stop start VOLKSWAGEN CORRADO 1990 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 403 of 906

ALTERNATOR & REGULATOR - BOSCH

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:42PM

(most vehicles) are clean and tight. Ensure alternator, engine and

body are properly grounded. Ensure alternator drive belt is tight and

in good condition.

2) Connect ammeter following manufacturer's instructions.

Connect voltmeter leads to battery terminals. Adjust carbon pile on

tester until voltmeter reads 13.5 volts. Alternator output should be

28-35 amps.

3) Repeat process at 1000 RPM. Alternator output should be

75-85 amps. Repeat test at 2000 RPM. Alternator output should be 89

amps. If alternator output is low, remove alternator for testing and

repairs.

4) Start engine and run at 3000 RPM. Adjust carbon pile on

tester to obtain maximum alternator output. Do not allow voltage to go

below 12.6 volts.

5) Alternator output should equal alternator rated output,

minus 16-20 amps. If reading is 16-20 amps below alternator rating,

replace regulator and retest. If output is still low, repair or

replace alternator.

REGULATOR CONTROL VOLTAGE TEST

1) Connect ammeter following manufacturer's instructions.

Connect voltmeter leads to battery terminals. Start engine and run at

3000 RPM.

2) Run engine until voltage stops rising. Voltage should be

13.5-14.5 volts. If reading is incorrect, remove regulator and ensure

brushes are longer than 7/32" (6 mm). Replace if necessary.

3) If brushes are okay and regulator fails to keep voltage

within specified limits, replace regulator and retest. If voltage is

still incorrect, repair or replace alternator.

BENCH TESTING

DIODE ASSEMBLY

1) Place ohmmeter on x 100 scale. Connect ohmmeter leads

across "B+" terminal and 3 stator terminals one at a time. Reverse

leads. Ohmmeter should indicate continuity in one direction only.

2) Connect ohmmeter leads across negative plate and 3 stator

terminals one at a time. See Fig. 1. Reverse leads. Ohmmeter should

indicate continuity in one direction only.

3) Connect ohmmeter leads across "D+" terminal and 3 stator

terminals one at a time. Reverse leads. Ohmmeter should indicate

continuity in one direction only. Replace diode assembly if defective.

Page 412 of 906

ANTI-LOCK BRAKE SYSTEM

Article Text (p. 4)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:42PM

seconds maximum and then stop. Depress brake pedal a few times; pump

should operate again for a few seconds. If pump motor does not

operate, check electrical system. If pump motor operates for more than

60 seconds, internal or external hydraulic leak may be indicated.

Check for external leaks. If external leak is not found, further

testing may be needed to check for internal leaks.

ANTI-LOCK WARNING LIGHT

Start engine. ANTI-LOCK warning light should come on, then

turn off after a few seconds. If light does not come on when engine is

started, check electrical system. If light comes on and stays on,

fault has been detected by the ECU and testing will be needed. See

SYSTEM TESTING under DIAGNOSIS & TESTING.

DIAGNOSIS & TESTING

SYSTEM TESTING

NOTE: Check battery condition, brake fluid level, electrical

connections and wiring for damage. If fluid level is

incorrect or battery and/or electrical connections are

faulty, correct problem before preceding. Perform each step,

in sequence, to test entire system, except for ECU. If

faulty ECU is suspected, replace with a known good one, and

retest system. Unplug ECU connector for all test steps.

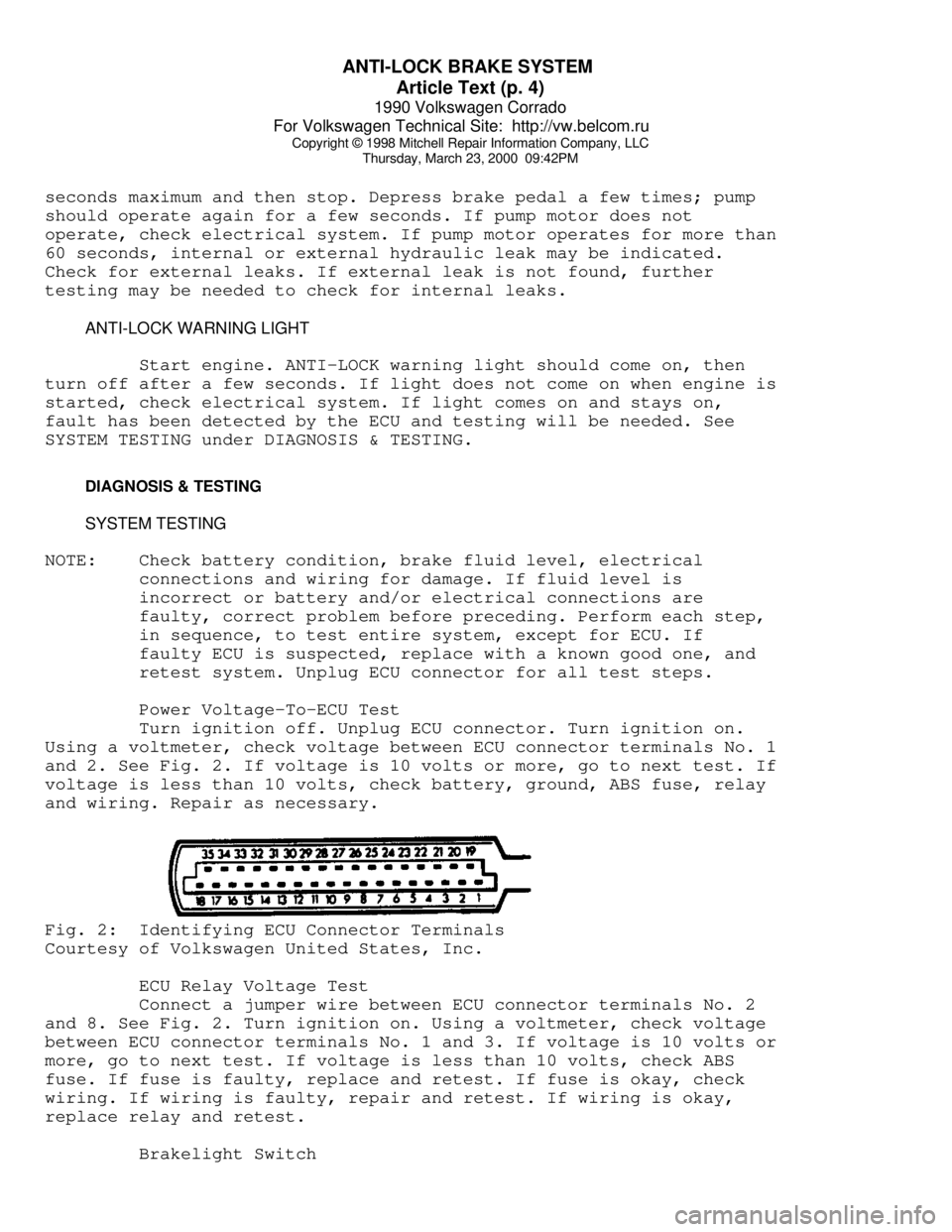

Power Voltage-To-ECU Test

Turn ignition off. Unplug ECU connector. Turn ignition on.

Using a voltmeter, check voltage between ECU connector terminals No. 1

and 2. See Fig. 2. If voltage is 10 volts or more, go to next test. If

voltage is less than 10 volts, check battery, ground, ABS fuse, relay

and wiring. Repair as necessary.Fig. 2: Identifying ECU Connector Terminals

Courtesy of Volkswagen United States, Inc.

ECU Relay Voltage Test

Connect a jumper wire between ECU connector terminals No. 2

and 8. See Fig. 2. Turn ignition on. Using a voltmeter, check voltage

between ECU connector terminals No. 1 and 3. If voltage is 10 volts or

more, go to next test. If voltage is less than 10 volts, check ABS

fuse. If fuse is faulty, replace and retest. If fuse is okay, check

wiring. If wiring is faulty, repair and retest. If wiring is okay,

replace relay and retest.

Brakelight Switch

Page 437 of 906

COMPUTER RELEARN PROCEDURES

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

"D" and allow engine to idle for one minute.

* Accelerate at normal throttle position (20-50%) until vehicle

shifts into top gear.

* Cruise at light to medium throttle.

* Decelerate to a stop, allowing vehicle to downshift, and use

brakes normally.

* Process may be repeated as necessary.

Manual Transmission

* Place transmission in Neutral position.

* Ensure emergency brake has been set and all accessories

are turned off.

* Start engine and bring to normal operating temperature.

* Allow vehicle to idle in Neutral for one minute.

* Initial relearn is complete: process will be completed during

normal driving.

Some manufacturers identify a specific relearn procedure

which will help establish suitable driveability during relearn stage.

These procedures are especially important if vehicle is equipped with

and electronically controlled automatic transmission or transaxle.

Always complete procedure before returning vehicle to customer.

END OF ARTICLE

Page 439 of 906

D - ADJUSTMENTS

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

connected, timing mark on flywheel should appear at pointer in hole.

NOTE: Before checking engine timing, raise engine speed above 2100

RPM at least 4 times. This must be done each time ignition

is turned off and restarted to clear ECU memory and by-pass

hot-start, fast-idle function.

3) If an adjustment is needed, turn ignition off and loosen

distributor hold-down bolt (2.0L has 2 hold-down bolts) just enough to

move distributor by hand. Start engine and allow to idle. Turn

distributor until timing mark is aligned with pointer in bellhousing.

4) Stop engine and tighten hold down bolt to 18 ft. lbs. (24

N.m). On 2.0L tighten hold-down bolts to 87 INCH lbs. (10 N.m). Check

and readjust if necessary and install plastic plug in inspection hole.

VANAGON

1) Engine oil temperature must be 176ø F (80ø C). Connect

timing light and tachometer. Start engine and allow to idle. Check

ignition timing at 800-1000 RPM.

NOTE: Before checking engine timing, raise engine speed above 2100

RPM at least 4 times. This must be done each time ignition

is turned off and restarted to clear ECU memory and by-pass

hot-start, fast-idle function.

2) If an adjustment is needed, turn ignition off and loosen

distributor hold-down bolt just enough to move distributor by hand.

Remove connectors from idle stabilizer by squeezing connectors then

pulling apart. Plug idle stabilizer connectors together.

3) Start and allow engine to idle. Turn distributor until

notch on V-belt pulley matches separation in case. Set timing and RPM.

Reconnect electrical connectors to idle stabilizer. Tighten

distributor clamp bolt.

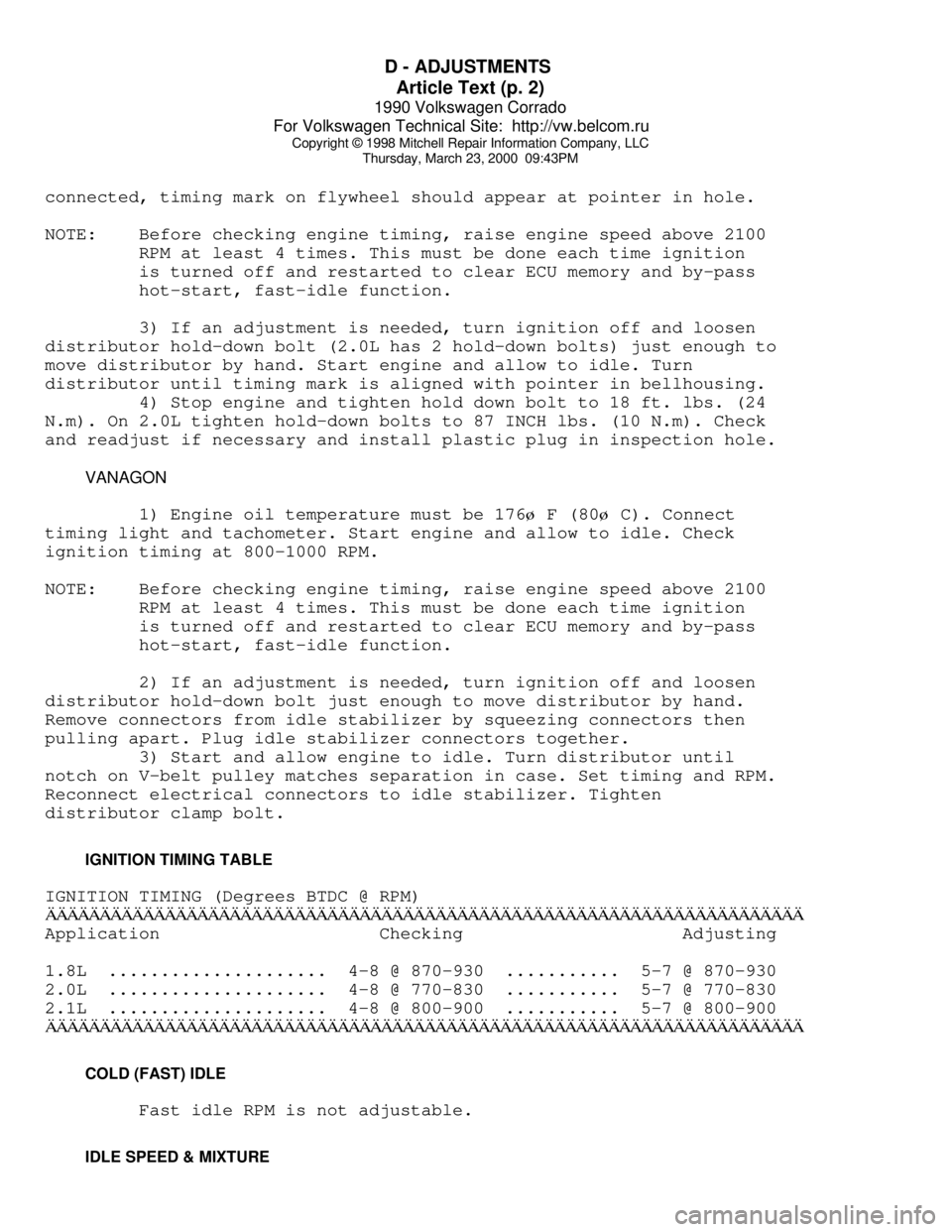

IGNITION TIMING TABLE

IGNITION TIMING (Degrees BTDC @ RPM)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Checking Adjusting

1.8L ..................... 4-8 @ 870-930 ........... 5-7 @ 870-930

2.0L ..................... 4-8 @ 770-830 ........... 5-7 @ 770-830

2.1L ..................... 4-8 @ 800-900 ........... 5-7 @ 800-900

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ COLD (FAST) IDLE

Fast idle RPM is not adjustable.

IDLE SPEED & MIXTURE

Page 444 of 906

D - ADJUSTMENTS

Article Text (p. 7)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:43PM

together. Turn idle speed screw until idle speed is correct. To adjust

timing, see CHECKING & ADJUSTING under IGNITION TIMING in this

article.

3) Ensure all vehicle electrical equipment is off. Place

exhaust gas analyzer in exhaust pipe. See IDLE SPEED & CO LEVEL table.

If adjustment is needed, go to next step.

4) If adjustment is needed in step 2). Remove intake air

sensor from engine. Center punch plug in CO adjusting hole. Using a

3/32" drill bit, drill hole 5/32" (4 mm) deep in center of plug.

Remove any metal shavings. Screw in a sheet metal screw and remove

plug using pliers to pry plug out.

5) Disconnect oxygen sensor connector on left side of engine

compartment (Green wire). Start engine. Set idle speed and CO reading

by alternately turning mixture and idle speed adjustment screws.

Reconnect oxygen sensor and idle stabilizer connectors. Let engine

idle for 2 minutes.

6) Check CO value. If incorrect, repeat adjusting procedure.

If correct turn ignition off. Drive in new adjusting hole plug flush

with air intake sensor. Remove all test equipment and reconnect all

hoses and wiring.

NOTE: Do not push down on adjustment screw and do not accelerate

engine with wrench in plate. Remove wrench after each

adjustment and accelerate engine briefly before measuring

current reading. Always adjust from a high to a low reading.

IDLE SPEED & CO LEVELÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Idle RPM CO Level

Cabriolet .................. 850-1000 ................... 0.3-1.2%

Fox ........................ 800-1000 ................... 0.3-1.2%

Golf ....................... 800-1000 ................... 0.3-1.2%

Golf GT ..................... 800-900 ................... 0.3-1.2%

GTI ........................ 800-1000 ................... 0.3-1.2%

Jetta ...................... 800-1000 ................... 0.3-1.2%

Vanagon ..................... 830-930 ................... 0.3-1.2%

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ THROTTLE STOP SCREW

NOTE: Stop screw is set by manufacturer and should not be moved.

If basic factory setting has been changed, turn throttle stop

screw counterclockwise until there is a gap between stop and screw.

Turn screw in until it just touches stop. Turn screw 1/2 turn (180

degrees) further. Check and adjust idle speed and CO.

IDLE & FULL THROTTLE SWITCH ADJUSTMENTS

IDLE SWITCH ADJUSTMENT DIGIFANT II (EXCEPT VANAGON)

Page 545 of 906

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 36)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

to ensure correct amount of oil has filled crankcase. Check oil level

while pre-oiling.

If pressure oiler is not available, disconnect ignition

system. Remove oil pressure sending unit and replace with oil pressure

test gauge. Using starter motor, rotate engine starter until gauge

shows normal oil pressure for several seconds. DO NOT crank engine

for more than 30 seconds to avoid starter motor damage.

Ensure oil pressure has reached the most distant point from

the oil pump. Reinstall oil pressure sending unit. Reconnect ignition

system.

INITIAL START-UP

Start the engine and operate engine at low speed while

checking for coolant, fuel and oil leaks. Stop engine. Recheck coolant

and oil level. Adjust if necessary.

CAMSHAFT

Break-in procedure is required when a new or reground

camshaft has been installed. Operate and maintain engine speed between

1500-2500 RPM for approximately 30 minutes. Procedure may vary due to

manufacturers recommendations.

PISTON RINGS

Piston rings require a break-in procedure to ensure seating

of rings to cylinder walls. Serious damage may occur to rings if

correct procedures are not followed.

Extremely high piston ring temperatures are produced obtained

during break-in process. If rings are exposed to excessively high RPM

or high cylinder pressures, ring damage can occur. Follow piston ring

manufacturer's recommended break-in procedure.

FINAL ADJUSTMENTS

Check or adjust ignition timing and dwell (if applicable).

Adjust valves (if necessary). Adjust carburetion or injection idle

speed and mixture. Retighten cylinder heads (if required). If

cylinder head or block is aluminum, retighten bolts when engine is

cold. Follow the engine manufacturer's recommended break-in procedure

and maintenance schedule for new engines.

NOTE: Some manufacturer's require that head bolts be retightened

after specified amount of operation. This must be done to

prevent head gasket failure.

END OF ARTICLE

Page 548 of 906

F - BASIC TESTING

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:44PM

CABRIOLET, GOLF GL/GTI, JETTA WITH AFC-DIGIFANT II

1) Install Fuel Pressure Gauge at service port on fuel

plenum. Fuel pressure gauge must be able to read 0-50 psi. Start

engine and allow it to idle. System fuel pressure should be

approximately 36 psi (2.5 kg/cmý).

2) Disconnect vacuum hose from top of the fuel pressure

regulator. Fuel pressure should increase to approximately 44 psi (3.0

kg/cm

ý). Turn engine off. After 10 minutes, residual pressure should

be 29 psi (2.0 kg/cm

ý). If system pressure is too high, the fuel

pressure regulator should be replaced.

3) If residual pressure is too low, run the engine until

system pressure is built up, pinch off Blue fuel return line. If

pressure holds, replace the fuel regulator.

CORRADO WITH AFC-DIGIFANT II

1) Install Fuel Pressure Gauge (VW 1318) and Adaptor (VW

3118-1 and 11) between the fuel distributor test port and pressure

switch. Bleed excess air from system cycling control valve with gauge

upside down.

2) Open fuel pressure gauge control lever, start engine and

allow to idle. Fuel pressure should be approximately 36.3 psi (2.5

kg/cm

ý). Pull hose off intake manifold fuel pressure should increase

to approximately 43.5 psi (3.0 kg/cm

ý).

3) Switch ignition off. After 10 minutes residual pressure

should be 29 psi (2.0 kg/cm

ý). If residual pressure is too low, run

the engine until system pressure is built up, pinch off Blue fuel

return line. If pressure holds, replace the fuel regulator.

If fuel pressure is low, check the following:

* Fuel lines for leaks.

* Fuel injectors leaking.

* Fuel pump check valve leaking.

* Pressure gauge stop-cock leaking.

FOX & JETTA GLI WITH CIS-E & CIS-MOTRONIC

1) Connect pressure gauge (VW 1318) between fuel distributor

port and the end of the fuel line to cold start valve. Ensure control

lever is in the closed position. See Fig. 1. Bleed excess air from

system by cycling control valve with gauge upside down.

2) Open fuel pressure gauge control lever. Start engine allow

to run. System fuel pressure should 75-82 psi (5.2-5.6 kg/cm

ý). On

Jetta GLi system pressure should be 89-95 psi (6.1-6.6 kg/cm

ý). If

system fuel pressure is low, perform fuel volume check. If fuel volume

is okay, replace fuel pressure regulator.

3) If fuel pressure is above specification, remove return

hose from pressure regulator and repeat test. If system pressure is

okay, check for restricted fuel return line. If pressure is incorrect,

replace fuel pressure regulator.

Page 597 of 906

I - SYSTEM/COMPONENT TESTS

Article Text (p. 10)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

FUEL CONTROL

COLD START VALVE (ALL MODELS EXCEPT VANAGON)

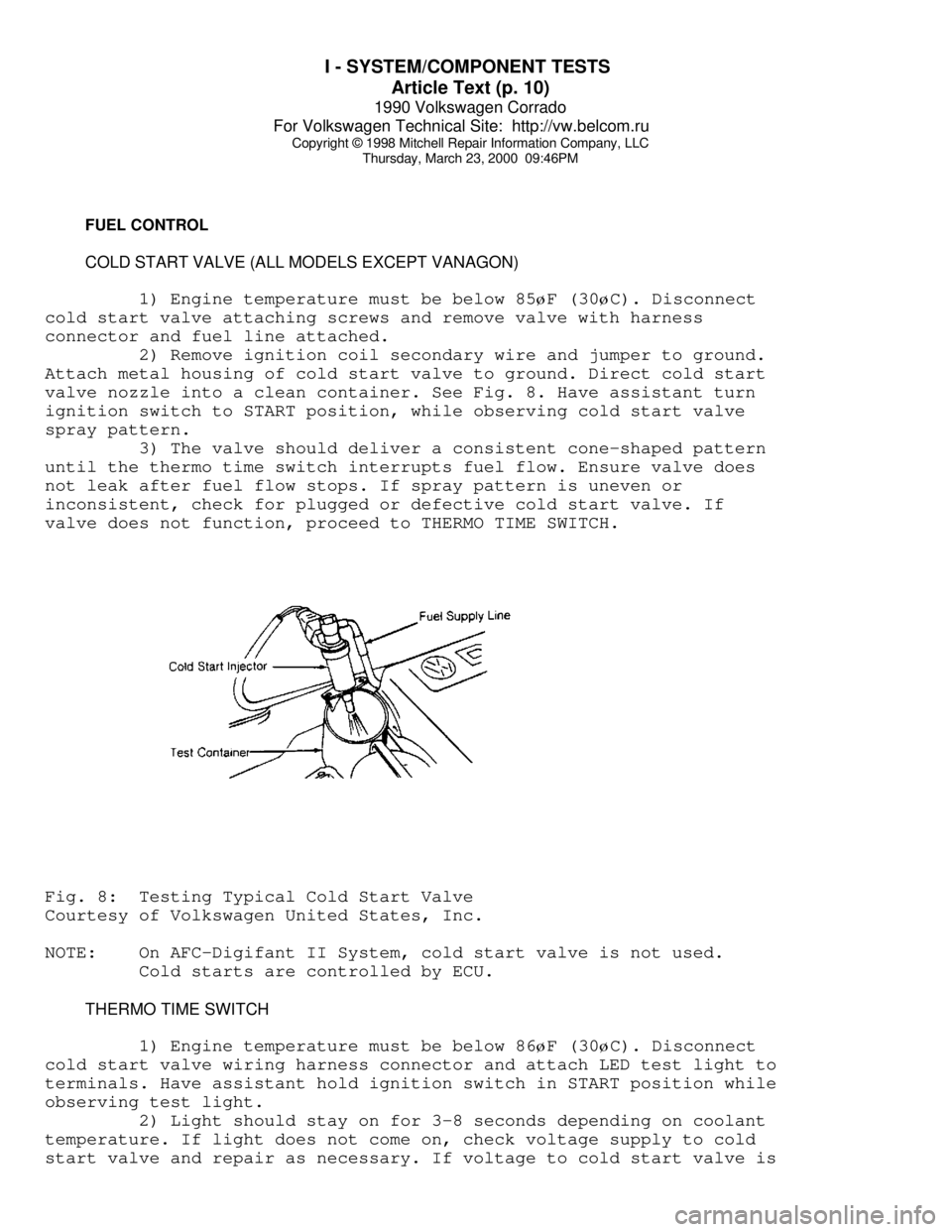

1) Engine temperature must be below 85øF (30øC). Disconnect

cold start valve attaching screws and remove valve with harness

connector and fuel line attached.

2) Remove ignition coil secondary wire and jumper to ground.

Attach metal housing of cold start valve to ground. Direct cold start

valve nozzle into a clean container. See Fig. 8. Have assistant turn

ignition switch to START position, while observing cold start valve

spray pattern.

3) The valve should deliver a consistent cone-shaped pattern

until the thermo time switch interrupts fuel flow. Ensure valve does

not leak after fuel flow stops. If spray pattern is uneven or

inconsistent, check for plugged or defective cold start valve. If

valve does not function, proceed to THERMO TIME SWITCH.Fig. 8: Testing Typical Cold Start Valve

Courtesy of Volkswagen United States, Inc.

NOTE: On AFC-Digifant II System, cold start valve is not used.

Cold starts are controlled by ECU.

THERMO TIME SWITCH

1) Engine temperature must be below 86

øF (30øC). Disconnect

cold start valve wiring harness connector and attach LED test light to

terminals. Have assistant hold ignition switch in START position while

observing test light.

2) Light should stay on for 3-8 seconds depending on coolant

temperature. If light does not come on, check voltage supply to cold

start valve and repair as necessary. If voltage to cold start valve is

Page 601 of 906

I - SYSTEM/COMPONENT TESTS

Article Text (p. 14)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:46PM

terminals. Disconnect Hall Effect sender wire harness connector from

distributor. Turn ignition on.

2) While observing DVOM reading, attach center terminal of

connector to ground for 3 seconds. Voltage reading should briefly

increase to 4.5 volts. If voltage reading did not increase, check

wiring for short or open circuit. If wiring is okay, replace ignition

control unit.

EMISSION SYSTEMS & SUB-SYSTEMS

EXHAUST GAS RECIRCULATION (EGR)

1) With engine idling, apply about 12 in. Hg to EGR valve

with a hand-held vacuum pump. Engine should run rough or stall. If

idle does not change, remove EGR valve and inspect for restricted port

passage. Clean as required.

2) If port is clean, apply about 12 in. Hg to EGR valve with

vacuum pump. If valve does not move, replace EGR valve. If valve

moves, go to next step.

3) Install EGR valve and new gasket. Connect vacuum gauge to

EGR vacuum line with a "T" fitting. Start engine and increase engine

speed to about 3000 RPM. Vacuum gauge should indicate vacuum. If okay,

test is complete. If not okay, vacuum source is plugged. Repair as

necessary and repeat test.

FUEL EVAPORATION

EVAP CANISTER BY-PASS VALVE (ALL MODELS EXCEPT VANAGON)

1) Remove both vent hoses and vacuum hose from canister by-

pass valve. Apply very low air pressure to vent hoses individually.

There should be no airflow. If air passes through, replace by-pass

valve.

2) Attach vacuum pump to vacuum hose and apply 5-10 in. Hg.

Apply low air pressure to vent hoses individually. Valve should be

open and air should flow. If air does not flow, replace by-pass valve.

EVAP CANISTER BY-PASS VALVE (VANAGON)

1) Start and warm engine to normal operating temperature.

Disconnect White nylon hose from rubber boot at rear of intake

manifold. Attach vacuum pump and apply 5-10 in. Hg. If vacuum holds,

control valve is okay.

2) If vacuum does not hold, disconnect Purple vacuum hose

from throttle body. Attach vacuum gauge. If less than one in. Hg is

present, replace control valve. If more than one in. Hg is present,

adjust throttle valve stop screw and repeat test.

Page 676 of 906

N - REMOVE/INSTALL/OVERHAUL

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:49PM

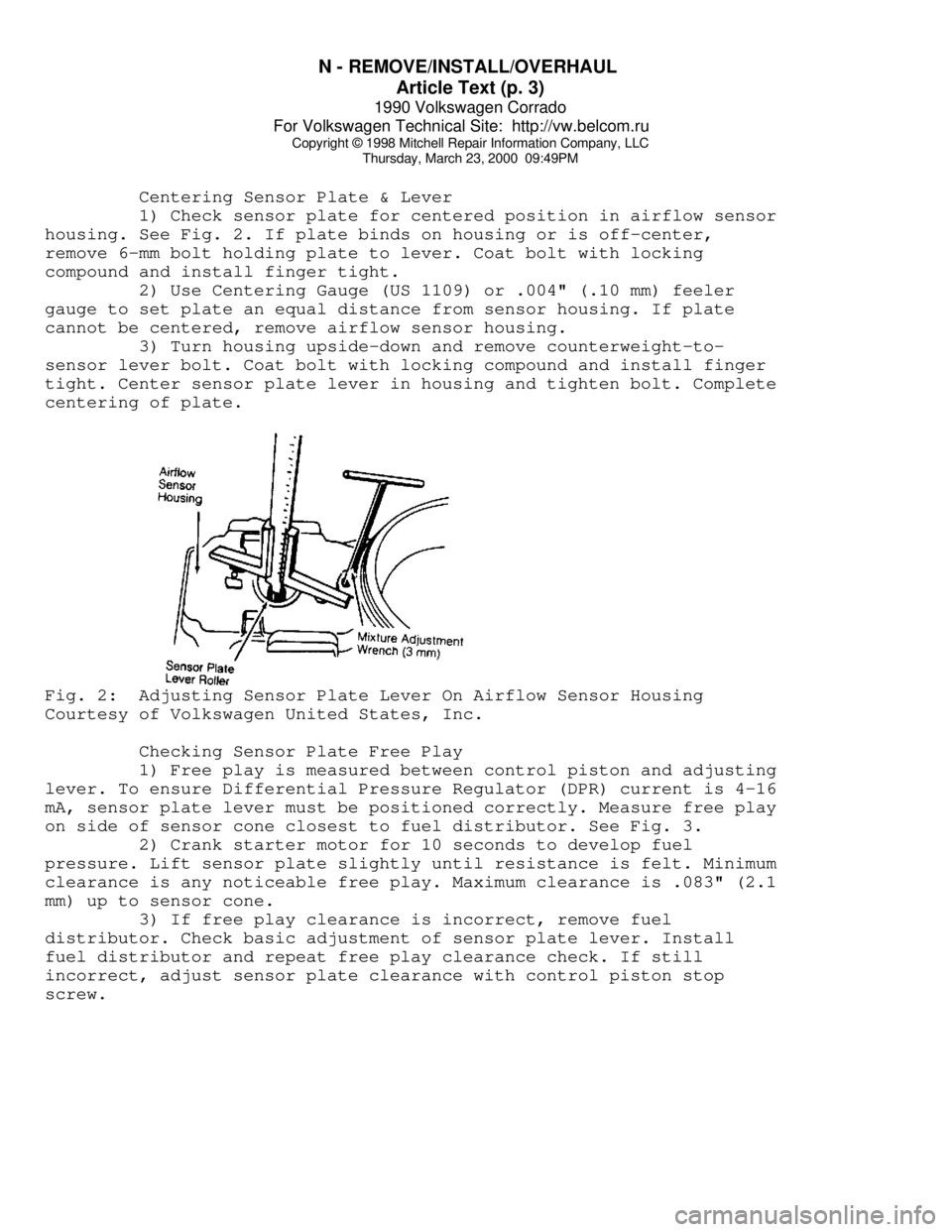

Centering Sensor Plate & Lever

1) Check sensor plate for centered position in airflow sensor

housing. See Fig. 2. If plate binds on housing or is off-center,

remove 6-mm bolt holding plate to lever. Coat bolt with locking

compound and install finger tight.

2) Use Centering Gauge (US 1109) or .004" (.10 mm) feeler

gauge to set plate an equal distance from sensor housing. If plate

cannot be centered, remove airflow sensor housing.

3) Turn housing upside-down and remove counterweight-to-

sensor lever bolt. Coat bolt with locking compound and install finger

tight. Center sensor plate lever in housing and tighten bolt. Complete

centering of plate.Fig. 2: Adjusting Sensor Plate Lever On Airflow Sensor Housing

Courtesy of Volkswagen United States, Inc.

Checking Sensor Plate Free Play

1) Free play is measured between control piston and adjusting

lever. To ensure Differential Pressure Regulator (DPR) current is 4-16

mA, sensor plate lever must be positioned correctly. Measure free play

on side of sensor cone closest to fuel distributor. See Fig. 3.

2) Crank starter motor for 10 seconds to develop fuel

pressure. Lift sensor plate slightly until resistance is felt. Minimum

clearance is any noticeable free play. Maximum clearance is .083" (2.1

mm) up to sensor cone.

3) If free play clearance is incorrect, remove fuel

distributor. Check basic adjustment of sensor plate lever. Install

fuel distributor and repeat free play clearance check. If still

incorrect, adjust sensor plate clearance with control piston stop

screw.