oil VOLKSWAGEN TRANSPORTER 2012 User Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2012, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2012Pages: 486, PDF Size: 69.28 MB

Page 58 of 486

A WARNING (Continued)

• Ensure that nobody obstructs the path of the electric windows, especially if the roll-back function is not active.

Opening and closing sliding windows

r-T'n First read and observe the introductory L-.lr::.U information and safety warnings & on page 55.

Opening the sliding window in the side panel

• Press the window handle and pull it towards the inside of the vehicle.

• Keep the window handle in this position and open the sliding window.

• Make sure that the sliding window is securely engaged in one of the available positions.

Closing the sliding window in the side panel

• Press the window handle and pull it towards the inside of the vehicle.

• Keep the window handle in this position and close the sliding window.

• Push the window frame below the window han-dle to the front to ensure that the sliding window locks properly.

Sliding/tilting roof

0::0 Introduction

This chapter contains information on the following subjects:

Opening and closing the sliding/tilting roof . . . 59

Sliding/tilting roof-functions . . . . . . . . . . . . 59 Roil-back function for the sliding/tilting roof 60

Additional information and warnings:

• Volkswagen information system 24

• Central locking system 39

• Manual pop-up roof, California 218

• Electric pop-up roof, California 221

• Manual opening and closing 413

58 Before the journey

A WARNING (Continued)

• The roll-back function does not prevent fingers or other body parts from being press-ed against the window frame and sustaining injury.

m The roll-back function is also activated if the W windows are closed using convenience clos-ing 57.

• Pull the window handle and open or close the sliding window.

A WARNING

In the event of a sudden braking manoeuvre or accident, a window not securely engaged could move forward and cause injuries.

• Always make sure that the sliding window is securely engaged in one of the 3 positions.

Improper or unsupervised use of the sliding/ tilting roof can cause serious Injuries.

• The sliding/tilting roof should therefore only be opened or closed when you are sure that nobody is In its operating area.

• Always take all vehicle keys with you ev-ery time you leave the vehicle. 11>

Page 59 of 486

A WARNING (Continued)

• Never leave children or people requiring assistance alone in the car, particularly if they have access to the vehicle key. Unsuper-vised use of the vehicle key can lock the ve-hicle, start the engine, switch on the ignition and operate the sliding/tilting roof.

• The sliding/tilting roof can be operated for a short period after the ignition has been switched off, provided that the driver door and front passenger door are not opened.

CD

• In order to avoid damage in winter, remove ice and snow from the roof of the vehicle be-fore opening or tilting the sliding/tilting roof.

m Leaves and other loose items must be re-L.!:J moved from the guide rails of the sliding/tilt-ing roof at regular inteNals, either by hand or using a vacuum cleaner.

m If there is a fault in the sliding/tilting roof, the L.!:J roil-back function will not work properly. Go to a qualified workshop.

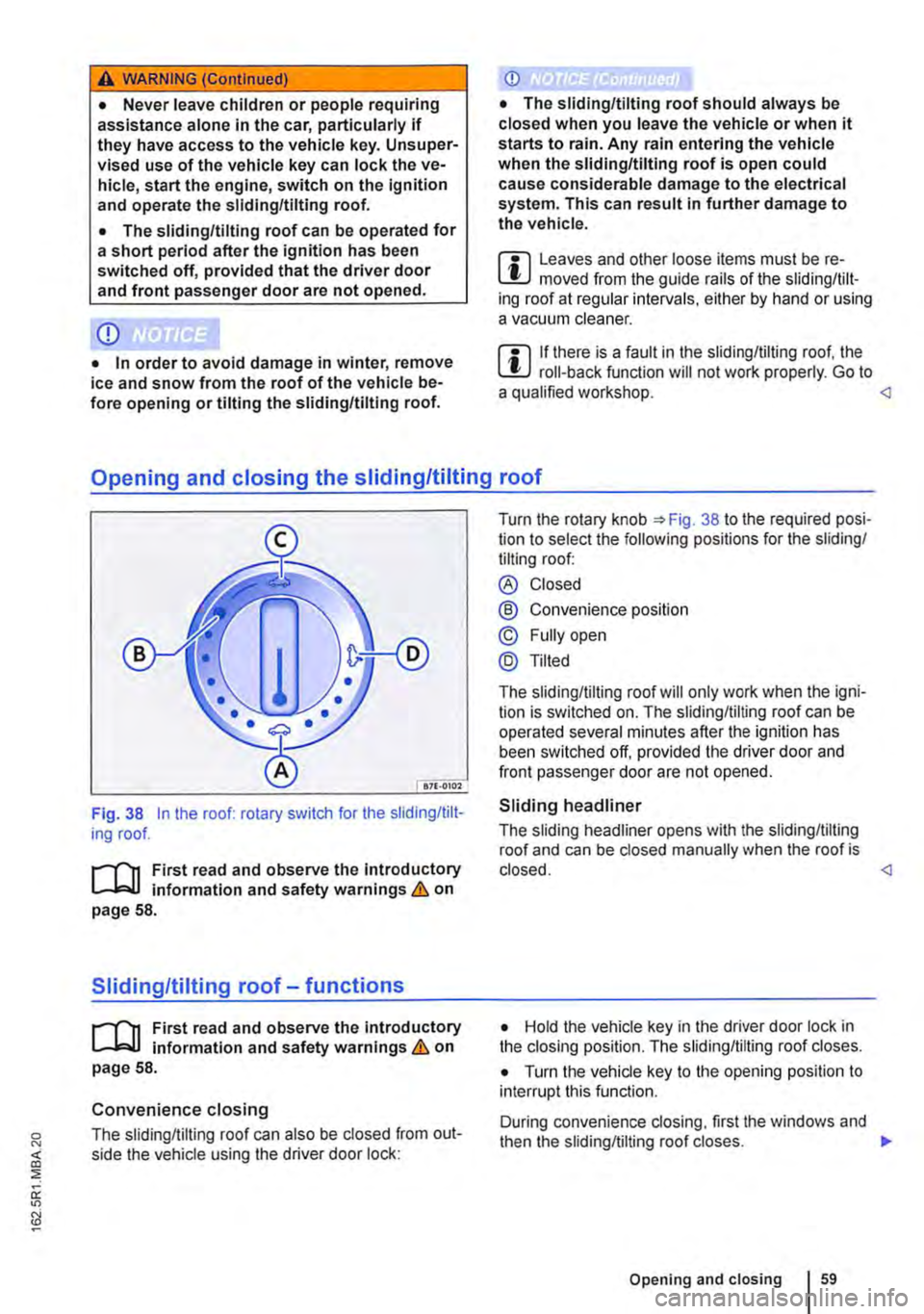

Fig. 38 In the roof: rotary switch for the sliding/tilt-ing roof.

r-T'n First read and observe the Introductory L-J,::.jJ information and safety warnings & on page 58.

Sliding/tilting roof-functions

r-T'n First read and obseNe the Introductory L-J,::.jJ information and safety warnings & on page 58.

Convenience closing

The sliding/tilting roof can also be closed from out-side the vehicle using the driver door lock:

Turn the rotary knob 38 to the required posi-tion to select the following positions for the sliding/ tilting roof:

® Closed

@ Convenience position

© Fully open

@Tilted

The sliding/tilting roof will only work when the igni-tion is switched on. The sliding/tilting roof can be operated several minutes after the ignition has been switched off, provided the driver door and front passenger door are not opened.

Sliding headliner

The sliding headliner opens with the sliding/tilting roof and can be closed manually when the roof is closed.

• Turn the vehicle key to the opening position to interrupt this function.

During convenience dosing, first the windows and then the sliding/tilting roof closes. .,..

Opening and closing 159

Page 72 of 486

Seat functions, rear

Cl:lJ Introduction

This chapter contains information on the following subjects:

Single seats .

3-seat bench

Drawers in the 3-seat bench ......•.....

Bed extension (multi-flex board) ... Centre armrest ......................... .

Additional information and warnings:

• Adjusting the seat position 61

• Seat belts ""page 79

• Airbag system 87

• Child seats (accessories) :;.page 96

• Luggage compartment :;. page 130

• Guide rail system in rear vehicle floor :;.page 133

• Stowage ""page 150

• Vehicle tool kit ""page 416

A WARNING

73

74

76

77 78

Incorrect use of the seat functions can cause serious injuries.

• Always assume a correct sitting position before you drive and maintain this position throughout the trip. This also applies to all passengers.

721 Before the journey

A WARNING (Continued)

• Keep hands, fingers, feet and other body parts away from the moving parts of the seats.

A WARNING

Incorrect adjustment or removing and fitting single seats and/or the bench seats can cause accidents and severe Injuries.

• All adjustments as well as removing/fitting should be carried out only when the vehicle is stationary; otherwise the single seats and/ or the bench seats could move suddenly when the vehicle Is In motion. Furthermore, an Incorrect seating position Is adopted while adjusting the seat.

• All single seats and the bench seats must always be fitted In their retainers and must be securely engaged.

• Never use the table while the vehicle is In motion. All backrests must be In the upright position and securely engaged in this posi-tion while the vehicle Is In motion.

• Never fit single seats behind the 3-seat bench.

• Never fit two 3-seat benches In the vehi-cle.

• While fitting and removing the single seats and/or the bench seat, make sure that the seat feet are not soiled or damaged.

• Never use child seats In the groups 0 or 0+ on single seats that face the rear of the vehicle. <

Page 77 of 486

Bed extension (multi-flex board)

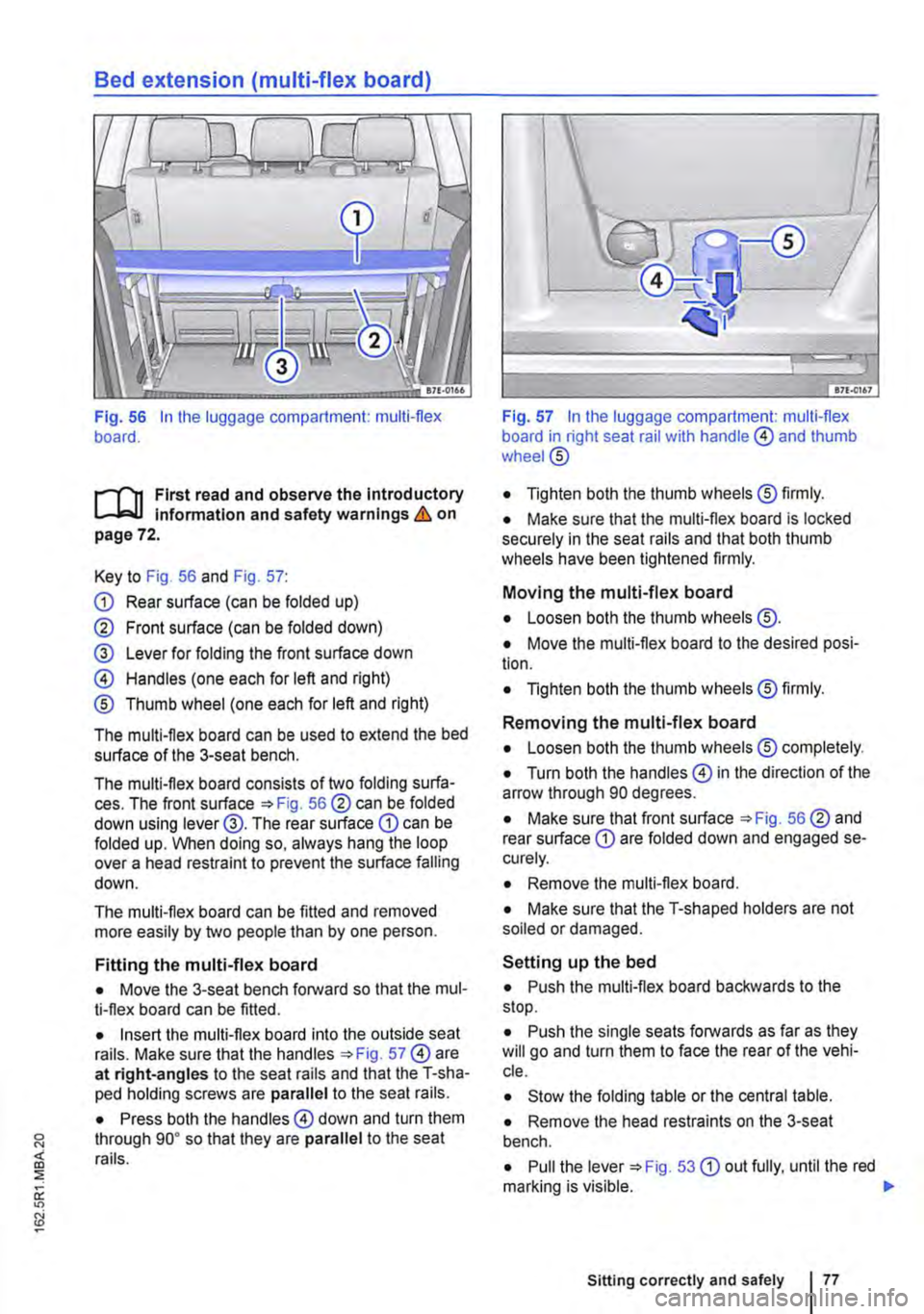

Fig. 56 In the luggage compartment: multi-flex board.

.--m First read and observe the Introductory L-.J,..U lnfonmatlon and safety warnings & on page 72.

Key to Fig. 56 and Fig. 57:

CD Rear surface (can be folded up)

@ Front surface (can be folded down)

@ Lever for folding the front surface down

@ Handles (one each for left and right)

® Thumb wheel (one each for left and right)

The multi-flex board can be used to extend the bed surface of the 3-seat bench.

The multi-flex board consists of two folding surfa-ces. The front surface =>Fig. 56@ can be folded down using lever@. The rear surface CD can be folded up. When doing so, always hang the loop over a head restraint to prevent the surface falling down.

The multi-flex board can be fitted and removed more easily by two people than by one person.

Fitting the multi-flex board

• Move the 3-seat bench forward so that the mul-ti-flex board can be fitted.

• Insert the multi-flex board into the outside seat rails. Make sure that the handles =>Fig. 57@ are at right-angles to the seat rails and that the T-sha-ped holding screws are parallel to the seat rails.

• Press both the handles@ down and turn them through go• so that they are parallel to the seat rails.

Fig. 57 In the luggage compartment: multi-flex board in right seat rail with handle @ and thumb wheel@

• Tighten both the thumb wheels® firmly.

• Make sure that the multi-flex board is locked securely in the seat rails and that both thumb wheels have been tightened firmly.

Moving the multi-flex board

• Loosen both the thumb wheels @.

• Move the multi-flex board to the desired posi-tion.

• Tighten both the thumb wheels® firmly.

Removing the multi-flex board

• Loosen both the thumb wheels® completely.

• Turn both the handles@ in the direction of the arrow through 90 degrees.

• Make sure that front surface =>Fig. 56@ and rear surface CD are folded down and engaged se-curely.

• Remove the multi-flex board.

• Make sure that the T-shaped holders are not soiled or damaged.

Setting up the bed

• Push the multi-flex board backwards to the stop.

• Push the single seats forwards as far as they will go and turn them to face the rear of the vehi-cle.

• Stow the folding table or the central table.

• Remove the head restraints on the 3-seat bench.

• Pull the lever =>Fig. 53 CD out fully, until the red marking is visible. 11>

Sitting correctly and safely

Page 107 of 486

Lit up Possible cause Solution

Main beam is switched on or the headlight 107. flasher is being operated.

Main beam assist (light Assist) is activated. 110.

Several warning and indicator lamps will light up briefly as a funclional check when the ignition is switched on. They will go out after a few seconds.

Indicator lamps in light switch

Lit up Possible cause

The automatic headlight control and, if applicable, the daytime headlights or daytime running Jl lights are switched on 108 .

.fD The fog light is switched on 108.

I) I The side lights are switched on 108.

A WARNING

Failure to observe illuminated warning lamps and text messages can lead to your vehicle breaking down in traffic, and can cause acci-dent and serious injury.

• Never Ignore any illuminated warning lamps or text messages.

• Stop the vehicle as soon as possible and when safe to do so.

• Stop the vehicle at a safe distance away from moving traffic and so that no part of the exhaust system can come into contact with any inflammable material underneath the ve-hicle, e.g. dry grass, fuel, oil etc.

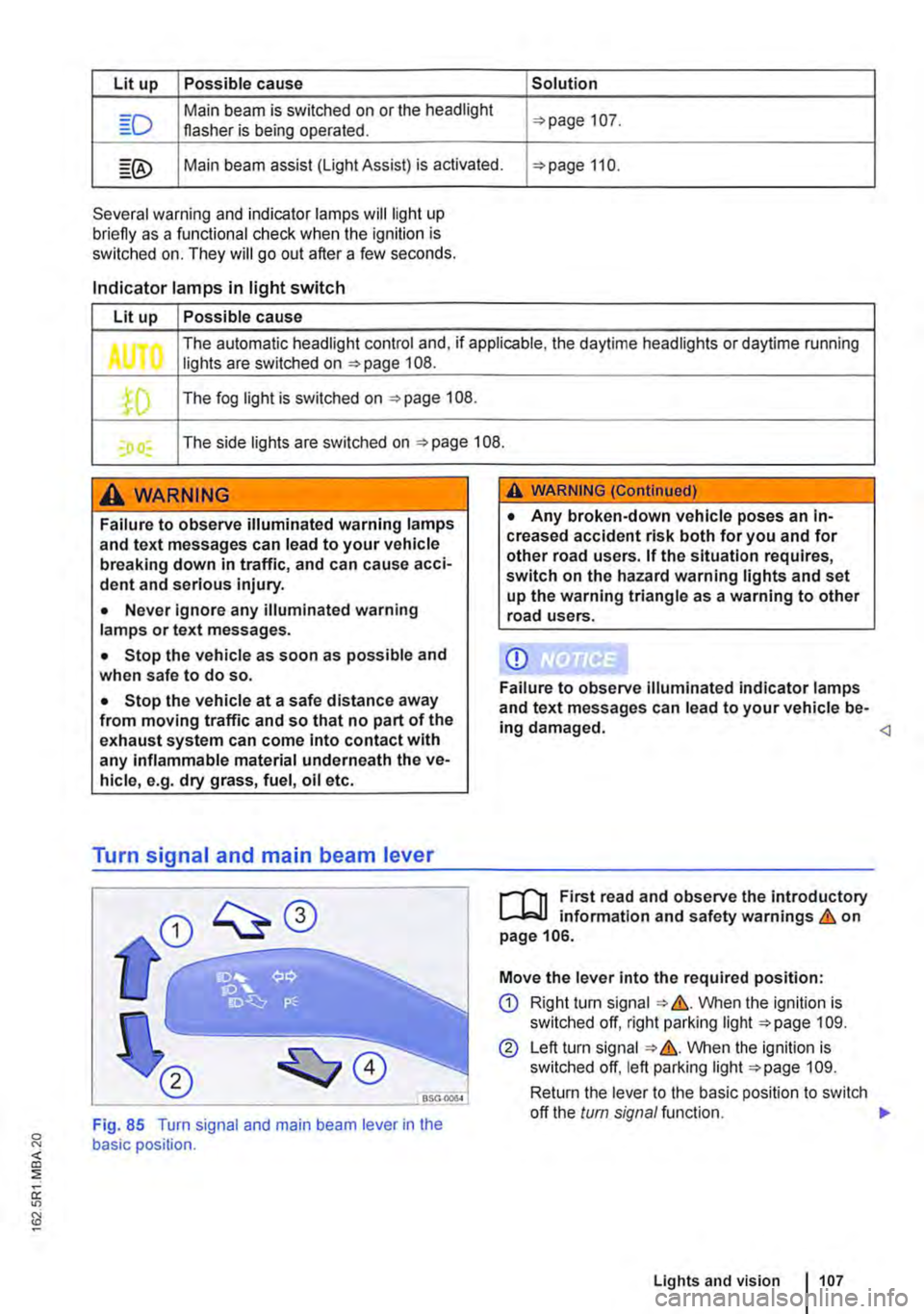

Turn signal and main beam lever

A WARNING (Continued)

• Any broken-down vehicle poses an In-creased accident risk both for you and for other road users. If the situation requires, switch on the hazard warning lights and set up the warning triangle as a warning to other road users.

CD

Failure to observe illuminated indicator lamps and text messages can lead to your vehicle be-ing damaged.

...--r'l1 First read and observe the introductory l.-Jo:JJ information and safety warnings & on page 106.

Move the lever into the required position:

CD Right tu m signal &. VVhen the ignition is switched off, right parking light 109.

@ Left turn signal &. VVhen the ignition is switched off, left parking light 109.

Return the lever to the basic position to switch

<]

Fig. 85 Turn signal and main beam lever in the basic position.

off the turn signal function. 1>

Lights and vision 1107

Page 120 of 486

The rain sensor will remain active after the ignition is switched off and back on again and will function again if the wiper lever is in position G) and if the vehicle is travelling at speeds higher than approxi-mately 16 km/h (10 mph).

Changes to the functioning of the rain sensor

Possible causes for faults and misinterpretations concerning the sensitive surface 96 of the rain sensor include:

• Damaged wiper blades: a film of water or smears caused by damaged wiper blades can in-crease the time the wipers are switched on, can shorten the length of the intervals between wipes or cause the wipers to run continuously.

• Insects: insects hitting the surface can cause the wipers to be activated.

• Salt deposits: in winter, salt deposits can cause the wipers to continue to wipe the windscreen when it is almost dry.

• Soiling: dry dust, wax, windscreen coatings (lo-tus effect) or detergent deposits (automatic car wash) can cause the rain sensor to become less sensitive and react too slowly or even not at all.

• Crack in the windscreen: when the windscreen is impacted by a stone, a wash cycle is triggered if the rain sensor is on. The rain sensor will then reg-

ister the reduction in sensitivity of the surface and adjust accordingly. The size of the crack could af-fect the way in which the sensor activates the wip-ers.

A WARNING

The rain sensor will not always detect every rain shower and activate the wipers.

• If necessary, switch on the wipers manual-ly if the water on the windscreen restricts the field of vision.

m At regular intervals, clean the sensitive sur-L!...J face of the rain sensor and check the wiper blades for damage 96 (arrow).

m We recommend that you use an alcohoi-W based glass cleaner to remove wax and pol-ish.

Checking and refilling the windscreen washer fluid level

Fig. 97 In the engine compartment: cap of washer fluid reservoir.

r--T'n First read and observe the introductory L-J,:,JJ information and safety warnings & on page 116.

The windscreen washer fluid level should be checked regularly and topped up as necessary.

120 I Before the journey

A filter can be found in the feed throat of the wash-er fluid reservoir. The filter keeps large dirt particles away from the washer jets when refilling. The filter should only be removed for cleaning. if the filter is damaged or cannot be found when refilling, these dirt particles will reach the system and will block the washer jets.

• Open the bonnet & 350.

• The washer fluid reservoir is identified by the $ symbol on the cap 97.

• Check whether there is enough windscreen washer fluid in the reservoir.

• To top up, mix clean water (not distilled water) with a washer fluid recommended by Volkswagen Commercial Vehicles Observe the dilution in-structions on the packaging.

• At low temperatures, add a special anti-freeze agent so that the fluid cannot freeze &.

Page 121 of 486

Recommended windscreen washer fluid

• For warm weather: summer windscreen wash G 052 184 A 1. Dilution 1:100 (1 part concen-trate, 100 parts water) in the washer fluid reservoir.

• All-year washer fluid G 052 164 A2. Dilution in winter to -18°C (0°F) approx. 1 :2 (1 part concen-trate, 2 parts water), otherwise dilute one part con-centrate to four parts water (1 :4) in the washer fluid reservoir.

Capacities

The capacity of the washer fluid reservoir is ap-proximately 3. 7 litres or approximately 5.0 litres in vehicles with a headlight washer system.

A WARNING

Never mix coolant additive or other unsuita-ble additives into the windscreen washer flu-id. An oily film may otherwise be left on the windscreen or rear window which will restrict the field of vision.

Mirrors

o:n Introduction

This chapter contains information on the following subjects:

Interior mirror .............. . 122

Exterior mirrors ............ . . .... 123

For safety reasons it is important that the driver po-sitions the exterior and interior mirrors correctly be-fore starting a journey '* &.

You can use the exterior mirrors and the interior mirror to observe traffic behind you and adjust driv-ing style accordingly. Looking in the exterior mir-rors and the interior mirror does not allow the driver to see the entre side and rear area of the vehicle. The area that cannot be seen is known as the blind spot. There may be objects and other road users in the blind spot.

Additional information and warnings:

• Exterior views '* page 5

• Changing gear '*page 260

• Braking, stopping and parking '*page 269

A WARNING (Continued)

• Use clean, clear water (not distilled water) with a washer fluid recommended by Volks-wagen Commercial Vehicles.

• A suitable anti-freeze agent should be added to the windscreen washer fluid If nec-essary.

CD

• Never mix other cleaning agents with the cleaning agents recommended by Volkswagen Commercial Vehicles. This can cause the ingre-dients to separate and block the windscreen washer jets.

• When refilling or changing service fluids, please ensure that the correct fluids are added through the correct openings. Incorrect service fluids can cause serious functional problems and engine damage.

Adjusting the exterior and interior mirrors while driving may cause the driver to become distracted. This can lead to accidents and se-rious Injuries.

• Exterior and interior mirrors should only be adjusted when the vehicle is stationary.

• When parking, changing lane, or perform-ing an overtaking or turning manoeuvre, al-ways pay careful attention to the area around the vehicle as objects and other road users may be located In the blind spot.

• Always ensure that the mirrors are posi-tioned correctly and that the rear view Is not restricted by ice, snow, condensation or any other objects.

A WARNING

Automatic anti-dazzle mirrors contain an electrolyte fluid which could leak If the mirror is broken.

• The leaking electrolyte fluid can cause lrri-tation to the skin, eyes and respiratory or-gans, especially In people who suffer from

Lights and vision 121

Page 127 of 486

Always stow all items of luggage in the vehicle securely.

• Distribute items in the vehicle, on the roof and on the trailer as evenly as possible.

• Place heavy objects as far forward in the lug-gage compartment as possible. Position the rear seat backrests securely in the upright position.

• Secure luggage in the luggage compartment to the fastening rings with suitable straps 130.

• Adjust the headlight range 106.

• Adjust the tyre pressure according to the vehi-cle load. Adhere to the tyre pressure plate 367.

• In vehicles with a tyre monitoring system, set the new vehicle load level as necessary 318.

Stowing cargo

r-111 First read and observe the introductory L-l=:.LI information and safety warnings & on page 125.

Stow the load securely in the vehicle or on the load surface

• Before loading the vehicle, place a sturdy mat or similar cover flush with the vehicle floor. Where necessary, do not cover protruding parts of the ve-hicle floor.

• If necessary, remove the seats to increase the load area.

• The vehicle floor must be free of oil and dust, dry and fully clean in order to help prevent the load from sliding.

• Observe gross axle weight ratings and the gross vehicle weight rating.

• Distribute items in the vehicle, on the load sur-face, on the roof and on the trailer as evenly as possible.

• Stow heavy objects directly on the floor and above or in front of the rear axle and engage the rear seat backrests securely in an upright position.

CD

Hard objects on the shelf can chafe against the wires of the heating element in the rear window and cause damage.

m • Observe any information concerning the l!J loading of a trailer 139 .

• Observe any information concerning the load-ing of a roof carrier 137.

• Protect the seat rails or seat anchor points from damage.

• Secure luggage with suitable securing straps on the fastening rings 130.

• Adjust the headlight range 106.

• Adjust the tyre pressure according to the vehi-cle load. Adhere to the tyre pressure plate 367.

• In vehicles with a tyre monitoring system, set the new vehicle load level as necessary 318.

CD

Hard objects on the shelf can chafe against the wires of the heating element in the rear window and cause damage.

m • Observe any information concerning the l!J loading of a trailer =>page 139 .

• Observe any information concerning the load-ing of a roof carrier =>page 137 .

Page 134 of 486

t"""""fl1 First read and observe the introductory l..--bll information and safety warnings & on page 133.

Removing plastic covers

The plastic covers=:. Fig. 107 must be removed from the seat rails, if seats or the central table are to be installed or removed.

• Take the screwdriver from the vehicle tootkit.

• Insert the flat blade of the screwdriver into the seat rail at an angle in front of the plastic cover you wish to remove G).

• Press the cover lug approx. 3 mm to the front and, at the same time, lever it out.

Removing split cover rail

• Grasp with both hands into the rubber lip of the shorter part (approx. 30 cm) of the aluminium cov-er rail ®. and push it towards the front until both clips are released.

• Remove cover rail@ upwards in a straight line.

• Now, also move the opposite part of the alumi-nium cover rail towards the front, and remove it up-wards in a straight line.

• Repeat this procedure for all seat rails.

Installing split cover rail

• Fit the aluminium cover rail so that it is flush with the longer part of the cover rail.

• Push the aluminium cover rail from above into the clips of the seat rail until it engages.

• Repeat this procedure for all seat rails.

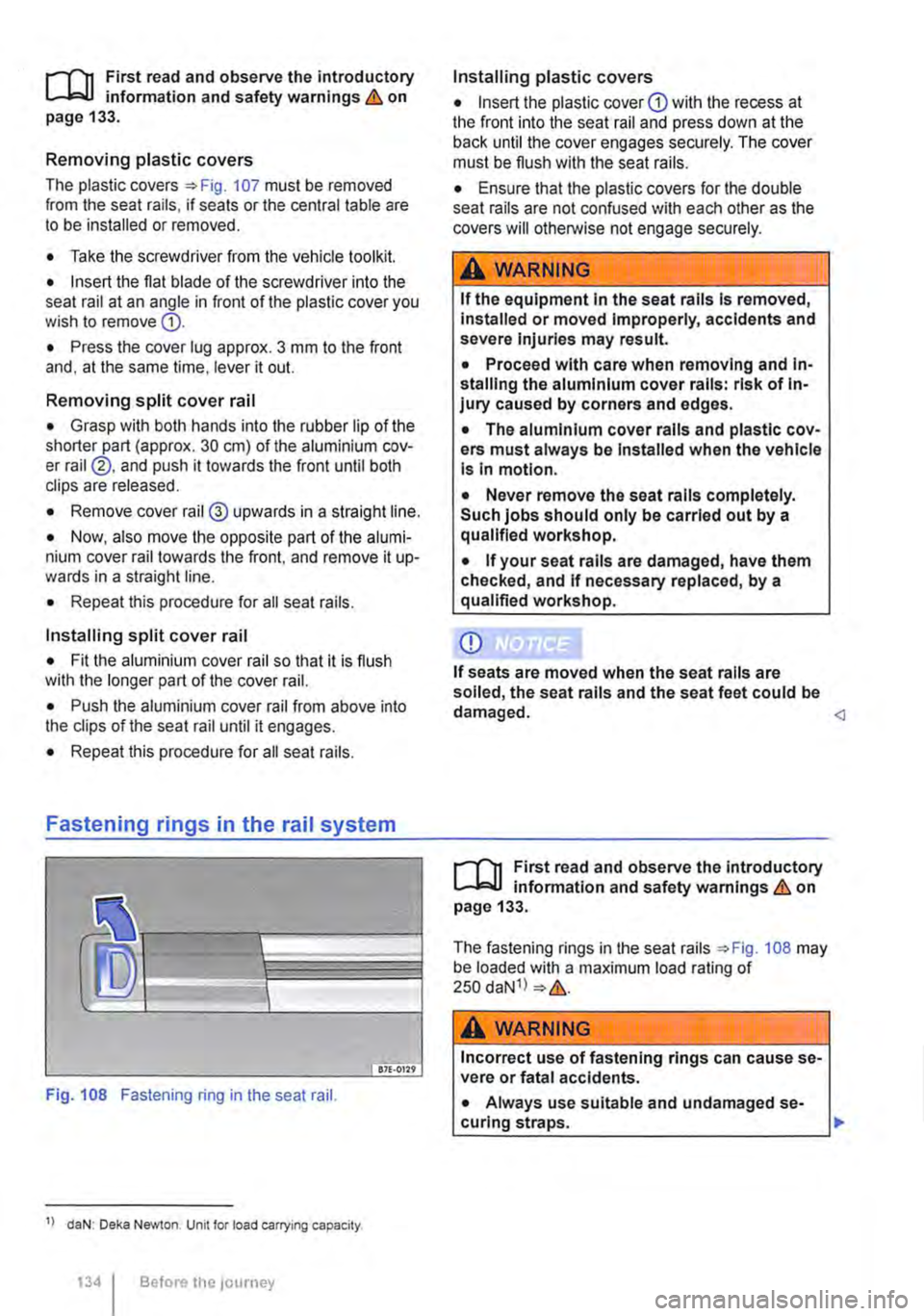

Fastening rings in the rail system

Fig. 108 Fastening ring in the seat rail.

1> daN: Deka Newton. Unit for load carrying capacity.

134 Before the JOUrney

Installing plastic covers

• Insert the plastic cover CD with the recess at the front into the seat rail and press down at the back until the cover engages securely. The cover must be flush with the seat rails.

• Ensure that the plastic covers for the double seat rails are not confused with each other as the covers will otherwise not engage securely.

A WARNING

If the equipment In the seat rails Is removed, Installed or moved Improperly, accidents and severe Injuries may result.

• Proceed with care when removing and In-stalling the aluminium cover rails: risk of In-jury caused by corners and edges.

• The aluminium cover rails and plastic cov-ers must always be Installed when the vehicle Is In motion.

• Never remove the seat rails completely. Such jobs should only be carried out by a qualified workshop.

• If your seat rails are damaged, have them checked, and If necessary replaced, by a qualified workshop.

CD

If seats are moved when the seat rails are soiled, the seat rails and the seat feet could be damaged.

The fastening rings in the seat rails ::.Fig. 108 may be loaded with a maximum load rating of 250 daN1l ::.&.

A wARNING

Incorrect use of fastening rings can cause se-vere or fatal accidents.

• Always use suitable and undamaged se-curing straps. ..,.

Page 144 of 486

A WARNING (Continued)

• If the ball coupling will not fit properly, the towing bracket should be checked by a quali-fied workshop.

• Do not use the towing bracket If the ball coupling does not engage properly or if you are unable to set it to the "ready" position.

• Do not use the towing bracket if you are unable to remove the key from the handwheel once the ball coupling has been mounted. This means that ball coupling Is not locked properly.

Removing the ball coupling

r--T'n First read and observe the Introductory L-J.:.IJ information and safety warnings & on page 139.

• Unhitch the trailer => &.

• Remove the cover =>Fig. 113 ®from the lock on the handwheel.

• Insert the key® into the lock and turn it clock-wise.

• Hold the ball coupling tightly in your left hand =>&.

• Use your right hand to pull out the handwheel 0 in the direction of arrow 1 and keep it in this po-sition.

• Turn the handwheel 0 in the direction of arrow 2 until it engages.

Hitching and connecting the trailer

Fig. 114 Pin assignment for the trailer socket.

1441 Before the journey

A WARNING (Continued)

• Always fasten the ball coupling securely In the luggage compartment once it has been removed.

CD

• The mounting on the vehicle, handwheel, shank and ball coupling retaining balls must all be clean and undamaged. Otherwise you may not be able to lock the ball coupling securely.

• Do not aim a high-pressure hose or steam cleaner directly at the ball coupling mounting. This could wash the grease required for lubri-cation out of the mounting.

• Pivot the trailer socket back fully from left to right to prevent soiling and damage to the mount-ing.

• Insert the cap in the mounting again.

A WARNING

The removable ball coupling Is heavy. The ball coupling could fall while it Is being re-moved. This could cause Injuries.

• Only unlock the ball coupling once the L-tr_a_ile_r_h_a_s __ be_e_n __ u_n_hi_tc_h_e_d_. ____________

r--T'n First read and observe the Introductory L-J.:.IJ information and safety warnings & on page 139.

Key to diagram Fig. 114:

Pin Meaning

1 Left turn signal

2 Rear fog light

3 Earth for pins 1 -8

4 Right turn signal

5 Rear light, right

6 Brake light

7 Rear light, left