width VOLKSWAGEN CORRADO 1993 User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 551 of 920

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 22)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM

rotated.

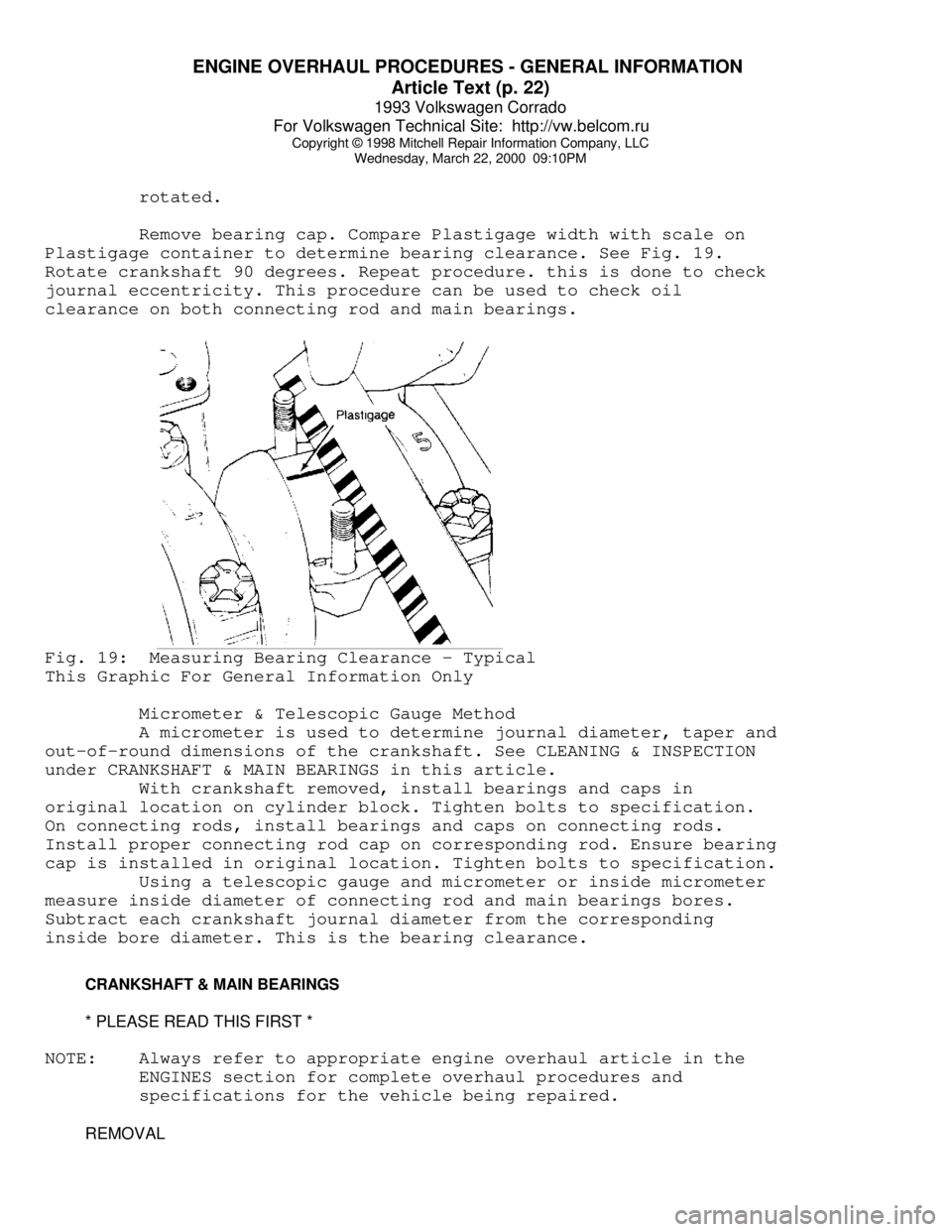

Remove bearing cap. Compare Plastigage width with scale on

Plastigage container to determine bearing clearance. See Fig. 19.

Rotate crankshaft 90 degrees. Repeat procedure. this is done to check

journal eccentricity. This procedure can be used to check oil

clearance on both connecting rod and main bearings.Fig. 19: Measuring Bearing Clearance - Typical

This Graphic For General Information Only

Micrometer & Telescopic Gauge Method

A micrometer is used to determine journal diameter, taper and

out-of-round dimensions of the crankshaft. See CLEANING & INSPECTION

under CRANKSHAFT & MAIN BEARINGS in this article.

With crankshaft removed, install bearings and caps in

original location on cylinder block. Tighten bolts to specification.

On connecting rods, install bearings and caps on connecting rods.

Install proper connecting rod cap on corresponding rod. Ensure bearing

cap is installed in original location. Tighten bolts to specification.

Using a telescopic gauge and micrometer or inside micrometer

measure inside diameter of connecting rod and main bearings bores.

Subtract each crankshaft journal diameter from the corresponding

inside bore diameter. This is the bearing clearance.

CRANKSHAFT & MAIN BEARINGS

* PLEASE READ THIS FIRST *

NOTE: Always refer to appropriate engine overhaul article in the

ENGINES section for complete overhaul procedures and

specifications for the vehicle being repaired.

REMOVAL

Page 555 of 920

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

Article Text (p. 26)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:10PM

CYLINDER BORE INSPECTION

Inspect the bore for scuffing or roughness. Cylinder bore

is dimensionally checked for out-of-round and taper using dial bore

gauge. For determining out-of-round, measure cylinder parallel and

perpendicular to the block centerline. Difference in the 2 readings

is the bore out-of-round. Cylinder bore must be checked at top, middle

and bottom of piston travel area.

Bore taper is obtained by measuring bore at the top and

bottom. If wear has exceeded allowable limits, block must be honed

or bored to next available oversize piston dimension.

CYLINDER HONING

Cylinder must be properly honed to allow new piston rings to

properly seat. Cross-hatching at correct angle and depth is critical

to lubrication of cylinder walls and pistons.

A flexible drive hone and power drill are commonly used.

Drive hone must be lubricated during operation. Mix equal parts of

kerosene and SAE 20w engine oil for lubrication.

Apply lubrication to cylinder wall. Operate cylinder hone

from top to bottom of cylinder using even strokes to produce 45 degree

cross-hatch pattern on the cylinder wall. DO NOT allow cylinder hone

to extend below cylinder during operation.

Recheck bore dimension after final honing. Wash cylinder

wall with hot soapy water to remove abrasive particles. Blow dry with

compressed air. Coat cleaned cylinder walls with lubricating oil.

DECK WARPAGE

Check deck for damage or warped head sealing surface. Place

a straightedge across gasket surface of the deck. Using feeler gauge,

measure clearance at center of straightedge. Measure across width and

length of cylinder block at several points.

If warpage exceeds specifications, deck must be resurfaced.

If warpage exceeds manufacturer's maximum tolerance for material

removal, replace block.

DECK HEIGHT

Distance from the crankshaft centerline to the block

deck is termed the deck height. Measure and record front and rear main

journals of crankshaft. To compute this distance, install crankshaft

and retain with center main bearing and cap only. Measure distance

from the crankshaft journal to the block deck, parallel to the

cylinder centerline.

Add one half of the main bearing journal diameter to distance

from crankshaft journal to block deck. This dimension should be

checked at front and rear of cylinder block. Both readings should be

the same.

If difference exceeds specifications, cylinder block must be

repaired or replaced. Deck height and warpage should be corrected at

Page 621 of 920

INSTRUMENT PANEL

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

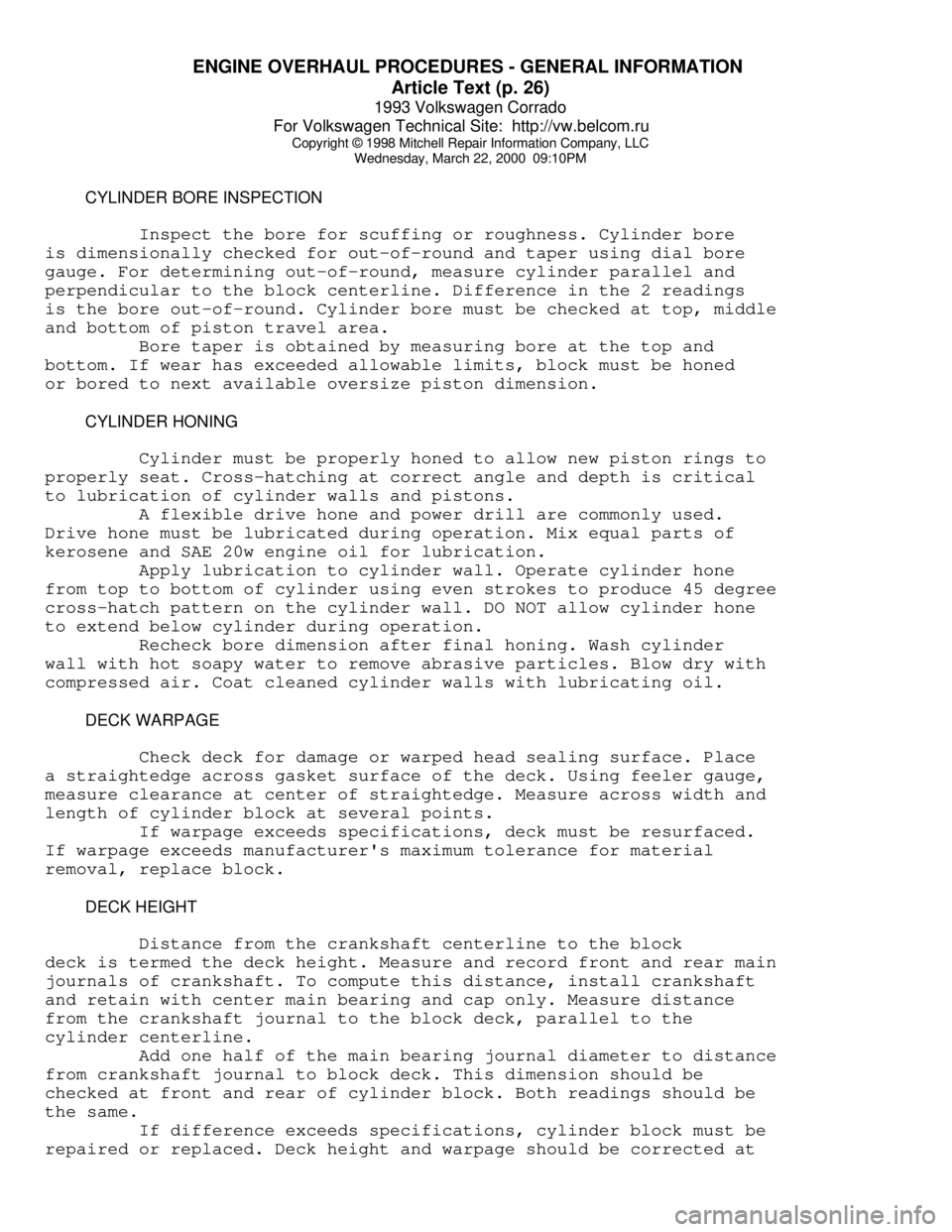

Wednesday, March 22, 2000 09:12PMFig. 2: Testing Voltage Regulator (Corrado SLC)

Courtesy of Volkswagen United States, Inc.

FUEL & TEMPERATURE GAUGE TEST

NOTE: Volkswagen Tester (VW 1301) is required for resistance

tests. Tester settings are numerical. Settings do not

indicate resistance in ohms. Manufacturer does not supply

resistance values in ohms.

1) Disconnect wire from fuel tank or temperature sending

unit. Connect VW Tester (VW 1301) between wire and ground. Turn

ignition on and allow 2 minutes for gauge reading to stabilize. Use

FUEL GAUGE TESTING or TEMPERATURE GAUGE TESTING table to compare gauge

reading. Gauge should be within one pointer width of specification.

2) If gauge needle does not move, check continuity between

sender wire and gauge. If needle moves but does not match

specifications, replace gauge. If gauge works correctly with tester

but not sending unit, replace sending unit.

FUEL GAUGE TESTING (1) TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Dial Setting Indicator

Corrado SLC ................... 50 .......................... Full

160 ......................... Half

350 ........................ Empty

(1) - Information for EuroVan not available from manufacturer.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTEMPERATURE GAUGE TESTING (1) TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Dial Setting Indicator

Page 684 of 920

SCHEDULED SERVICES

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:22PM

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR BAR WARNING

NOTE: For information on air bag DIAGNOSIS & TESTING or DISPOSAL

PROCEDURES, see AIR BAGS article in the ACCESSORIES/SAFETY

EQUIPMENT Section.

System circuit is grounded by 2 screws beneath the driver's

seat. DO NOT use these screws to ground any other accessory. DO NOT

ground any other components near this system.

AIR CONDITIONING SERVICING (1993 & LATER)

CAUTION: Avoid breathing R-134a refrigerant and PAG lubricant vapors,

exposure may irritate eyes, nose and throat. To remove

R-134a from system use R-134a recycling equipment that meets

SAE J2210 specifications. If accidental system discharge

occurs, ventilate work area before resuming service.

WARNING: R-134a service equipment or vehicle A/C systems SHOULD NOT

be pressure tested or leak tested with compressed air. Some

mixtures of air/R134a have shown to be combustible at

elevated pressures. These mixtures are dangerous and may

cause fire and/or explosions. See AIR CONDITIONING SERVICE

article in GENERAL INFORMATION section.

ANTI-LOCK BRAKE SYSTEM

The anti-lock brake system contains electronic equipment that

can be susceptible to interference caused by improperly installed or

high output radio transmitting equipment. Since this interference

could cause the possible loss of the anti-lock braking capability,

such equipment should be installed by qualified professionals.

On models equipped with anti-lock brake systems, ALWAYS

observe the following cautions:

* DO NOT attempt to bleed hydraulic system without first

referring to the appropriate ANTI-LOCK BRAKE SYSTEM article

in the BRAKES Section.

* DO NOT mix tire sizes. As long as tires remain close to the

original diameter, increasing the width is acceptable.

Rolling diameter must be identical for all 4 tires. Some

manufacturers recommend tires of the same brand, style and

type. Failure to follow this precaution may cause inaccurate

wheel speed readings.

* Use ONLY recommended brake fluids. DO NOT use silicone brake

fluids in an ABS-equipped vehicle.

BATTERY WARNING

WARNING: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

Page 823 of 920

TROUBLE SHOOTING - BASIC PROCEDURES

Article Text (p. 32)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

Loose rocker arms Retighten rocker arms,

See ENGINES

Excessive valve seat Reface valve seats, See

run-out ENGINES

Missing valve lock Install new valve lock

Excessively worn camshaft Replace camshaft, See

lobes ENGINES

Plugged valve lifter oil Eliminate restriction

holes or replace lifter

Faulty valve lifter check Replace lifter check

ball ball, See ENGINES

Rocker arm nut installed Remove and reinstall

upside down correctly

Valve lifter incorrect for Remove and replace

engine valve lifters

Faulty push rod seat or Replace plunger or push

lifter plunger rodÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄNoisy Valves Improper valve lash Re-adjust valve lash,

See ENGINES

Worn or dirty valve lifters Clean and/or replace

lifters

Worn valve guides Replace valve guides,

See ENGINES

Excessive valve seat or Reface seats or valve

face run-out face

Worn camshaft lobes Replace camshaft, See

ENGINES

Loose rocker arm studs Re-tighten rocker arm

studs, See ENGINES

Bent push rods Replace push rods, See

ENGINES

Broken valve springs Replace valve springs,

See ENGINES

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄBurned,Sticking Weak valve springs or Replace valves and/or

or Broken Valves warped valves springs, See ENGINES

Improper lifter clearance Re-adjust clearance or

replace lifters

Worn guides or improper Replace valve guides,

guide clearance See ENGINES

Out-of-round valve seats Re-grind valve seats

or improper seat width

Gum deposits on valve Remove deposits

stems, seats or guides

Improper spark timing Re-adjust spark timing

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄBroken Undersize pistons Replace with larger

Pistons/Rings pistons, See ENGINES

Wrong piston rings Replace with correct

rings, See ENGINES

Out-of-round cylinder bore Re-bore cylinder bore

Page 861 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

necessary to do a thorough job, or will a set of noid lights and a

multifunction DVOM do just as well?"

In the following text, we are going to look at what noid

lights and DVOMs do best, do not do very well, and when they can

mislead you. As you might suspect, the lab scope, with its ability to

look inside an active circuit, comes to the rescue by answering for

the deficiencies of these other tools.

OVERVIEW OF NOID LIGHT

The noid light is an excellent "quick and dirty" tool. It can

usually be hooked to a fuel injector harness fast and the flashing

light is easy to understand. It is a dependable way to identify a no-

pulse situation.

However, a noid light can be very deceptive in two cases:

* If the wrong one is used for the circuit being tested.

Beware: Just because a connector on a noid light fits the

harness does not mean it is the right one.

* If an injector driver is weak or a minor voltage drop is

present.

Use the Right Noid Light

In the following text we will look at what can happen if the

wrong noid light is used, why there are different types of noid lights

(besides differences with connectors), how to identify the types of

noid lights, and how to know the right type to use.

First, let's discuss what can happen if the incorrect type of

noid light is used. You might see:

* A dimly flashing light when it should be normal.

* A normal flashing light when it should be dim.

A noid light will flash dim if used on a lower voltage

circuit than it was designed for. A normally operating circuit would

appear underpowered, which could be misinterpreted as the cause of a

fuel starvation problem.

Here are the two circuit types that could cause this problem:

* Circuits with external injector resistors. Used predominately

on some Asian & European systems, they are used to reduce the

available voltage to an injector in order to limit the

current flow. This lower voltage can cause a dim flash on a

noid light designed for full voltage.

* Circuits with current controlled injector drivers (e.g. "Peak

and Hold"). Basically, this type of driver allows a quick

burst of voltage/current to flow and then throttles it back

significantly for the remainder of the pulse width duration.

If a noid light was designed for the other type of driver

(voltage controlled, e.g. "Saturated"), it will appear dim

because it is expecting full voltage/current to flow for the

entire duration of the pulse width.

Page 864 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

second, all measurements in between are averaged. Because a potential

voltage drop is visible for such a small amount of time, it gets

"averaged out", causing you to miss it.

Only a DVOM that has a "min-max" function that checks EVERY

MILLISECOND will catch this fault consistently (if used in that mode).

The Fluke 87 among others has this capability.

A "min-max" DVOM with a lower frequency of checking (100

millisecond) can miss the fault because it will probably check when

the injector is not on. This is especially true with current

controlled driver circuits. The Fluke 88, among others fall into this

category.

Outside of using a Fluke 87 (or equivalent) in the 1 mS "min-

max" mode, the only way to catch a voltage drop fault is with a lab

scope. You will be able to see a voltage drop as it happens.

One final note. It is important to be aware that an injector

circuit with a solenoid resistor will always show a voltage drop when

the circuit is energized. This is somewhat obvious and normal; it is a

designed-in voltage drop. What can be unexpected is what we already

covered--a voltage drop disappears when the circuit is unloaded. The

unloaded injector circuit will show normal battery voltage at the

injector. Remember this and do not get confused.

Checking Injector On-Time With Built-In Function

Several DVOMs have a feature that allows them to measure

injector on-time (mS pulse width). While they are accurate and fast to

hookup, they have three limitations you should be aware of:

* They only work on voltage controlled injector drivers (e.g

"Saturated Switch"), NOT on current controlled injector

drivers (e.g. "Peak & Hold").

* A few unusual conditions can cause inaccurate readings.

* Varying engine speeds can result in inaccurate readings.

Regarding the first limitation, DVOMs need a well-defined

injector pulse in order to determine when the injector turns ON and

OFF. Voltage controlled drivers provide this because of their simple

switch-like operation. They completely close the circuit for the

entire duration of the pulse. This is easy for the DVOM to interpret.

The other type of driver, the current controlled type, start

off well by completely closing the circuit (until the injector pintle

opens), but then they throttle back the voltage/current for the

duration of the pulse. The DVOM understands the beginning of the pulse

but it cannot figure out the throttling action. In other words, it

cannot distinguish the throttling from an open circuit (de-energized)

condition.

Yet current controlled injectors will still yield a

millisecond on-time reading on these DVOMs. You will find it is also

always the same, regardless of the operating conditions. This is

because it is only measuring the initial completely-closed circuit on-

time, which always takes the same amount of time (to lift the injector

pintle off its seat). So even though you get a reading, it is useless.

The second limitation is that a few erratic conditions can

Page 866 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

everything together it does not miss anything (though this is also a

severe weakness that we will look at later). If an injector has a

fault where it occasionally skips a pulse, the meter registers it and

the reading changes accordingly.

Let's go back to figuring out dwell/duty readings by using

injector on-time specification. This is not generally practical, but

we will cover it for completeness. You NEED to know three things:

* Injector mS on-time specification.

* Engine RPM when specification is valid.

* How many times the injectors fire per crankshaft revolution.

The first two are self-explanatory. The last one may require

some research into whether it is a bank-fire type that injects every

360ø of crankshaft rotation, a bank-fire that injects every 720ø, or

an SFI that injects every 720

ø. Many manufacturers do not release this

data so you may have to figure it out yourself with a frequency meter.

Here are the four complete steps to convert millisecond on-

time:

1) Determine the injector pulse width and RPM it was obtained

at. Let's say the specification is for one millisecond of on-time at a

hot idle of 600 RPM.

2) Determine injector firing method for the complete 4 stroke

cycle. Let's say this is a 360

ø bank-fired, meaning an injector fires

each and every crankshaft revolution.

3) Determine how many times the injector will fire at the

specified engine speed (600 RPM) in a fixed time period. We will use

100 milliseconds because it is easy to use.

Six hundred crankshaft Revolutions Per Minute (RPM) divided

by 60 seconds equals 10 revolutions per second.

Multiplying 10 times .100 yields one; the crankshaft turns

one time in 100 milliseconds. With exactly one crankshaft rotation in

100 milliseconds, we know that the injector fires exactly one time.

4) Determine the ratio of injector on-time vs. off-time in

the fixed time period, then figure duty cycle and/or dwell. The

injector fires one time for a total of one millisecond in any given

100 millisecond period.

One hundred minus one equals 99. We have a 99% duty cycle. If

we wanted to know the dwell (on 6 cylinder scale), multiple 99% times

.6; this equals 59.4

ø dwell.

Weaknesses of Dwell/Duty Meter

The weaknesses are significant. First, there is no one-to-one

correspondence to actual mS on-time. No manufacturer releases

dwell/duty data, and it is time-consuming to convert the mS on-time

readings. Besides, there can be a large degree of error because the

conversion forces you to assume that the injector(s) are always firing

at the same rate for the same period of time. This can be a dangerous

assumption.

Second, all level of detail is lost in the averaging process.

This is the primary weakness. You cannot see the details you need to

make a confident diagnosis.

Page 867 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

Here is one example. Imagine a vehicle that has a faulty

injector driver that occasionally skips an injector pulse. Every

skipped pulse means that that cylinder does not fire, thus unburned O2

gets pushed into the exhaust and passes the O2 sensor. The O2 sensor

indicates lean, so the computer fattens up the mixture to compensate

for the supposed "lean" condition.

A connected dwell/duty meter would see the fattened pulse

width but would also see the skipped pulses. It would tally both and

likely come back with a reading that indicated the "pulse width" was

within specification because the rich mixture and missing pulses

offset each other.

This situation is not a far-fetched scenario. Some early GM

3800 engines were suffering from exactly this. The point is that a

lack of detail could cause misdiagnosis.

As you might have guessed, a lab scope would not miss this.

RELATIONSHIP BETWEEN DWELL & DUTY CYCLE READINGS TABLE (1)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDwell Meter (2) Duty Cycle Meter

1

ø .................................................... 1%

15

ø .................................................. 25%

30

ø .................................................. 50%

45

ø .................................................. 75%

60

ø ................................................. 100%

(1) - These are just some examples for your understanding.

It is okay to fill in the gaps.

(2) - Dwell meter on the six-cylinder scale.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ THE TWO TYPES OF INJECTOR DRIVERS

OVERVIEW

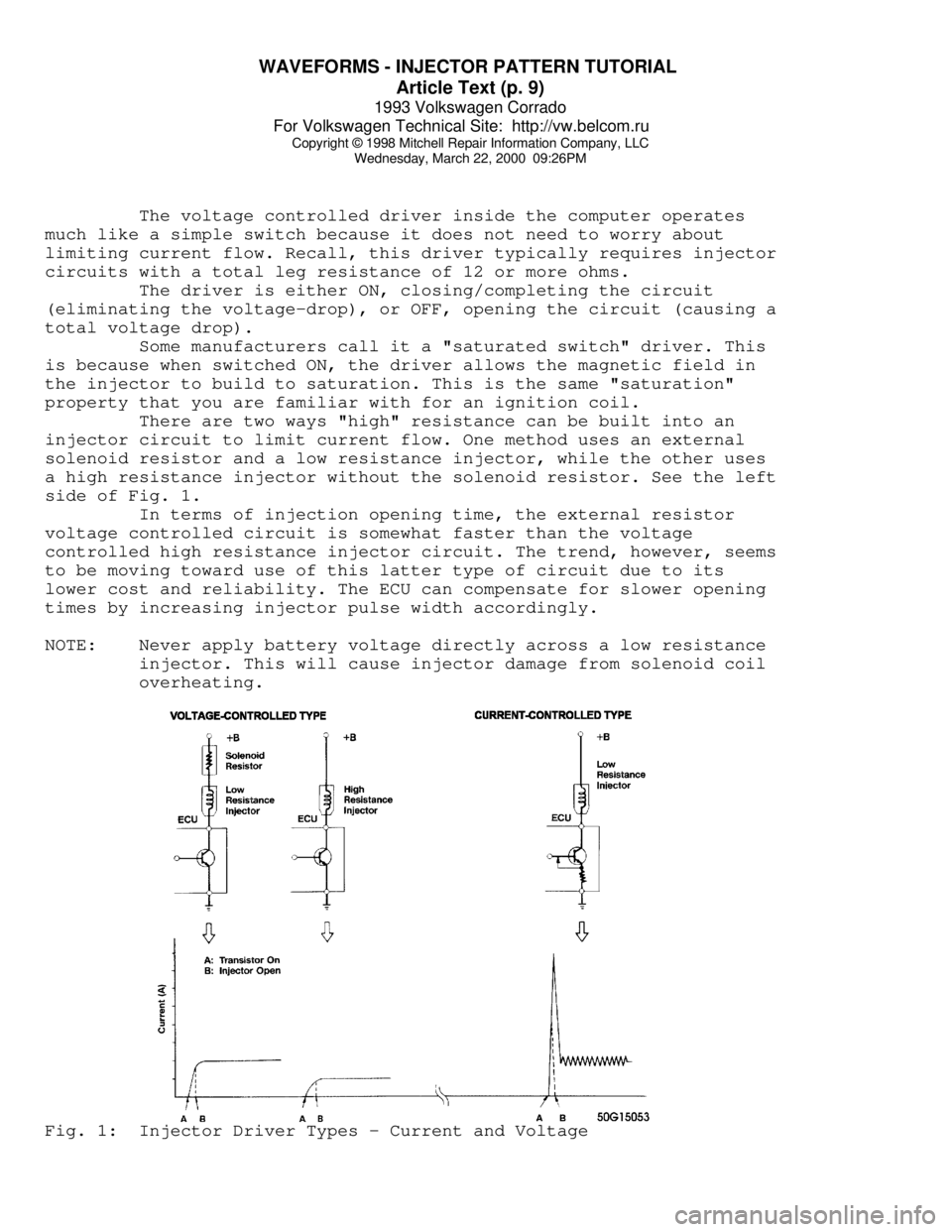

There are two types of transistor driver circuits used to

operate electric fuel injectors: voltage controlled and current

controlled. The voltage controlled type is sometimes called a

"saturated switch" driver, while the current controlled type is

sometimes known as a "peak and hold" driver.

The basic difference between the two is the total resistance

of the injector circuit. Roughly speaking, if a particular leg in an

injector circuit has total resistance of 12 or more ohms, a voltage

control driver is used. If less than 12 ohms, a current control driver

is used.

It is a question of what is going to do the job of limiting

the current flow in the injector circuit; the inherent "high"

resistance in the injector circuit, or the transistor driver. Without

some form of control, the current flow through the injector would

cause the solenoid coil to overheat and result in a damaged injector.

VOLTAGE CONTROLLED CIRCUIT ("SATURATED SWITCH")

Page 868 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 9)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

The voltage controlled driver inside the computer operates

much like a simple switch because it does not need to worry about

limiting current flow. Recall, this driver typically requires injector

circuits with a total leg resistance of 12 or more ohms.

The driver is either ON, closing/completing the circuit

(eliminating the voltage-drop), or OFF, opening the circuit (causing a

total voltage drop).

Some manufacturers call it a "saturated switch" driver. This

is because when switched ON, the driver allows the magnetic field in

the injector to build to saturation. This is the same "saturation"

property that you are familiar with for an ignition coil.

There are two ways "high" resistance can be built into an

injector circuit to limit current flow. One method uses an external

solenoid resistor and a low resistance injector, while the other uses

a high resistance injector without the solenoid resistor. See the left

side of Fig. 1.

In terms of injection opening time, the external resistor

voltage controlled circuit is somewhat faster than the voltage

controlled high resistance injector circuit. The trend, however, seems

to be moving toward use of this latter type of circuit due to its

lower cost and reliability. The ECU can compensate for slower opening

times by increasing injector pulse width accordingly.

NOTE: Never apply battery voltage directly across a low resistance

injector. This will cause injector damage from solenoid coil

overheating.Fig. 1: Injector Driver Types - Current and Voltage