check engine light VOLKSWAGEN PASSAT 1996 B3, B4 / 3.G Service Workshop Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1996, Model line: PASSAT, Model: VOLKSWAGEN PASSAT 1996 B3, B4 / 3.GPages: 369, PDF Size: 12.33 MB

Page 5 of 369

Downloaded from www.Manualslib.com manuals search engine Front brakes, servicing (Teves/Ate)

Brake pads, removing and installing

Rear wheel brakes, servicing (drum brakes)

Brake shoe adjustment, releasing

Rear wheel brakes, servicing

Brake shoes, removing and installing

Parking brake, adjusting (drum brakes)

Rear wheel brakes, servicing (disc brakes)

Girling rear wheel disc brakes (front and four wheel drive vehicles)

Brake pads, removing and installing

Parking brake, adjusting (disc brakes)

Parking brake lever assembly overview

Brake pedal/brake servo, removing and installing

Brake pedal, removing and installing

Brake Light Switch, adjusting

47 - Brakes - Hydraulic components

Assembly overview: brake master cylinder/brake servo

Girling front brake caliper, servicing

Front brake caliper pistons, removing and installing

Front brake caliper, servicing (Teves/Ate)

Rear brake caliper, servicing

Rear brake caliper piston, removing and installing

Pre-bleeding brake caliper

Brake pressure regulator, checking and adjusting

Vehicles without ABS, vehicles with ABS, ABS/EDS, Teves 04

Load dependent brake pressure regulator specifications

Adjusting regulator

Brake system, bleeding

Brake system, bleeding (vehicles with and without ABS, ABS/EDL)

Brake system, bleeding (with pressure bleeder VAS 5234)

Brake system, bleeding (without pressure bleeder)

Page 168 of 369

Downloaded from www.Manualslib.com manuals search engine 44-6

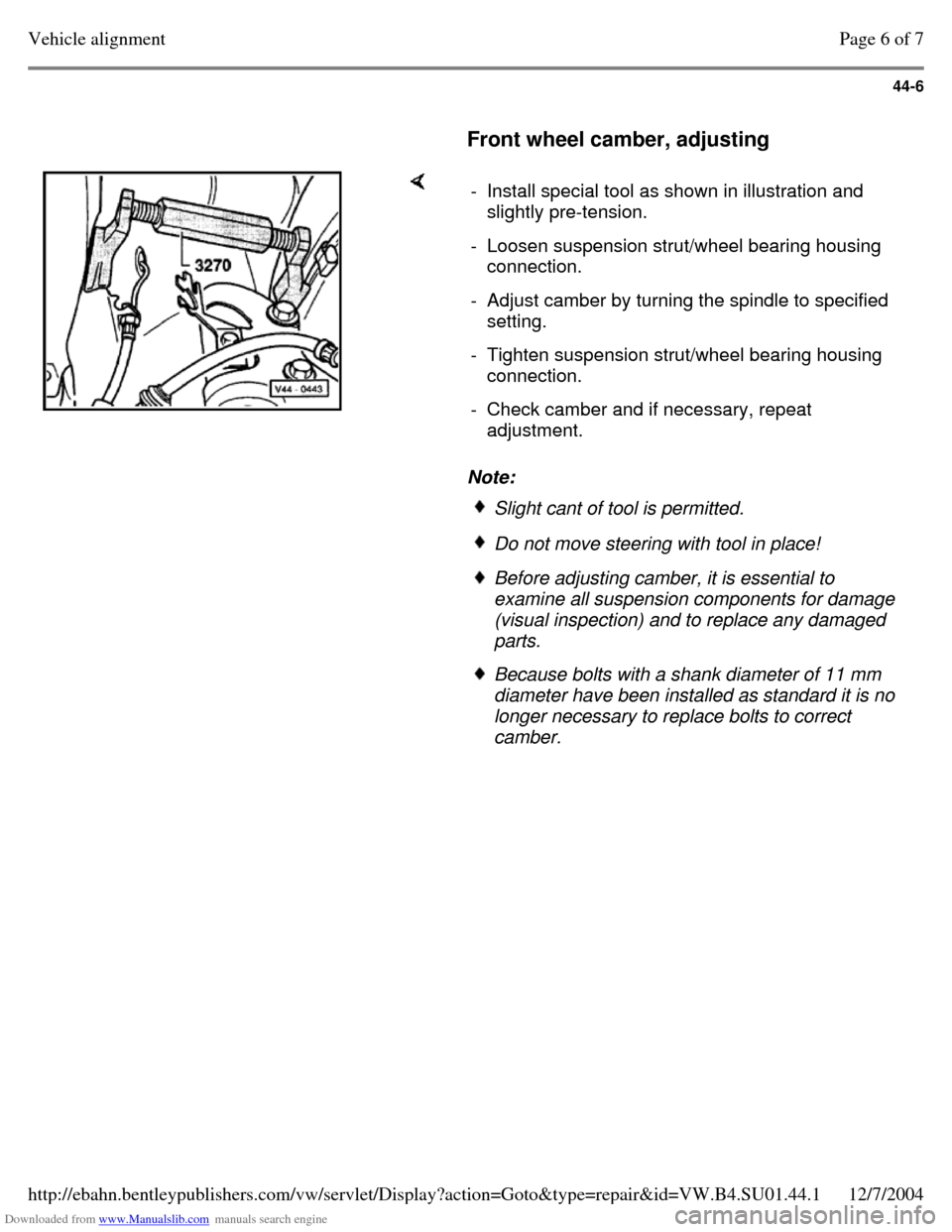

Front wheel camber, adjusting Note: - Install special tool as shown in illustration and

slightly pre-tension.

- Loosen suspension strut/wheel bearing housing

connection.

- Adjust camber by turning the spindle to specified

setting.

- Tighten suspension strut/wheel bearing housing

connection.

- Check camber and if necessary, repeat

adjustment. Slight cant of tool is permitted. Do not move steering with tool in place! Before adjusting camber, it is essential to

examine all suspension components for damage

(visual inspection) and to replace any damaged

parts. Because bolts with a shank diameter of 11 mm

diameter have been installed as standard it is no

longer necessary to replace bolts to correct

camber. Page 6 of 7Vehicle alignment12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.44.1

Page 241 of 369

Downloaded from www.Manualslib.com manuals search engine 46-45

Brake Light Switch, adjusting

Note:

The Brake Light Switch must be removed for

adjusting.

- Remove trim under instrument panel.

- Disconnect harness connector for Brake Light

Switch.

- Remove Brake Light Switch by turning to right

through 90.

- Pull Brake Light Switch plunger fully out.

- Depress brake pedal as far as possible by hand,

guide Brake Light Switch through the locating

hole and secure by turning through 90to left.

- Pull brake pedal back up by hand to stop (Brake

Light Switch is pushed back by one notch).

- Connect harness connector for Brake Light

Switch

- Check function of Brake Light Switch.

- Install instrument panel trim. Page 9 of 9Parking brake lever assembly overview12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.46.6

Page 243 of 369

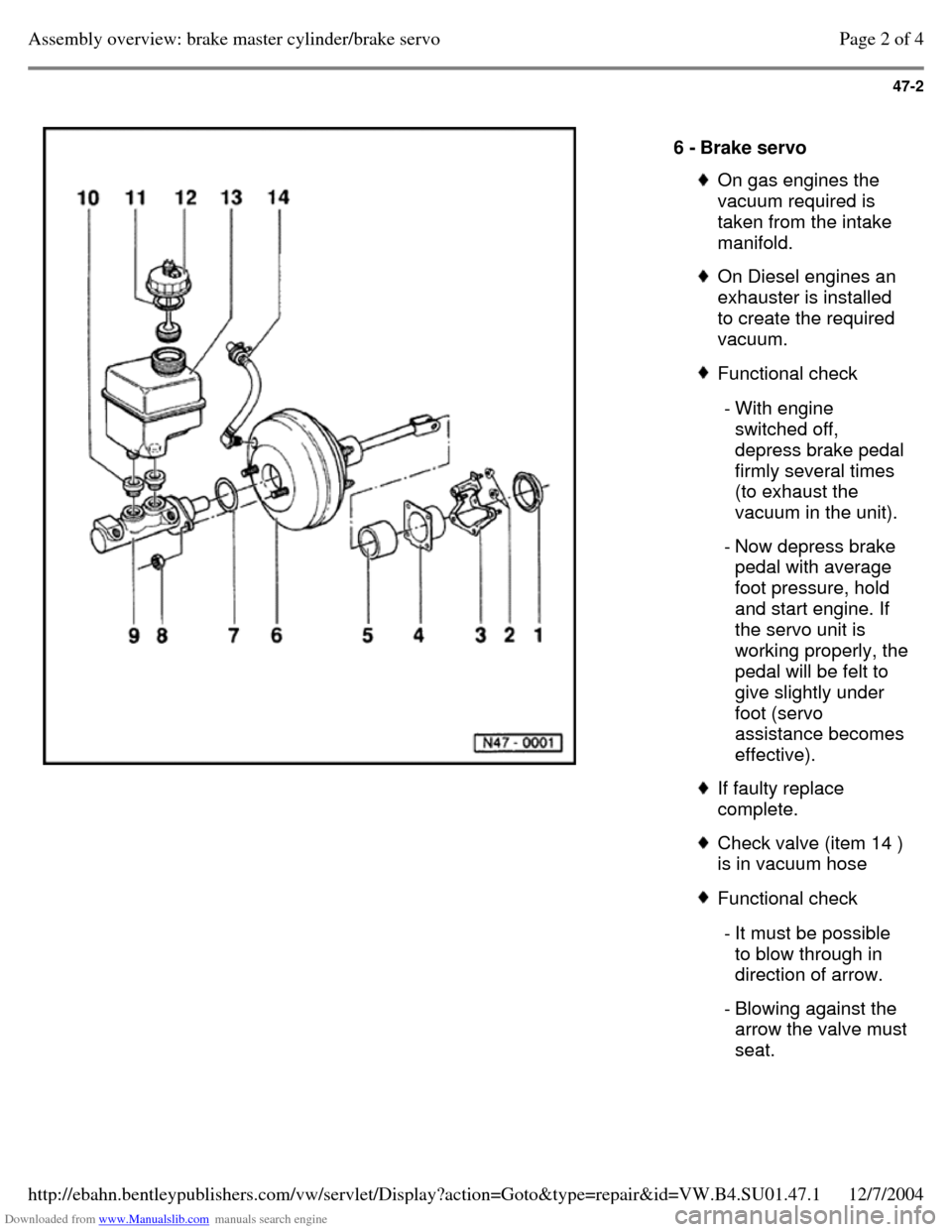

Downloaded from www.Manualslib.com manuals search engine 47-2

6 - Brake servo On gas engines the

vacuum required is

taken from the intake

manifold. On Diesel engines an

exhauster is installed

to create the required

vacuum. Functional check - With engine

switched off,

depress brake pedal

firmly several times

(to exhaust the

vacuum in the unit).

- Now depress brake

pedal with average

foot pressure, hold

and start engine. If

the servo unit is working properly, the pedal will be felt to

give slightly under

foot (servo

assistance becomes

effective). If faulty replace

complete. Check valve (item 14 )

is in vacuum hose Functional check - It must be possible

to blow through in

direction of arrow.

- Blowing against the arrow the valve must seat. Page 2 of 4Assembly overview: brake master cylinder/brake servo12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.47.1

Page 310 of 369

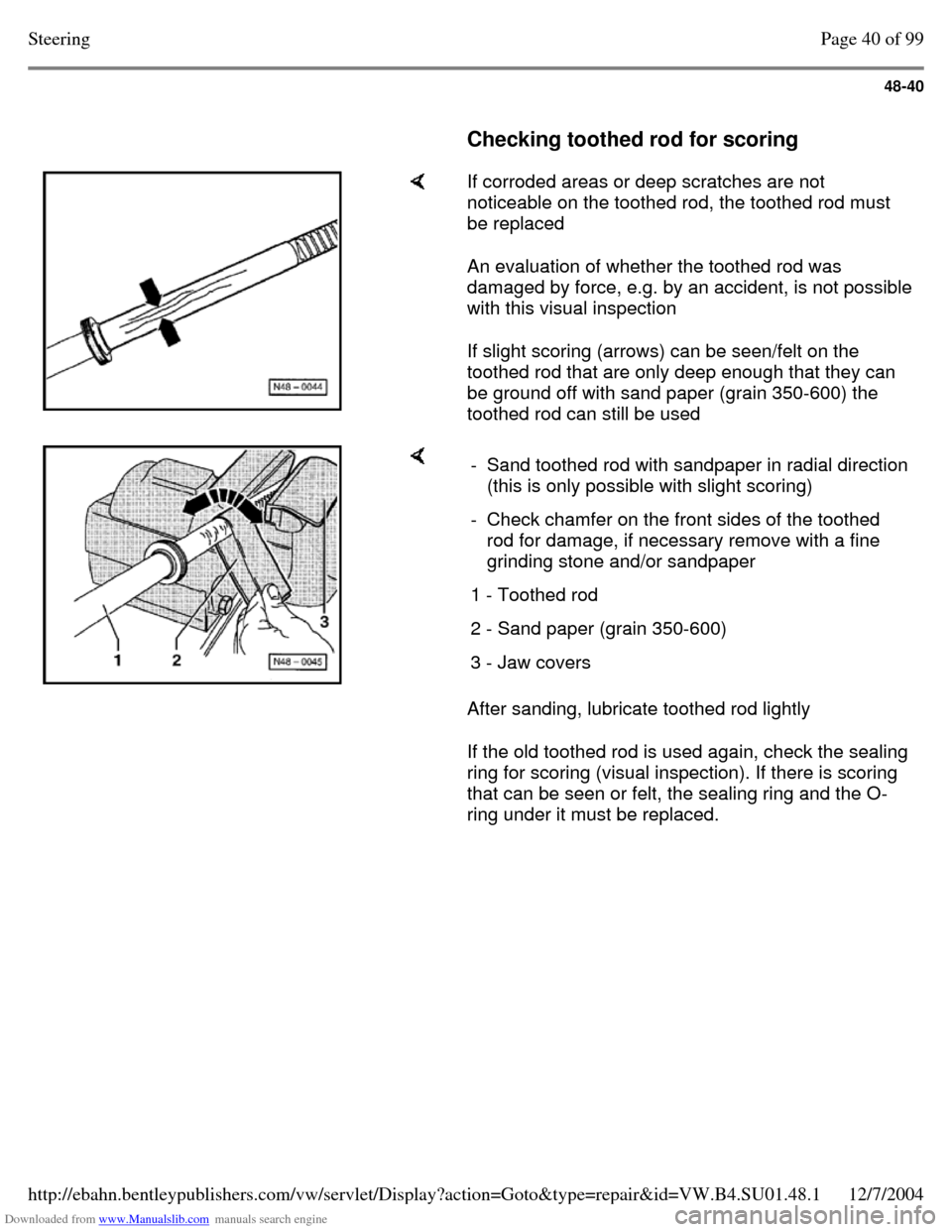

Downloaded from www.Manualslib.com manuals search engine 48-40

Checking toothed rod for scoring If corroded areas or deep scratches are not

noticeable on the toothed rod, the toothed rod must

be replaced

An evaluation of whether the toothed rod was

damaged by force, e.g. by an accident, is not possible

with this visual inspection

If slight scoring (arrows) can be seen/felt on the

toothed rod that are only deep enough that they can

be ground off with sand paper (grain 350-600) the

toothed rod can still be used After sanding, lubricate toothed rod lightly

If the old toothed rod is used again, check the sealing

ring for scoring (visual inspection). If there is scoring

that can be seen or felt, the sealing ring and the O-

ring under it must be replaced. - Sand toothed rod with sandpaper in radial direction (this is only possible with slight scoring)

- Check chamfer on the front sides of the toothed

rod for damage, if necessary remove with a fine

grinding stone and/or sandpaper

1 - Toothed rod 2 - Sand paper (grain 350-600) 3 - Jaw covers Page 40 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1

Page 323 of 369

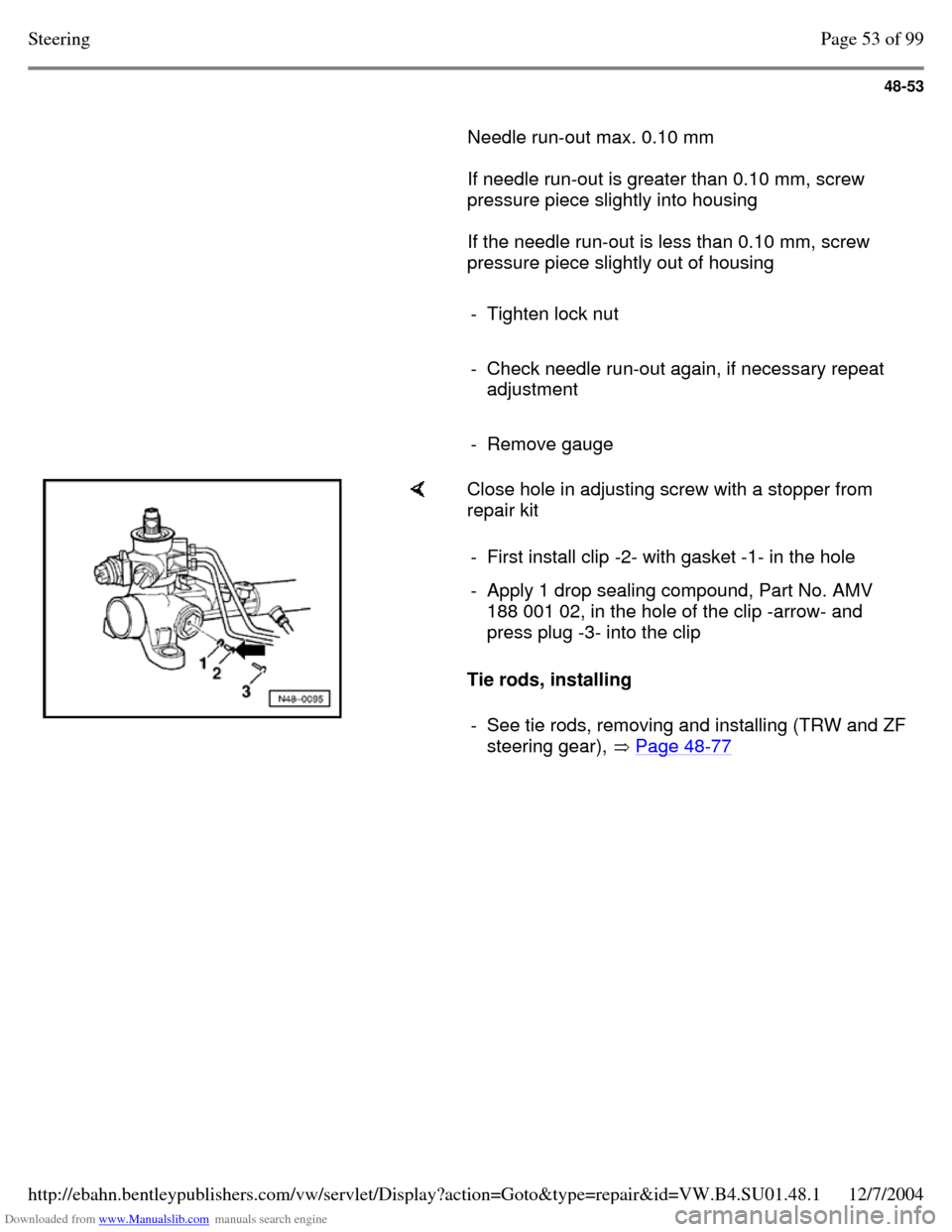

Downloaded from www.Manualslib.com manuals search engine 48-53

Needle run-out max. 0.10 mm

If needle run-out is greater than 0.10 mm, screw

pressure piece slightly into housing

If the needle run-out is less than 0.10 mm, screw

pressure piece slightly out of housing

- Tighten lock nut

- Check needle run-out again, if necessary repeat

adjustment

- Remove gauge Close hole in adjusting screw with a stopper from

repair kit

Tie rods, installing - First install clip -2- with gasket -1- in the hole - Apply 1 drop sealing compound, Part No. AMV

188 001 02, in the hole of the clip -arrow- and

press plug -3- into the clip

- See tie rods, removing and installing (TRW and ZF steering gear), Page 48-77 Page 53 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1

Page 339 of 369

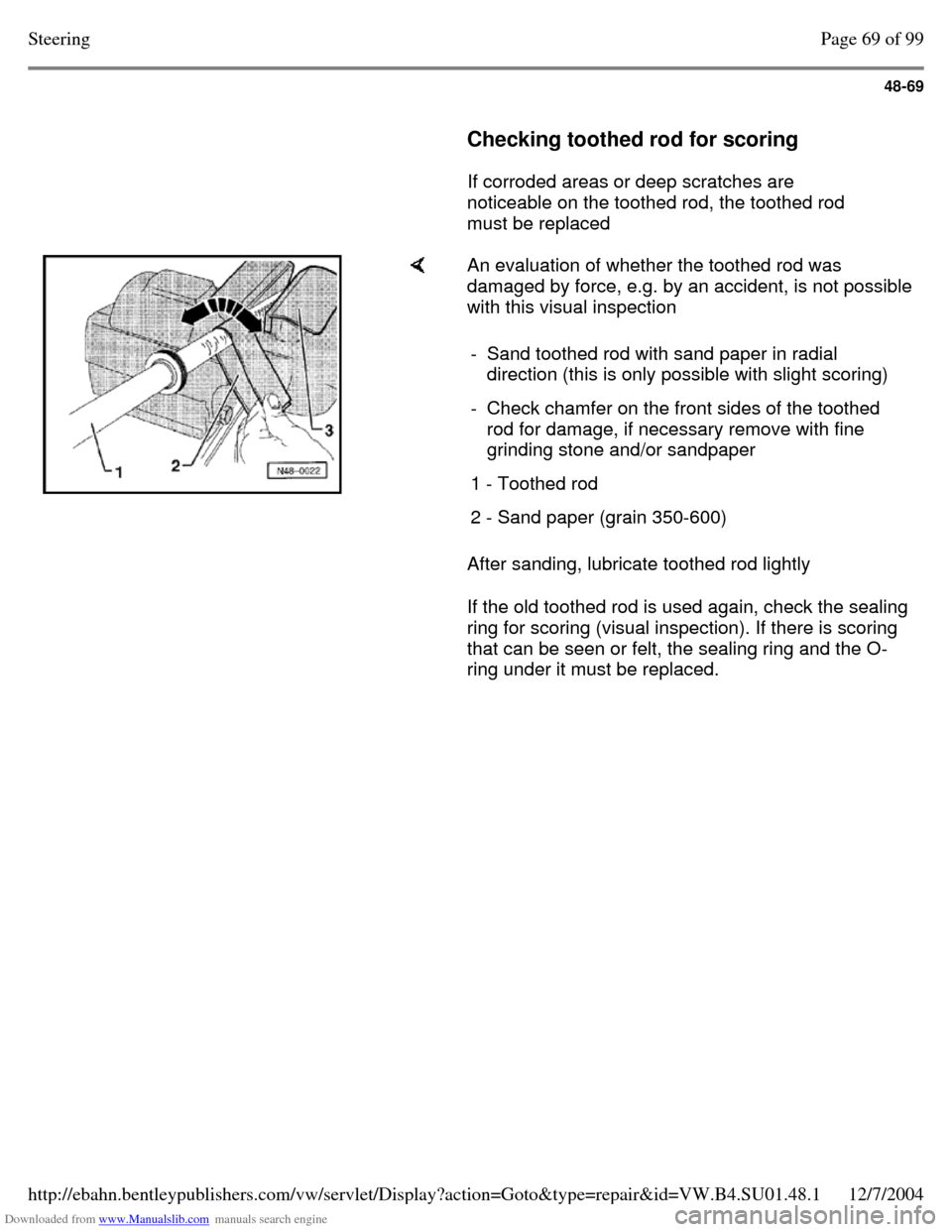

Downloaded from www.Manualslib.com manuals search engine 48-69

Checking toothed rod for scoring

If corroded areas or deep scratches are

noticeable on the toothed rod, the toothed rod

must be replaced An evaluation of whether the toothed rod was

damaged by force, e.g. by an accident, is not possible

with this visual inspection

After sanding, lubricate toothed rod lightly

If the old toothed rod is used again, check the sealing

ring for scoring (visual inspection). If there is scoring

that can be seen or felt, the sealing ring and the O-

ring under it must be replaced. - Sand toothed rod with sand paper in radial

direction (this is only possible with slight scoring)

- Check chamfer on the front sides of the toothed

rod for damage, if necessary remove with fine

grinding stone and/or sandpaper

1 - Toothed rod 2 - Sand paper (grain 350-600) Page 69 of 99Steering12/7/2004http://ebahn.bentleypublishers.com/vw/servlet/Display?action=Goto&type=repair&id=VW.B4.SU01.48.1