light VOLKSWAGEN CORRADO 1993 Manual PDF

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 579 of 920

FUSES & CIRCUIT BREAKERS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ARTICLE BEGINNING

1990-94 ELECTRICAL

Volkswagen Fuses & Circuit Breakers

Corrado

FUSES & CIRCUIT BREAKERS

FUSE PANEL LOCATION

Fuse panel is located under left side of dash board by

driver's knee. Fuses are numbered from left to right.

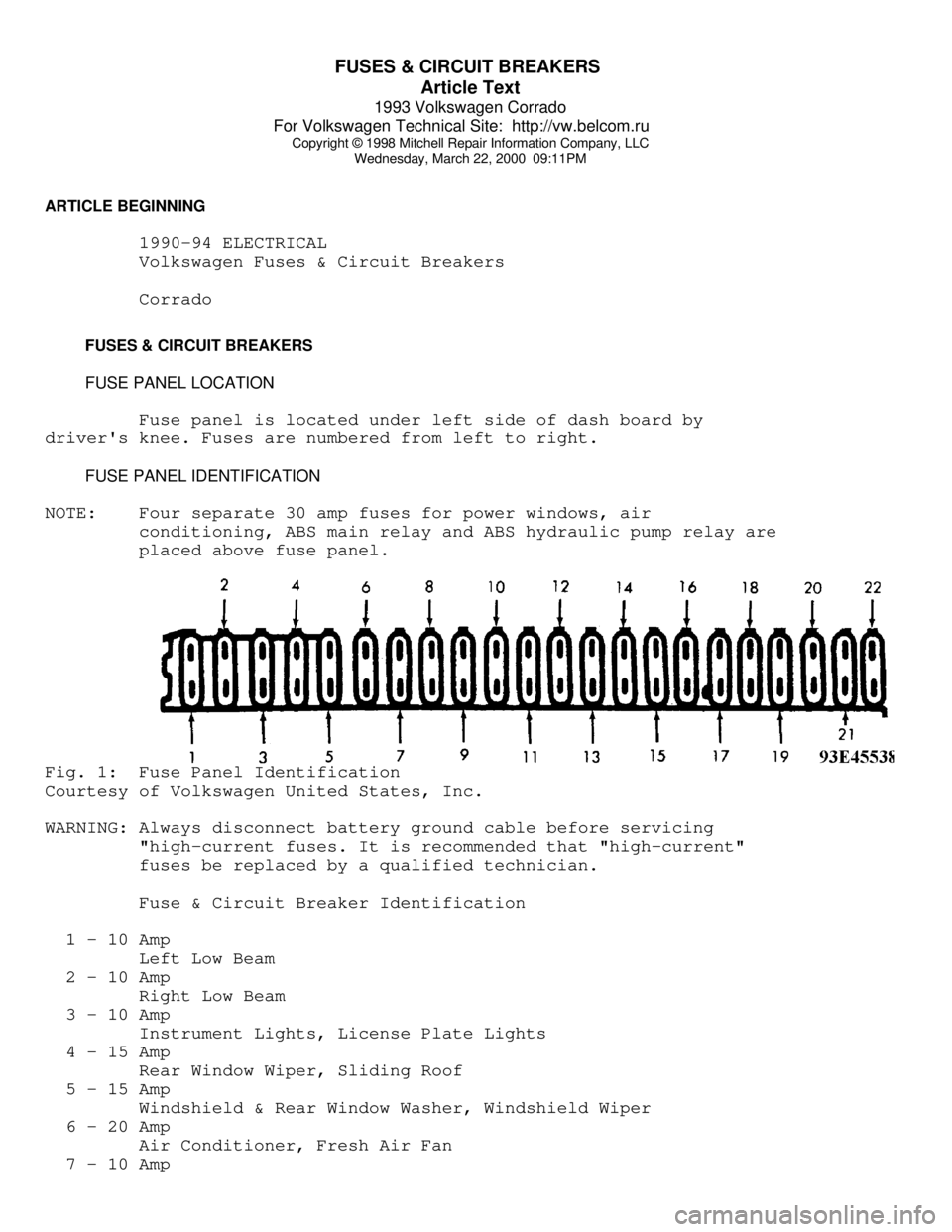

FUSE PANEL IDENTIFICATION

NOTE: Four separate 30 amp fuses for power windows, air

conditioning, ABS main relay and ABS hydraulic pump relay are

placed above fuse panel.Fig. 1: Fuse Panel Identification

Courtesy of Volkswagen United States, Inc.

WARNING: Always disconnect battery ground cable before servicing

"high-current fuses. It is recommended that "high-current"

fuses be replaced by a qualified technician.

Fuse & Circuit Breaker Identification

1 - 10 Amp

Left Low Beam

2 - 10 Amp

Right Low Beam

3 - 10 Amp

Instrument Lights, License Plate Lights

4 - 15 Amp

Rear Window Wiper, Sliding Roof

5 - 15 Amp

Windshield & Rear Window Washer, Windshield Wiper

6 - 20 Amp

Air Conditioner, Fresh Air Fan

7 - 10 Amp

Page 580 of 920

FUSES & CIRCUIT BREAKERS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

Right Tail & Side Lights

8 - 10 Amp

Left Tail & Side Lights

9 - 20 Amp

Rear Window & Mirror Heating

10 - 15 Amp

Foglights

11 - 10 Amp

Left High Beam, High Beam Indicator

12 - 10 Amp

Right High Beam

13 - 10 Amp

Horn, Radiator Fan

14 - 15 Amp

Back-Up Lights, Electric Mirrors, Heated Windshield Washer

Jets

15 - 10 Amp

Engine Electronic

16 - 15 Amp

Warning/Indicator Lights, Multi-Function Indicator, Glove Box

Light, Cassette Storage Light, Rear Spoiler

17 - 10 Amp

Turn Signals

18 - 20 Amp

Fuel Pump, Oxygen Sensor

19 - 30 Amp

Radiator Fan, Air Conditioner

20 - 10 Amp

Brakelights, Cruise Control

21 - 15 Amp

Dome & Luggage Compartment Lights, Cigarette Lighter, Central

Locking System, Multi-Function Indicator

22 - 10 Amp

Radio

CAUTIONS & WARNINGS

ELECTRICAL SHOCK

WARNING: Contact with live components of ignition system while

engine is running could lead to a fatal electric shock.

RADIATOR FAN

Keep hands away from radiator fan. Fan is controlled by a

thermostatic switch which may come on or run for up to 15 minutes even

after engine is turned off.

RADIATOR CAP

CAUTION: Always disconnect the fan motor when working near the

radiator fan. The fan is temperature controlled and could

Page 581 of 920

FUSES & CIRCUIT BREAKERS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

start at any time even when the ignition key is in the OFF

position. DO NOT loosen or remove radiator cap when cooling

system is hot.

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off

all lights and accessories to avoid damaging the electrical system. Be

sure to use fuse with the correct indicated amperage rating. The use

of an incorrect amperage rating fuse may result in a dangerous

electrical system overload.

BATTERY WARNING

WARNING: When battery is disconnected, vehicles equipped with

computers may lose memory data. When battery power is

restored, driveability problems may exist on some vehicles.

These vehicles may require a relearn procedure. See COMPUTER

RELEARN PROCEDURES article in GENERAL INFORMATION section.

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning

that brake pads need replacement.

HALOGEN BULBS

Halogen bulbs contain pressurized gas which may explode if

overheated. DO NOT touch glass portion of bulb with bare hands. Eye

protection should be worn when handling or working around halogen

bulbs.

SUPPLEMENTAL RESTRAINT SYSTEM (AIR BAG)

NOTE: See the AIR BAGS article in the ACCESSORIES/SAFETY EQUIPMENT

Section.

Modifications or improper maintenance, including incorrect

removal and installation of the Supplemental Restraint System (SRS),

can adversely affect system performance. DO NOT cover, obstruct or

change the steering wheel horn pad in any way, as such action could

cause improper function of the system. Use only plain water when

cleaning the horn pad. Solvents or cleaners could adversely affect the

air bag cover and cause improper deployment of the system.

WARNING: To avoid injury from accidental air bag deployment, read and

carefully follow all warnings and service precautions. See

appropriate AIR BAGS article in ACCESSORIES/SAFETY EQUIPMENT.

CAUTION: Disconnect negative battery cable before servicing any air

bag system, steering column or passenger side dash

component. After any repair, turn ignition key to the ON

Page 583 of 920

G - TESTS W/CODES

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ARTICLE BEGINNING

1993 ENGINE PERFORMANCE

Volkswagen Self-Diagnostics

Corrado SLC

INTRODUCTION

If no faults were found while performing preliminary

inspection procedures, proceed with self-diagnostics. If no fault

codes or only pass codes are present after entering self-diagnostics,

proceed to H - TESTS W/O CODES article for diagnosis by symptom (i.e.,

ROUGH IDLE, NO START, etc.).

NOTE: Scan Tester (VAG 1551) must be used to make full use of the

self-diagnostic system capabilities.

SELF-DIAGNOSTIC SYSTEM DESCRIPTION

Hard Failures

Hard failures of monitored sensors and/or components, cause

Malfunction Indicator Light (MIL) to come on and remain on until

problem is repaired. If malfunction indicator CHECK ENGINE light comes

on and remains on during vehicle operation, cause of malfunction must

be determined.

If malfunctions are present for more than 5 seconds, they are

stored as Diagnostic Trouble Codes (DTCs) and will be displayed as a

permanent malfunction even though the malfunction is not occurring at

the time DTCs are displayed. Malfunctions that affect oxygen sensor

control can only be read accurately after a test drive of at least 5

minutes.

Intermittent Failures

If a malfunction occurs for a maximum of 5 seconds, they are

stored and considered to be "sporadic" (intermittent failures). When

displayed on scan tester, malfunctions will have "SP" (sporadic) code.

RETRIEVING CODES

NOTE: See ENTERING SELF-DIAGNOSTICS for additional scan tester

operating instructions.

Corrado SLC

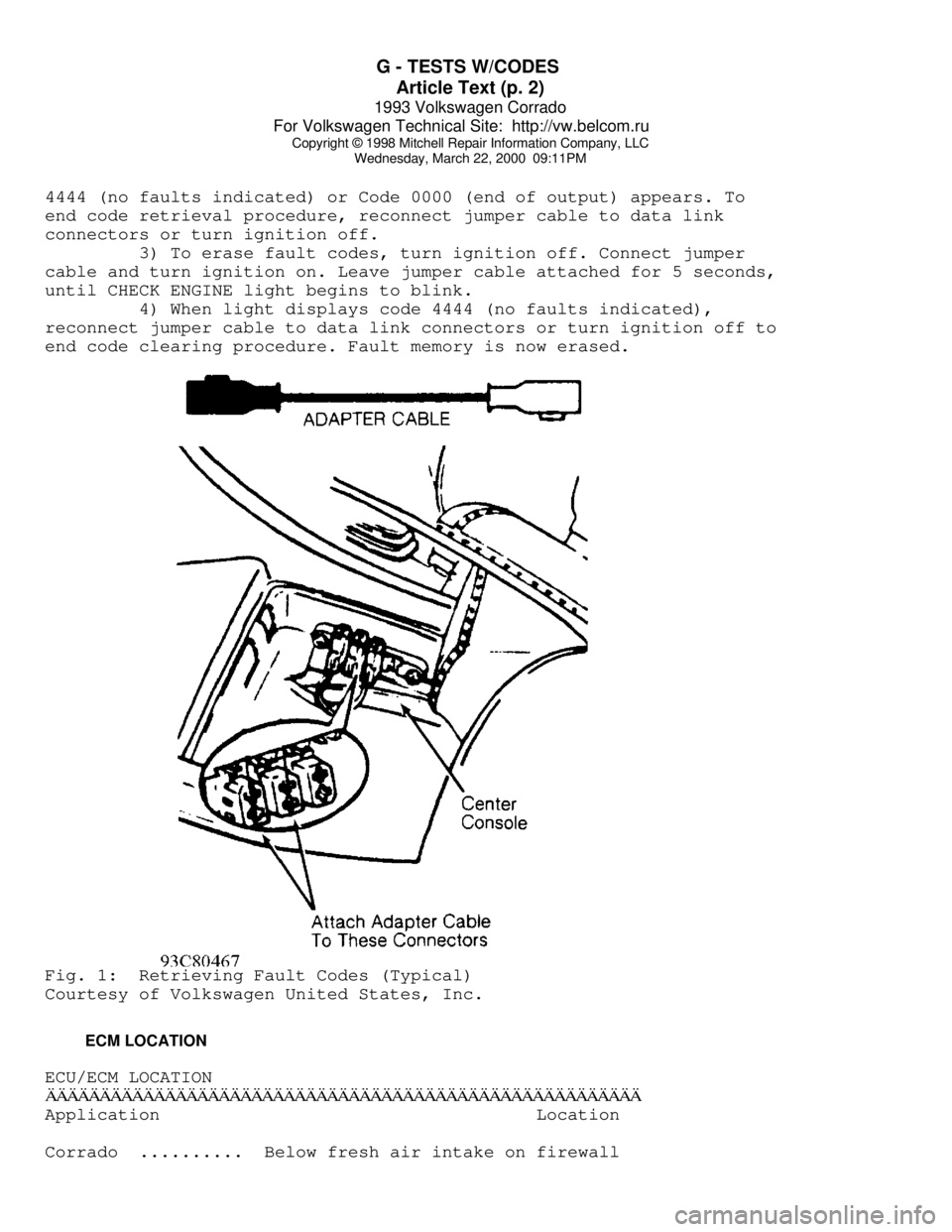

1) Turn ignition on. Connect Jumper Cable (357 971 514E) to

Data Link Connectors (DLC) located in center console. See Fig. 1.

Black end of jumper cable attaches to Black data link connector; White

end of cable attaches to White connector.

2) Leave jumper cable attached for 5 seconds, until on-board

diagnostic CHECK ENGINE light begins to blink. Remove jumper cable.

Allow on-board diagnostic code retrieval procedure to run until Code

Page 584 of 920

G - TESTS W/CODES

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

4444 (no faults indicated) or Code 0000 (end of output) appears. To

end code retrieval procedure, reconnect jumper cable to data link

connectors or turn ignition off.

3) To erase fault codes, turn ignition off. Connect jumper

cable and turn ignition on. Leave jumper cable attached for 5 seconds,

until CHECK ENGINE light begins to blink.

4) When light displays code 4444 (no faults indicated),

reconnect jumper cable to data link connectors or turn ignition off to

end code clearing procedure. Fault memory is now erased.Fig. 1: Retrieving Fault Codes (Typical)

Courtesy of Volkswagen United States, Inc.

ECM LOCATION

ECU/ECM LOCATIONÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Location

Corrado .......... Below fresh air intake on firewall

Page 586 of 920

G - TESTS W/CODES

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

Exceeded

00585 (2411) ... EGR Temperature Sensor ...... Short Ckt To Ground

Or Faulty Sensor

00586 (----) ........ EGR Control ........ EGR Valve Sticking Open

01025 (----) .. Malfunction Indicator Light .... Open/Short Ckt To

Ground Or Battery

Voltage

01242 (4332) ...... ECM Output Stage ........ Faulty Ckt To Output

Check Controlled

Components

01247 (4343) ... EVAP Frequency Solenoid ...... Open/Short Ckt To

Ground Or Battery

Voltage

01249 (4411) ....... Injector No. 1 ............ Open/Short Ckt To

Ground Or Battery

Voltage

01250 (4412) ....... Injector No. 2 ............ Open/Short Ckt To

Ground Or Battery

Voltage

01251 (4413) ....... Injector No. 3 ............ Open/Short Ckt To

Ground Or Battery

Voltage

01252 (4414) ....... Injector No. 4 ............ Open/Short Ckt To

Ground Or Battery

Voltage

01253 (4415) ....... Injector No. 5 ............ Open/Short Ckt To

Ground Or Battery

Voltage

01254 (4422) ....... Injector No. 6 ............ Open/Short Ckt To

Ground Or Battery

Voltage

01257 (4431) .. Idle Air Control (IAC) Valve ... Open/Short Ckt To

Ground Or Battery

Voltage

01259 (4433) ....... Fuel Pump Relay ....... Open Ckt Or Short Ckt

To Battery Voltage

01265 (4312) .. EGR Frequency (2-Way) Valve .... Open/Short Ckt To

Ground Or Battery

Voltage

65535 (1111) ... Electronic Control Module .... Replace Faulty ECM

(1) - For testing information, see J - PIN VOLTAGE CHARTS article.

(2) - Blink code is 4-digit malfunction indicator CHECK ENGINE

light code.

(3) - Check intake and exhaust systems for leaks. Check for too low

or too high a fuel pressure. Also check for malfunctioning

fuel injectors or engine misfire.

(4) - Check intake and exhaust systems for leaks. Check for mass

airflow sensor hot wire not burning off cleanly. Check for

faulty oxygen sensor control and for EVAP frequency solenoid

sticking open. Also check for malfunctioning fuel injectors or

engine misfire.

Page 591 of 920

GEAR TOOTH CONTACT PATTERNS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ARTICLE BEGINNING

GENERAL INFORMATION

Gear Tooth Contact Patterns

* PLEASE READ THIS FIRST *

The following article is for GENERAL INFORMATION purposes

only. Information does not SPECIFICALLY apply to all years, makes and

models, but is to be used as a general reference guide.

INSPECTION

PRELIMINARY INSPECTION

Wipe lubricant from internal parts. Rotate gears and inspect

for wear or damage. Mount dial indicator to housing, and check

backlash at several points around ring gear. Backlash must be within

specifications at all points. If no defects are found, check gear

tooth contact pattern.

GEAR TOOTH CONTACT PATTERN

NOTE: Drive pattern should be well centered on ring gear teeth.

Coast pattern should be centered, but may be slightly toward

toe of ring gear teeth.

1) Paint ring gear teeth with marking compound. Wrap cloth or

rope around drive pinion flange to act as brake. Rotate ring gear

until clear tooth contact pattern is obtained.

2) Contact pattern will indicate whether correct pinion

bearing mounting shim has been installed and if drive gear backlash

has been set properly. Backlash between drive gear and pinion must be

maintained within specified limits, until correct tooth pattern is

obtained.

Page 602 of 920

H - TESTS W/O CODES

Article Text (p. 6)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

* Check full throttle switch.

* Check ignition timing.

ENGINE RUNS UNEVENLY OVER ENTIRE SPEED RANGE

* Check auxiliary air intake system.

* Check injector fuel pressure and volume.

* Check ignition timing, spark plugs, distributor, secondary

ignition wiring and coil.

INTERMITTENTS

INTERMITTENT PROBLEM DIAGNOSIS

Intermittent fault testing requires duplicating circuit or

component failure to identify the problem. These procedures may lead

to the computer setting a fault code (on some systems) which may help

in diagnosis.

If problem vehicle does not produce fault codes, monitor

voltage or resistance values using a DVOM while attempting to

reproduce conditions causing intermittent fault. A status change on

DVOM indicates a fault has been located.

Use a DVOM to pinpoint faults. When monitoring voltage,

ensure ignition switch is in ON position or engine is running. Ensure

ignition switch is in OFF position or negative battery cable is

disconnected when monitoring circuit resistance. Status changes on

DVOM during test procedures indicate area of fault.

TEST PROCEDURES

Intermittent Simulation

To reproduce the conditions creating an intermittent fault,

use the following methods:

* Lightly vibrate component.

* Heat component.

* Wiggle or bend wiring harness.

* Spray component with water.

* Remove/apply vacuum source.

Monitor circuit/component voltage or resistance while

simulating intermittent. If engine is running, monitor for self-

diagnostic codes. Use the test results to identify a faulty component

or circuit. For system or component testing refer to the appropriate

I - SYS/COMP TESTS article in this section. See the menu below:

* For Cabriolet, see: I - SYSTEM/COMPONENT TESTS

* For Corrado SLC, see: I - SYSTEM/COMPONENT TESTS

* For EuroVan, see: I - SYSTEM/COMPONENT TESTS

* For Fox, see: I - SYSTEM/COMPONENT TESTS

* For Golf, GTI, Jetta, see: I - SYSTEM/COMPONENT TESTS

* For Passat GL 2.0L 4-Cylinder, see:

Page 604 of 920

HOW TO USE SYSTEM WIRING DIAGRAMS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

ARTICLE BEGINNING

GENERAL INFORMATION

Using Wiring Diagrams

All Models

INTRODUCTION

Mitchell obtains wiring diagrams and technical service

bulletins, containing wiring diagram changes from the domestic and

import manufacturers. These are checked for accuracy and are all

redrawn into a consistent format for easy use.

In the past, when cars were simpler, diagrams were simpler.

All components were connected by wires and diagrams seldom exceeded 4

pages in length. Today, some wiring diagrams require more than 16

pages. It would be impractical to expect a service technician to trace

a wire from page 1 across every page to page 16.

Removing some of the wiring maze reduces eyestrain and time

wasted searching across several pages. Today the majority of Mitchell

diagrams follow a much improved format, which permits space for

internal switch details.

Wiring diagrams are drawn in a "top-down" format. The

diagrams are drawn with the power source at the top of the diagram and

the ground point at the bottom of the diagram. Components locations

are identified on the wiring diagrams. Any wires that don't connect

directly to a component are identified on the diagram to indicate

where they go.

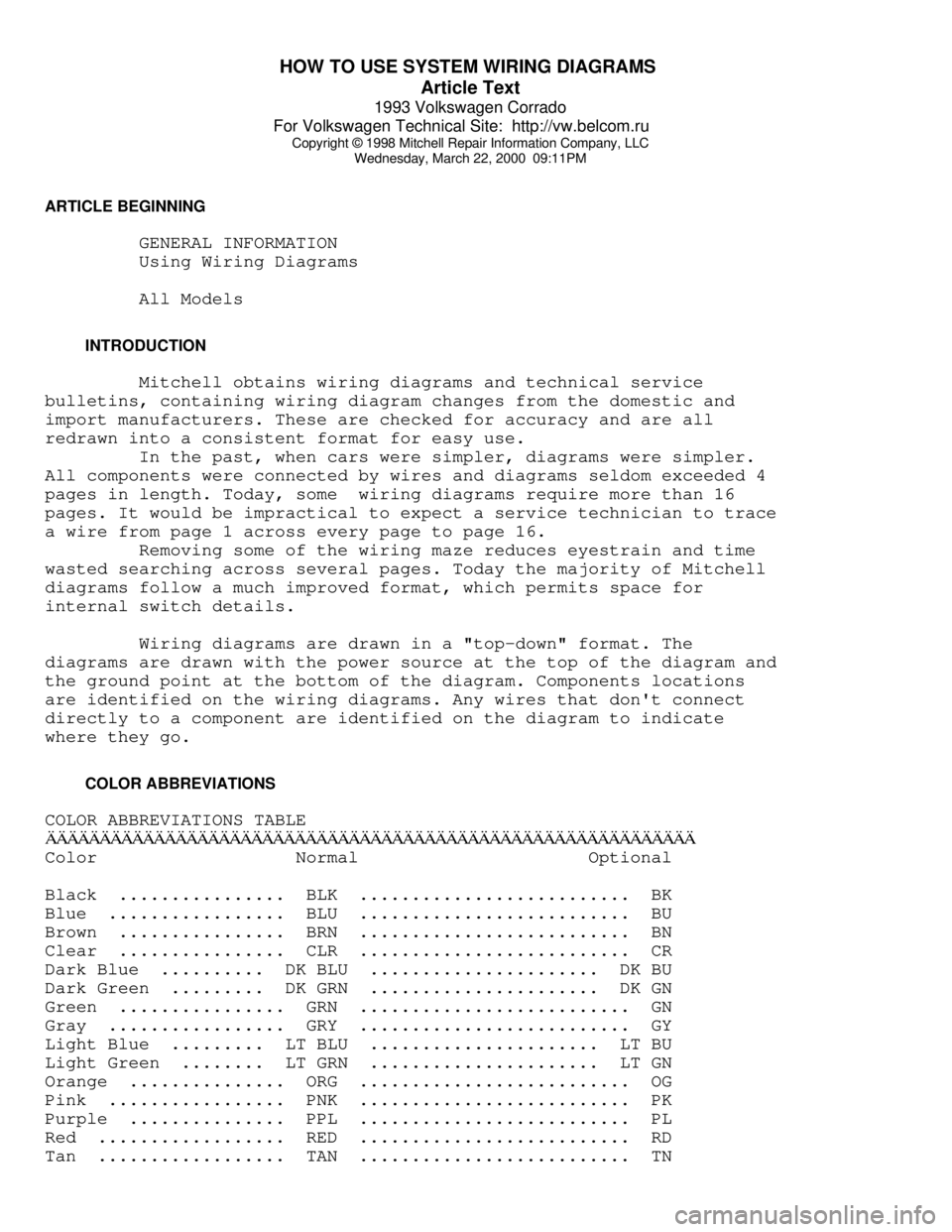

COLOR ABBREVIATIONS

COLOR ABBREVIATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄColor Normal Optional

Black ................ BLK .......................... BK

Blue ................. BLU .......................... BU

Brown ................ BRN .......................... BN

Clear ................ CLR .......................... CR

Dark Blue .......... DK BLU ...................... DK BU

Dark Green ......... DK GRN ...................... DK GN

Green ................ GRN .......................... GN

Gray ................. GRY .......................... GY

Light Blue ......... LT BLU ...................... LT BU

Light Green ........ LT GRN ...................... LT GN

Orange ............... ORG .......................... OG

Pink ................. PNK .......................... PK

Purple ............... PPL .......................... PL

Red .................. RED .......................... RD

Tan .................. TAN .......................... TN

Page 607 of 920

HOW TO USE SYSTEM WIRING DIAGRAMS

Article Text (p. 4)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:11PM

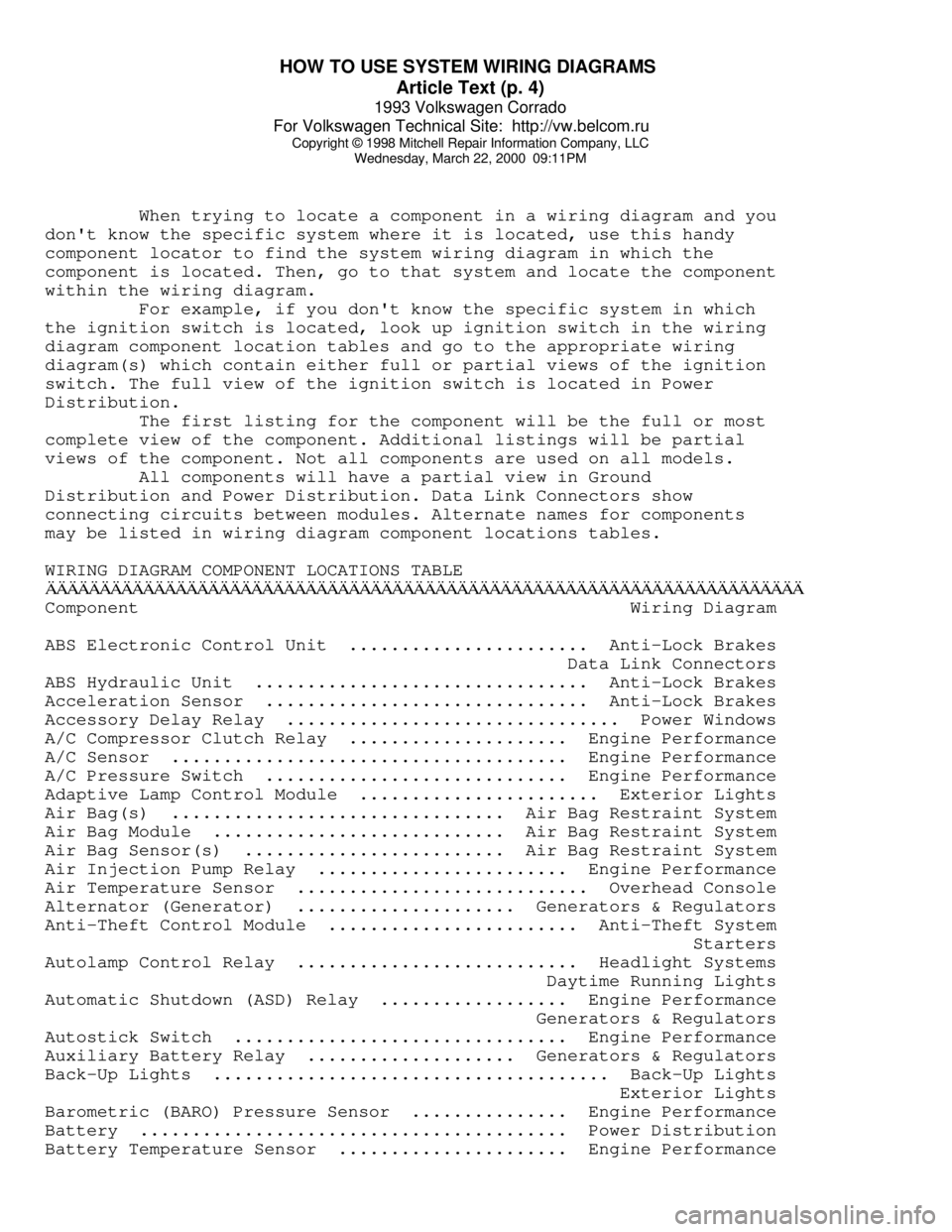

When trying to locate a component in a wiring diagram and you

don't know the specific system where it is located, use this handy

component locator to find the system wiring diagram in which the

component is located. Then, go to that system and locate the component

within the wiring diagram.

For example, if you don't know the specific system in which

the ignition switch is located, look up ignition switch in the wiring

diagram component location tables and go to the appropriate wiring

diagram(s) which contain either full or partial views of the ignition

switch. The full view of the ignition switch is located in Power

Distribution.

The first listing for the component will be the full or most

complete view of the component. Additional listings will be partial

views of the component. Not all components are used on all models.

All components will have a partial view in Ground

Distribution and Power Distribution. Data Link Connectors show

connecting circuits between modules. Alternate names for components

may be listed in wiring diagram component locations tables.

WIRING DIAGRAM COMPONENT LOCATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄComponent Wiring Diagram

ABS Electronic Control Unit ....................... Anti-Lock Brakes

Data Link Connectors

ABS Hydraulic Unit ................................ Anti-Lock Brakes

Acceleration Sensor ............................... Anti-Lock Brakes

Accessory Delay Relay ................................ Power Windows

A/C Compressor Clutch Relay ..................... Engine Performance

A/C Sensor ...................................... Engine Performance

A/C Pressure Switch ............................. Engine Performance

Adaptive Lamp Control Module ....................... Exterior Lights

Air Bag(s) ................................ Air Bag Restraint System

Air Bag Module ............................ Air Bag Restraint System

Air Bag Sensor(s) ......................... Air Bag Restraint System

Air Injection Pump Relay ........................ Engine Performance

Air Temperature Sensor ............................ Overhead Console

Alternator (Generator) ..................... Generators & Regulators

Anti-Theft Control Module ........................ Anti-Theft System

Starters

Autolamp Control Relay ........................... Headlight Systems

Daytime Running Lights

Automatic Shutdown (ASD) Relay .................. Engine Performance

Generators & Regulators

Autostick Switch ................................ Engine Performance

Auxiliary Battery Relay .................... Generators & Regulators

Back-Up Lights ...................................... Back-Up Lights

Exterior Lights

Barometric (BARO) Pressure Sensor ............... Engine Performance

Battery ......................................... Power Distribution

Battery Temperature Sensor ...................... Engine Performance