oil type VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 12 of 906

* A/C-HEATER SYSTEM UNIFORM INSPECTION GUIDELINES *

Article Text (p. 10)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:27PM

³ ³ components as necessary.

³ ³ Discoloration of oil does not

³ ³ necessarily indicate a system

³ ³ problem.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ REFRIGERANT

REFRIGERANT

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄOvercharge/undercharge

³ Require service to manufacturer's

³ specifications.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCross-contamination

³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´ Require service following

Different types of refrigerants

³ manufacturer's procedures and

in the same system

³ specifications.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ´Incompatible refrigerants mixed

³together

³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ AIR DISTRIBUTION

PLENUM/EVAPORATOR CASE/HEATER CASE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÂÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCondition

³ Procedure ³ Note

ÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCracked

³ Suggest repair or ³

³ replacement. ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄAir leaks

³ Require repair or ³

³ replacement ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄRestricted

³ Suggest cleaning, ³

³ repair or replacement.³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄOdor

³ Further inspection ³ Identify source. Suggest

³ required. ³ cleaning or repair.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄNoisy

³ Further inspection ³ Identify source. Suggest

³ required. ³ cleaning or repair.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÅÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCold water

³ Further inspection ³ Determine source of leak. Leak

leak in

³ required. ³ may be caused due to restricted

passenger

³ ³ drain tube, cracked evaporator

compartment

³ ³ case, leaking seal or gasket.

³ ³ Require repair or replacement.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÁÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Page 319 of 906

A/C COMPRESSOR OIL CHECKING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

ARTICLE BEGINNING

1990 AIR CONDITIONING & HEAT

Compressor Oil Checking

ISOLATING COMPRESSOR

NOTE: Only compressors with stem-type service valves can be

isolated.

1) Connect service gauge set to the compressor service valves

and open compressor valves slightly (turn in clockwise). Start engine

and operate air conditioning. Slowly turn compressor suction valve

clockwise toward closed (front-seated) position.

2) When suction pressure is reduced to zero or less, turn off

engine and compressor and quickly turn suction valve stem in to full

front-seated position. Suction pressure should be slightly above zero.

Turn discharge valve into front-seated position.

3) To check oil level, slowly open compressor crankcase plug

to relieve any remaining pressure. After oil level is corrected, cap

service gauge ports on both valves. Back-seat suction service valve to

allow refrigerant to enter compressor. Open discharge valve halfway.

4) Loosen discharge service valve cap, allowing refrigerant

pressure to force air out of compressor. Back-seat service valve and

tighten cap. Compressor is now ready for operation.

REFRIGERANT OIL

Only new, pure, moisture-free refrigerant oil should be used

in the air conditioning system. This oil is highly refined and

dehydrated to a point where moisture content is less than 10 parts per

million. The oil container must be tightly closed at all times when

not in use, or moisture will be absorbed into the refrigerant oil from

the air.

SERVICING PRECAUTIONS

NOTE: Recent findings by the EPA indicate that refrigerant is

harmful to the earth's protective Ozone layer. When

discharging refrigerant, DO NOT allow refrigerant to enter

the atmosphere. If available, use refrigerant

recovery/recycle systems when discharging system. Always

follow manufacturer's instructions.

DISCHARGING SYSTEM PRECAUTIONS

If compressor has stem-type service valves, it can be

isolated and removed without discharging entire system. See ISOLATING

COMPRESSOR at the beginning of this article. Otherwise, discharge

system completely before loosening any fittings.

Page 327 of 906

A/C COMPRESSOR SERVICING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

ARTICLE BEGINNING

1990 AIR CONDITIONING & HEAT

Compressor Service

* PLEASE READ THIS FIRST *

CAUTION: When discharging air conditioning system, use only approved

refrigerant recovery/recycling equipment. Make every attempt

to avoid discharging refrigerant into the atmosphere.

ISOLATING COMPRESSOR

NOTE: Only compressors with stem-type service valves can be

isolated.

1) Connect service gauge set to the compressor service valves

and open compressor valves slightly (turn in clockwise). Start engine

and operate air conditioning. Slowly turn compressor suction valve

clockwise toward closed (front-seated) position.

2) When suction pressure is reduced to zero or less, turn off

engine and compressor and quickly turn suction valve stem in to full

front-seated position. Suction pressure should be slightly above zero.

Turn discharge valve into front-seated position.

3) To check oil level, slowly open compressor crankcase plug

to relieve any remaining pressure. After oil level is corrected, cap

service gauge ports on both valves. Back-seat suction service valve to

allow refrigerant to enter compressor. Open discharge valve halfway.

4) Loosen discharge service valve cap, allowing refrigerant

pressure to force air out of compressor. Back-seat service valve and

tighten cap. Compressor is now ready for operation.

REFRIGERANT OIL

Only new, pure, moisture-free refrigerant oil should be used

in the air conditioning system. This oil is highly refined and

dehydrated to a point where moisture content is less than 10 parts per

million. The oil container must be tightly closed at all times when

not in use, or moisture will be absorbed into the refrigerant oil from

the air.

DISCHARGING SYSTEM PRECAUTIONS

CAUTION: When discharging air conditioning system, use only approved

refrigerant recovery/recycling equipment. Make every attempt

to avoid discharging refrigerant into the atmosphere.

If compressor has stem-type service valves, it can be

isolated and removed without discharging entire system. Otherwise,

discharge system completely using approved refrigerant

Page 355 of 906

A/C SYSTEM PRECAUTIONS

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

Compressor oil Check article, as well as, Component Oil Replacement

Quantities" chart under "A/C SYSTEM SPECS" article in this section.

USING R-12 REFRIGERANT - SAFETY PRECAUTIONS

1) Always work in a well-ventilated, clean area. Refrigerant

(R-12) is heavier than oxygen, and will displace oxygen in a confined

area. Always wear eye protection when working around air conditioning

systems and R-12. The system's high pressure can cause severe injury

to eyes and skin if a hose were to burst. R-12 evaporates quickly

when exposed to atmosphere, freezing anything it contacts.

2) Use care when handling refrigerant containers. DO NOT drop

or strike containers or expose refrigerant containers to excessive

heat. Containers must never be heated more than 125øF (52øC). Never

expose R-12 directly to open flame.

CAUTION: When R-12 is exposed to an open flame, drawn into a running

engine, or detected with a Halide (propane) leak tester,

poisonous phosgene gas is formed. Keep work areas ventilated

and avoid running engines near work area.

USING INDIVIDUAL R-12 CANS

Disposable refrigerant cans (referred to as one pound cans)

have a flat type seal or a screw type seal, and proper can tap must be

used for each type. Be sure sealing gasket on can tap is in good

condition. A proper safety can tap will prevent refrigerant from

flowing back into open can, as tap has a one-way flow control.

NOTE: Recent findings by the EPA indicate that refrigerant is

harmful to the Earth's protective Ozone layer. When

discharging refrigerant avoid allowing refrigerant to enter

the atmosphere. Refrigerant recovery system should be used

when discharging the system.

MULTI-CAN DISPENSING VALVES

A multi-can dispensing valve allows attachment of several

cans of refrigerant, and is a good substitute when a bulk container is

not available. Cans are installed onto each leg of multi-can

dispensing valve in the same manner as the individual cans, and each

leg has its own can tap.

CAN TAP INSTALLATION FLAT TYPE SEAL CANS

On cam-lock or one-piece can taps, first turn the handle

outward to the fully open position. Securely engage locking lugs over

the can flange, and lock them in place by turning cam lock or locking

nut. Screw tap assembly into adapter so sealing gasket is fully seated

against the can top. Turn tap inward to pierce the can and close the

tap. DO NOT open tap until ready to purge the service hose or dispense

Page 356 of 906

A/C SYSTEM PRECAUTIONS

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

refrigerant into the system.

On 2-piece can taps, be certain tap handle is turned fully

inward to the closed position. Check that locking base is turned to

its outer limit. Securely engage locking lugs over the can flange.

Turn entire tap assembly (without disturbing the closed setting)

downward into the locking base to pierce the can. DO NOT open tap

until ready to dispense into system.

SCREW TYPE SEAL CANS

Ensure can tap is fully closed. Screw refrigerant can into

can tap fitting until tight. This will pierce the can. Connect tap to

center hose on manifold gauge set. DO NOT open tap until ready to

dispense R-12 into system.

WARNING: DO NOT open high side hand valve while air conditioning

system is in operation. This high pressure could rupture can

or fitting at safety can valve, resulting in damage and

personal injury.

CONNECTING LINES & FITTINGS

A new "O" ring should be used in all instances when

connecting lines and fittings (dip "O" ring in clean refrigeration oil

and make certain it is not twisted during installation). Always use

two wrenches to avoid twisting or distorting lines and fittings,

tighten coupling nuts securely.

PLACING SYSTEM IN OPERATION

After component replacement and/or system servicing has been

completed and all connections have been made, proceed as follows:

1) Evacuate the system using a vacuum pump.

2) Charge the system with new R-12 (refrigerant) according to

each individual vehicle as outlined in the GENERAL SERVICING article.

Also see Refrigerant Capacity in this Section.

3) Leak test the system, with particular attention to all new

connections and components.

4) Make a performance test of the system. Never assume that a

recharging has automatically corrected a problem.

COMPRESSOR REMOVAL INFORMATION - ISOLATION METHOD

On systems which have compressors equipped with stem-type

service valves (Tecumseh), it is possible to isolate the compressor

for removal.

Isolating

Turn both high and low pressure manual valves to extreme

clockwise (front seat) position. Loosen cap on high pressure manual

Page 365 of 906

A/C-HEATER SYSTEM - MANUAL

Article Text (p. 8)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

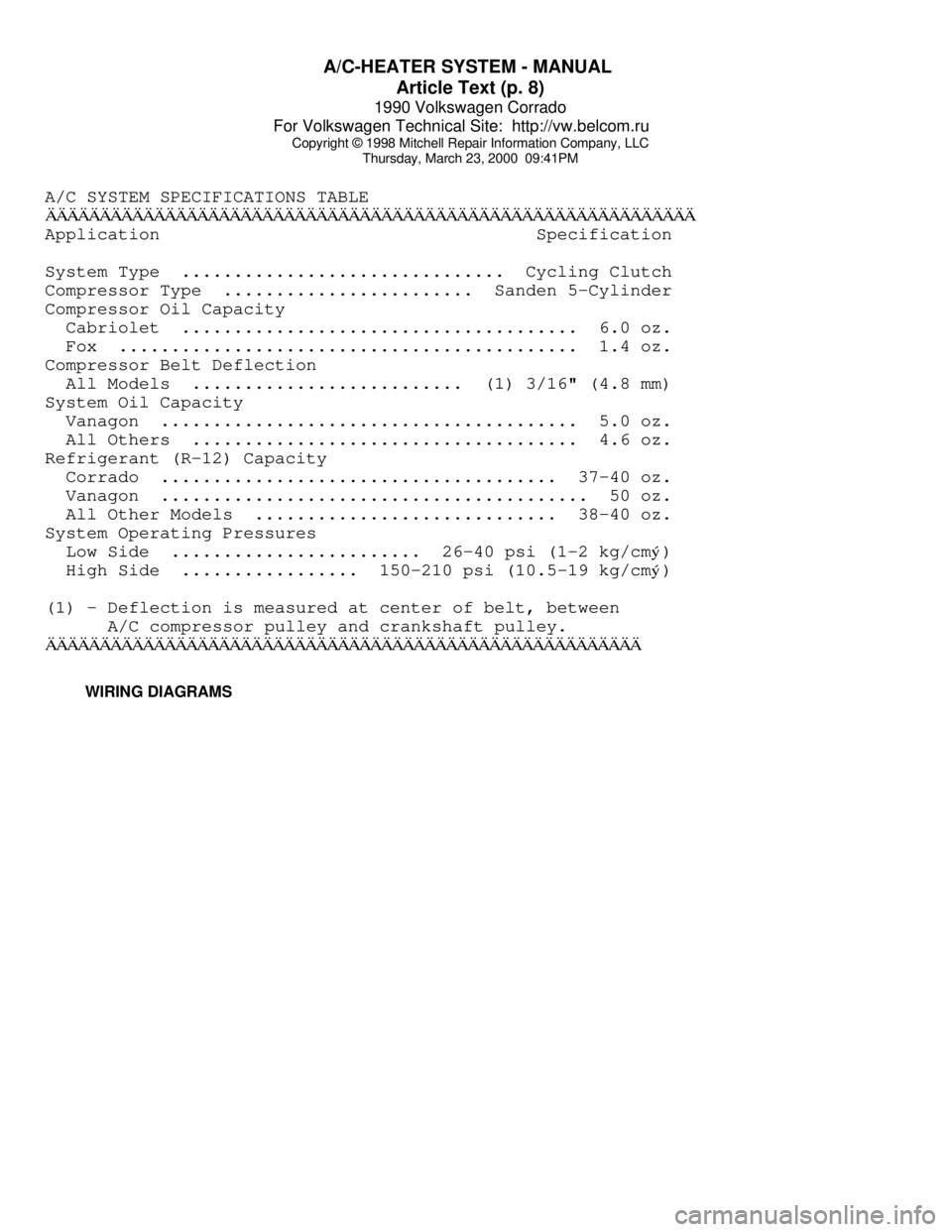

A/C SYSTEM SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Specification

System Type ............................... Cycling Clutch

Compressor Type ........................ Sanden 5-Cylinder

Compressor Oil Capacity

Cabriolet ...................................... 6.0 oz.

Fox ............................................ 1.4 oz.

Compressor Belt Deflection

All Models .......................... (1) 3/16" (4.8 mm)

System Oil Capacity

Vanagon ........................................ 5.0 oz.

All Others ..................................... 4.6 oz.

Refrigerant (R-12) Capacity

Corrado ...................................... 37-40 oz.

Vanagon ......................................... 50 oz.

All Other Models ............................. 38-40 oz.

System Operating Pressures

Low Side ........................ 26-40 psi (1-2 kg/cm

ý)

High Side ................. 150-210 psi (10.5-19 kg/cm

ý)

(1) - Deflection is measured at center of belt, between

A/C compressor pulley and crankshaft pulley.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ WIRING DIAGRAMS

Page 374 of 906

AA - USING THIS SECTION (GENERAL HELP INFORMATION)

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

* Replacement intervals.

* Belt adjustment.

* Engine Compression.

* Valve clearance.

* Valve Arrangement.

* Ignition coil specifications.

* High tension wire resistance.

* Spark plug type and gap.

* Firing order.

* Ignition timing.

* Fuel pump performance and injector resistance specifications

* Slow and fast idle speed and mixture specifications.

* Carbon monoxide (CO) level specifications.

* Throttle position sensor/switch specifications.

C - SPECIFICATIONS

This is a collection of quick-reference type specifications.

This article is helpful when you are familiar with proper adjustment

procedures and only need specifications. Included in this section are:

* Battery specifications.

* Fluid capacities.

* Replacement intervals.

* Belt adjustment.

* Engine Compression.

* Valve clearance.

* Valve Arrangement.

* Ignition coil specifications.

* High tension wire resistance.

* Spark plug type and gap.

* Firing order.

* Ignition timing.

* Fuel pump performance and injector resistance specifications

* Slow and fast idle speed and mixture specifications.

* Carbon monoxide (CO) level specifications.

* Throttle position sensor/switch specifications.

D - ADJUSTMENTS

This article contains the information that use to be included

in the TUNE-UP section. Checking and adjusting valves, spark plugs,

spark plug wires, base ignition timing and idle speed are found in

this section. Use this article for routine maintenance. Also, if you

have a driveability problem, ensure all on-vehicle adjustments are

correct before proceeding with any diagnosis.

E - THEORY/OPERATION

Page 432 of 906

C - SPECIFICATIONS

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

HIGH TENSION WIRE RESISTANCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Ohms

Vanagon

Coil Wire With Connectors ........................ 1200-2800

Spark Plug Wire/Connector ........................ 4600-7400

Spark Plug Connector ............................. 4000-6000

Suppressor (1) .................................... 600-1400

All Other Models

Coil Wire Only ......................................... (1)

Coil Wire With Connector ......................... 1600-2400

Spark Plug Wire/ Connector ....................... 4000-6000

Suppressor (2) .................................... 600-1400

(1) - Check for continuity.

(2) - Suppressor is located between ignition wire and

distributor cap.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ SPARK PLUG TYPE TABLE

SPARK PLUG TYPE TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Bosch Champion

Cabriolet .................... W7DTC .................. N7BYC

Corrado ...................... WR7DS ................... N8GY

Fox .......................... WR7DS ................... N8GY

Golf GL/Jetta 1.8L ........... WR7DS ................... N8GY

Jetta GLi 2.0L ............... F6DSR ................... N8GY

Vanagon ...................... W7CCO ................... N288

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ SPARK PLUG SPECIFICATIONS TABLE

SPARK PLUG SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Gap Torque

Application In. (mm) Ft. Lbs. (N.m)

All Models ....... .028-.032 (.70-.80) .............. 14 (19)

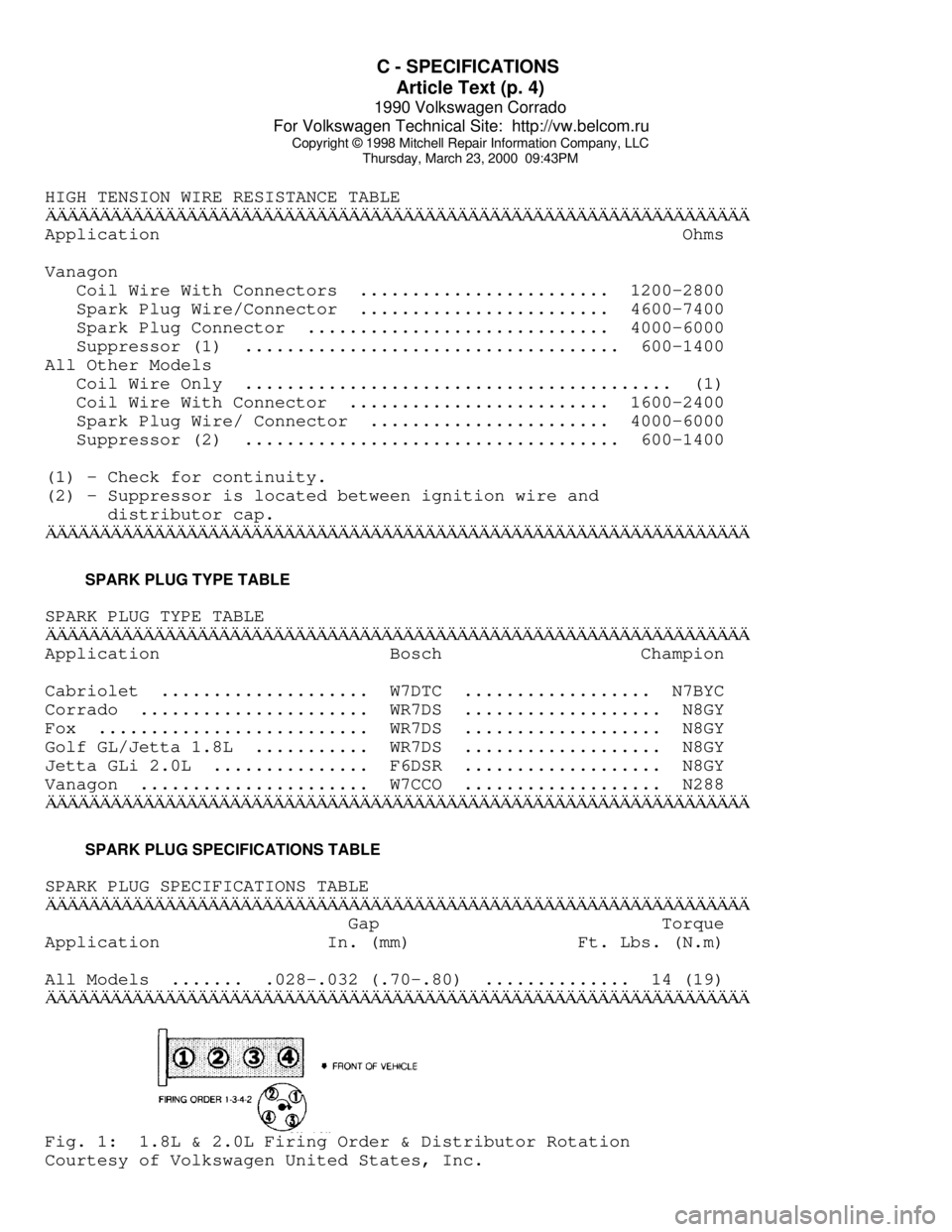

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄFig. 1: 1.8L & 2.0L Firing Order & Distributor Rotation

Courtesy of Volkswagen United States, Inc.

Page 513 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

specifications for the vehicle being repaired.

SHEET METAL PARTS

Examples of sheet metal parts are the rocker covers, front

and side covers, oil pan and bellhousing dust cover. Glass bead

blasting or hot tank may be used for cleaning.

Ensure all mating surfaces are flat. Deformed surfaces should

be straightened. Check all sheet metal parts for cracks and dents.

INTAKE & EXHAUST MANIFOLDS

Using solvent cleaning or bead blasting, clean manifolds for

inspection. If the intake manifold has an exhaust crossover, all

carbon deposits must be removed. Inspect manifolds for cracks, burned

or eroded areas, corrosion and damage to fasteners.

Exhaust heat and products of combustion cause threads of

fasteners to corrode. Replace studs and bolts as necessary. On "V"

type intake manifolds, the sheet metal oil shield must be removed for

proper cleaning and inspection. Ensure that all manifold parting

surfaces are flat and free of burrs.

CYLINDER HEAD REPLACEMENT

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

REMOVAL

Remove intake and exhaust manifolds and valve cover. Cylinder

head and camshaft carrier bolts (if equipped), should be removed only

when the engine is cold. On many aluminum cylinder heads, removal

while hot will cause cylinder head warpage. Mark rocker arm or

overhead cam components for location.

Remove rocker arm components or overhead cam components.

Components must be installed in original location. Individual design

rocker arms may utilize shafts, ball-type pedestal mounts or no rocker

arms. For all design types, wire components together and identify

according to the corresponding valve. Remove cylinder head bolts.

Note length and location. Some applications require cylinder head

bolts be removed in proper sequence to prevent cylinder head damage.

See Fig. 1. Remove cylinder head.

Page 516 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

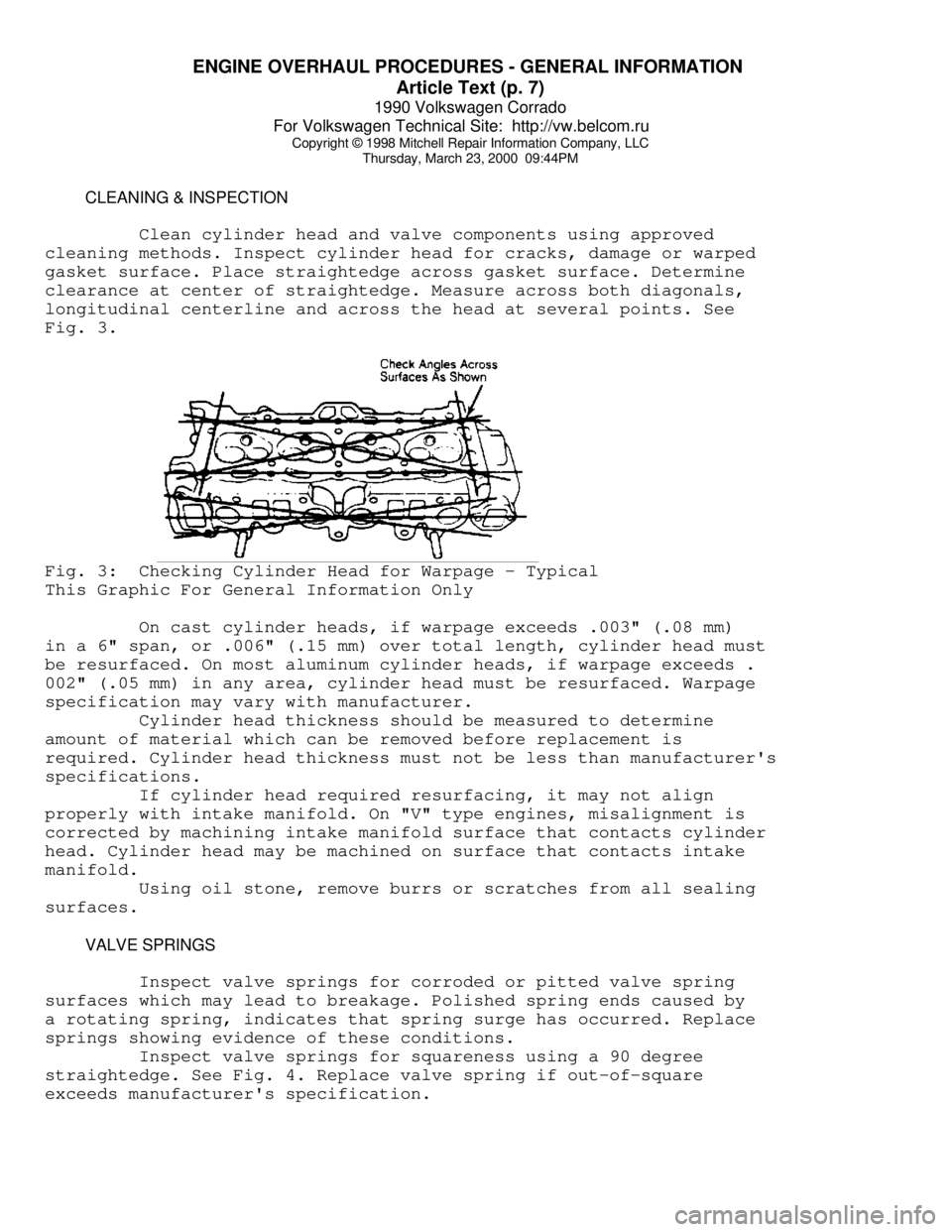

CLEANING & INSPECTION

Clean cylinder head and valve components using approved

cleaning methods. Inspect cylinder head for cracks, damage or warped

gasket surface. Place straightedge across gasket surface. Determine

clearance at center of straightedge. Measure across both diagonals,

longitudinal centerline and across the head at several points. See

Fig. 3.Fig. 3: Checking Cylinder Head for Warpage - Typical

This Graphic For General Information Only

On cast cylinder heads, if warpage exceeds .003" (.08 mm)

in a 6" span, or .006" (.15 mm) over total length, cylinder head must

be resurfaced. On most aluminum cylinder heads, if warpage exceeds .

002" (.05 mm) in any area, cylinder head must be resurfaced. Warpage

specification may vary with manufacturer.

Cylinder head thickness should be measured to determine

amount of material which can be removed before replacement is

required. Cylinder head thickness must not be less than manufacturer's

specifications.

If cylinder head required resurfacing, it may not align

properly with intake manifold. On "V" type engines, misalignment is

corrected by machining intake manifold surface that contacts cylinder

head. Cylinder head may be machined on surface that contacts intake

manifold.

Using oil stone, remove burrs or scratches from all sealing

surfaces.

VALVE SPRINGS

Inspect valve springs for corroded or pitted valve spring

surfaces which may lead to breakage. Polished spring ends caused by

a rotating spring, indicates that spring surge has occurred. Replace

springs showing evidence of these conditions.

Inspect valve springs for squareness using a 90 degree

straightedge. See Fig. 4. Replace valve spring if out-of-square

exceeds manufacturer's specification.