VOLKSWAGEN PASSAT 1996 B3, B4 / 3.G Service Repair Manual

PASSAT 1996 B3, B4 / 3.G

VOLKSWAGEN

VOLKSWAGEN

https://www.carmanualsonline.info/img/18/7419/w960_7419-0.png

VOLKSWAGEN PASSAT 1996 B3, B4 / 3.G Service Repair Manual

Trending: ABS, front suspension, brake rotor, length, wheel size, horn, airbag off

Page 61 of 369

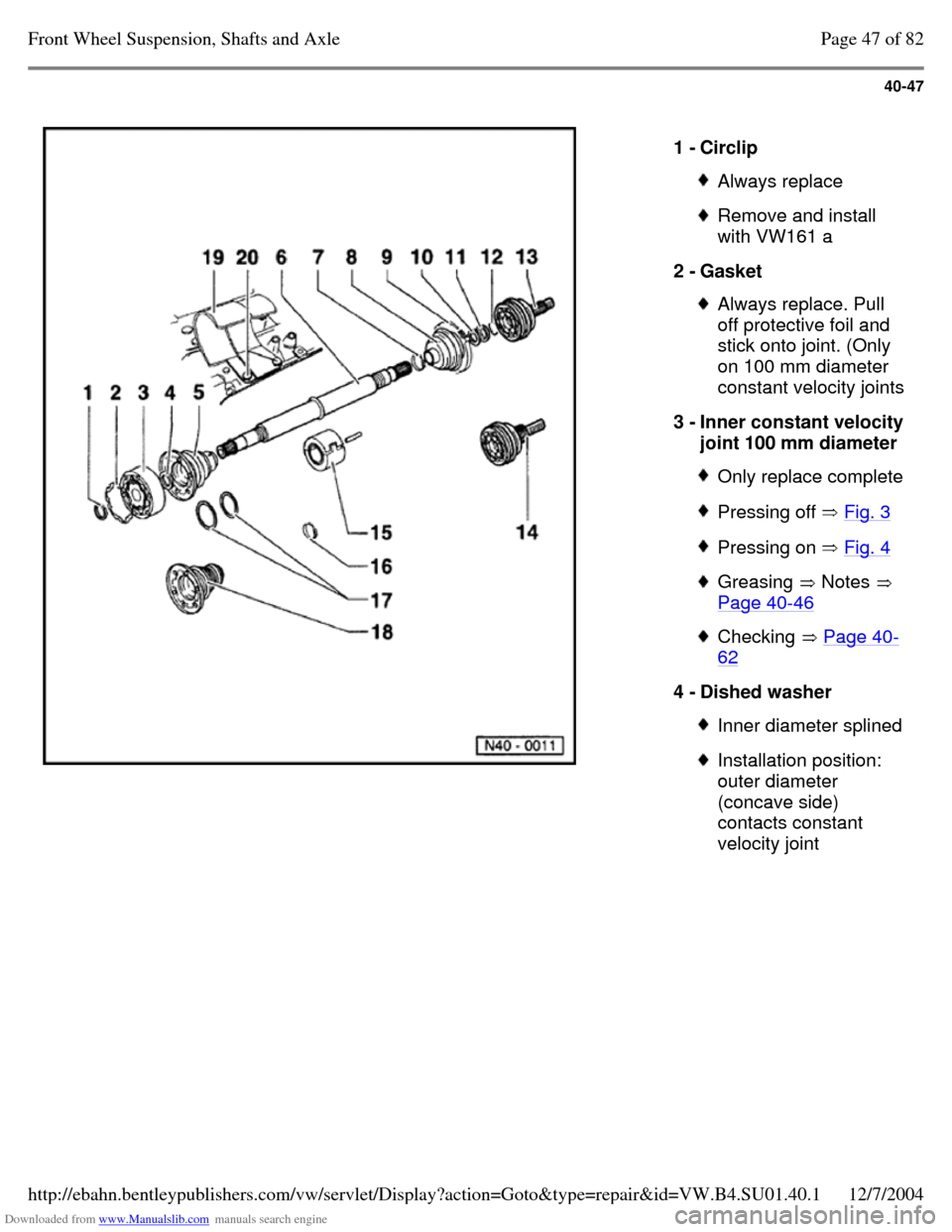

Downloaded from www.Manualslib.com manuals search engine 40-47

1 - Circlip Always replace Remove and install

with VW161 a

2 - Gasket Always replace. Pull

off protective foil and

stick onto joint. (Only

on 100 mm diameter

constant velocity joints

3 - Inner constant velocity

joint 100 mm diameter Only replace complete Pressing off Fig. 3 Pressing on Fig. 4 Greasing Notes

Page 40-46 Checking Page 40-62 4 - Dished washer Inner diameter splined Installation position:

outer diameter

(concave side)

contacts constant

velocity joint Page 47 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 62 of 369

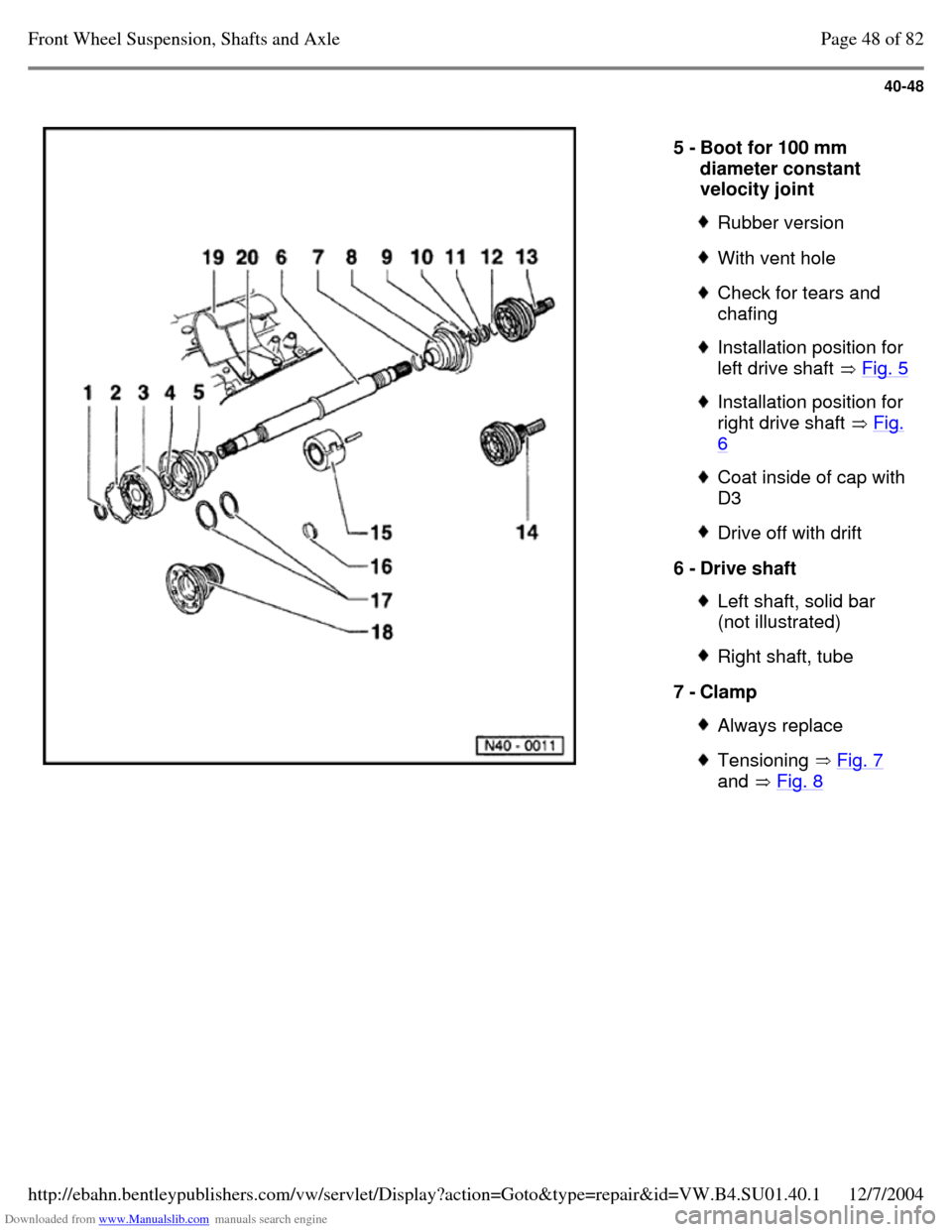

Downloaded from www.Manualslib.com manuals search engine 40-48

5 - Boot for 100 mm

diameter constant

velocity joint Rubber version With vent hole Check for tears and

chafing Installation position for

left drive shaft Fig. 5 Installation position for

right drive shaft Fig. 6 Coat inside of cap with D3 Drive off with drift 6 - Drive shaft Left shaft, solid bar

(not illustrated) Right shaft, tube 7 - Clamp Always replace Tensioning Fig. 7

and Fig. 8 Page 48 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 63 of 369

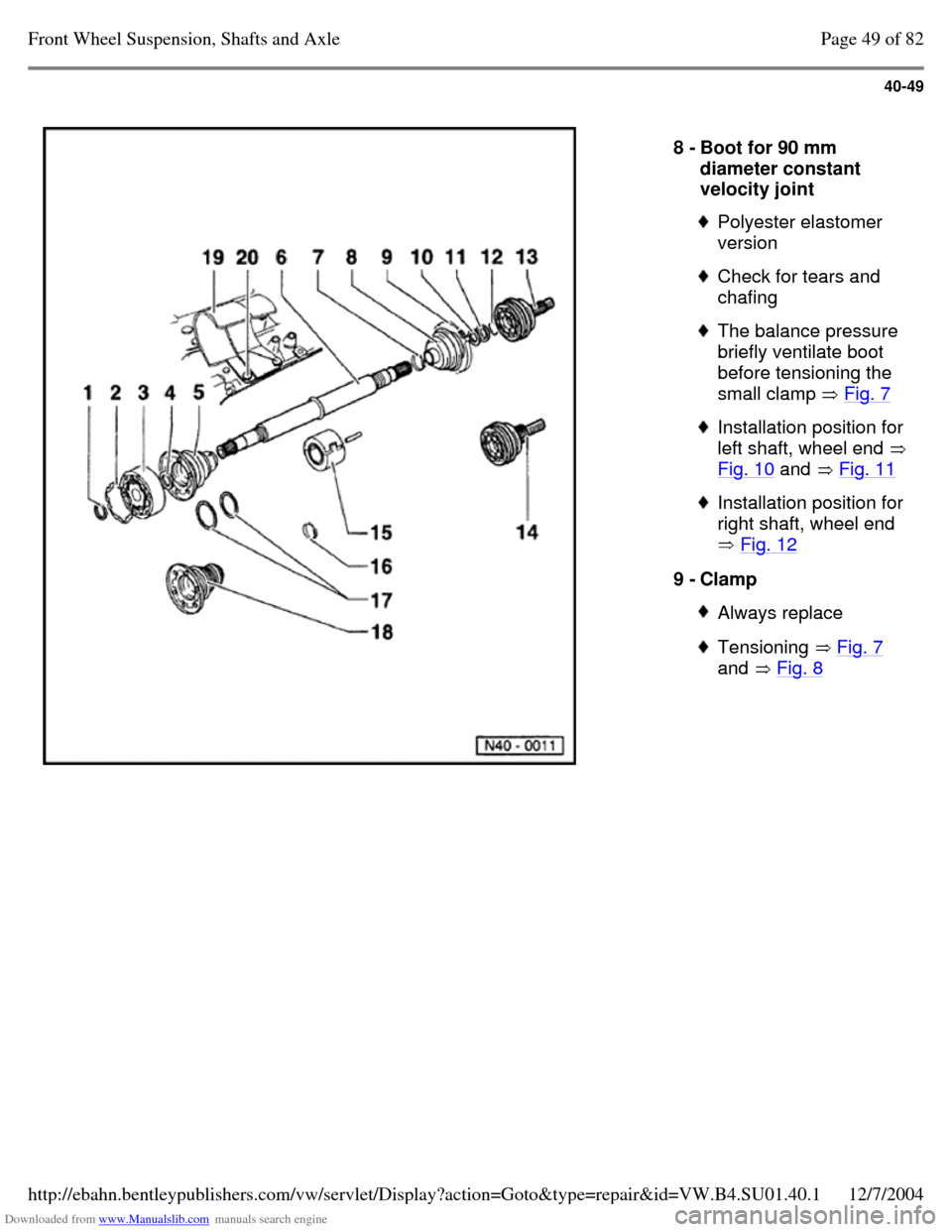

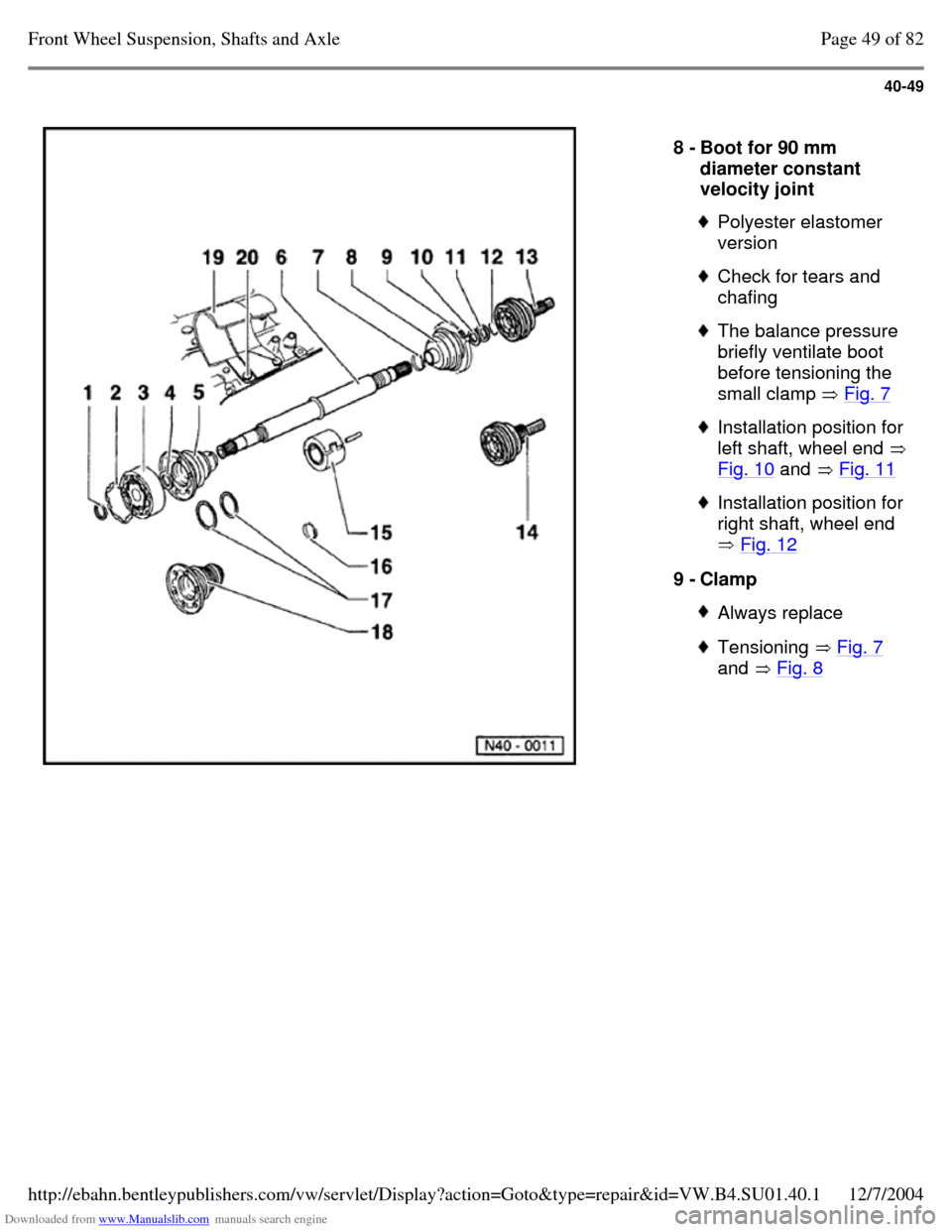

Downloaded from www.Manualslib.com manuals search engine 40-49

8 - Boot for 90 mm

diameter constant

velocity joint Polyester elastomer

version Check for tears and

chafing The balance pressure

briefly ventilate boot

before tensioning the

small clamp Fig. 7 Installation position for

left shaft, wheel end Fig. 10 and Fig. 11 Installation position for

right shaft, wheel end

Fig. 12 9 - Clamp Always replace Tensioning Fig. 7

and Fig. 8 Page 49 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 64 of 369

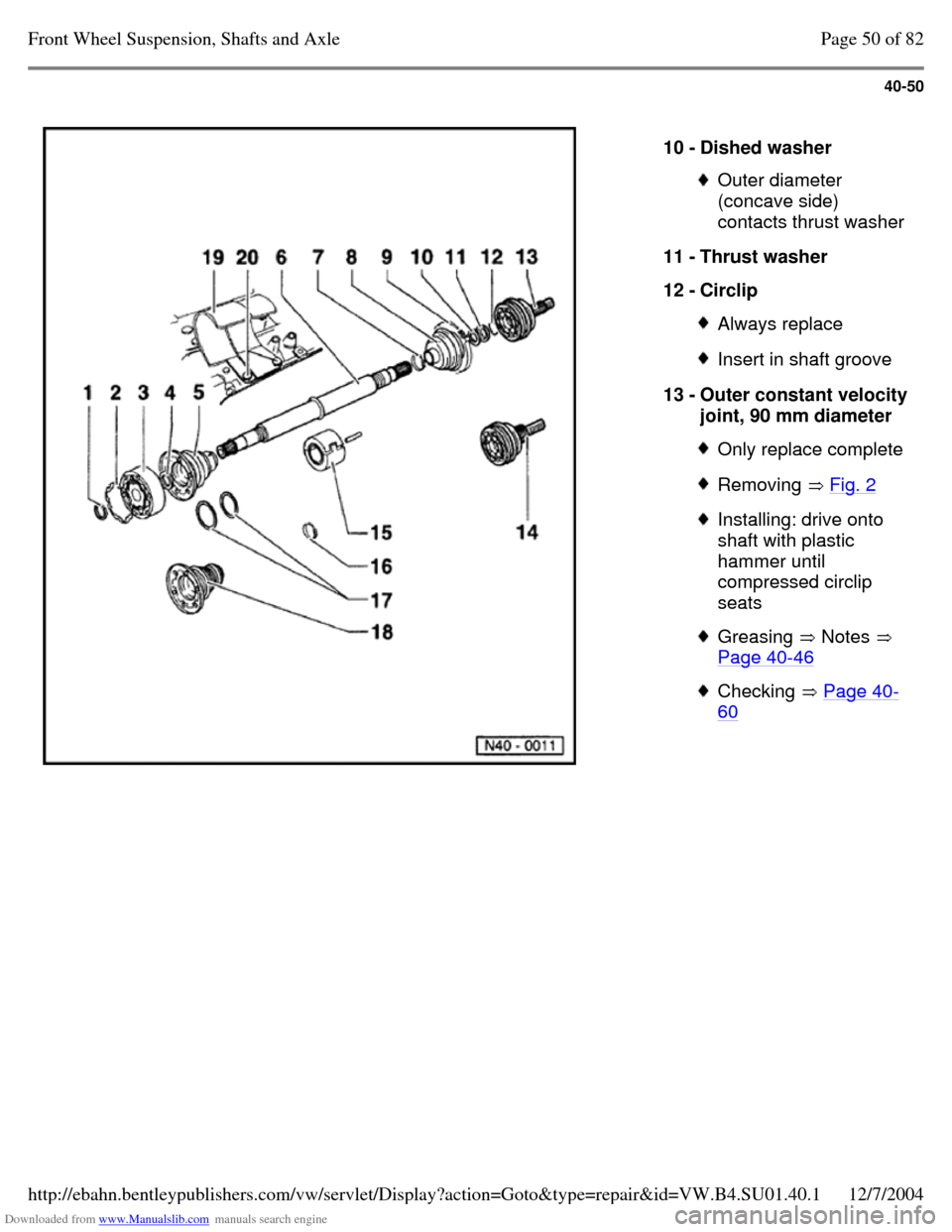

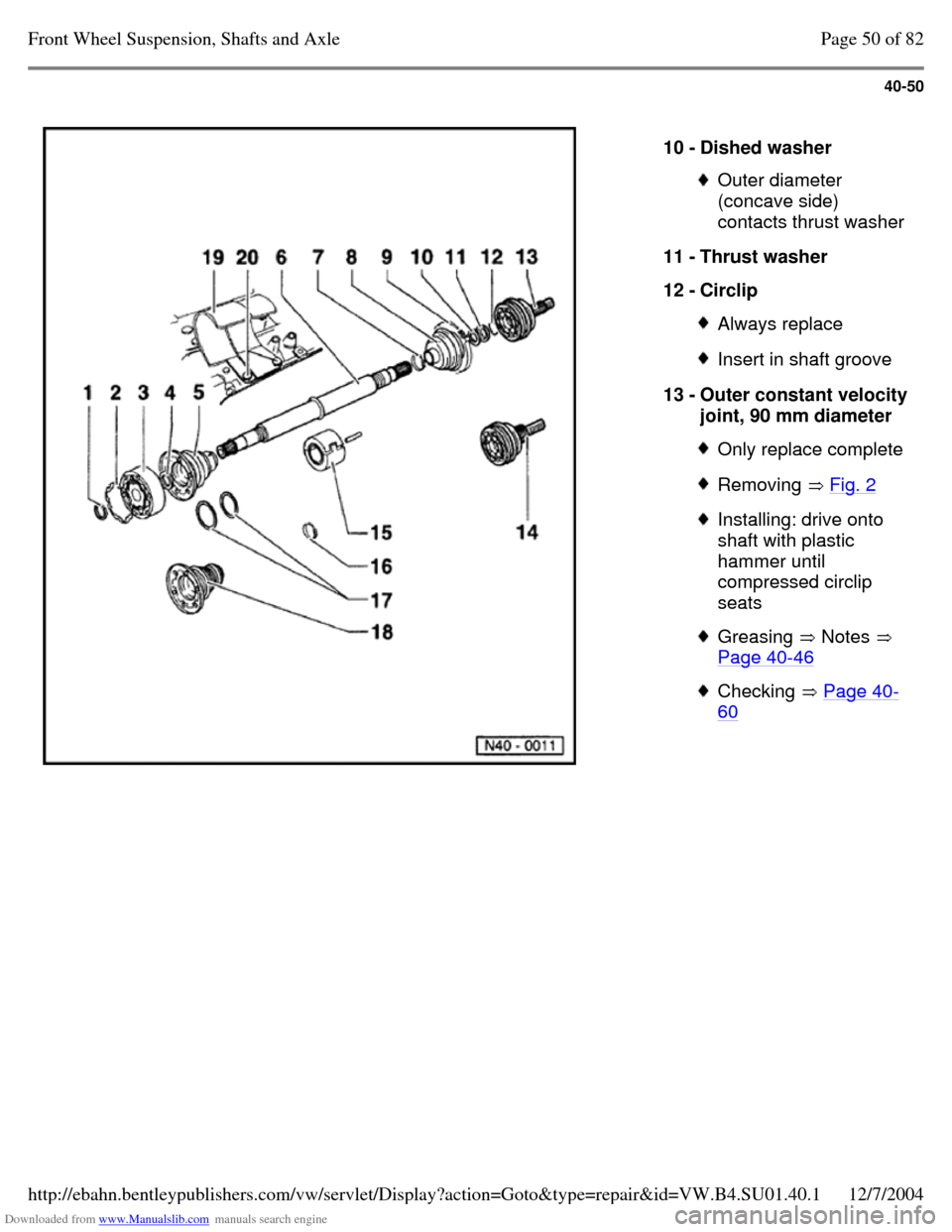

Downloaded from www.Manualslib.com manuals search engine 40-50

10 - Dished washer Outer diameter

(concave side)

contacts thrust washer

11 - Thrust washer

12 - Circlip Always replace Insert in shaft groove 13 - Outer constant velocity joint, 90 mm diameter Only replace complete Removing Fig. 2 Installing: drive onto

shaft with plastic

hammer until

compressed circlip

seats Greasing Notes

Page 40-46 Checking Page 40-60 Page 50 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 65 of 369

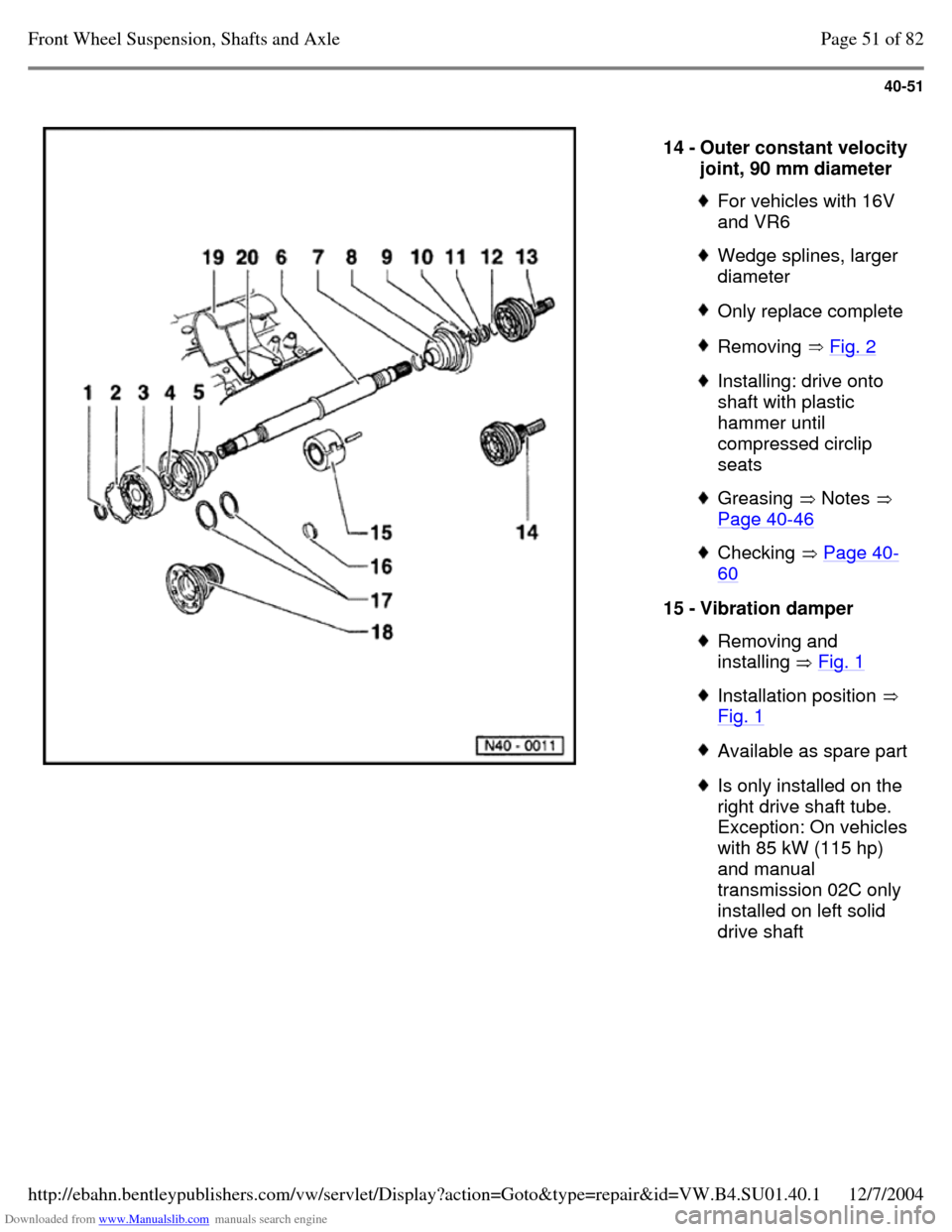

Downloaded from www.Manualslib.com manuals search engine 40-51

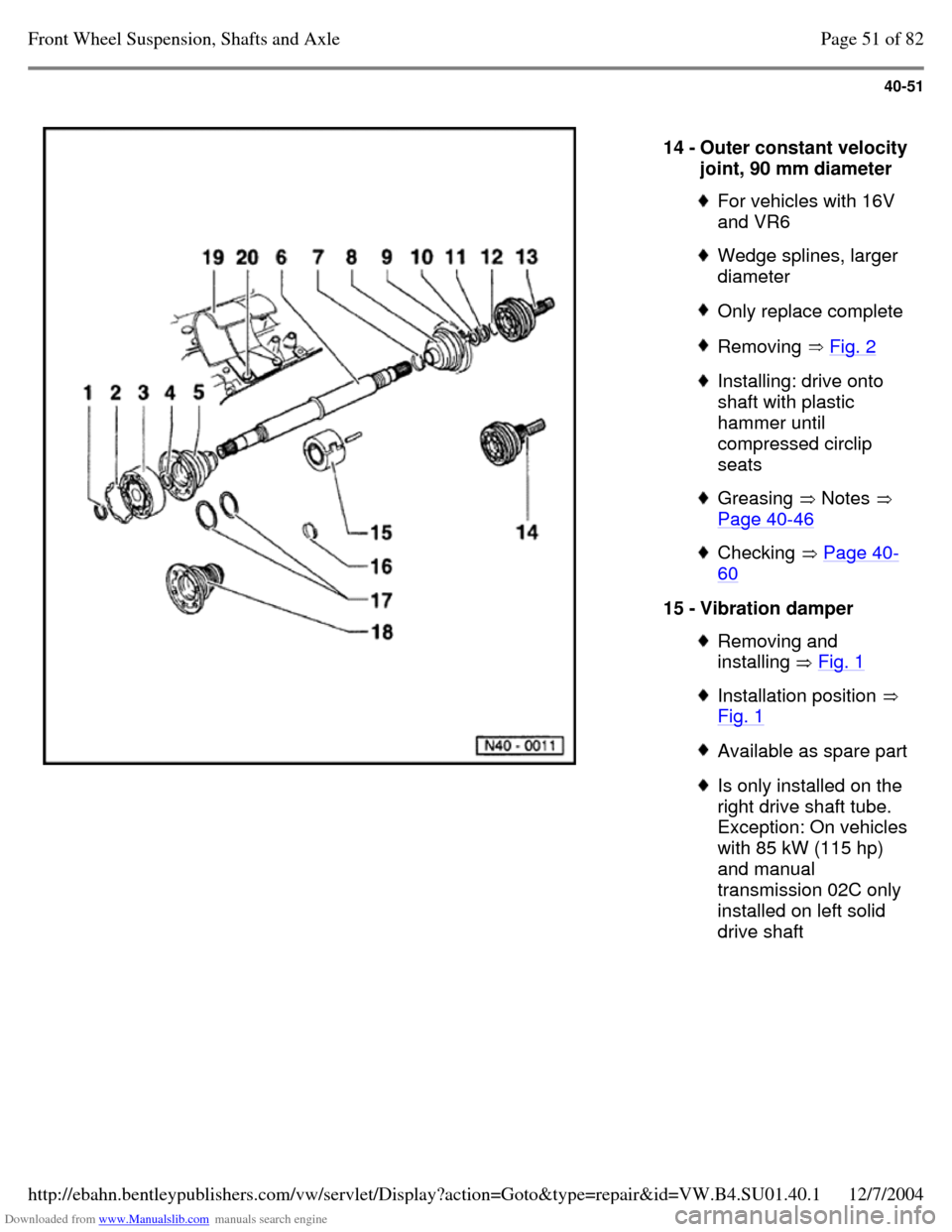

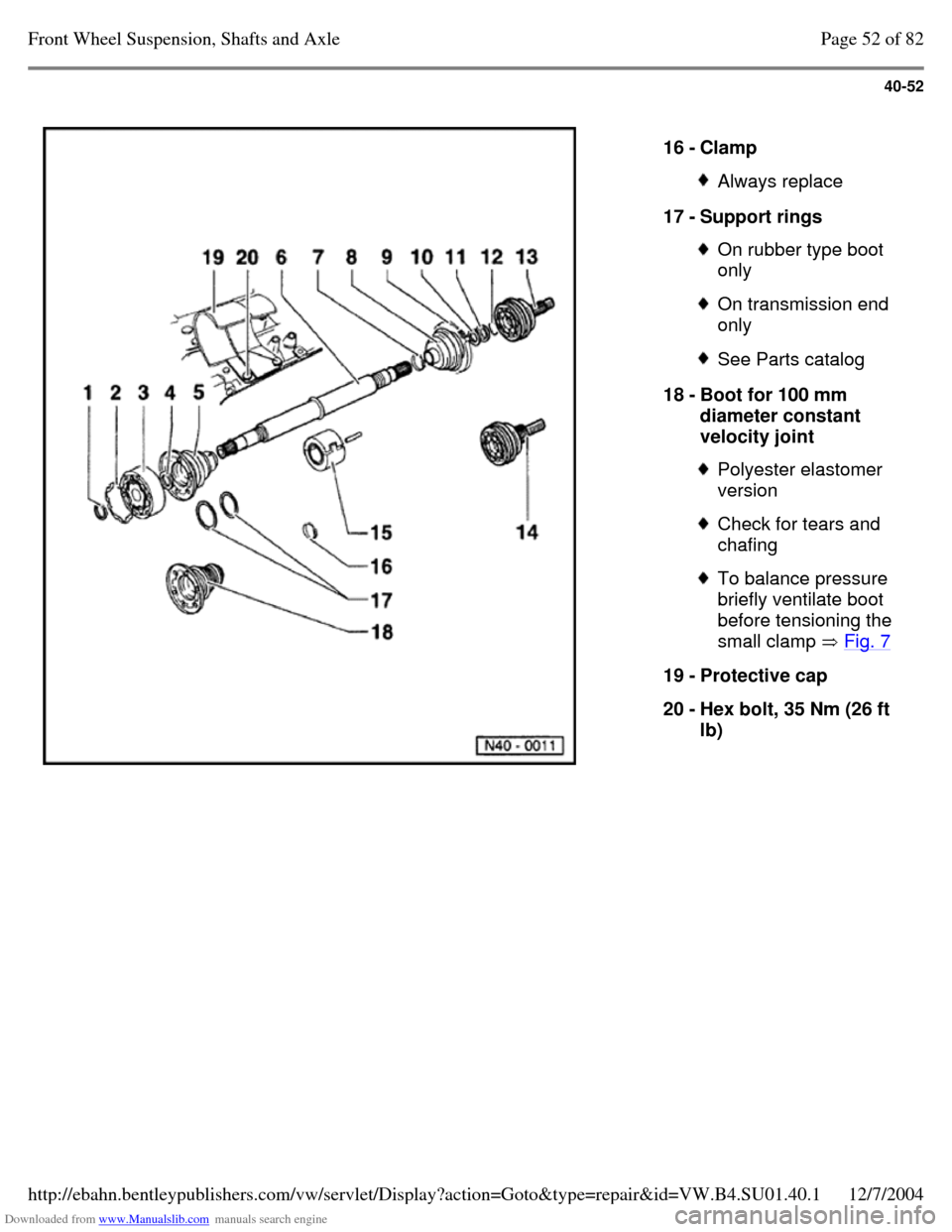

14 - Outer constant velocity joint, 90 mm diameter For vehicles with 16V

and VR6 Wedge splines, larger

diameter Only replace complete Removing Fig. 2 Installing: drive onto

shaft with plastic

hammer until

compressed circlip

seats Greasing Notes

Page 40-46 Checking Page 40-60 15 - Vibration damper Removing and

installing Fig. 1 Installation position

Fig. 1 Available as spare part Is only installed on the

right drive shaft tube. Exception: On vehicles with 85 kW (115 hp)

and manual

transmission 02C only

installed on left solid

drive shaft Page 51 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 66 of 369

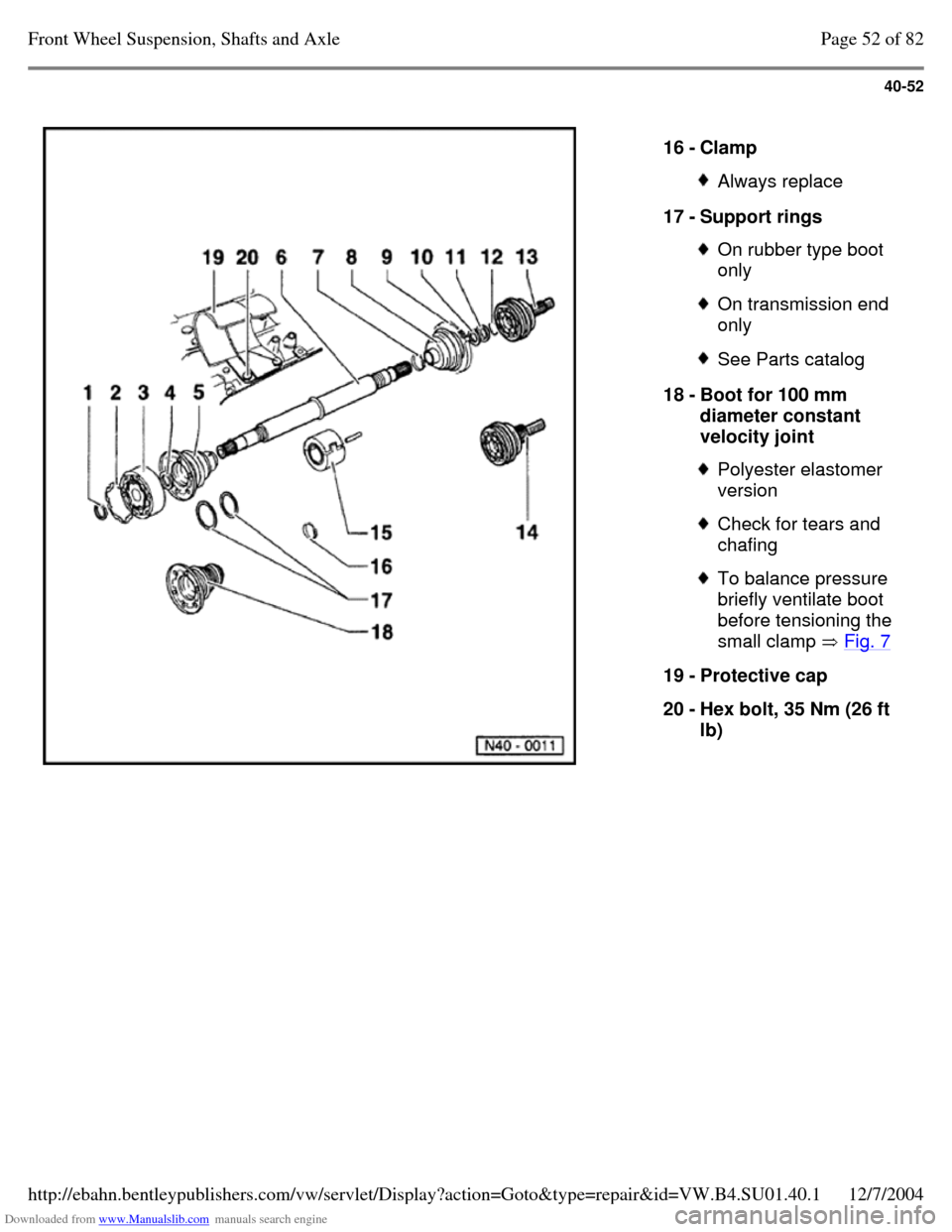

Downloaded from www.Manualslib.com manuals search engine 40-52

16 - Clamp Always replace 17 - Support rings On rubber type boot

only On transmission end

only See Parts catalog 18 - Boot for 100 mm

diameter constant

velocity joint Polyester elastomer

version Check for tears and

chafing To balance pressure

briefly ventilate boot

before tensioning the

small clamp Fig. 7 19 - Protective cap

20 - Hex bolt, 35 Nm (26 ft

lb) Page 52 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 67 of 369

Downloaded from www.Manualslib.com manuals search engine 40-53

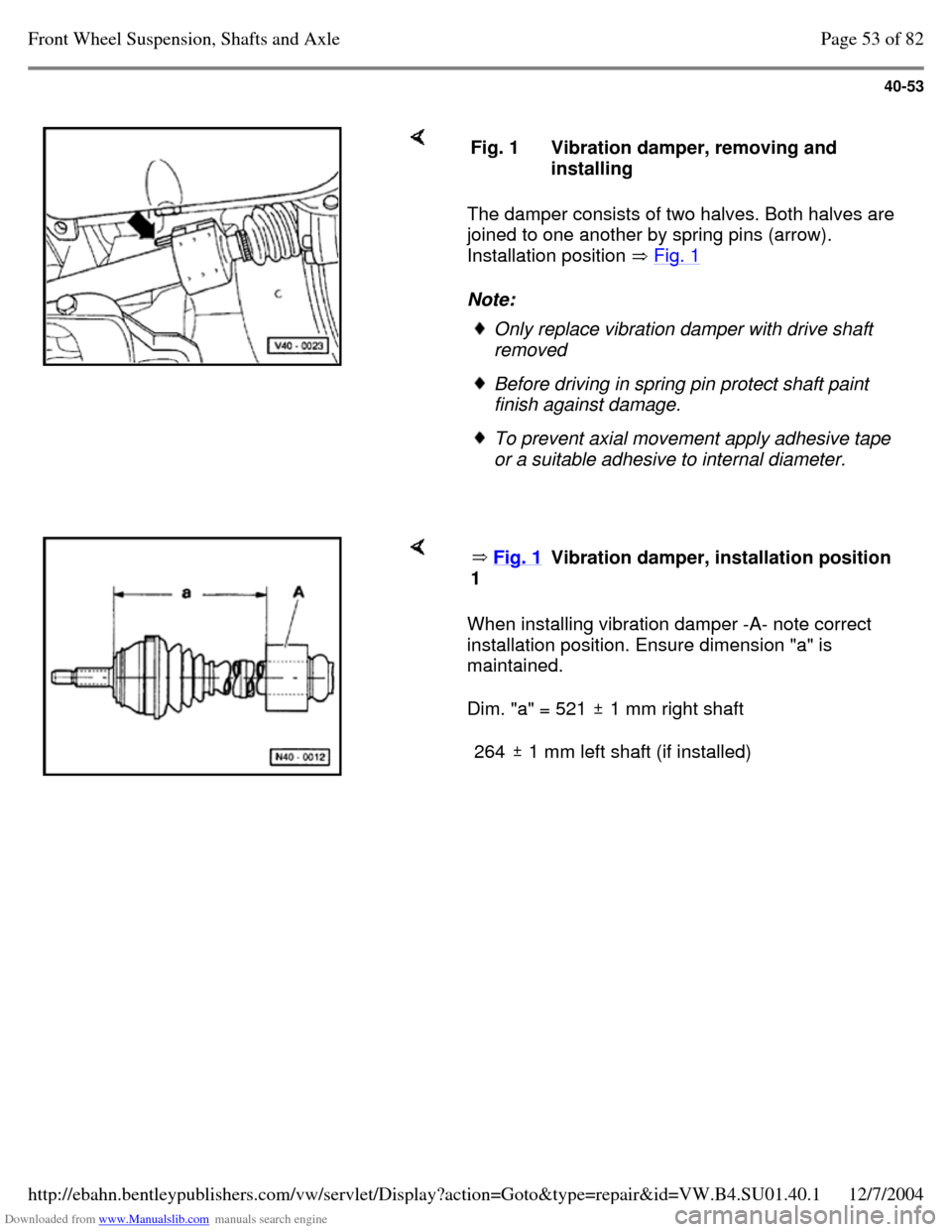

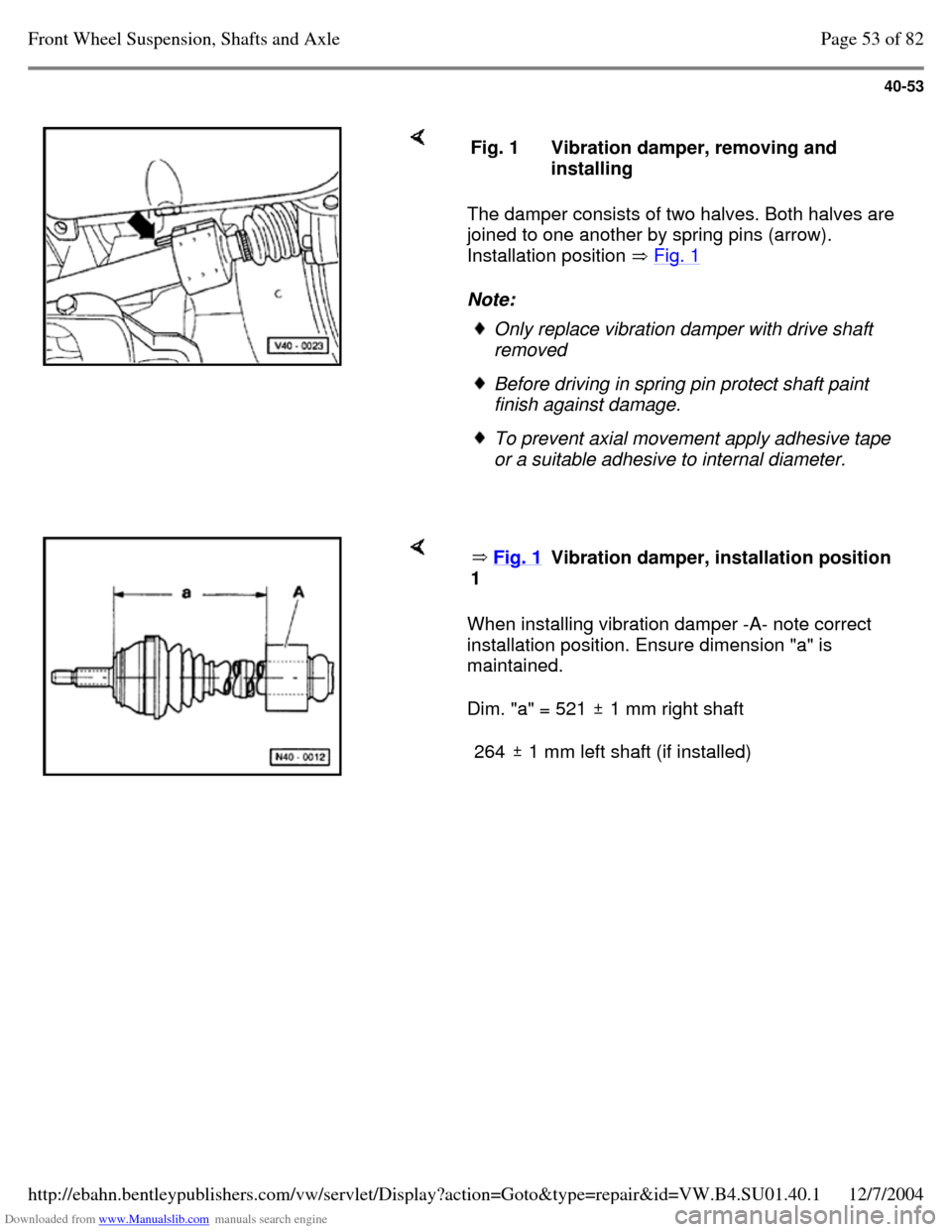

The damper consists of two halves. Both halves are

joined to one another by spring pins (arrow).

Installation position Fig. 1

Note:

Fig. 1 Vibration damper, removing and

installing Only replace vibration damper with drive shaft

removed Before driving in spring pin protect shaft paint

finish against damage. To prevent axial movement apply adhesive tape

or a suitable adhesive to internal diameter. When installing vibration damper -A- note correct

installation position. Ensure dimension "a" is

maintained.

Dim. "a" = 521 1 mm right shaft

264 1 mm left shaft (if installed) Fig. 1

1 Vibration damper, installation position Page 53 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 68 of 369

Downloaded from www.Manualslib.com manuals search engine 40-54

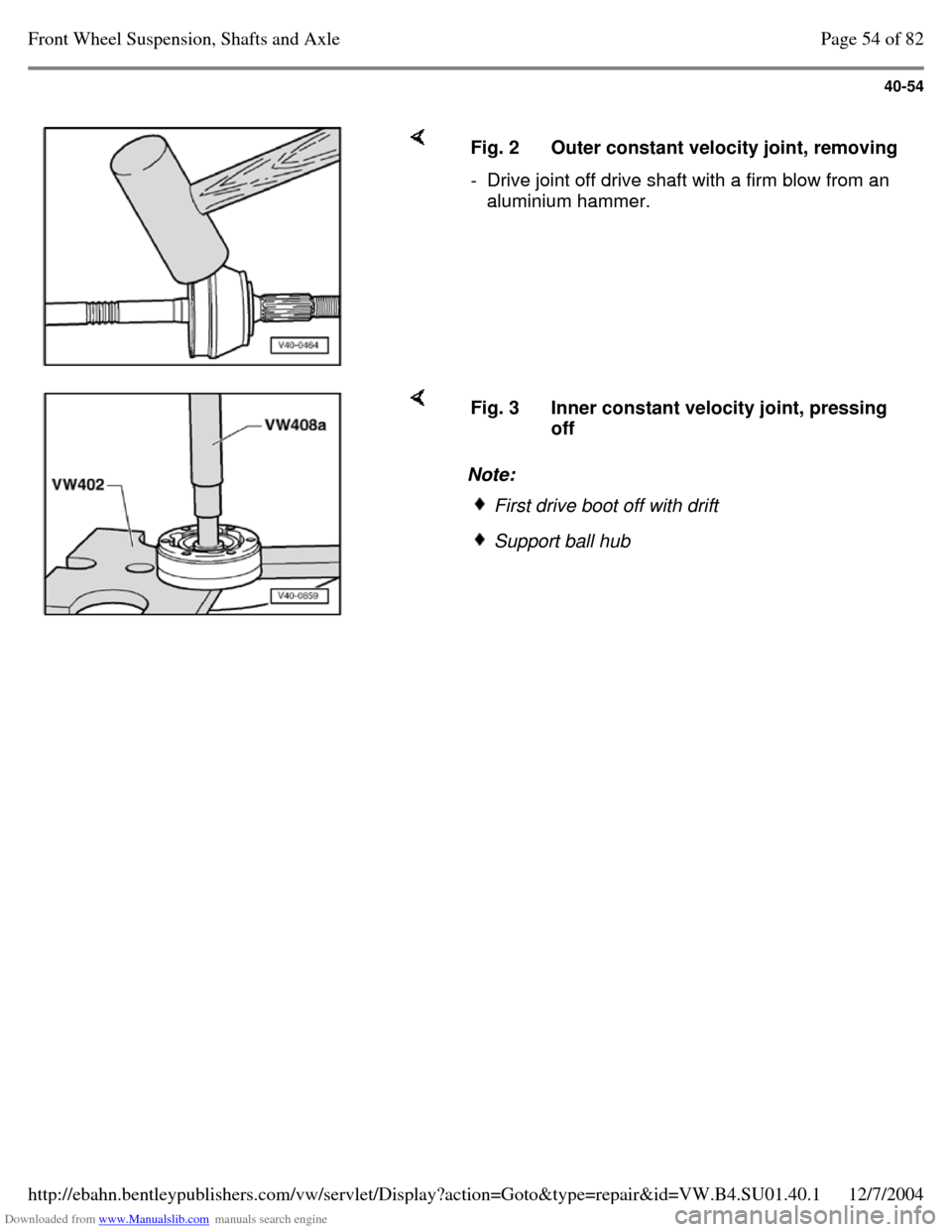

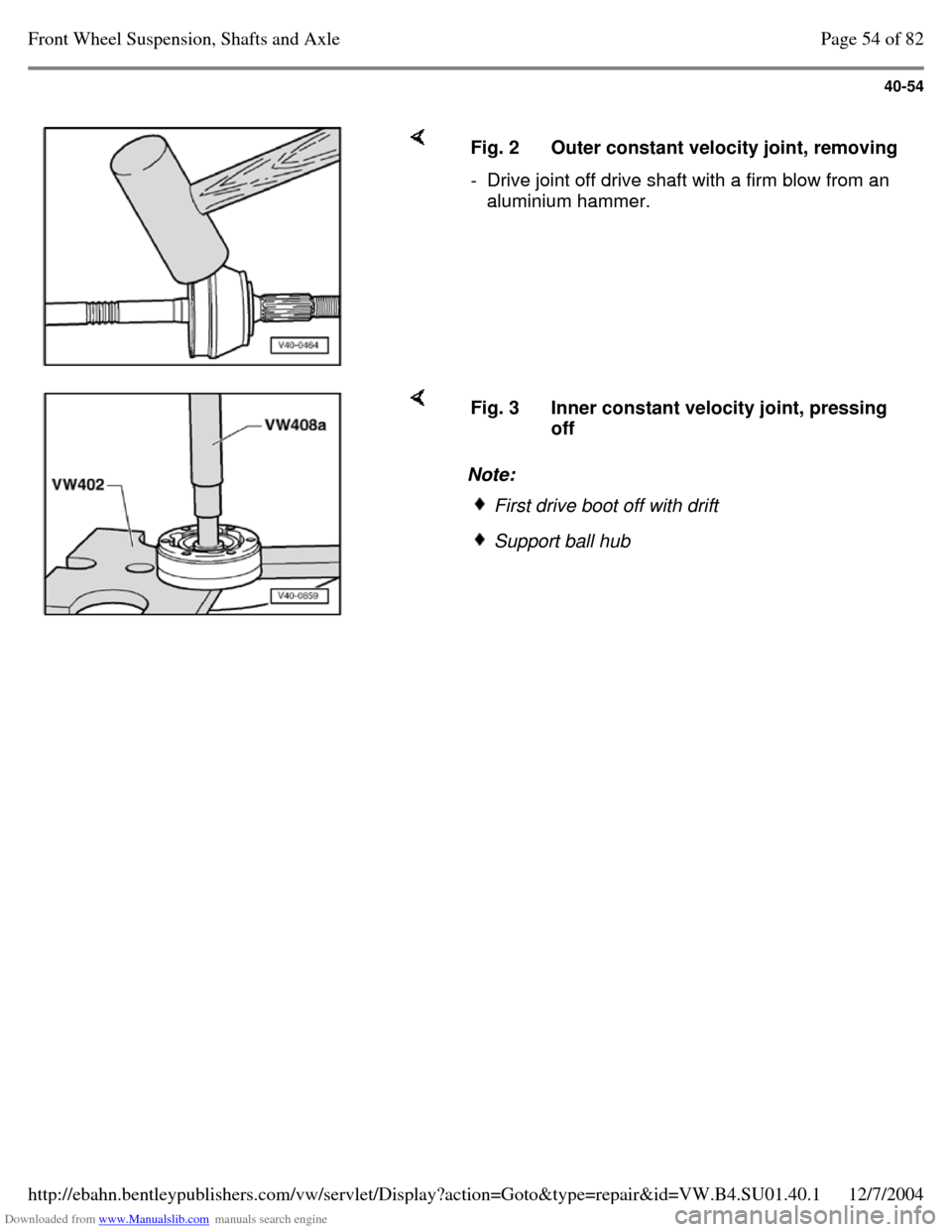

Fig. 2 Outer constant velocity joint, removing - Drive joint off drive shaft with a firm blow from an

aluminium hammer. Note: Fig. 3 Inner constant velocity joint, pressing

off First drive boot off with drift Support ball hub Page 54 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 69 of 369

Downloaded from www.Manualslib.com manuals search engine 40-55

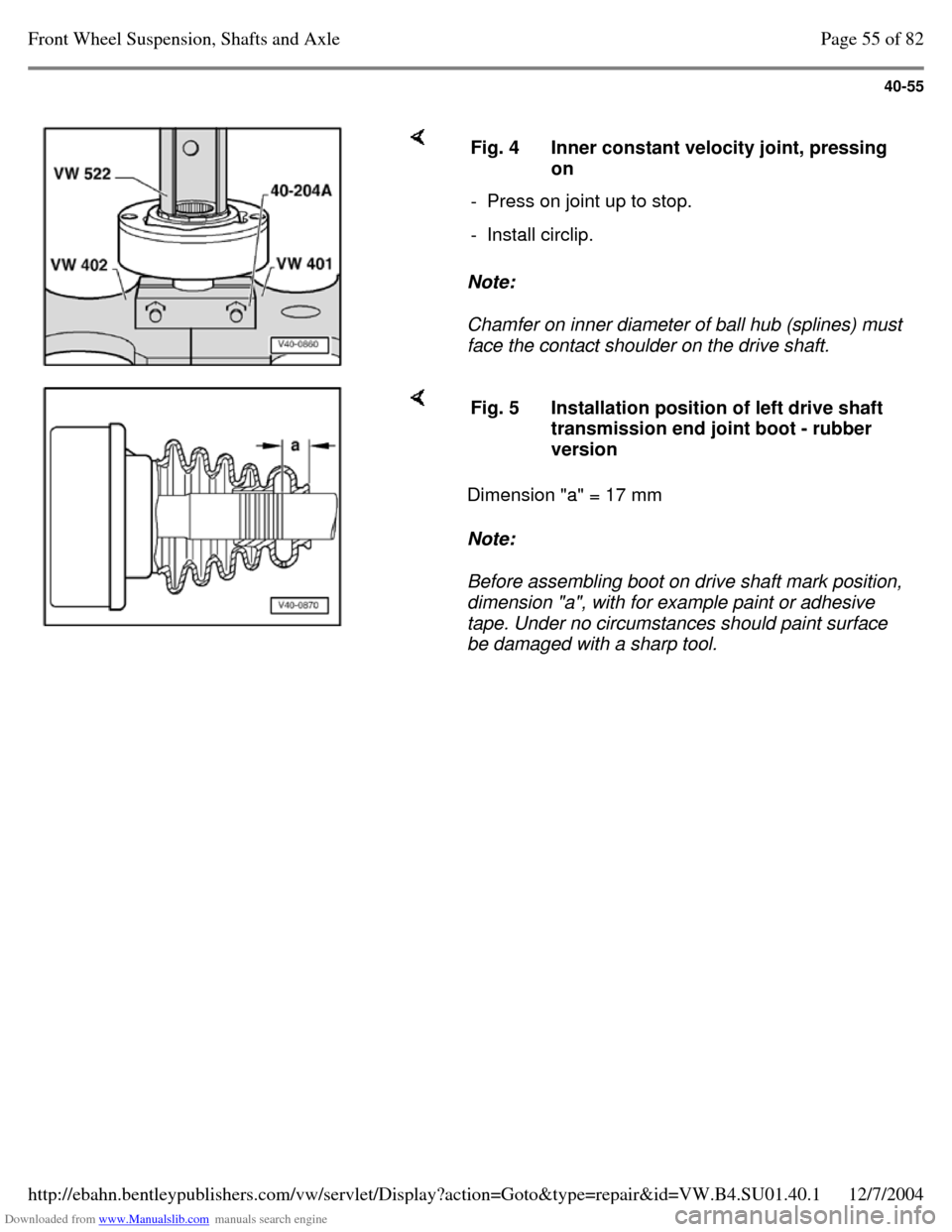

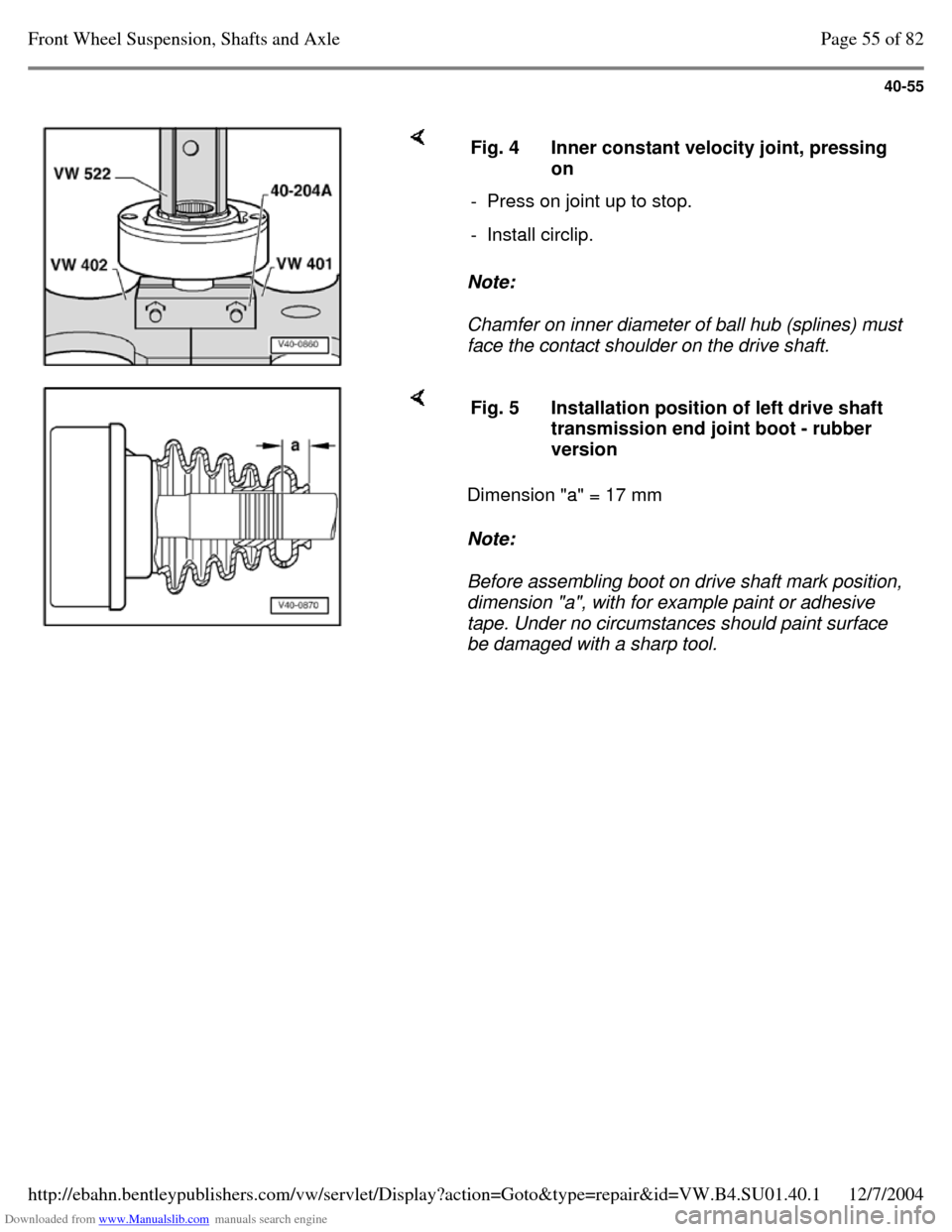

Note:

Chamfer on inner diameter of ball hub (splines) must

face the contact shoulder on the drive shaft. Fig. 4 Inner constant velocity joint, pressing

on

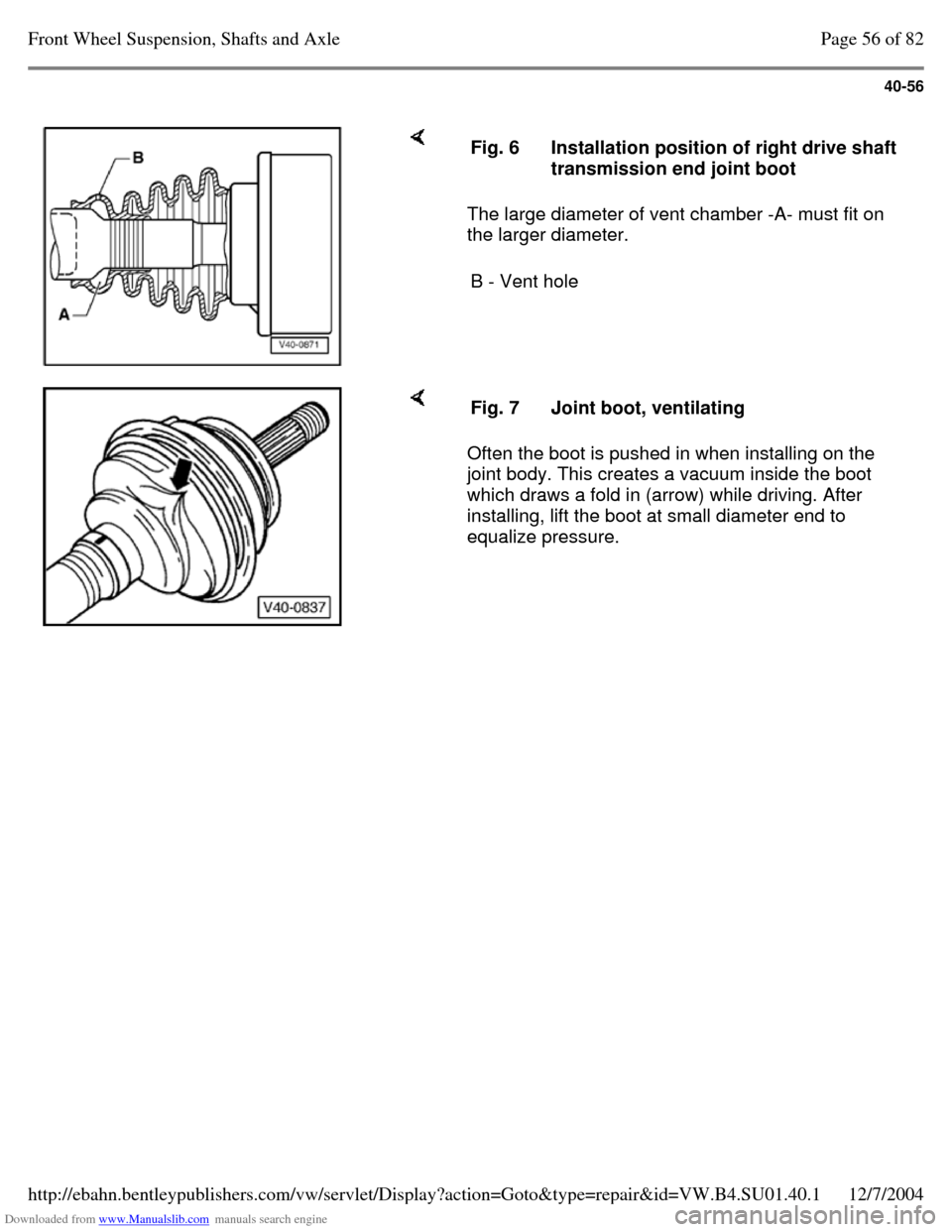

- Press on joint up to stop. - Install circlip. Dimension "a" = 17 mm

Note:

Before assembling boot on drive shaft mark position,

dimension "a", with for example paint or adhesive

tape. Under no circumstances should paint surface

be damaged with a sharp tool. Fig. 5 Installation position of left drive shaft

transmission end joint boot - rubber

version Page 55 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Page 70 of 369

Downloaded from www.Manualslib.com manuals search engine 40-56

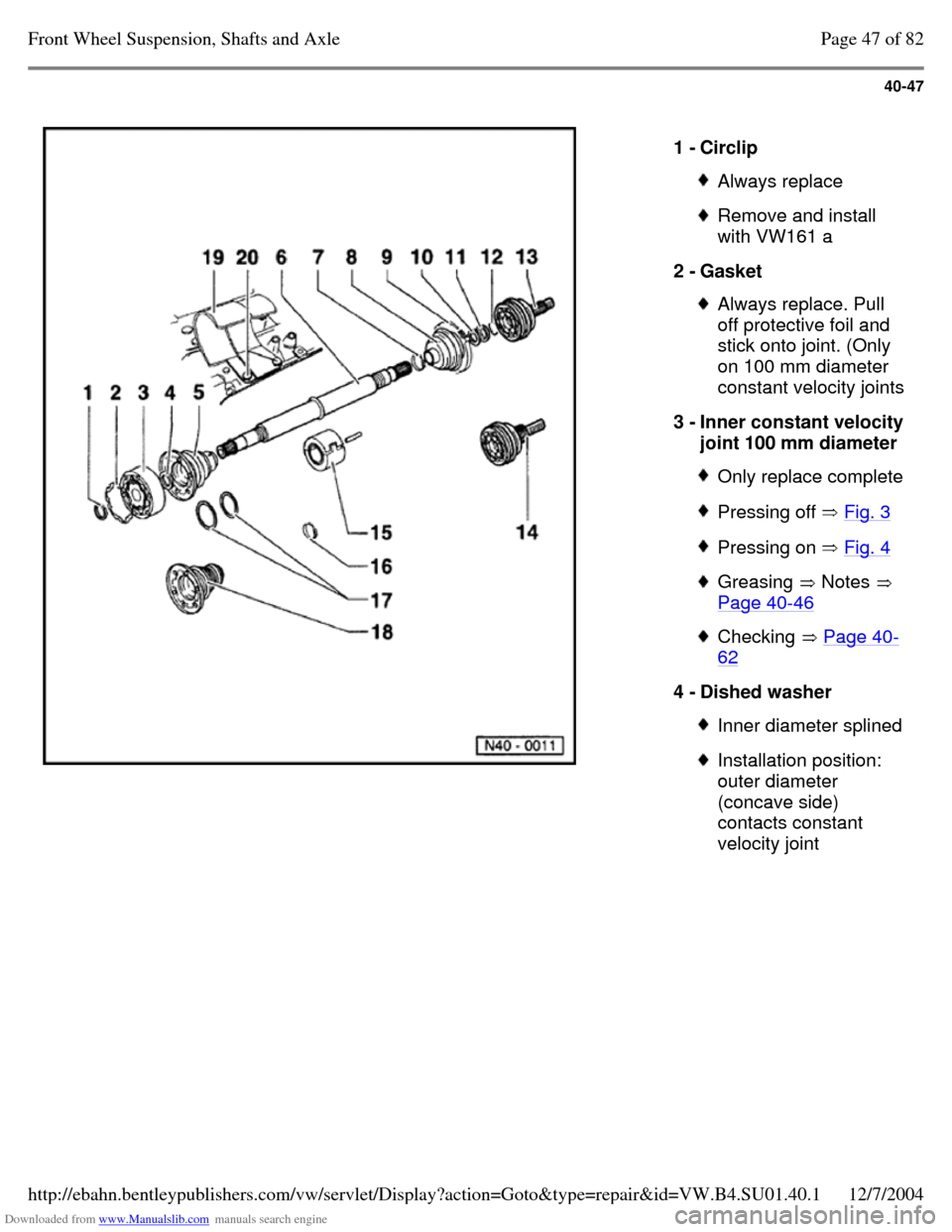

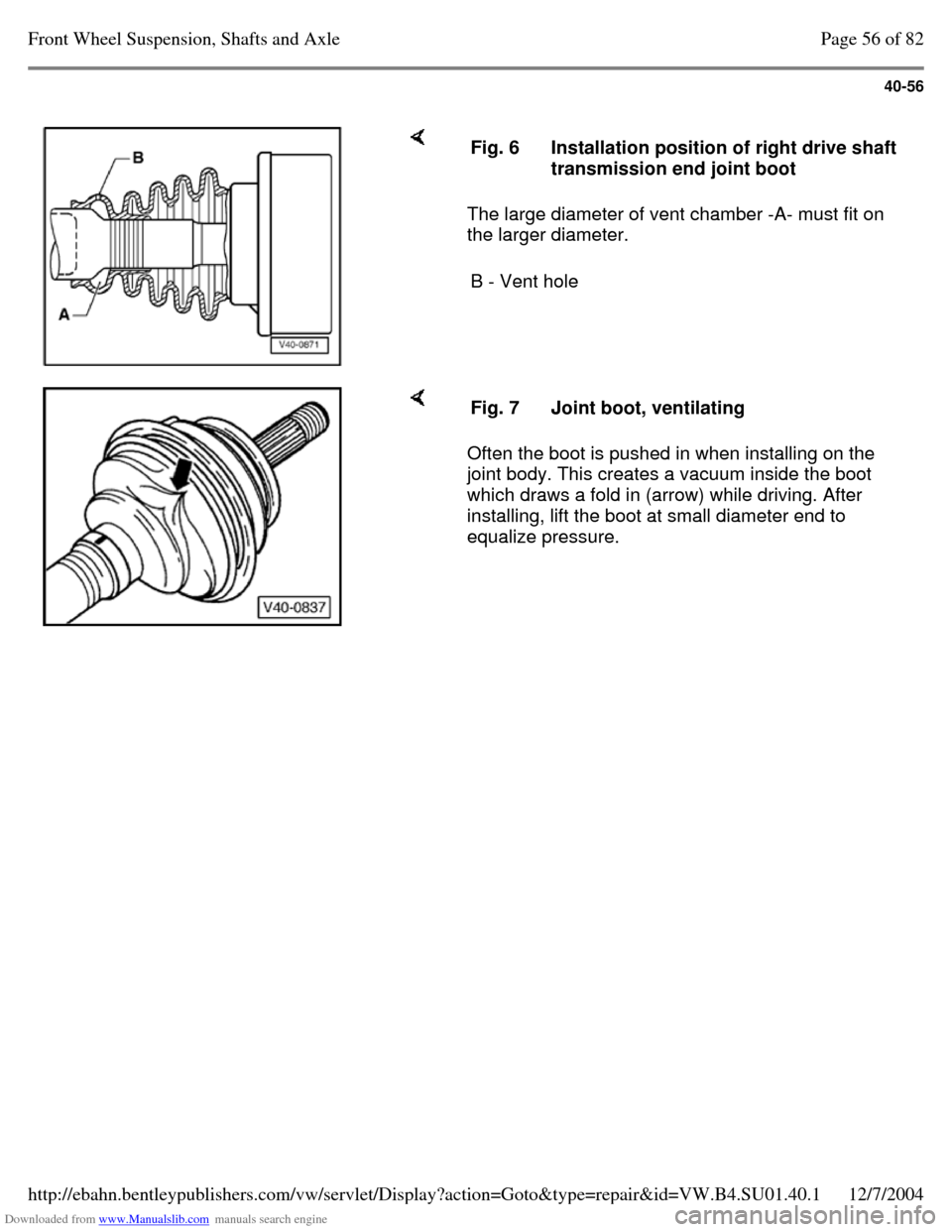

The large diameter of vent chamber -A- must fit on

the larger diameter. Fig. 6 Installation position of right drive shaft

transmission end joint boot

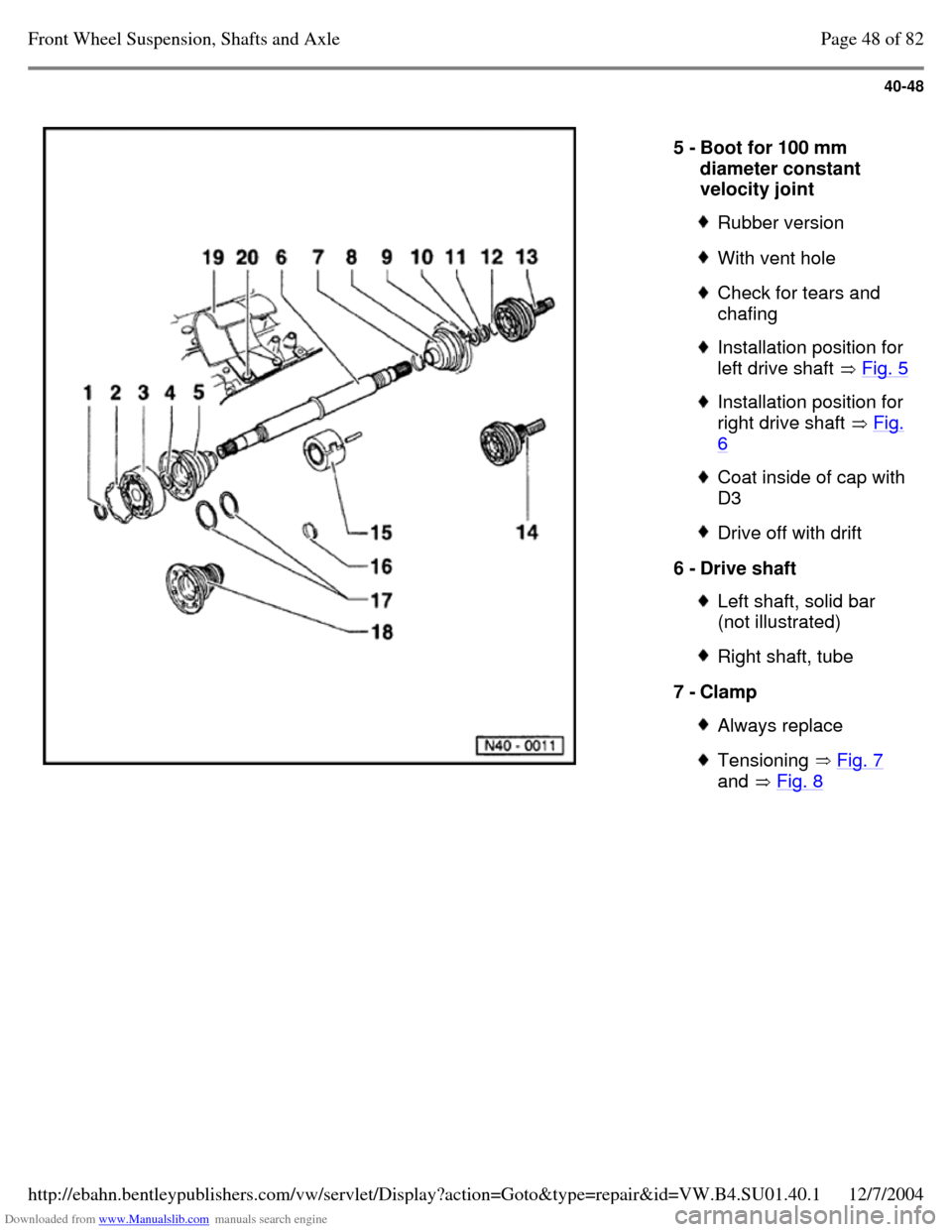

B - Vent hole Often the boot is pushed in when installing on the

joint body. This creates a vacuum inside the boot

which draws a fold in (arrow) while driving. After

installing, lift the boot at small diameter end to

equalize pressure. Fig. 7 Joint boot, ventilating Page 56 of 82Front Wheel Suspension, Shafts and Axle12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.40.1

Trending: rear strut, front suspension, display, shock, Intake, wheel size, length