engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 855 of 920

TROUBLE SHOOTING - BASIC PROCEDURES

Article Text (p. 64)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

Carburetor setting too lean Readjust mixture

setting, see ENGINE

PERFORMANCE

Vacuum leak Eliminate vacuum leak

EGR valve malfunction Replace EGR valveÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄPoor Gasoline Cracked or broken vacuum Replace vacuum hoses

Mileage hoses

Vacuum leaks Repair vacuum leaks

Defective ignition wires Replace wires

Incorrect choke setting Readjust setting, see

ENGINE PERFORMANCE

Defective vacuum advance Replace vacuum advance

Defective spark plugs Replace spark plugs

Binding carburetor power Eliminate binding

piston

Dirt in carburetor jets Clean and/or replace

jets

Incorrect float adjustment Readjust float

setting, see FUEL

Defective power valve Replace power valve,

see ENGINE PERFORMANCE

Incorrect idle speed Readjust idle speed

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEngine Stalls Improper float level Readjust float level

Leaking needle valve and Replace needle valve

seat and seat

Vacuum leaks Eliminate vacuum

leaks

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ VACUUM PUMP - DIESEL TROUBLE SHOOTING

WARNING: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle

configuration. The purpose of this Trouble Shooting

information is to provide a list of common causes to

Page 856 of 920

TROUBLE SHOOTING - BASIC PROCEDURES

Article Text (p. 65)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

problem symptoms. For model-specific Trouble Shooting,

refer to SUBJECT, DIAGNOSTIC, or TESTING articles available

in the section(s) you are accessing.

NOTE: Diesel engines mechanical diagnosis is the same as gasoline

engines for items such as noisy valves, bearings, pistons,

etc. The following trouble shooting covers only items

pertaining to diesel engines.

VACUUM PUMP (DIESEL) TROUBLE SHOOTING CHARTÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCONDITION POSSIBLE CAUSE CORRECTION

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄExcessive Noise Loose pump-to-drive Tighten screws

assembly screws

Loose tube on pump assembly Tighten tube

Valves not functioning Replace valves

properly

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄOil Leakage Loose end plug Tighten end plug

Bad seal crimp Remove and re-crimp

seal

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ WHEEL ALIGNMENT TROUBLE SHOOTING

WARNING: This is GENERAL information. This article is not intended

to be specific to any unique situation or individual vehicle

configuration. The purpose of this Trouble Shooting

information is to provide a list of common causes to

problem symptoms. For model-specific Trouble Shooting,

refer to SUBJECT, DIAGNOSTIC, or TESTING articles available

in the section(s) you are accessing.

BASIC WHEEL ALIGNMENT TROUBLE SHOOTING CHART

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄCONDITION POSSIBLE CAUSE CORRECTION

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄPremature Tire Improper tire inflation Check tire pressure

Wear

Front alignment out of See ALIGNMENT SPECS in

tolerance WHEEL ALIGNMENT section

Suspension components worn See SUSPENSION section

Steering system components See STEERING section

worn

Improper standing height See WHEEL ALIGNMENT

Uneven or sagging springs See SUSPENSION section

Page 860 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

ARTICLE BEGINNING

GENERAL INFORMATION

Waveforms - Injector Pattern Tutorial

* PLEASE READ THIS FIRST *

NOTE: This article is intended for general information purposes

only. This information may not apply to all makes and models.

PURPOSE OF THIS ARTICLE

Learning how to interpret injector drive patterns from a Lab

Scope can be like learning ignition patterns all over again. This

article exists to ease you into becoming a skilled injector pattern

interpreter.

You will learn:

* How a DVOM and noid light fall short of a lab scope.

* The two types of injector driver circuits, voltage controlled

& current controlled.

* The two ways injector circuits can be wired, constant

ground/switched power & constant power/switched ground.

* The two different pattern types you can use to diagnose with,

voltage & current.

* All the valuable details injector patterns can reveal.

SCOPE OF THIS ARTICLE

This is NOT a manufacturer specific article. All different

types of systems are covered here, regardless of the specific

year/make/model/engine.

The reason for such broad coverage is because there are only

a few basic ways to operate a solenoid-type injector. By understanding

the fundamental principles, you will understand all the major points

of injector patterns you encounter. Of course there are minor

differences in each specific system, but that is where a waveform

library helps out.

If this is confusing, consider a secondary ignition pattern.

Even though there are many different implementations, each still has

a primary voltage turn-on, firing line, spark line, etc.

If specific waveforms are available in On Demand for the

engine and vehicle you are working on, you will find them in the

Engine Performance section under the Engine Performance category.

IS A LAB SCOPE NECESSARY?

INTRODUCTION

You probably have several tools at your disposal to diagnose

injector circuits. But you might have questioned "Is a lab scope

Page 864 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 5)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

second, all measurements in between are averaged. Because a potential

voltage drop is visible for such a small amount of time, it gets

"averaged out", causing you to miss it.

Only a DVOM that has a "min-max" function that checks EVERY

MILLISECOND will catch this fault consistently (if used in that mode).

The Fluke 87 among others has this capability.

A "min-max" DVOM with a lower frequency of checking (100

millisecond) can miss the fault because it will probably check when

the injector is not on. This is especially true with current

controlled driver circuits. The Fluke 88, among others fall into this

category.

Outside of using a Fluke 87 (or equivalent) in the 1 mS "min-

max" mode, the only way to catch a voltage drop fault is with a lab

scope. You will be able to see a voltage drop as it happens.

One final note. It is important to be aware that an injector

circuit with a solenoid resistor will always show a voltage drop when

the circuit is energized. This is somewhat obvious and normal; it is a

designed-in voltage drop. What can be unexpected is what we already

covered--a voltage drop disappears when the circuit is unloaded. The

unloaded injector circuit will show normal battery voltage at the

injector. Remember this and do not get confused.

Checking Injector On-Time With Built-In Function

Several DVOMs have a feature that allows them to measure

injector on-time (mS pulse width). While they are accurate and fast to

hookup, they have three limitations you should be aware of:

* They only work on voltage controlled injector drivers (e.g

"Saturated Switch"), NOT on current controlled injector

drivers (e.g. "Peak & Hold").

* A few unusual conditions can cause inaccurate readings.

* Varying engine speeds can result in inaccurate readings.

Regarding the first limitation, DVOMs need a well-defined

injector pulse in order to determine when the injector turns ON and

OFF. Voltage controlled drivers provide this because of their simple

switch-like operation. They completely close the circuit for the

entire duration of the pulse. This is easy for the DVOM to interpret.

The other type of driver, the current controlled type, start

off well by completely closing the circuit (until the injector pintle

opens), but then they throttle back the voltage/current for the

duration of the pulse. The DVOM understands the beginning of the pulse

but it cannot figure out the throttling action. In other words, it

cannot distinguish the throttling from an open circuit (de-energized)

condition.

Yet current controlled injectors will still yield a

millisecond on-time reading on these DVOMs. You will find it is also

always the same, regardless of the operating conditions. This is

because it is only measuring the initial completely-closed circuit on-

time, which always takes the same amount of time (to lift the injector

pintle off its seat). So even though you get a reading, it is useless.

The second limitation is that a few erratic conditions can

Page 865 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

cause inaccurate readings. This is because of a DVOM's slow display

rate; roughly two to five times a second. As we covered earlier,

measurements in between display updates get averaged. So conditions

like skipped injector pulses or intermittent long/short injector

pulses tend to get "averaged out", which will cause you to miss

important details.

The last limitation is that varying engine speeds can result

in inaccurate readings. This is caused by the quickly shifting

injector on-time as the engine load varies, or the RPM moves from a

state of acceleration to stabilization, or similar situations. It too

is caused by the averaging of all measurements in between DVOM display

periods. You can avoid this by checking on-time when there are no RPM

or load changes.

A lab scope allows you to overcome each one of these

limitations.

Checking Injector On-Time With Dwell Or Duty

If no tool is available to directly measure injector

millisecond on-time measurement, some techs use a simple DVOM dwell or

duty cycle functions as a replacement.

While this is an approach of last resort, it does provide

benefits. We will discuss the strengths and weaknesses in a moment,

but first we will look at how a duty cycle meter and dwell meter work.

How A Duty Cycle Meter and Dwell Meter Work

All readings are obtained by comparing how long something has

been OFF to how long it has been ON in a fixed time period. A dwell

meter and duty cycle meter actually come up with the same answers

using different scales. You can convert freely between them. See

RELATIONSHIP BETWEEN DWELL & DUTY CYCLE READINGS TABLE.

The DVOM display updates roughly one time a second, although

some DVOMs can be a little faster or slower. All measurements during

this update period are tallied inside the DVOM as ON time or OFF time,

and then the total ratio is displayed as either a percentage (duty

cycle) or degrees (dwell meter).

For example, let's say a DVOM had an update rate of exactly 1

second (1000 milliseconds). Let's also say that it has been

measuring/tallying an injector circuit that had been ON a total of 250

mS out of the 1000 mS. That is a ratio of one-quarter, which would be

displayed as 25% duty cycle or 15ø dwell (six-cylinder scale). Note

that most duty cycle meters can reverse the readings by selecting the

positive or negative slope to trigger on. If this reading were

reversed, a duty cycle meter would display 75%.

Strengths of Dwell/Duty Meter

The obvious strength of a dwell/duty meter is that you can

compare injector on-time against a known-good reading. This is the

only practical way to use a dwell/duty meter, but requires you to have

known-good values to compare against.

Another strength is that you can roughly convert injector mS

on-time into dwell reading with some computations.

A final strength is that because the meter averages

Page 866 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 7)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

everything together it does not miss anything (though this is also a

severe weakness that we will look at later). If an injector has a

fault where it occasionally skips a pulse, the meter registers it and

the reading changes accordingly.

Let's go back to figuring out dwell/duty readings by using

injector on-time specification. This is not generally practical, but

we will cover it for completeness. You NEED to know three things:

* Injector mS on-time specification.

* Engine RPM when specification is valid.

* How many times the injectors fire per crankshaft revolution.

The first two are self-explanatory. The last one may require

some research into whether it is a bank-fire type that injects every

360ø of crankshaft rotation, a bank-fire that injects every 720ø, or

an SFI that injects every 720

ø. Many manufacturers do not release this

data so you may have to figure it out yourself with a frequency meter.

Here are the four complete steps to convert millisecond on-

time:

1) Determine the injector pulse width and RPM it was obtained

at. Let's say the specification is for one millisecond of on-time at a

hot idle of 600 RPM.

2) Determine injector firing method for the complete 4 stroke

cycle. Let's say this is a 360

ø bank-fired, meaning an injector fires

each and every crankshaft revolution.

3) Determine how many times the injector will fire at the

specified engine speed (600 RPM) in a fixed time period. We will use

100 milliseconds because it is easy to use.

Six hundred crankshaft Revolutions Per Minute (RPM) divided

by 60 seconds equals 10 revolutions per second.

Multiplying 10 times .100 yields one; the crankshaft turns

one time in 100 milliseconds. With exactly one crankshaft rotation in

100 milliseconds, we know that the injector fires exactly one time.

4) Determine the ratio of injector on-time vs. off-time in

the fixed time period, then figure duty cycle and/or dwell. The

injector fires one time for a total of one millisecond in any given

100 millisecond period.

One hundred minus one equals 99. We have a 99% duty cycle. If

we wanted to know the dwell (on 6 cylinder scale), multiple 99% times

.6; this equals 59.4

ø dwell.

Weaknesses of Dwell/Duty Meter

The weaknesses are significant. First, there is no one-to-one

correspondence to actual mS on-time. No manufacturer releases

dwell/duty data, and it is time-consuming to convert the mS on-time

readings. Besides, there can be a large degree of error because the

conversion forces you to assume that the injector(s) are always firing

at the same rate for the same period of time. This can be a dangerous

assumption.

Second, all level of detail is lost in the averaging process.

This is the primary weakness. You cannot see the details you need to

make a confident diagnosis.

Page 867 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 8)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

Here is one example. Imagine a vehicle that has a faulty

injector driver that occasionally skips an injector pulse. Every

skipped pulse means that that cylinder does not fire, thus unburned O2

gets pushed into the exhaust and passes the O2 sensor. The O2 sensor

indicates lean, so the computer fattens up the mixture to compensate

for the supposed "lean" condition.

A connected dwell/duty meter would see the fattened pulse

width but would also see the skipped pulses. It would tally both and

likely come back with a reading that indicated the "pulse width" was

within specification because the rich mixture and missing pulses

offset each other.

This situation is not a far-fetched scenario. Some early GM

3800 engines were suffering from exactly this. The point is that a

lack of detail could cause misdiagnosis.

As you might have guessed, a lab scope would not miss this.

RELATIONSHIP BETWEEN DWELL & DUTY CYCLE READINGS TABLE (1)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄDwell Meter (2) Duty Cycle Meter

1

ø .................................................... 1%

15

ø .................................................. 25%

30

ø .................................................. 50%

45

ø .................................................. 75%

60

ø ................................................. 100%

(1) - These are just some examples for your understanding.

It is okay to fill in the gaps.

(2) - Dwell meter on the six-cylinder scale.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ THE TWO TYPES OF INJECTOR DRIVERS

OVERVIEW

There are two types of transistor driver circuits used to

operate electric fuel injectors: voltage controlled and current

controlled. The voltage controlled type is sometimes called a

"saturated switch" driver, while the current controlled type is

sometimes known as a "peak and hold" driver.

The basic difference between the two is the total resistance

of the injector circuit. Roughly speaking, if a particular leg in an

injector circuit has total resistance of 12 or more ohms, a voltage

control driver is used. If less than 12 ohms, a current control driver

is used.

It is a question of what is going to do the job of limiting

the current flow in the injector circuit; the inherent "high"

resistance in the injector circuit, or the transistor driver. Without

some form of control, the current flow through the injector would

cause the solenoid coil to overheat and result in a damaged injector.

VOLTAGE CONTROLLED CIRCUIT ("SATURATED SWITCH")

Page 875 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 16)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

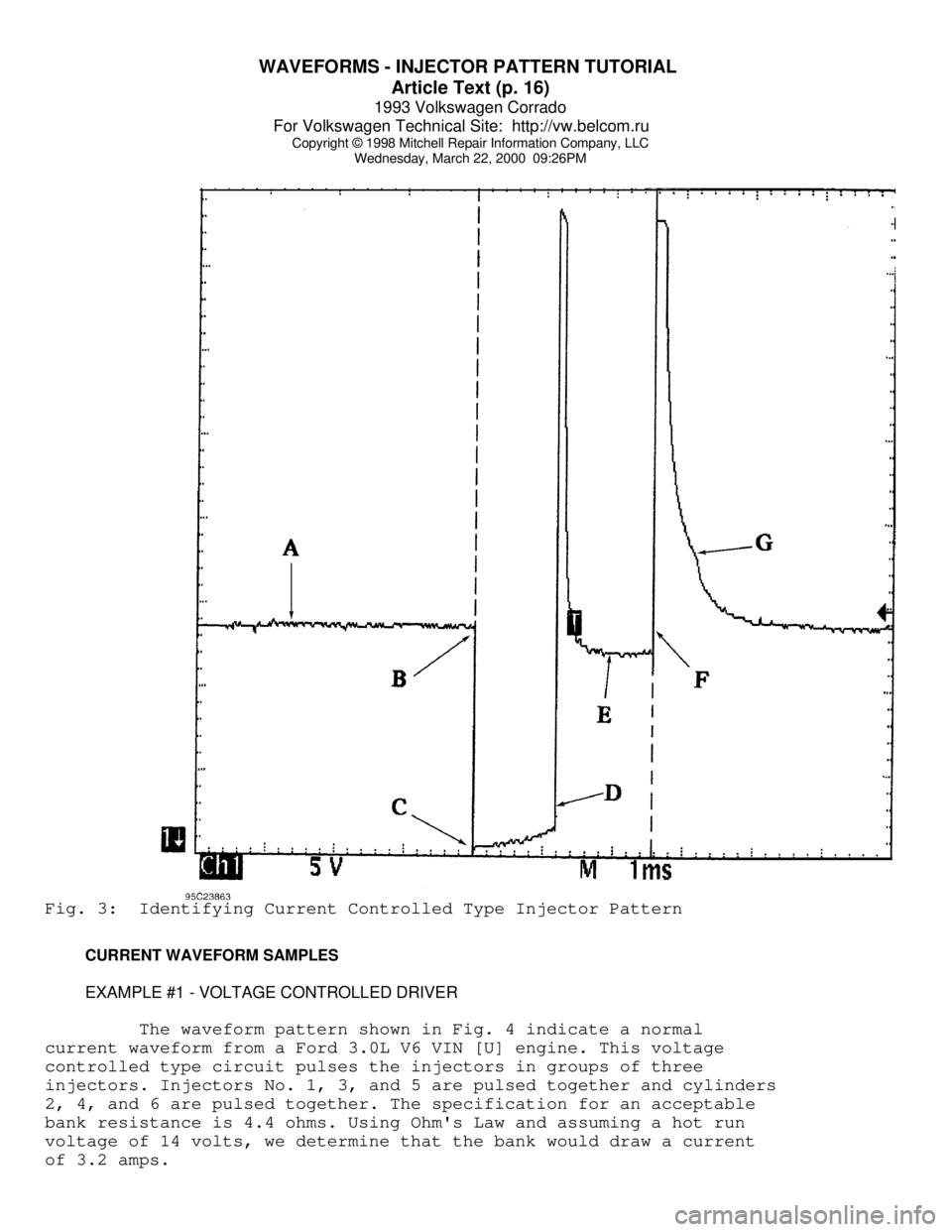

Wednesday, March 22, 2000 09:26PMFig. 3: Identifying Current Controlled Type Injector Pattern

CURRENT WAVEFORM SAMPLES

EXAMPLE #1 - VOLTAGE CONTROLLED DRIVER

The waveform pattern shown in Fig. 4 indicate a normal

current waveform from a Ford 3.0L V6 VIN [U] engine. This voltage

controlled type circuit pulses the injectors in groups of three

injectors. Injectors No. 1, 3, and 5 are pulsed together and cylinders

2, 4, and 6 are pulsed together. The specification for an acceptable

bank resistance is 4.4 ohms. Using Ohm's Law and assuming a hot run

voltage of 14 volts, we determine that the bank would draw a current

of 3.2 amps.

Page 878 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 19)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PM

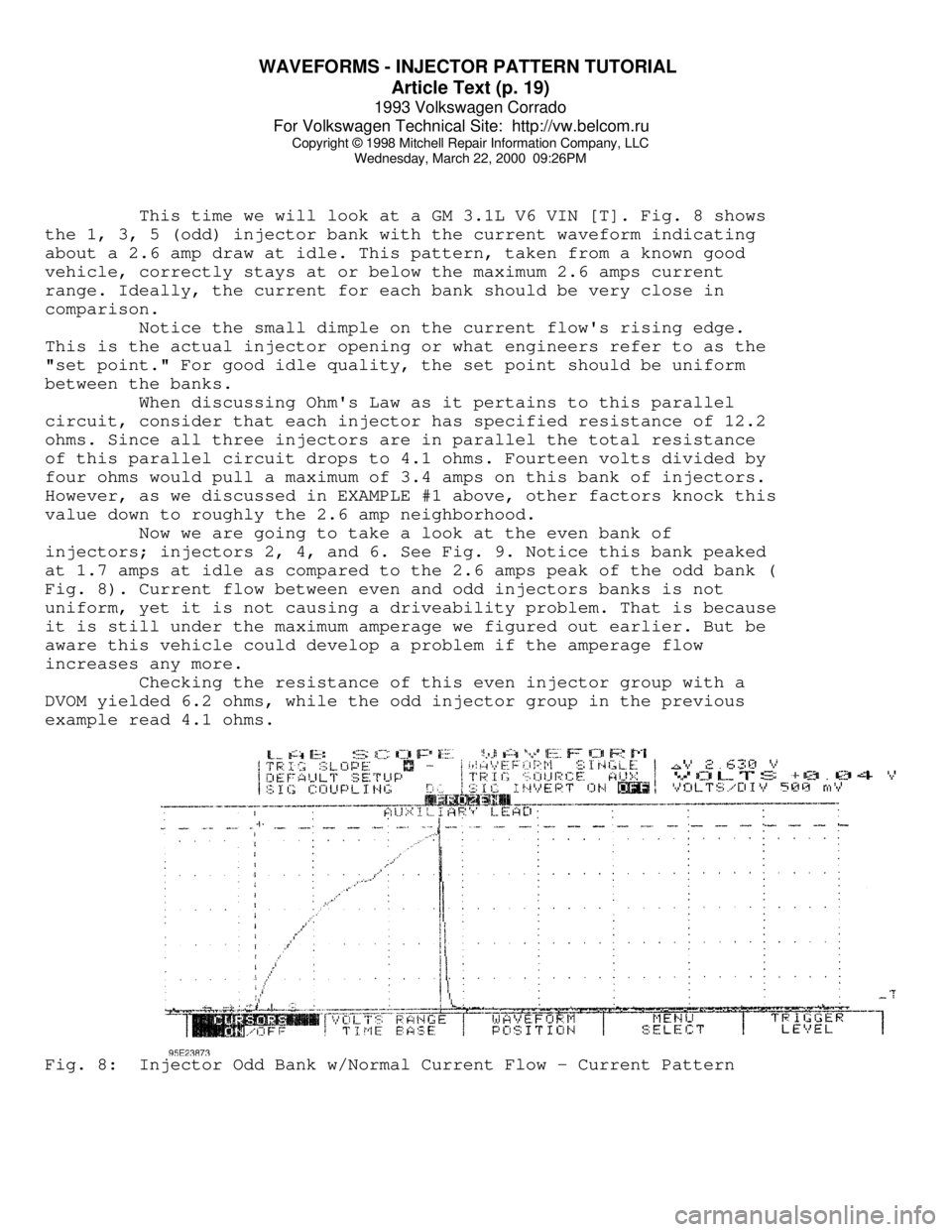

This time we will look at a GM 3.1L V6 VIN [T]. Fig. 8 shows

the 1, 3, 5 (odd) injector bank with the current waveform indicating

about a 2.6 amp draw at idle. This pattern, taken from a known good

vehicle, correctly stays at or below the maximum 2.6 amps current

range. Ideally, the current for each bank should be very close in

comparison.

Notice the small dimple on the current flow's rising edge.

This is the actual injector opening or what engineers refer to as the

"set point." For good idle quality, the set point should be uniform

between the banks.

When discussing Ohm's Law as it pertains to this parallel

circuit, consider that each injector has specified resistance of 12.2

ohms. Since all three injectors are in parallel the total resistance

of this parallel circuit drops to 4.1 ohms. Fourteen volts divided by

four ohms would pull a maximum of 3.4 amps on this bank of injectors.

However, as we discussed in EXAMPLE #1 above, other factors knock this

value down to roughly the 2.6 amp neighborhood.

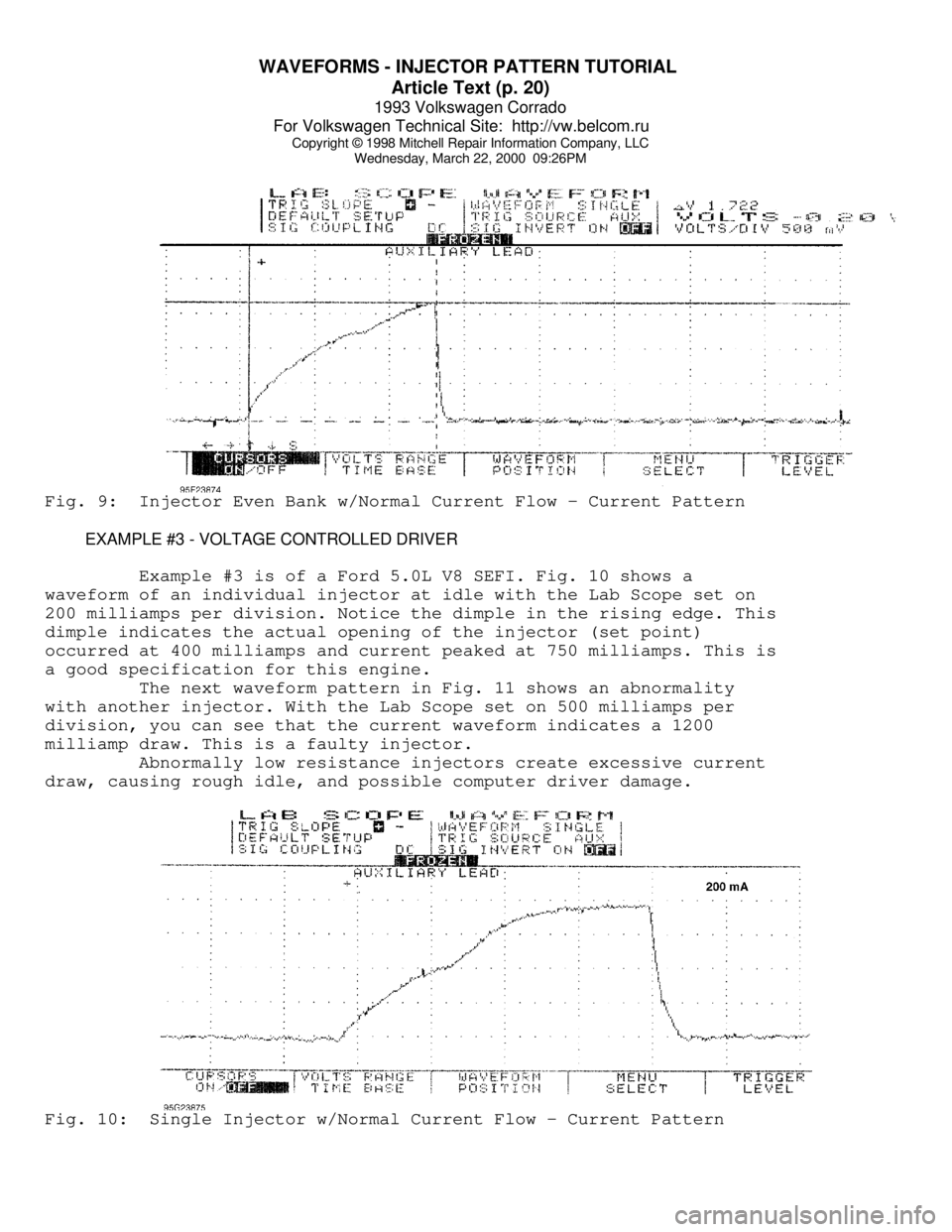

Now we are going to take a look at the even bank of

injectors; injectors 2, 4, and 6. See Fig. 9. Notice this bank peaked

at 1.7 amps at idle as compared to the 2.6 amps peak of the odd bank (

Fig. 8). Current flow between even and odd injectors banks is not

uniform, yet it is not causing a driveability problem. That is because

it is still under the maximum amperage we figured out earlier. But be

aware this vehicle could develop a problem if the amperage flow

increases any more.

Checking the resistance of this even injector group with a

DVOM yielded 6.2 ohms, while the odd injector group in the previous

example read 4.1 ohms.Fig. 8: Injector Odd Bank w/Normal Current Flow - Current Pattern

Page 879 of 920

WAVEFORMS - INJECTOR PATTERN TUTORIAL

Article Text (p. 20)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:26PMFig. 9: Injector Even Bank w/Normal Current Flow - Current Pattern

EXAMPLE #3 - VOLTAGE CONTROLLED DRIVER

Example #3 is of a Ford 5.0L V8 SEFI. Fig. 10 shows a

waveform of an individual injector at idle with the Lab Scope set on

200 milliamps per division. Notice the dimple in the rising edge. This

dimple indicates the actual opening of the injector (set point)

occurred at 400 milliamps and current peaked at 750 milliamps. This is

a good specification for this engine.

The next waveform pattern in Fig. 11 shows an abnormality

with another injector. With the Lab Scope set on 500 milliamps per

division, you can see that the current waveform indicates a 1200

milliamp draw. This is a faulty injector.

Abnormally low resistance injectors create excessive current

draw, causing rough idle, and possible computer driver damage.Fig. 10: Single Injector w/Normal Current Flow - Current Pattern