check engine light VOLKSWAGEN TIGUAN 2017 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2017, Model line: TIGUAN, Model: VOLKSWAGEN TIGUAN 2017Pages: 341, PDF Size: 9.14 MB

Page 256 of 341

⇒ Fig. 204Dipped beam

headlights

Side

lights/daytime

running lights

Turn signalMain beam

headlights

Insert the bulb

holder ③ into

the headlight and

turn it clockwise as

far as it will go.

Insert the bulb

holder ④ into

the headlight and

turn it clockwise as

far as it will go.

Insert the bulb

holder ⑤ into

the headlight and

turn it clockwise as

far as it will go.

Insert the bulb holder

⑥ into the

headlight and turn it

clockwise as far as it

will go.

8.Fit the rubber

cover ①.

Fit the rubber

cover ①.

Fit the rubber cover

②.

9.Close the bonnet ⇒ In the engine compartment.

The illustrations show the left-hand headlight from the rear. The right-hand headlight is a

mirror image of the one shown.

There are various types of headlight, so the position and design of covers, bulbs and bulb

holders may vary from those shown in the illustrations.

It is not possible for customers to change the LEDs in daytime running lights with LED

technology. Go to a qualified workshop.

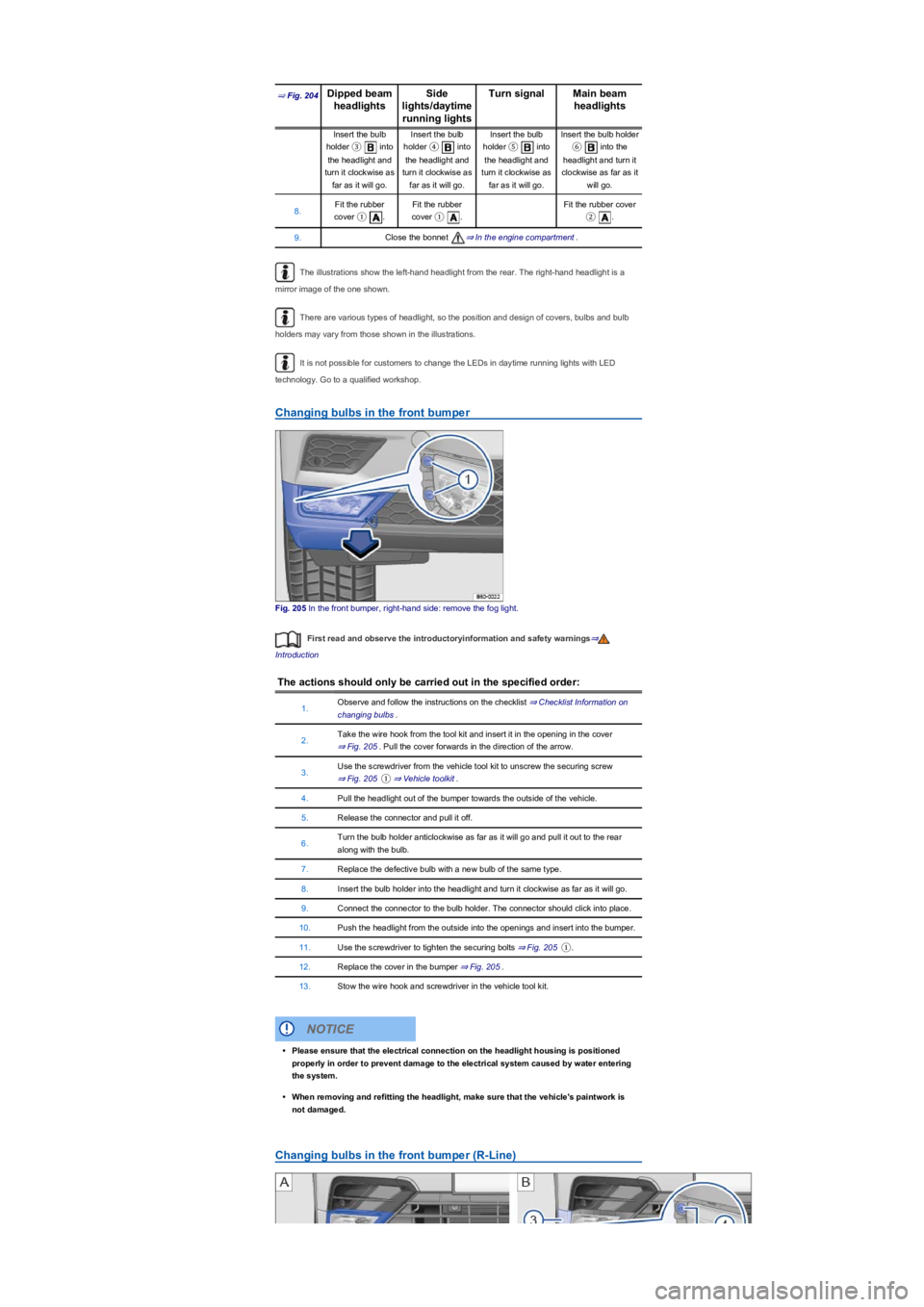

Changing bulbs in the front bumper

Fig. 205 In the front bumper, right-hand side: remove the fog light.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The actions should only be carried out in the specified order:

1.Observe and follow the instructions on the checklist ⇒ Checklist Information on

changing bulbs.

2.Take the wire hook from the tool kit and insert it in the opening in the cover

⇒ Fig. 205. Pull the cover forwards in the direction of the arrow.

3.Use the screwdriver from the vehicle tool kit to unscrew the securing screw

⇒ Fig. 205①⇒ Vehicle toolkit.

4.Pull the headlight out of the bumper towards the outside of the vehicle.

5.Release the connector and pull it off.

6.Turn the bulb holder anticlockwise as far as it will go and pull it out to the rear

along with the bulb.

7.Replace the defective bulb with a new bulb of the same type.

8.Insert the bulb holder into the headlight and turn it clockwise as far as it will go.

9.Connect the connector to the bulb holder. The connector should click into place.

10.Push the headlight from the outside into the openings and insert into the bumper.

11.Use the screwdriver to tighten the securing bolts ⇒ Fig. 205①.

12.Replace the cover in the bumper ⇒ Fig. 205.

13.Stow the wire hook and screwdriver in the vehicle tool kit.

Changing bulbs in the front bumper (R-Line)

•Please ensure that the electrical connection on the headlight housing is positioned

properly in order to prevent damage to the electrical system caused by water entering

the system.

•When removing and refitting the headlight, make sure that the vehicle's paintwork is

not damaged.

NOTICE

Page 258 of 341

Changing the bulb

7.Turn the bulb holder anticlockwise as far as it will go and carefully pull it out of the tail

light cluster together with the bulb.

9.Replace the defective bulb with a new bulb of the same type.

10.Carefully insert the bulb holder into the tail light cluster and turn it anticlockwise until

the bulb holder engages.

Fitting the tail light cluster

11.Carefully put the tail light cluster into the opening in the body.

12.Use one hand to hold the tail light in the fitting position while using the other hand to

screw the securing bolt firmly back in ⇒ Fig. 207③.

13.Check that the tail light cluster is positioned correctly and securely.

14.Connect the connector to the bulb holder and press into place.

15.Close the section of side trim in the luggage compartment near the tail light cluster

against the direction of the arrow

16.Close the boot lid ⇒ Boot lid.

The illustrations show the left-hand tail light cluster. The right-hand tail light cluster housing is

a mirror image of the one shown.

There are various types of tail light cluster, so the position and design of covers, bulbs and

bulb holders may vary from those shown in the illustrations.

In tail light clusters with LEDs, some light elements may be fitted with normal bulbs. These

bulbs can be changed.

Troubleshooting

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Lighting

Vehicle lighting not working partially or completely. A separate display appears in the

instrument cluster if there is a cornering light fault.A trailer turn signal or all trailer lights have

stopped working.

Check the exterior lighting and change the appropriate bulb as required ⇒ Changing bulbs. If all

bulbs are OK or there is a fault in the dynamic cornering light, go to a qualified workshop.

Monitoring the lights on a connected trailer

For vehicles with a factory-fitted towing bracket, the vehicle will also monitor certain bulbs on a

trailer which has been connected properly via the trailer socket.

If a trailer turn signal or all the trailer lights fail, the indicator lamp in the instrument cluster will

go out.

Changing fuses

Introduction

This chapter contains information on the followingsubjects:

⇒ Fuses in the dash panel

⇒ Fuses in the engine compartment

⇒ Fuse table for fuses in the dash panel

⇒ Fuse tables for fuses in the engine compartment

⇒ Changing a blown fuse

At the time of print we are unable to provide an complete overview of the locations of the fuses for

the electrical consumers. This is because the vehicle is under constant development, because

fuses are assigned differently depending on the vehicle equipment level and because several

consumers may use a single fuse. You can get more information about the fuse layout from a

Volkswagen dealership.

Several electrical consumers could share a single fuse. Conversely, a single consumer could have

more than one fuse.

Therefore fuses should only be replaced when the cause of the fault has been rectified. If a new

fuse blows shortly after insertion, have the electrical system checked by a qualified workshop as

soon as possible.

Page 266 of 341

•Connect the other end of the red jump lead to the positive terminal (+) of the vehicle battery

providing assistance ⇒ Fig. 217②.

•On the vehicle with the flat 12-volt battery, connect the other end of the black jump lead

⇒ Fig. 217③ preferably to the jump lead connection point (earth connection), or otherwise to a

solid metal part that is securely bolted onto the cylinder block, or to the cylinder block itself ⇒

.

•Position the leads in such a way that they cannot come into contact with any moving parts in the

engine compartment.

Connecting jump leads (vehicles with 12-volt battery in the luggage

compartment)

The jump leads should only be connected in the order A – B – C – D⇒ Fig. 218.

•Switch off the ignition in both vehicles ⇒ Starting and stopping the engine.

•Fold open the cover of the jump lead connection point in the engine compartment ⇒ Jump lead

connection point (positive terminal).

•Connect one end of the red jump lead to the jump lead connection point (positive terminal) (+)

of the vehicle with the discharged 12-volt vehicle battery ⇒ Fig. 218①⇒.

•Connect the other end of the red jump lead to the positive terminal (+) of the vehicle battery

providing assistance ⇒ Fig. 218②.

•On the vehicle with the 12-volt battery providing assistance, connect one end of the black jump

lead ⇒ Fig. 218③ preferably to the jump lead connection point (earth connection), or

otherwise to a solid metal part that is securely bolted onto the cylinder block, or to the cylinder

block itself.

•On the vehicle with the flat 12-volt battery, connect the other end of the black jump lead

⇒ Fig. 218③ preferably to the jump lead connection point (earth connection), or otherwise to a

solid metal part that is securely bolted onto the cylinder block, or to the cylinder block itself ⇒

.

•Position the leads in such a way that they cannot come into contact with any moving parts in the

engine compartment.

Starting the engine

•Start the engine of the vehicle providing assistance and let it run at idle.

•Start the engine of the vehicle with the discharged 12-volt vehicle battery and wait two or three

minutes until the engine is running smoothly.

Removing the jump leads

•Before disconnecting the jump leads, switch off the dipped beam headlights if they are switched

on.

•Turn on the blower of the air conditioning system or the heating and fresh air system and the

rear window heating in the vehicle with the discharged 12-volt vehicle battery. This helps to

minimise voltage peaks which are generated when the leads are disconnected.

•When the engine is running, the jump leads should be removed only in the order

D – C – B – A⇒ Fig. 217 or ⇒ Fig. 218.

•Close the battery cover or fold back the cover of the jump lead connection point ⇒ Jump lead

connection point (positive terminal).

•Go to a qualified workshop and have the 12-volt vehicle battery checked.

Page 267 of 341

Tow-starting or towing

Introduction

This chapter contains information on the followingsubjects:

⇒ Notes on tow-starting and towing

⇒ Fitting the rear towing eye

⇒ Fitting the front towing eye

⇒ Fitting the front towing eye (R-Line)

⇒ Driving notes when towing

Tow-starting is where a vehicle is started from it being set in motion by a vehicle that is hitched up

to it.

Towing is where a vehicle that cannot be driven is pulled away with the aid of another vehicle.

Observe any legal requirements when towing or tow-starting.

For technical reasons, vehicles with a discharged 12-volt battery must not be towed.⇒ Jump

starting

Vehicles with Keyless Access must only be towed with the ignition switched on.

Towing a vehicle when the engine is switched off and the ignition is switched on discharges the 12-

volt vehicle battery. Depending on the charge level of the 12-volt vehicle battery, the drop in voltage

can be large enough after just a few minutes that electrical consumers in the vehicle will no longer

function, e.g. the hazard warning lights.

Jump starting the vehicle incorrectly can cause the 12-volt vehicle battery to explode,

which can lead to serious injuries. Please observe the following in order to reduce the risk

of the 12-volt vehicle battery exploding:

•All work on the 12-volt vehicle battery and the electrical system can cause serious

chemical burns, fire or electric shocks. Always read the warnings and safety

information before carrying out any kind of work on the 12-volt vehicle battery ⇒ 12-

volt vehicle battery.

•Always wear suitable eye protection and gloves and never lean over the 12-volt vehicle

battery.

•Attach the connector cables in the correct order – the positive cable first, followed by

the negative.

•Never connect the negative cable to parts of the fuel system or to the brake lines.

•The non-insulated parts of the battery clamps must not be allowed to touch. The jump

lead attached to the positive terminal on the 12-volt vehicle battery must not touch

electrically conductive parts of the vehicle.

•m/k/a995MK Vehicles with battery in the engine compartment: check the battery

window on the 12-volt vehicle battery. Use a torch for this if necessary. If the display is

light yellow or colourless, do not jump start the vehicle. Seek expert assistance.

•Avoid electrostatic discharge in the vicinity of the 12-volt vehicle battery. The explosive

gas emitted from the 12-volt vehicle battery could be ignited by sparks.

•Do not carry out jump starting if the 12-volt vehicle battery is damaged or if it is or has

ever been frozen.

WARNING

Once the vehicle has been successfully jump-started, go to a qualified workshop and have

the 12-volt vehicle battery checked.

NOTICE

Page 271 of 341

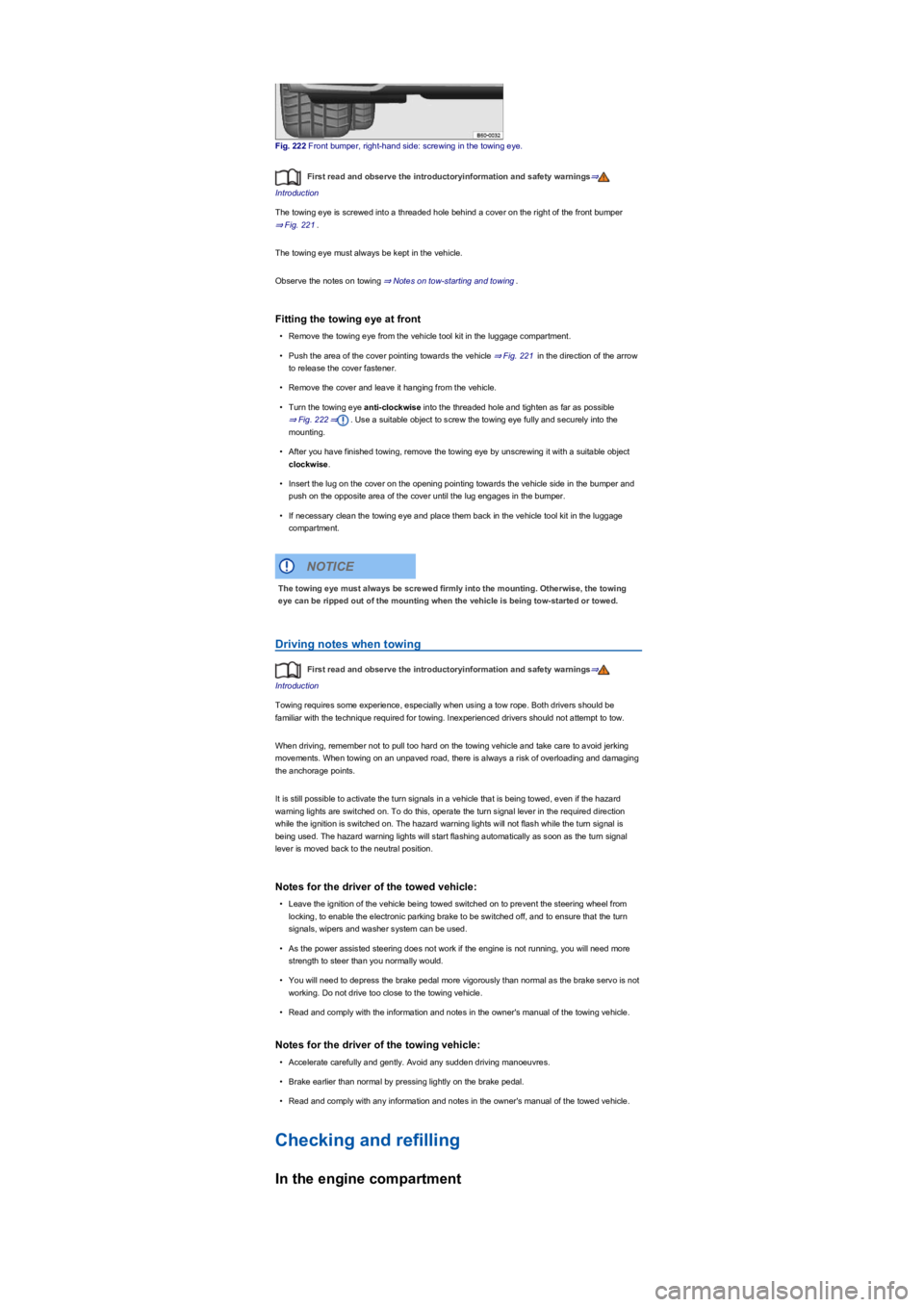

Fig. 222 Front bumper, right-hand side: screwing in the towing eye.

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The towing eye is screwed into a threaded hole behind a cover on the right of the front bumper

⇒ Fig. 221.

The towing eye must always be kept in the vehicle.

Observe the notes on towing ⇒ Notes on tow-starting and towing.

Fitting the towing eye at front

•Remove the towing eye from the vehicle tool kit in the luggage compartment.

•Push the area of the cover pointing towards the vehicle ⇒ Fig. 221 in the direction of the arrow

to release the cover fastener.

•Remove the cover and leave it hanging from the vehicle.

•Turn the towing eye anti-clockwise into the threaded hole and tighten as far as possible

⇒ Fig. 222⇒. Use a suitable object to screw the towing eye fully and securely into the

mounting.

•After you have finished towing, remove the towing eye by unscrewing it with a suitable object

clockwise.

•Insert the lug on the cover on the opening pointing towards the vehicle side in the bumper and

push on the opposite area of the cover until the lug engages in the bumper.

•If necessary clean the towing eye and place them back in the vehicle tool kit in the luggage

compartment.

Driving notes when towing

First read and observe the introductoryinformation and safety warnings⇒

Introduction

Towing requires some experience, especially when using a tow rope. Both drivers should be

familiar with the technique required for towing. Inexperienced drivers should not attempt to tow.

When driving, remember not to pull too hard on the towing vehicle and take care to avoid jerking

movements. When towing on an unpaved road, there is always a risk of overloading and damaging

the anchorage points.

It is still possible to activate the turn signals in a vehicle that is being towed, even if the hazard

warning lights are switched on. To do this, operate the turn signal lever in the required direction

while the ignition is switched on. The hazard warning lights will not flash while the turn signal is

being used. The hazard warning lights will start flashing automatically as soon as the turn signal

lever is moved back to the neutral position.

Notes for the driver of the towed vehicle:

•Leave the ignition of the vehicle being towed switched on to prevent the steering wheel from

locking, to enable the electronic parking brake to be switched off, and to ensure that the turn

signals, wipers and washer system can be used.

•As the power assisted steering does not work if the engine is not running, you will need more

strength to steer than you normally would.

•You will need to depress the brake pedal more vigorously than normal as the brake servo is not

working. Do not drive too close to the towing vehicle.

•Read and comply with the information and notes in the owner's manual of the towing vehicle.

Notes for the driver of the towing vehicle:

•Accelerate carefully and gently. Avoid any sudden driving manoeuvres.

•Brake earlier than normal by pressing lightly on the brake pedal.

•Read and comply with any information and notes in the owner's manual of the towed vehicle.

Checking and refilling

In the engine compartment

The towing eye must always be screwed firmly into the mounting. Otherwise, the towing

eye can be ripped out of the mounting when the vehicle is being tow-started or towed.

NOTICE

Page 274 of 341

Allow the engine to cool sufficiently.

Children and other people should be kept well away from the engine compartment.

Ensure that the vehicle cannot roll away unexpectedly.

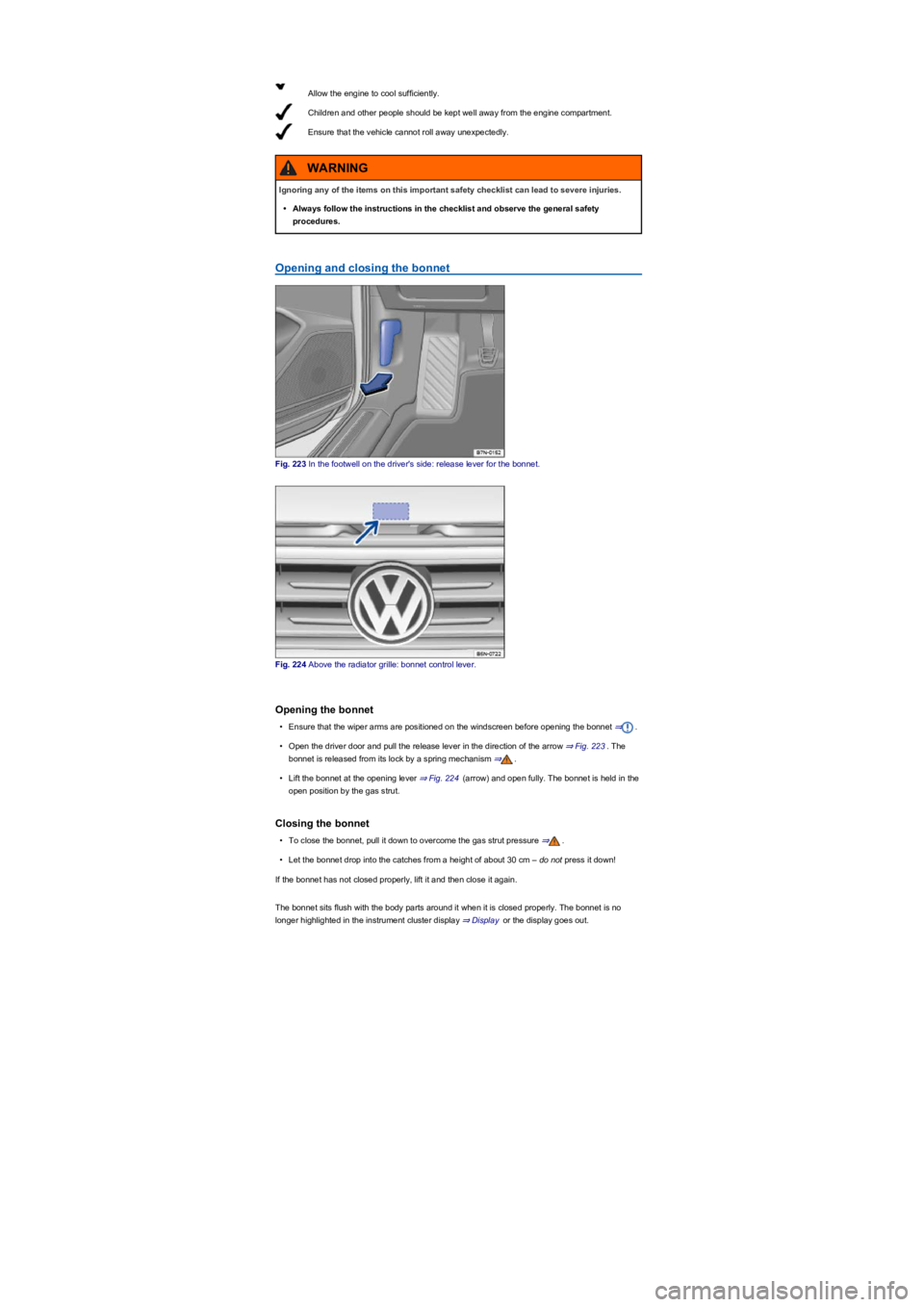

Opening and closing the bonnet

Fig. 223 In the footwell on the driver's side: release lever for the bonnet.

Fig. 224 Above the radiator grille: bonnet control lever.

Opening the bonnet

•Ensure that the wiper arms are positioned on the windscreen before opening the bonnet ⇒.

•Open the driver door and pull the release lever in the direction of the arrow ⇒ Fig. 223. The

bonnet is released from its lock by a spring mechanism ⇒.

•Lift the bonnet at the opening lever ⇒ Fig. 224 (arrow) and open fully. The bonnet is held in the

open position by the gas strut.

Closing the bonnet

•To close the bonnet, pull it down to overcome the gas strut pressure ⇒.

•Let the bonnet drop into the catches from a height of about 30 cm – do not press it down!

If the bonnet has not closed properly, lift it and then close it again.

The bonnet sits flush with the body parts around it when it is closed properly. The bonnet is no

longer highlighted in the instrument cluster display ⇒ Display or the display goes out.

Ignoring any of the items on this important safety checklist can lead to severe injuries.

•Always follow the instructions in the checklist and observe the general safety

procedures.

WARNING

Page 278 of 341

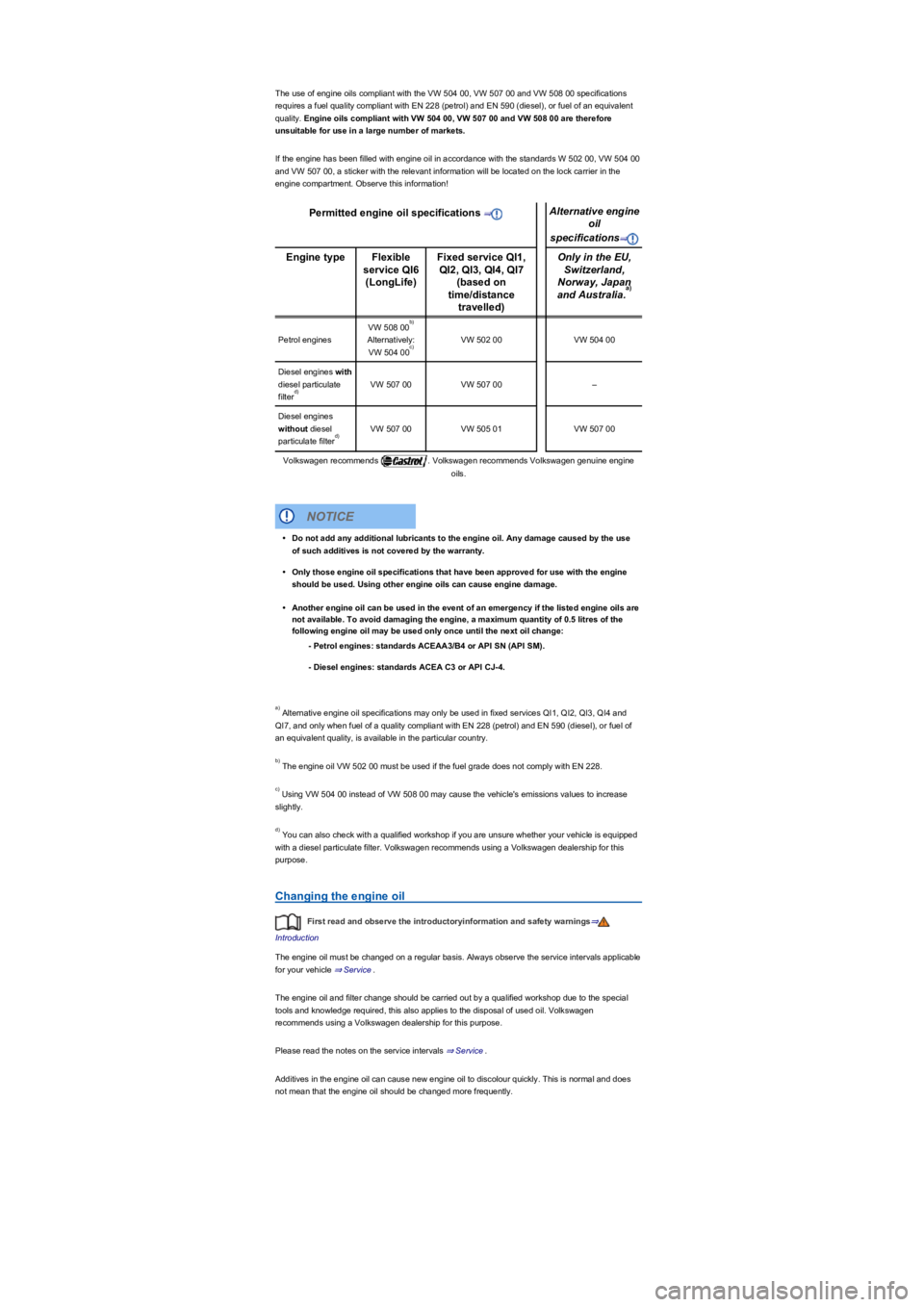

The use of engine oils compliant with the VW 504 00, VW 507 00 and VW 508 00 specifications

requires a fuel quality compliant with EN 228 (petrol) and EN 590 (diesel), or fuel of an equivalent

quality. Engine oils compliant with VW 504 00, VW 507 00 and VW 508 00 are therefore

unsuitable for use in a large number of markets.

If the engine has been filled with engine oil in accordance with the standards W 502 00, VW 504 00

and VW 507 00, a sticker with the relevant information will be located on the lock carrier in the

engine compartment. Observe this information!

Permitted engine oil specifications ⇒Alternative engine

oil

specifications⇒

Engine typeFlexible

service QI6

(LongLife)

Fixed service QI1,

QI2, QI3, QI4, QI7

(based on

time/distance

travelled)

Only in the EU,

Switzerland,

Norway, Japan

and Australia.

Petrol engines

VW 508 00

Alternatively:

VW 504 00

VW 502 00VW 504 00

Diesel engines with

diesel particulate

filter

VW 507 00VW 507 00–

Diesel engines

without diesel

particulate filter

VW 507 00VW 505 01VW 507 00

Volkswagen recommends . Volkswagen recommends Volkswagen genuine engine

oils.

Alternative engine oil specifications may only be used in fixed services QI1, QI2, QI3, QI4 and

QI7, and only when fuel of a quality compliant with EN 228 (petrol) and EN 590 (diesel), or fuel of

an equivalent quality, is available in the particular country.

The engine oil VW 502 00 must be used if the fuel grade does not comply with EN 228.

Using VW 504 00 instead of VW 508 00 may cause the vehicle's emissions values to increase

slightly.

You can also check with a qualified workshop if you are unsure whether your vehicle is equipped

with a diesel particulate filter. Volkswagen recommends using a Volkswagen dealership for this

purpose.

Changing the engine oil

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The engine oil must be changed on a regular basis. Always observe the service intervals applicable

for your vehicle ⇒ Service.

The engine oil and filter change should be carried out by a qualified workshop due to the special

tools and knowledge required, this also applies to the disposal of used oil. Volkswagen

recommends using a Volkswagen dealership for this purpose.

Please read the notes on the service intervals ⇒ Service.

Additives in the engine oil can cause new engine oil to discolour quickly. This is normal and does

not mean that the engine oil should be changed more frequently.

a)

b)

c)

d)

d)

•Do not add any additional lubricants to the engine oil. Any damage caused by the use

of such additives is not covered by the warranty.

•Only those engine oil specifications that have been approved for use with the engine

should be used. Using other engine oils can cause engine damage.

•Another engine oil can be used in the event of an emergency if the listed engine oils are

not available. To avoid damaging the engine, a maximum quantity of 0.5 litres of the

following engine oil may be used only once until the next oil change:

- Petrol engines: standards ACEAA3/B4 or API SN (API SM).

- Diesel engines: standards ACEA C3 or API CJ-4.

NOTICE

a)

b)

c)

d)

Page 282 of 341

Coolant and coolant additives can pollute the environment. Spilt service fluids must be

collected then disposed of properly and in an environmentally responsible way.

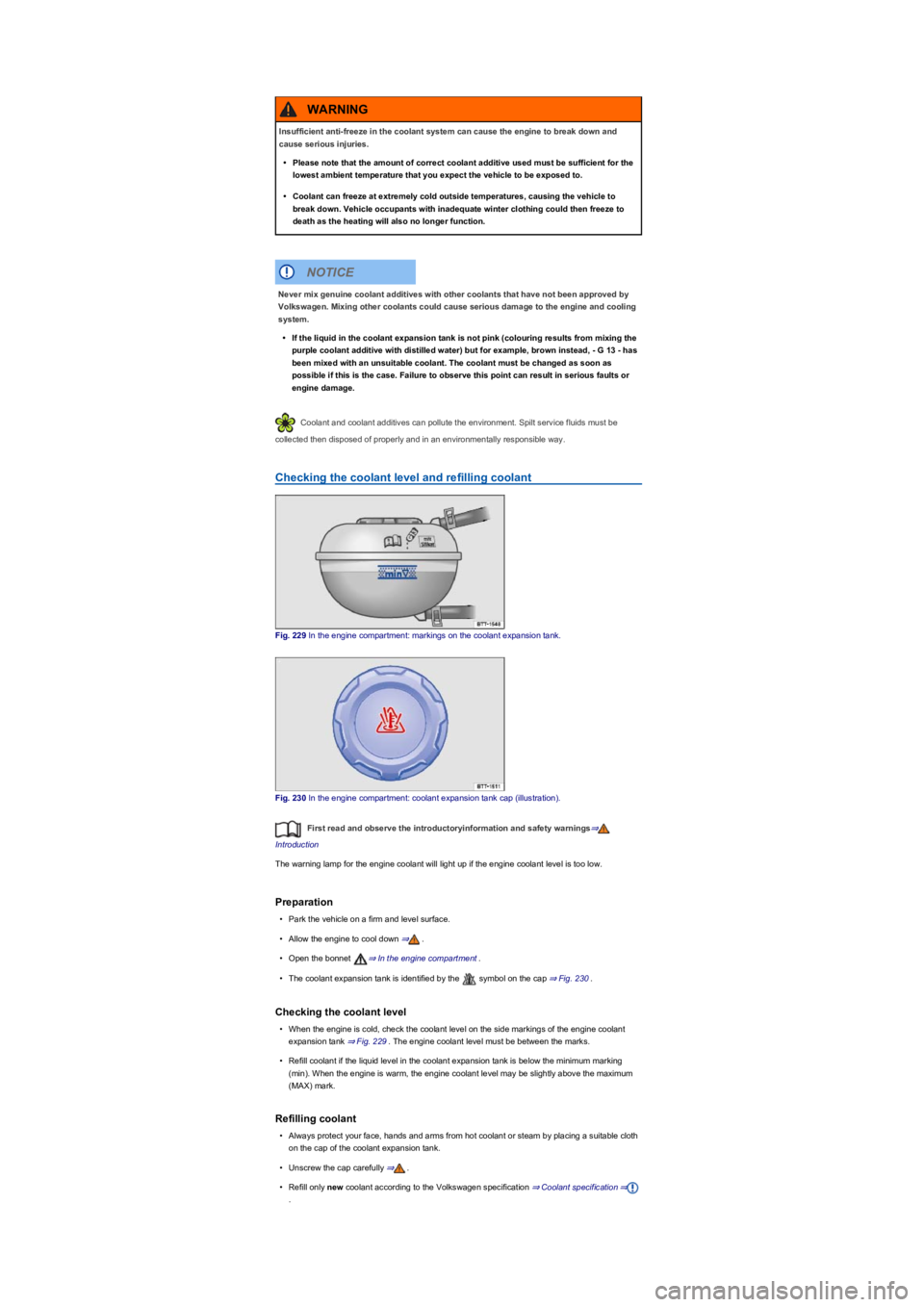

Checking the coolant level and refilling coolant

Fig. 229 In the engine compartment: markings on the coolant expansion tank.

Fig. 230 In the engine compartment: coolant expansion tank cap (illustration).

First read and observe the introductoryinformation and safety warnings⇒

Introduction

The warning lamp for the engine coolant will light up if the engine coolant level is too low.

Preparation

•Park the vehicle on a firm and level surface.

•Allow the engine to cool down ⇒.

•Open the bonnet ⇒ In the engine compartment.

•The coolant expansion tank is identified by the symbol on the cap ⇒ Fig. 230.

Checking the coolant level

•When the engine is cold, check the coolant level on the side markings of the engine coolant

expansion tank ⇒ Fig. 229. The engine coolant level must be between the marks.

•Refill coolant if the liquid level in the coolant expansion tank is below the minimum marking

(min). When the engine is warm, the engine coolant level may be slightly above the maximum

(MAX) mark.

Refilling coolant

•Always protect your face, hands and arms from hot coolant or steam by placing a suitable cloth

on the cap of the coolant expansion tank.

•Unscrew the cap carefully ⇒.

•Refill only new coolant according to the Volkswagen specification ⇒ Coolant specification⇒

.

Insufficient anti-freeze in the coolant system can cause the engine to break down and

cause serious injuries.

•Please note that the amount of correct coolant additive used must be sufficient for the

lowest ambient temperature that you expect the vehicle to be exposed to.

•Coolant can freeze at extremely cold outside temperatures, causing the vehicle to

break down. Vehicle occupants with inadequate winter clothing could then freeze to

death as the heating will also no longer function.

WARNING

Never mix genuine coolant additives with other coolants that have not been approved by

Volkswagen. Mixing other coolants could cause serious damage to the engine and cooling

system.

•If the liquid in the coolant expansion tank is not pink (colouring results from mixing the

purple coolant additive with distilled water) but for example, brown instead, - G 13 - has

been mixed with an unsuitable coolant. The coolant must be changed as soon as

possible if this is the case. Failure to observe this point can result in serious faults or

engine damage.

NOTICE

Page 284 of 341

Fig. 231 In the engine compartment: cap on the brake fluid container.

Brake fluid will gradually absorb water from the surrounding air. The brake system will be damaged

if there is too much water in the brake fluid. The boiling point of the brake fluid is also considerably

reduced by the water content. Heavy use of the brakes may cause a vapour lock in the brake

system if the water content is too high. Vapour locks reduce levels of braking power, considerably

increase braking distance and can even cause the brake system to fail completely. Your own safety

and that of other road users depends on having a brake system that functions properly at all times

⇒.

Brake fluid specification

Volkswagen has developed a brake fluid that has been optimised for the brake system in the

vehicle. To ensure optimal operation of the brake system, Volkswagen expressly recommends the

use of brake fluid compliant with VW standard 501 14.

Before using a particular brake fluid, check that the specifications printed on the container

correspond to the vehicle requirements.

Brake fluid that is compliant with VW standard 501 14 is available from Volkswagen dealerships.

If this brake fluid is not available and it is necessary to use another high-quality brake fluid instead,

brake fluid that is compliant with DIN ISO 4925 CLASS 4 or US standard FMVSS 116 DOT 4 can

be used.

Not all brake fluids that are compliant with DIN ISO 4925 CLASS 4 or US standard FMVSS 116

DOT 4 have the same chemical composition. Some of these brake fluids may contain chemicals

that can damage or destroy brake system components over time.

Volkswagen therefore recommends the use of brake fluid that is compliant with

VW standard 501 14 to ensure sustained optimal operation of the brake system.

Brake fluid that is compliant with VW standard 501 14 fulfils the requirements of DIN ISO 4925

CLASS 4 or US standard FMVSS 116 DOT 4.

Brake fluid level

Brake fluid level is too low. Do not drive on! Check the brake fluid level.

The brake fluid level must always be between the MIN and MAX marking on the brake fluid

reservoir or above the MIN marking ⇒.

The brake fluid level cannot be checked accurately in all models as engine components may

partially conceal the brake fluid container. If the brake fluid level cannot be read exactly, please go

to a qualified workshop.

The brake fluid level drops slightly when the vehicle is being used as the brake pads wear and the

brakes are automatically adjusted.

Changing the brake fluid

The brake fluid should be changed by a qualified workshop. Volkswagen recommends using a

Volkswagen dealership for this purpose. Only brake fluid that conforms with the required

specification should be used.

Page 285 of 341

Brake fluid can pollute the environment. Any spilt service fluids must be cleaned up and

disposed of properly.

12-volt vehicle battery

Introduction

This chapter contains information on the followingsubjects:

⇒ Checking the electrolyte level of the 12-volt vehicle battery

⇒ Charging, replacing, disconnecting and connecting the 12-volt vehicle battery

⇒ Troubleshooting

The 12-volt vehicle battery is a component of the electrical system and serves to supply power in

the vehicle.

You should only carry out work on the electrical system if you know exactly how to perform the

required tasks, are aware of the general safety procedures and have access to the correct

equipment, service fluids and suitable tools. Failing to carry out work correctly can cause serious

injuries ⇒. All work should be carried out by a qualified workshop. Volkswagen recommends

using a Volkswagen dealership for this purpose.

Location of the 12-volt vehicle battery

Depending on the vehicle equipment level, the 12-volt vehicle battery may be located in the engine

compartment or in the luggage compartment under the luggage compartment floor.

Explanation of the warnings on the 12-volt vehicle battery

m/k/n948MKAlways wear eye protection!m/k/n947MKElectrolyte is very corrosive

and caustic. Always wear protective gloves and eye protection!m/k/n944MKNo fires,

sparks, naked lights or smoking!m/k/n946MKA highly explosive mixture of gases is given

off when the 12-volt vehicle battery is charging!m/k/n945MKAlways keep children away

from battery acid and the 12-volt vehicle battery!m/k/n949MKAlways observe the owner's

manual!

Brake failure or reduced braking effect can be caused by the brake fluid level being too

low or by brake fluid that is too old or unsuitable.

•The brake system and brake fluid level must be checked regularly.

•The brake fluid should be changed regularly.

•Heavy use of the brakes may cause a vapour lock if the brake fluid is left in the system

for too long. Vapour locks reduce levels of braking power, considerably increase

braking distance and can cause the brake system to fail completely.

•Please ensure that the correct brake fluid is used. Only use brake fluid that is explicitly

compliant with VW standard 501 14.

•Any other brake fluid or a low-quality one can affect the functioning of the brakes and

reduce their effectiveness.

•If a brake fluid compliant with VW standard 501 14 is not available, use a high-quality

brake fluid compliant with DIN ISO 4925 CLASS 4 or the US standard FMVSS 116 DOT

4, but only in exceptional circumstances.

•The refilled brake fluid must be new.

WARNING

Brake fluid is toxic.

•In order to reduce the risk of poisoning, never use bottles or other containers to store

brake fluid. There is always a risk of someone drinking from such containers, even if

they are labelled appropriately.

•Brake fluid must always be stored in its original sealed container and kept out of the

reach of children.

WARNING

Brake fluid that has leaked or been spilt can damage the vehicle paintwork, plastic parts

and tyres. Wipe off brake fluid that has leaked or been spilled immediately from all parts of

the vehicle.

NOTICE