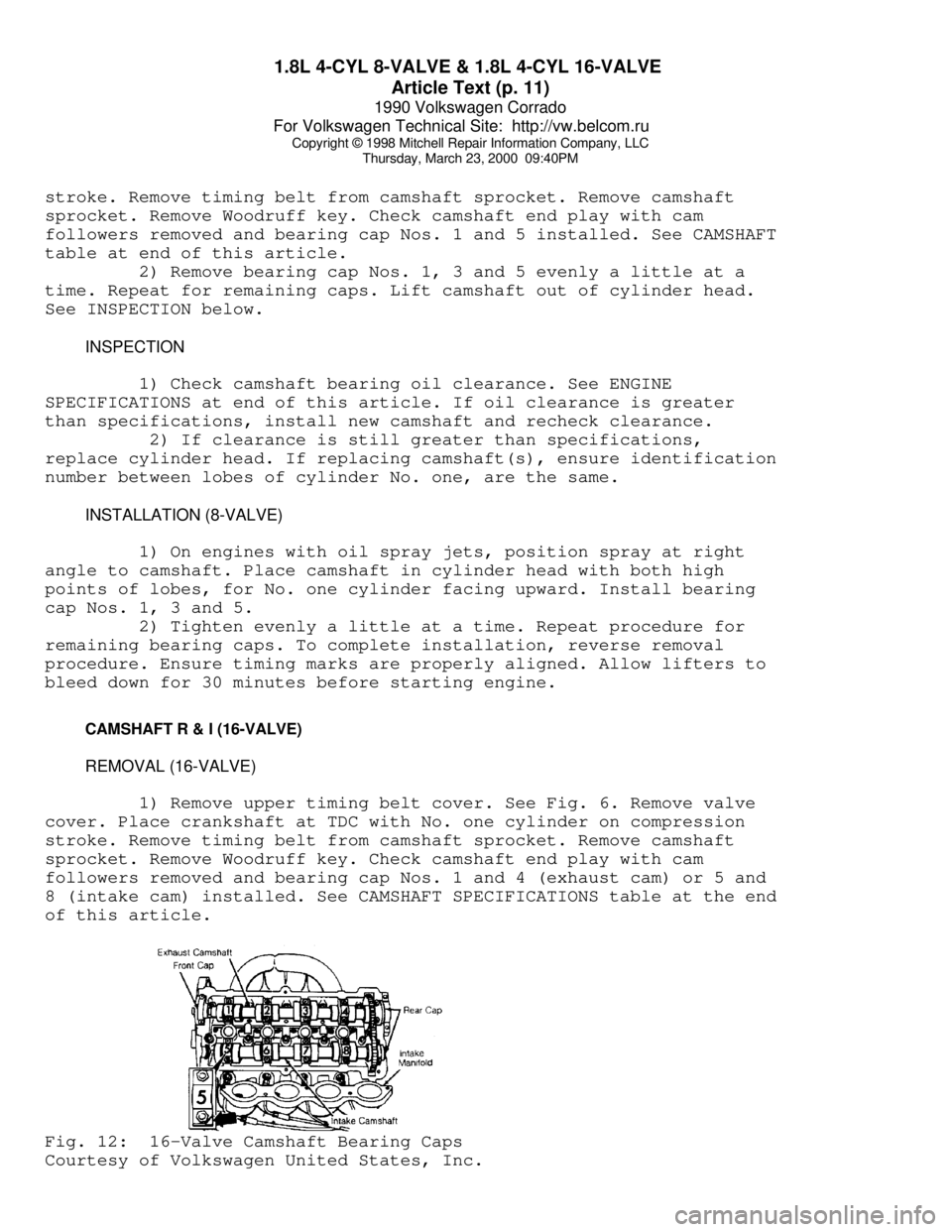

1) Remove upper timing belt cover. See Fig. 6. Remove valve

cover. Place crankshaft at TDC with No. one cylinder on compression

stroke. Remove timing belt from camshaft sprocket. Remove camshaft

sprocket. Remove Woodruff key. Check camshaft end play with cam

followers removed and bearing cap Nos. 1 and 4 (exhaust cam) or 5 and

8 (intake cam) installed. See CAMSHAFT SPECIFICATIONS table at the end

of this article.Fig. 12: 16-Valve Camshaft Bearing Caps

Courtesy of Volkswagen United States, Inc.

Page 303 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 12)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

2) Remove intake camshaft bearing cap Nos. 5, 7 and rear

evenly a little at a time. See Fig. 12. Loosen remaining intake

camshaft bearing caps evenly a little at a time. Remove exhaust

camshaft bearing cap Nos. 1, 3, front and rear evenly a little at a

time. Loosen remaining exhaust camshaft bearing caps evenly a little

at a time. Remove loosened caps. Lift camshafts out of cylinder head

together.

INSPECTION

1) Check camshaft bearing oil clearance. See ENGINE

SPECIFICATIONS at end of this article. If oil clearance is greater

than specifications, install new camshaft and recheck clearance.

2) If clearance is still greater than specifications, replace

cylinder head. If replacing camshaft(s), ensure identification number

between lobes of cylinder No. one, are the same.

INSTALLATION (16-VALVE)

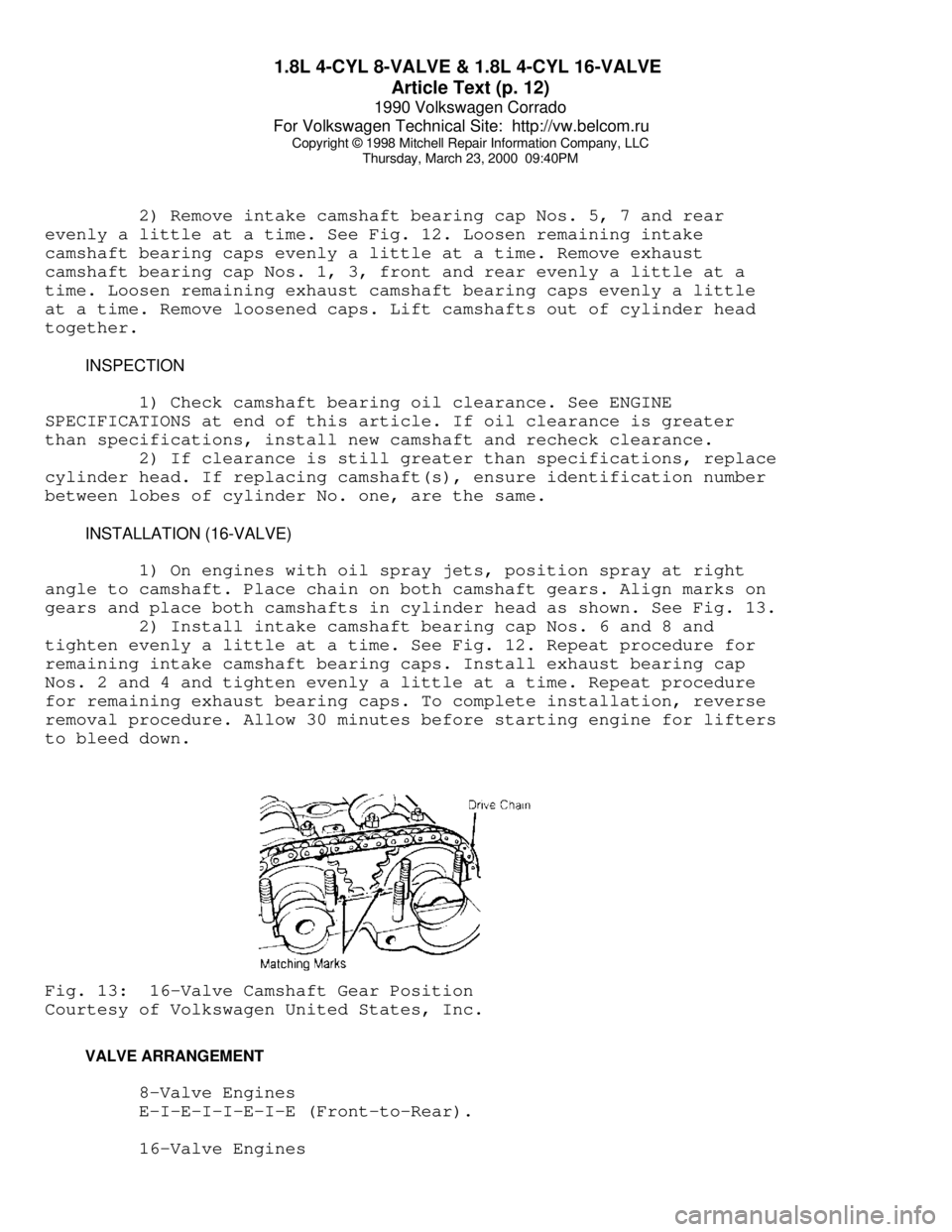

1) On engines with oil spray jets, position spray at right

angle to camshaft. Place chain on both camshaft gears. Align marks on

gears and place both camshafts in cylinder head as shown. See Fig. 13.

2) Install intake camshaft bearing cap Nos. 6 and 8 and

tighten evenly a little at a time. See Fig. 12. Repeat procedure for

remaining intake camshaft bearing caps. Install exhaust bearing cap

Nos. 2 and 4 and tighten evenly a little at a time. Repeat procedure

for remaining exhaust bearing caps. To complete installation, reverse

removal procedure. Allow 30 minutes before starting engine for lifters

to bleed down.Fig. 13: 16-Valve Camshaft Gear Position

Courtesy of Volkswagen United States, Inc.

VALVE ARRANGEMENT

8-Valve Engines

E-I-E-I-I-E-I-E (Front-to-Rear).

16-Valve Engines