Engine oil VOLKSWAGEN PASSAT 1995 B3, B4 / 3.G Service User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1995, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1995 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 128 of 369

Downloaded from www.Manualslib.com manuals search engine 42-32

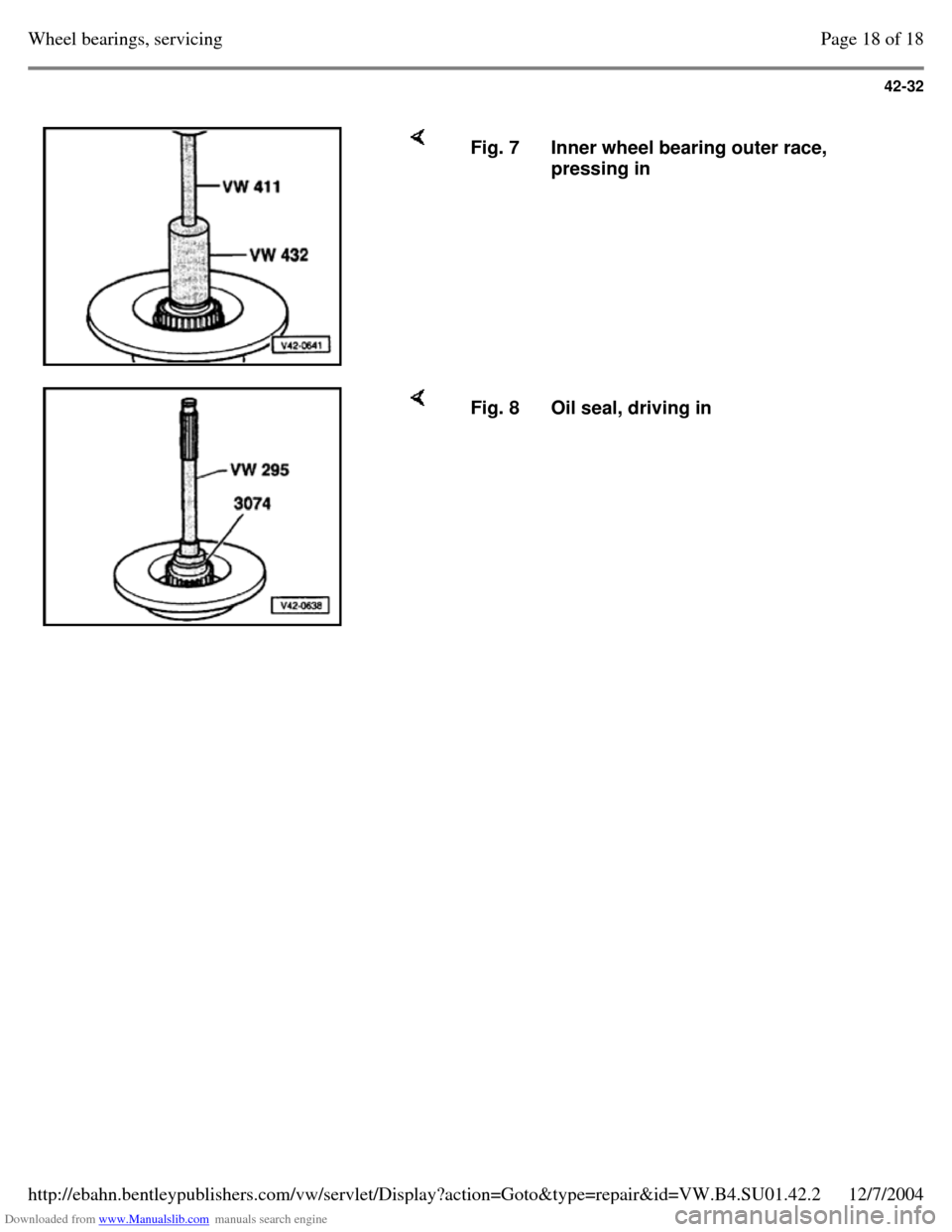

Fig. 7 Inner wheel bearing outer race,

pressing in Fig. 8 Oil seal, driving in Page 18 of 18Wheel bearings, servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.2

Page 151 of 369

Downloaded from www.Manualslib.com manuals search engine 42-55

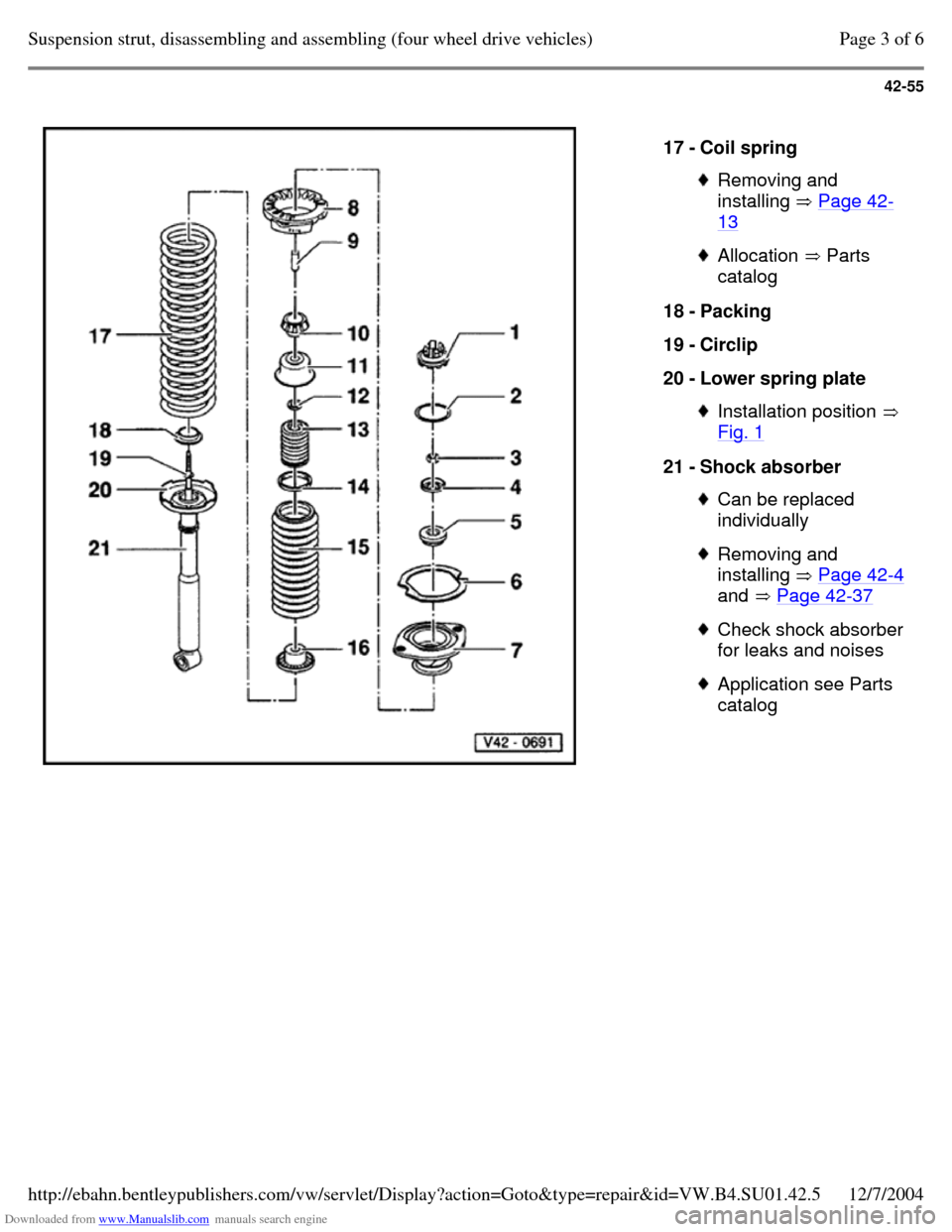

17 - Coil spring Removing and

installing Page 42-13 Allocation Parts

catalog 18 - Packing

19 - Circlip

20 - Lower spring plate Installation position

Fig. 1 21 - Shock absorber Can be replaced

individually Removing and

installing Page 42-4

and Page 42-37 Check shock absorber

for leaks and noises Application see Parts

catalog Page 3 of 6Suspension strut, disassembling and assembling (four wheel drive vehicles)12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.42.5

Page 163 of 369

Downloaded from www.Manualslib.com manuals search engine 44-1

Vehicle alignment

Test requirements:

Measuring equipment correctly calibrated

Vehicle unladen1)

Tires inflated to correct pressure

Vehicle accurately aligned, suspension

bounced and rocked several times

Suspension, steering and steering linkage

checked for excessive play and damage.

Note:

Vehicle alignment should not be checked

before the vehicle has completed 1000 to 2000

km (600 to 1200 miles) as then the coil springs

have had time to settle.

The cause of vehicle imbalance may also be,

excessive residual imbalance and/or vertical

wheel runout.

1)

Unladened means: the weight of the vehicle

ready for the road (fuel tank completely filled,

spare wheel, vehicle tools and vehicle jack). Page 1 of 7Vehicle alignment12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.44.1

Page 171 of 369

Downloaded from www.Manualslib.com manuals search engine 45-2

Notes for repair work on ABS, ABS/EDL

Before doing any repair work on the anti-locking system, determine the cause of the malfunction

using On Board Diagnostic (OBD).

Repair Manual, Brake System On Board Diagnostic (OBD), Repair Group 01 Before working on the ABS, ABS/EDL system,

disconnect the battery Ground strap. On

vehicles with coded radio, obtain cooling.

When working with brake fluid, observe the

relevant safety precautions and notes Page 47-27 . After work for which the brake system had to be opened, bleed the brake system with brake filler and bleeder unit VAS 5234 Page 47-27 . During the final road test, make sure that a

controlled brake test is performed at least once

(pulsations must be felt at the brake pedal).

Absolute cleanliness is required when working

on the anti-locking brake system; it is not

permitted to use any products which contain

mineral oils, such as oils, greases etc. Page 2 of 5Anti-locking Brake System (ABS) and Anti-locking Brake System with Electronic Differential Lock (A...12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.45.1

Page 177 of 369

Downloaded from www.Manualslib.com manuals search engine 45-8

CAUTION!

During the final road test, make sure that at

least one controlled brake test is included

(pulsations must be felt at the brake pedal).

Absolute cleanliness is required when

working on the ABS or ABS/EDL system. DO

NOT use any products that contain mineral

oil, such as oils, greases, etc.

Thoroughly clean all connections and the

immediate vicinity before loosening. DO NOT

use aggressive cleaning agents such as

brake cleaner, gasoline or thinners.

Place removed parts on a clean surface and

cover. DO NOT use fluffy cloths.

Carefully seal or cover opened components

if a repair cannot be completed immediately.

After separating the ABS hydraulic unit and

ABS control module, always use the plastic

foam transportation protection for the valve

dome, and always use the sealing plug kit

Part No. 1 H0 693 311 A.

Only install replacement parts that were

packed in their original packaging. Only

remove them immediately before installation. When the hydraulic system is open DO NOT

work with compressed air in the vicinity and

DO NOT move the vehicle.

Take precautions to make sure that brake

fluid does not enter any wiring harness

connectors. Page 3 of 3Anti-lock Brake System (ABS) and ABS with Electronic Differential Lock (ABS/EDL), Teves 20 GI12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.45.2

Page 183 of 369

Downloaded from www.Manualslib.com manuals search engine 45-14

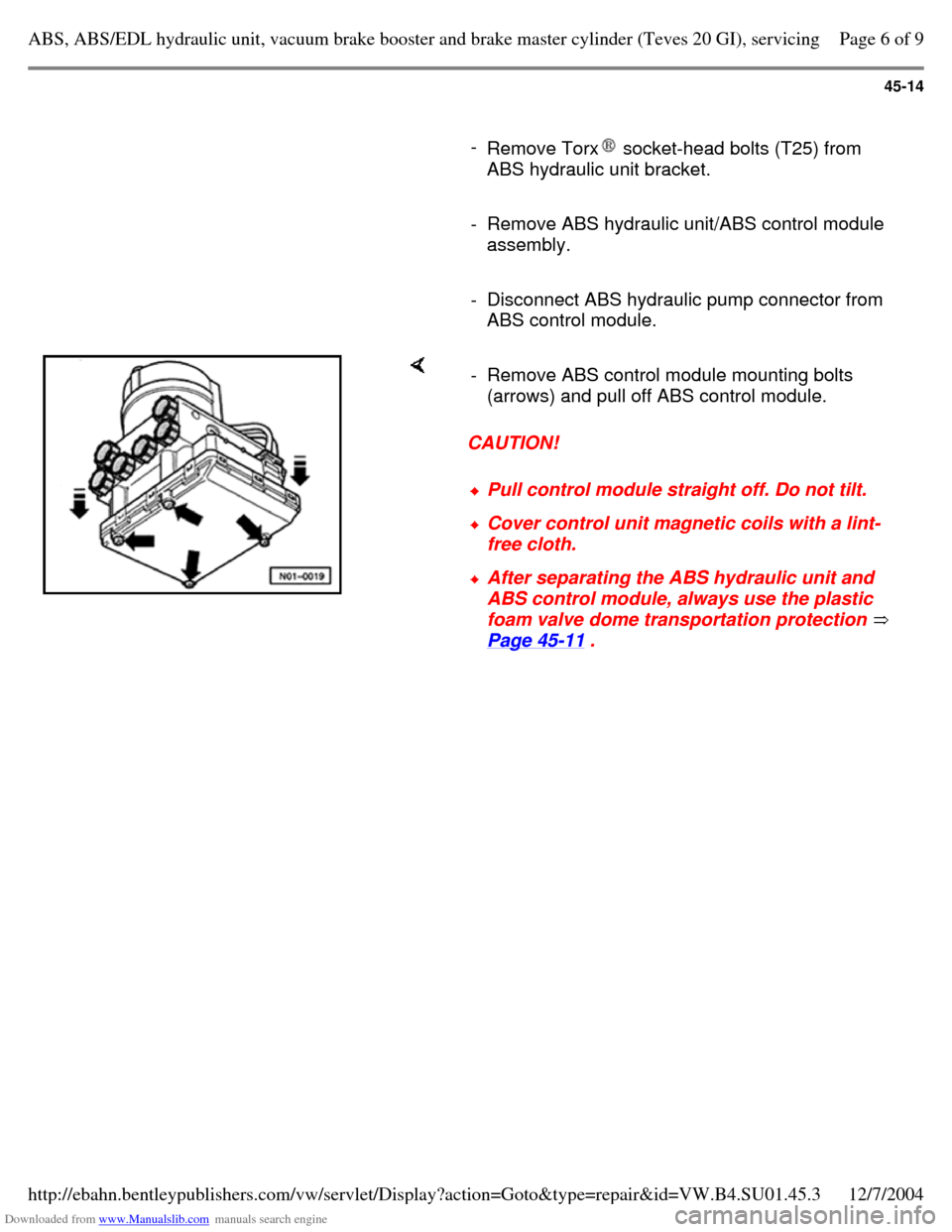

-

Remove Torx socket-head bolts (T25) from

ABS hydraulic unit bracket.

- Remove ABS hydraulic unit/ABS control module

assembly.

- Disconnect ABS hydraulic pump connector from

ABS control module. CAUTION! - Remove ABS control module mounting bolts

(arrows) and pull off ABS control module. Pull control module straight off. Do not tilt. Cover control unit magnetic coils with a lint-

free cloth. After separating the ABS hydraulic unit and

ABS control module, always use the plastic

foam valve dome transportation protection

Page 45-11 . Page 6 of 9ABS, ABS/EDL hydraulic unit, vacuum brake booster and brake master cylinder (Teves 20 GI), servicing12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.45.3

Page 286 of 369

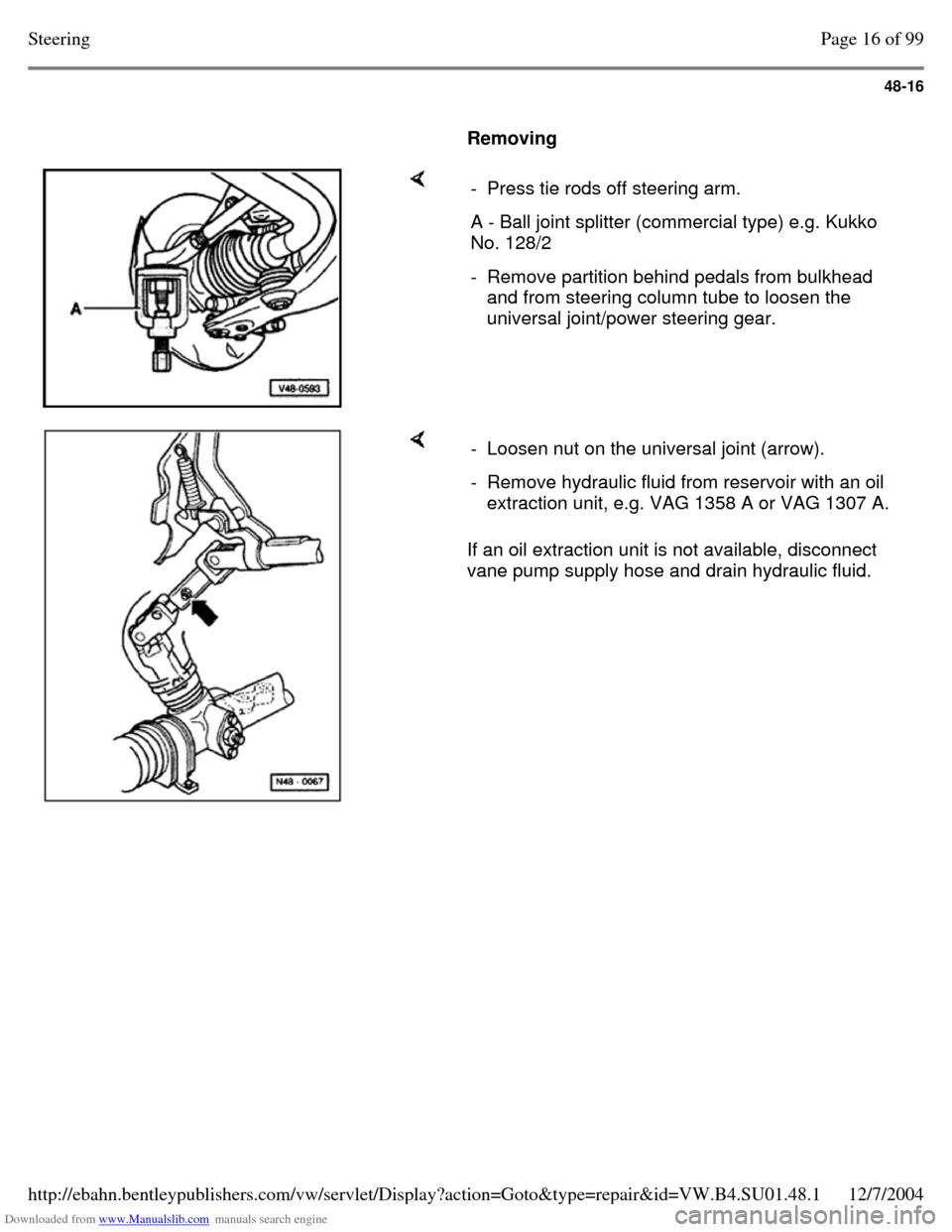

Downloaded from www.Manualslib.com manuals search engine 48-16

Removing - Press tie rods off steering arm. A - Ball joint splitter (commercial type) e.g. Kukko

No. 128/2

- Remove partition behind pedals from bulkhead

and from steering column tube to loosen the

universal joint/power steering gear. If an oil extraction unit is not available, disconnect

vane pump supply hose and drain hydraulic fluid. - Loosen nut on the universal joint (arrow). - Remove hydraulic fluid from reservoir with an oil

extraction unit, e.g. VAG 1358 A or VAG 1307 A. Page 16 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1

Page 289 of 369

Downloaded from www.Manualslib.com manuals search engine 48-19

Assembly overview: power assisted

steering box (TRW)

Determine cause of any malfunctions using

pressure and leak testing, Page 48-13 .

Note:

Always replace self-locking nuts and bolts. Welding and straightening work on steering

components is not permitted.

To grease the rack only use steering gear

grease, Part No. AOF 063 000 04.

Type of oil: Hydraulic oil G 002 000 Oil system capacity: 0.7 - 0.9 ltr. (0.74 - 0.95

qt)

Supply and pressure line routing from Page 48-85 . Page 19 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1

Page 297 of 369

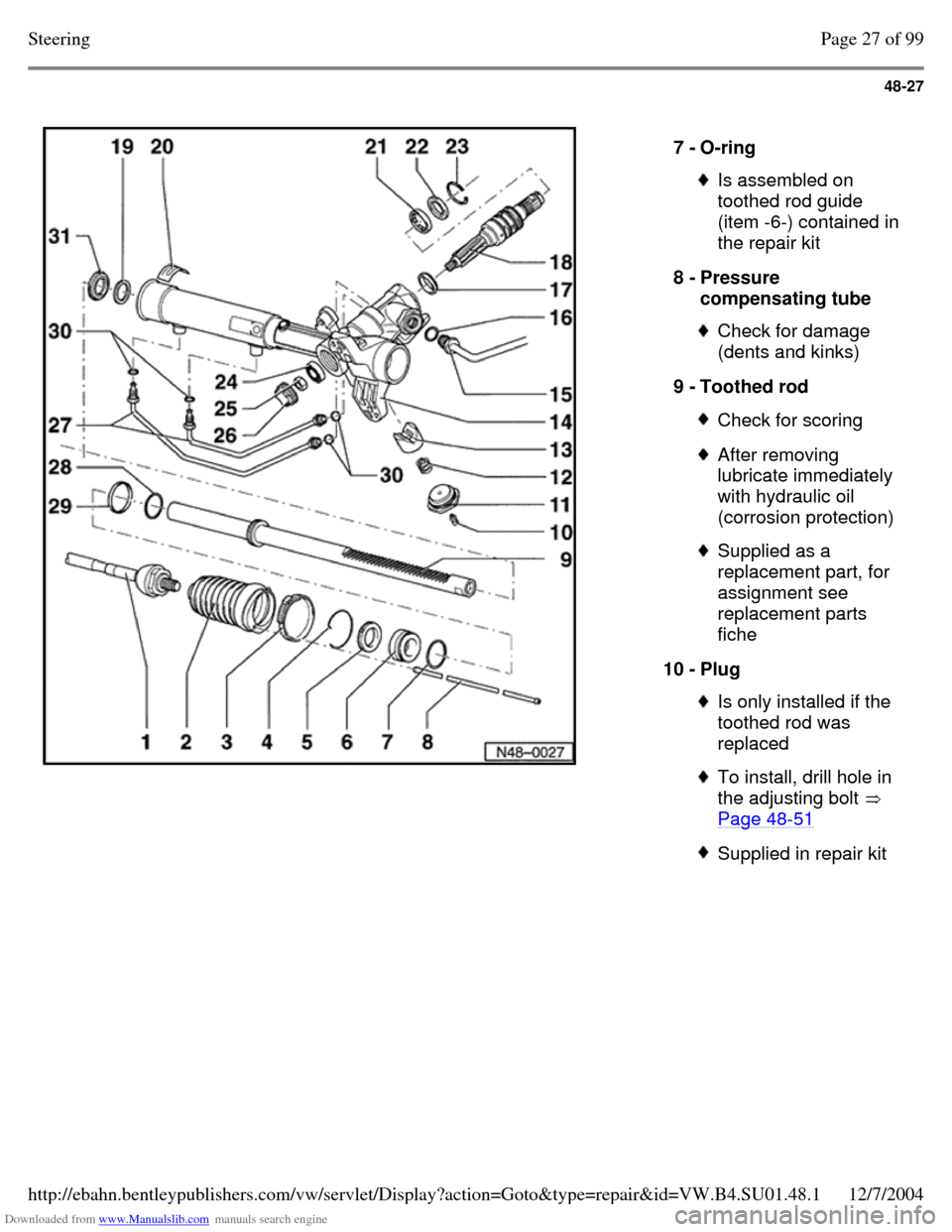

Downloaded from www.Manualslib.com manuals search engine 48-27

7 - O-ring Is assembled on

toothed rod guide

(item -6-) contained in

the repair kit

8 - Pressure

compensating tube Check for damage

(dents and kinks)

9 - Toothed rod Check for scoring After removing

lubricate immediately

with hydraulic oil

(corrosion protection) Supplied as a

replacement part, for

assignment see

replacement parts

fiche

10 - Plug Is only installed if the

toothed rod was

replaced To install, drill hole in

the adjusting bolt

Page 48-51 Supplied in repair kit Page 27 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1

Page 299 of 369

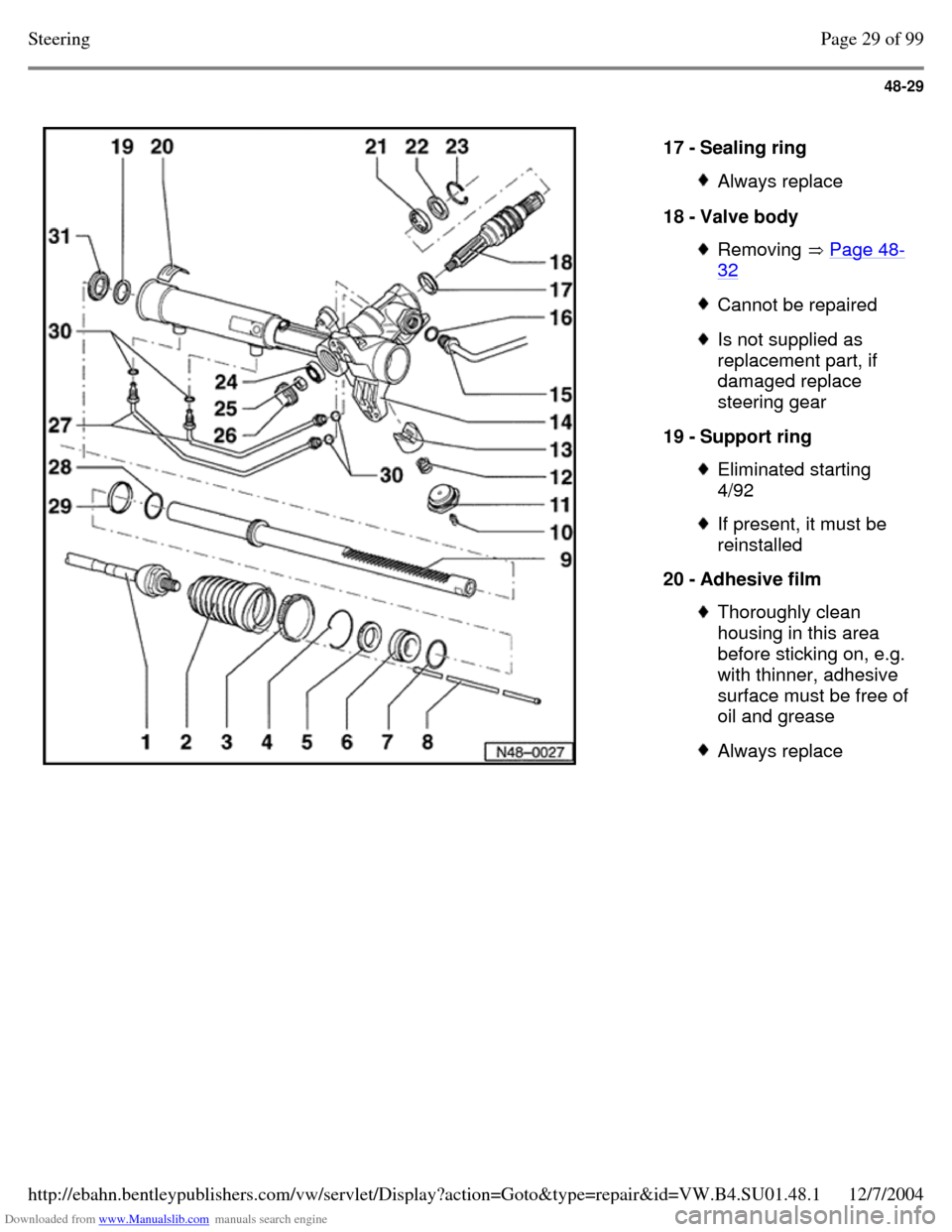

Downloaded from www.Manualslib.com manuals search engine 48-29

17 - Sealing ring Always replace 18 - Valve body Removing Page 48-32 Cannot be repaired Is not supplied as

replacement part, if

damaged replace

steering gear

19 - Support ring Eliminated starting

4/92 If present, it must be

reinstalled

20 - Adhesive film Thoroughly clean

housing in this area before sticking on, e.g. with thinner, adhesive surface must be free of oil and grease Always replace Page 29 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1