psi VOLKSWAGEN TRANSPORTER 2015 Owner´s Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2015, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2015Pages: 486, PDF Size: 72.17 MB

Page 26 of 486

Unlock doors (door unlocking)

Back

-Window op. (window operation)

Off

All

Driver

Back

-Factory setting (factory setting)

-Back

• Lights & Vision

-Coming Home

System on/off

+ 10 Sec.

-10 Sec.

Back

-Leaving Home

System on/off

+ 10 Sec.

-10 Sec.

Back

-Backgrnd light.

System on/off

+5%

-5%

Back

-Footwelllight

System on/off

+5%

-5%

Back

-Lane change flash on/off

-Travel mode on/off

-Factory setting (factory setting)

-Back

• Coasting on/off

• Time

-Hours

-Minutes

Overview of the vehicle

-24 hr mode on/off

-Summer on/off

-Back

• Winter tyres

-System on/off

- + 10 km/h (6 mph)

--10 km/h (6 mph)

-Back

• Units

-Temperature oc

OF

Back

-Consump./dist.

l/100km, km

km/1, km

MPG(GB), mi

MPG(US), mi

Back

-Air pressure

bar

psi

kPa

Back

-Back

• Tyre pressure

-Save

-Back

• Alt. speed dis. (secondary speed display) on/off

• Service

-Information

-Back

• Factory settings

Page 240 of 486

Waste water tank

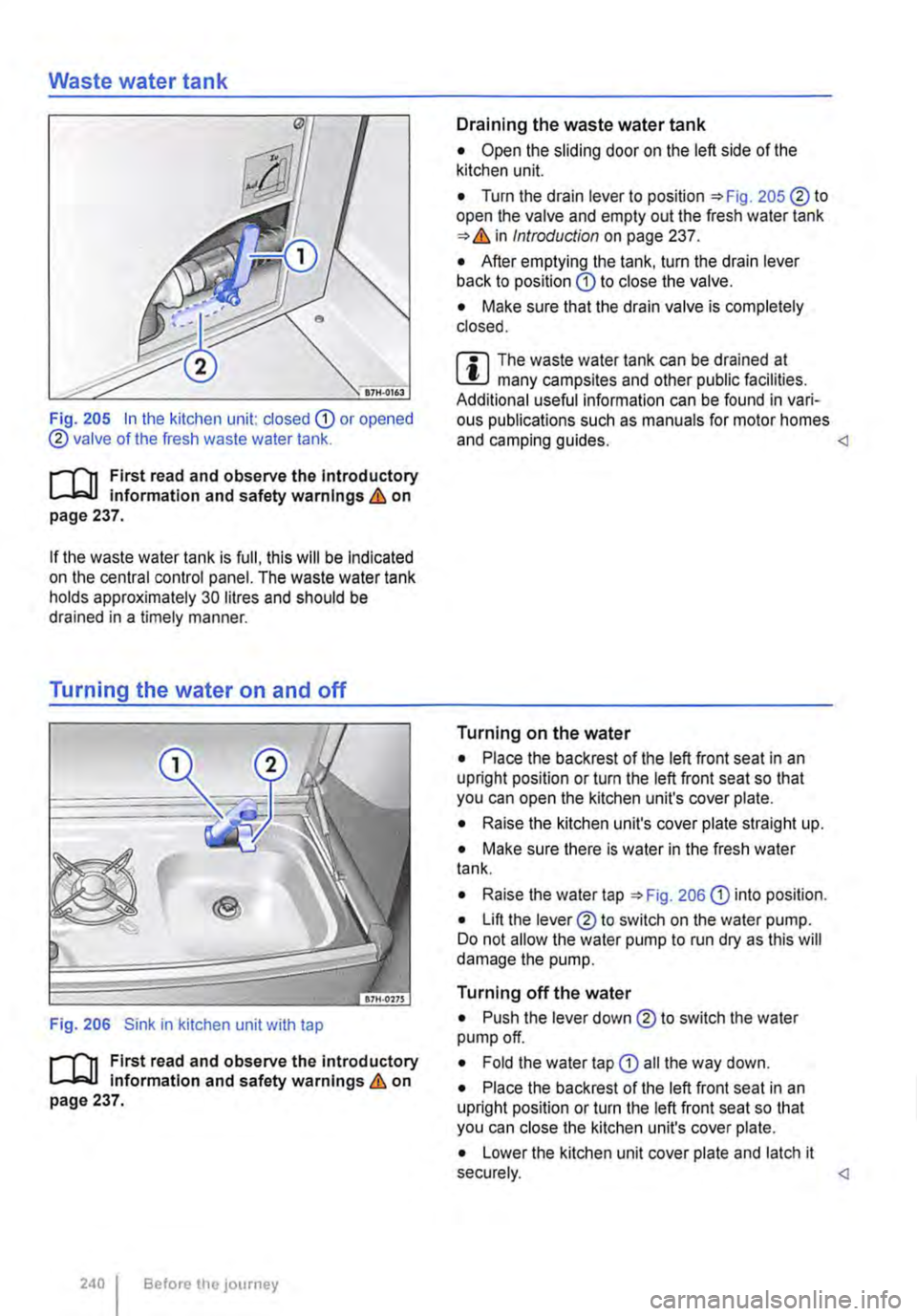

Fig. 205 In the kitchen unit: dosed CD or opened ® valve of the fresh waste water tank.

r-1'11 First read and observe the Introductory L-lo:.U information and safety on page 237.

if the waste water tank is full, this will be Indicated on the central control panel. The waste water tank holds approximately 30 litres and should be drained in a timely manner.

Turning the water on and off

Fig. 206 Sink in kitchen unit with tap

r-1'11 First read and observe the introductory L-lo:.U information and safety warnings & on page 237.

240 Before the journey

Draining the waste water tank

• Open the sliding door on the left side of the kitchen unit.

• Turn the drain lever to position 205 ®to open the valve and empty out the fresh water tank Introduction on page 237.

• After emptying the tank, turn the drain lever back to position CD to close the valve.

• Make sure that the drain valve is completely closed.

r.:l The waste water tank can be drained at l!..J many campsites and other public facilities. Additional useful information can be found in vari-ous publications such as manuals for motor homes and camping guides.

• Place the backrest of the left front seat in an upright position or turn the left front seat so that you can open the kitchen unit's cover plate.

• Raise the kitchen unit's cover plate straight up.

• Make sure there is water in the fresh water tank.

• Raise the water tap 206 CD into position.

• Lift the lever® to switch on the water pump. Do not allow the water pump to run dry as this will damage the pump.

Turning off the water

• Push the lever down ® to switch the water pump off.

• Fold the water tap CD all the way down.

• Place the backrest of the left front seat in an upright position or turn the left front seat so that you can close the kitchen unit's cover plate.

• Lower the kitchen unit cover plate and latch it securely.

Page 376 of 486

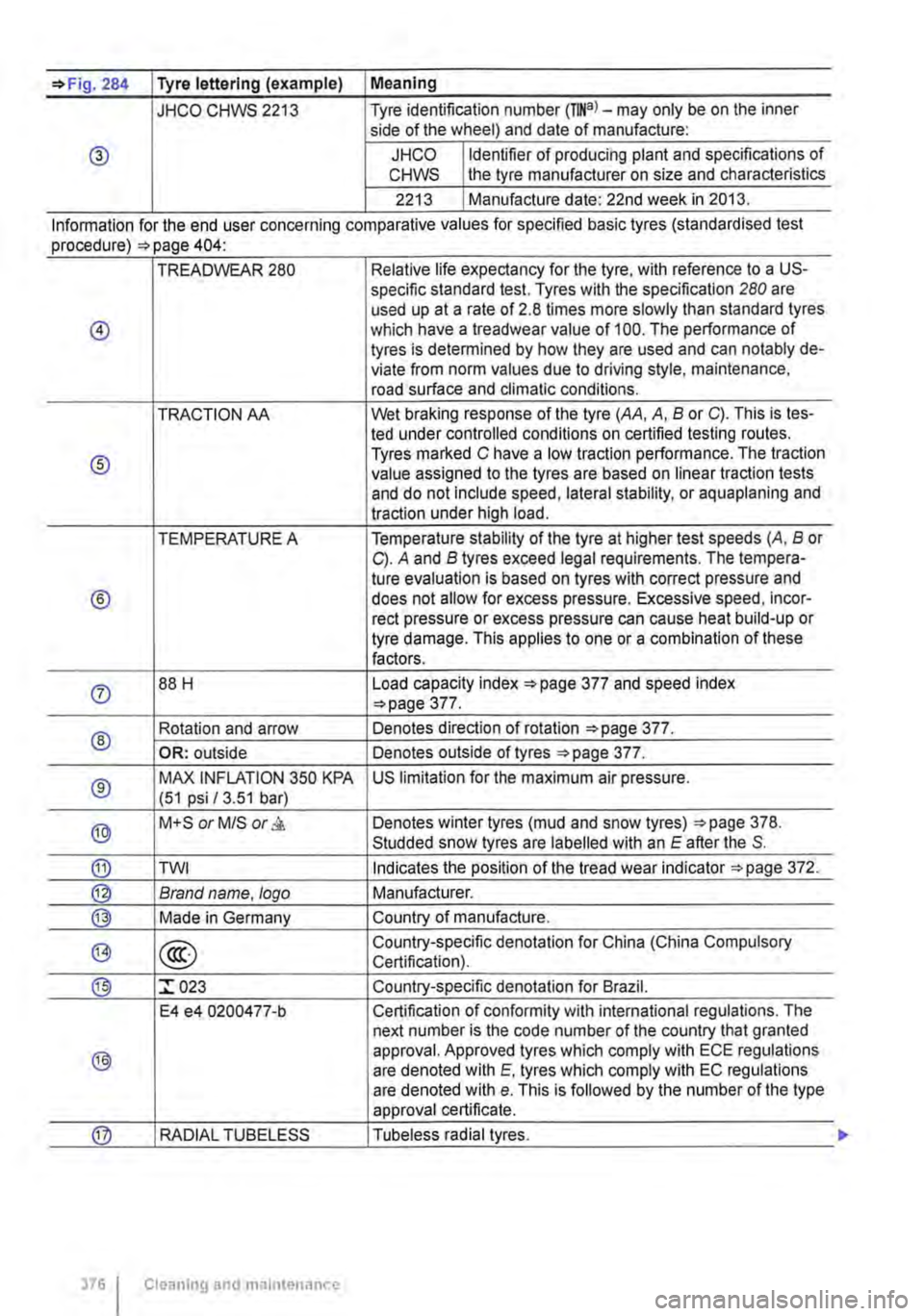

=>Fig. 284 Tyre lettering (example) I Meaning

JHCO CHWS 2213 Tyre identification number (TINa)-may only be on the inner side of the wheel) and date of manufacture:

® JHCO Identifier of producing plant and specifications of CHWS the tyre manufacturer on size and characteristics

2213 Manufacture date: 22nd week in 2013.

Information for the end user concernmg comparat1ve values for spec1fied bas1c tyres (standardised test procedure) =>page 404·

TREADWEAR 280 Relative life expectancy for the tyre, with reference to a US-specific standard test. Tyres with the specification 280 are used up at a rate of 2.8 times more slowly than standard tyres

@ which have a treadwear value of 100. The performance of tyres is determined by how they are used and can notably de-viate from norm values due to driving style, maintenance, road surface and climatic conditions.

TRACTION AA Wet braking response of the tyre (AA, A, B or C). This is tes-led under controlled conditions on certified testing routes.

® Tyres marked C have a low traction performance. The traction value assigned to the tyres are based on linear traction tests and do not include speed, lateral stability, or aquaplaning and traction under high load.

TEMPERATURE A Temperature stability of the tyre at higher test speeds (A, B or C). A and B tyres exceed legal requirements. The tempera-tu re evaluation is based on tyres with correct pressure and

® does not allow for excess pressure. Excessive speed, incor-reel pressure or excess pressure can cause heat build-up or tyre damage. This applies to one or a combination of these factors.

0 88 H Load capacity index ::.page 377 and speed index ::.page 377.

® Rotation and arrow Denotes direction of rotation ::.page 377.

OR: outside Denotes outside of tyres ::.page 377.

® MAX INFLATION 350 KPA US limitation for the maximum air pressure. (51 psi /3.51 bar)

® M+S or M/S or & Denotes winter tyres (mud and snow tyres) ::.page 378. Studded snow tyres are labelled with an E after the S.

® TWI Indicates the position of the tread wear indicator ::.page 372.

@ Brand name. logo Manufacturer.

@ Made in Germany Country of manufacture.

@> @ Country-specific denotation for China (China Compulsory Certification).

® :r 023 Country-specific denotation for Brazil.

E4 e4 0200477-b Certification of conformity with international regulations. The next number is the code number of the country that granted

® approval. Approved tyres which comply with ECE regulations are denoted with E. tyres which comply with EC regulations are denoted with e. This is followed by the number of the type approval certificate.

@ RADIAL TUBELESS Tubeless radial tyres.

376 I Cleaning and maintenance

Page 423 of 486

Lifting the vehicle with the jack

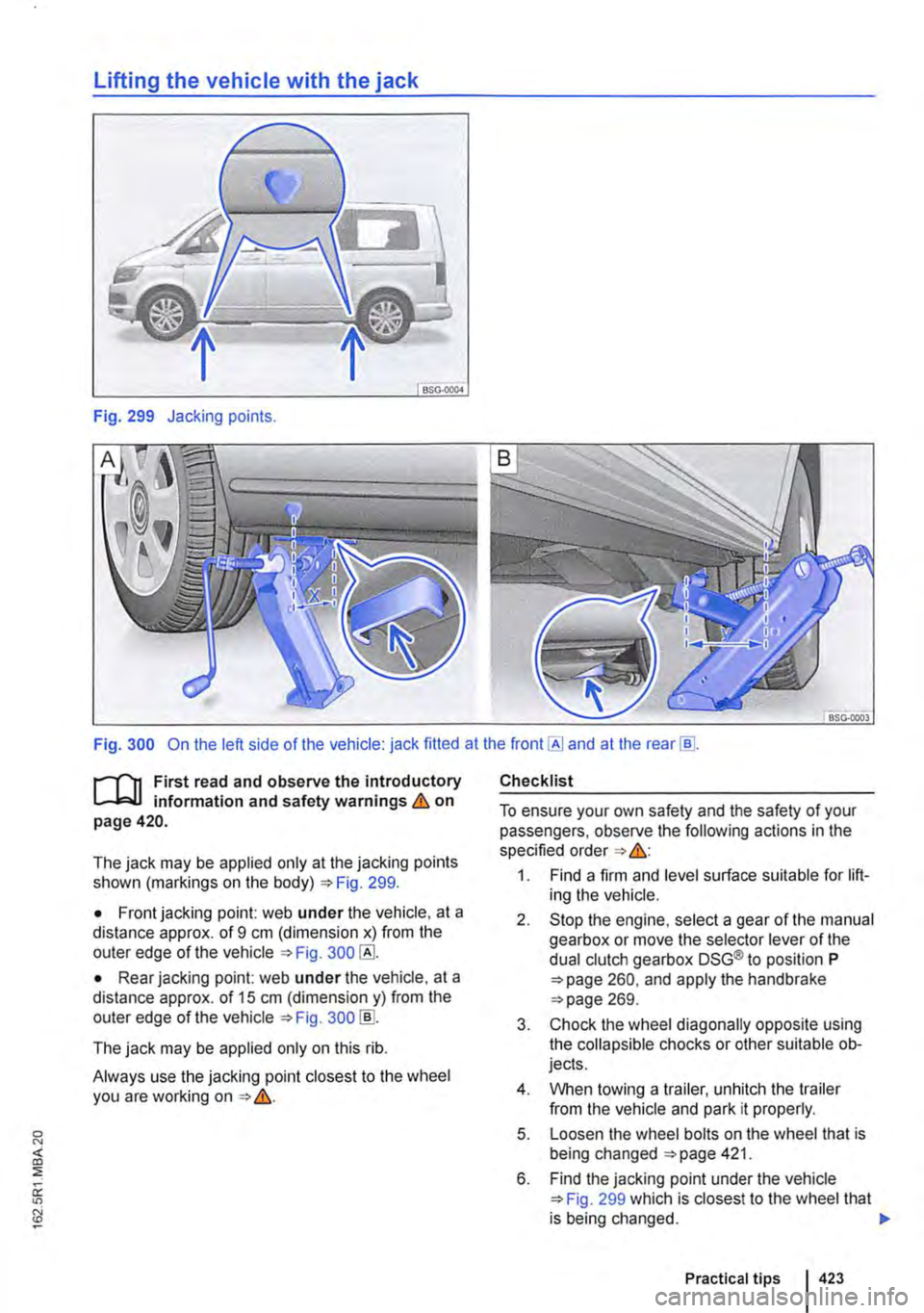

Fig. 299 Jacking points.

Fig. 300 On the left side of the vehicle: jack fitted at the front [AI and at the rear [ID.

r-('n First read and observe the introductory l.,...Jc.ll information and safety warnings & on page 420.

The jack may be applied only at the jacking points shown (markings on the body) '*Fig. 299.

• Front jacking point: web under the vehicle, at a distance approx. of 9 cm (dimension x) from the outer edge of the vehicle 300

• Rear jacking point: web under the vehicle, at a distance approx. of 15 cm (dimension y) from the outer edge of the vehicle 300 [ID.

The jack may be applied only on this rib.

Always use the jacking point closest to the wheel you are working on &.

Checklist

To ensure your own safety and the safety of your passengers, observe the following actions in the specified order &:

1. Find a firm and level surface suitable for lift-ing the vehicle.

2. Stop the engine, select a gear of the manual gearbox or move the selector lever of the dual clutch gearbox DSG® to position P '*page 260, and apply the handbrake 269.

3. Chock the wheel diagonally opposite using the collapsible chocks or other suitable ob-jects.

4. When towing a trailer, unhitch the trailer from the vehicle and park it properly.

5. Loosen the wheel bolts on the wheel that is being changed 421.

6. Find the jacking point under the vehicle '*Fig. 299 which is closest to the wheel that is being changed. .,.

Practical tips I 423

Page 428 of 486

A WARNING (Continued)

• Always follow the instructions In the checklist and observe the general safety pro-

Sealing and inflating tyres

r-"'('n First read and observe the Introductory L-J,.:.U Information and safety warnings & on page 425.

Sealing a tyre

• Unscrew the cap from the tyre valve.

• Use the valve core extractor 302 CD to screw the valve core out of the tyre valve. Place the core on a clean surface.

• Shake the tyre filler bottle 302 ® vigo-rously up and down several times.

• Screw the filler hose 302 @tightly onto the tyre filler bottle in a clockwise direction. The plastic foil on the plug is pierced automatically.

• Remove the plug from the filler hose 302@ and place the open end fully on the tyre valve.

• Hold the bottle upside down and inject the en-tire contents of the tyre filler bottle into the tyre.

• Remove the empty tyre filler bottle from the valve.

• Use the valve core extractor 302 CD to screw the valve core back onto the tyre valve.

Inflating the tyre

• Screw the tyre filler hose 302 ® of the air compressor tightly onto the tyre valve.

• Check that the bleed screw 302 (?) is closed.

• Start the engine and let it run.

• Insert the plug 302 ®into one of the ve-hicle's 12-volt sockets 163.

• Use the on/off switch 302 ®to switch on the air compressor.

• Run the compressor until the tyre pressure has reached 2.0-2.5 bar (29-36 psi I 200-250 kPa) maximum running time is 6 minutes

• Switch off the air compressor.

• If a pressure level of 2.0-2.5 bar (29-36 psi I 200 -250 kPa) cannot be achieved unscrew the tyre filler hose from the tyre valve.

428 I If and when

• Drive (or reverse) the vehicle approximately 1 0 metres so that the sealing compound is more evenly distributed in the tyre.

• Screw the tyre filler hose for the air compressor firmly back onto the tyre valve and inflate the tyre again.

• If the required pressure still cannot be reached, the tyre is too badly damaged. The tyre cannot be sealed with the breakdown set. Do not drive on. Seek expert assistance &.

• Disconnect the air compressor and unscrew the tyre filler hose from the tyre valve.

• Drive the vehicle no faster than 80 km/h (50 mph) once a tyre pressure of 2.0-2.5 bar (29-36 psi I 200-250 kPa) has been reached.

• Check the tyre pressure after driving for 10 mi-nutes 429.

A WARNING

The tyre filler hose and the air compressor can get hot during Inflation.

• Protect your hands and skin from the hot components.

• Do not place the hot tyre filler hose or the hot air compressor on any Inflammable mate-rials.

• Allow the device to cool down fully before stowing.

• If the tyre will not Inflate to at least 2.0 bar (29 psi/ 200 kPa), the tyre Is too damaged. The sealant Is unable to seal the tyre. Do not drive on. Seek expert assistance.

CD

Switch the air compressor off after a maximum of 6 minutes to avoid overheating. Let the air compressor cool down for a few minutes be-fore switching it back on.

Page 429 of 486

Test after driving for 10 minutes

r-'('n First read and observe the Introductory L-J,:.LI Information and safety warnings & on page 425.

Reconnect the tyre filler hose =>Fig. 302 ®and check the tyre pressure on the Tyre Pressure Loss Indicator®.

1.3 bar (19 psi /130 kPa) and lower:

• Do not drive on I The tyre cannot be sealed adequately with the breakdown set.

• Seek expert assistance => &.

1.4 bar (20 psi /140 kPa) and higher:

• Set the tyre pressure back to the correct value =>page 367.

• Resume your journey to the nearest qualified workshop. Do not exceed a maximum speed of 80 km/h (50 mph).

• The damaged tyre should be replaced at the qualified workshop.

Fuses

i:llJ Introduction

This chapter contains information on the following subjects:

Fuse box in the dash panel . . . . . . . . . . . . . . . 430

Fuses in the engine compartment . . . . . . . . . . 431 Changing a blown fuse ................... 431

At the time of print we are unable to provide an up-to-date overview of the locations of the fuses for the electrical consumers. This is because the vehi-cle is under constant development, because fuses are assigned differently depending on the vehicle equipment level and because several consumers may use a single fuse. You can get more informa-tion about the fuse layout from a Volkswagen Com-mercial Vehicles dealership.

Several electrical consumers could share a single fuse. Conversely, a single consumer could have more than one fuse.

Therefore fuses should only be replaced when the cause of the fault has been rectified. If a new fuse blows shortly after insertion, have the electrical system checked by a qualified workshop as soon as possible.

A WARNING

Driving with an unsealed tyre is dangerous as it can cause accidents and serious Injuries.

• Do not carry on driving if the tyre pressure Is 1.3 bar (19 psi /130 kPa) or lower.

• Seek expert assistance.

• Drink holder =>page 153

• Preparation for working in the engine compart-ment =>page 350

• Battery =>page 362

A WARNING

High voltages in the electrical system can cause electric shocks, serious burns and death.

• Never touch the electrical wiring of the ig-nition system.

• Avoid causing short circuits in the electri-cal system.

A WARNING

Using unsuitable or repaired fuses and bridg-ing an electrical circuit without fuses can cause a fire and serious injuries.

Practical tips I 429

Page 463 of 486

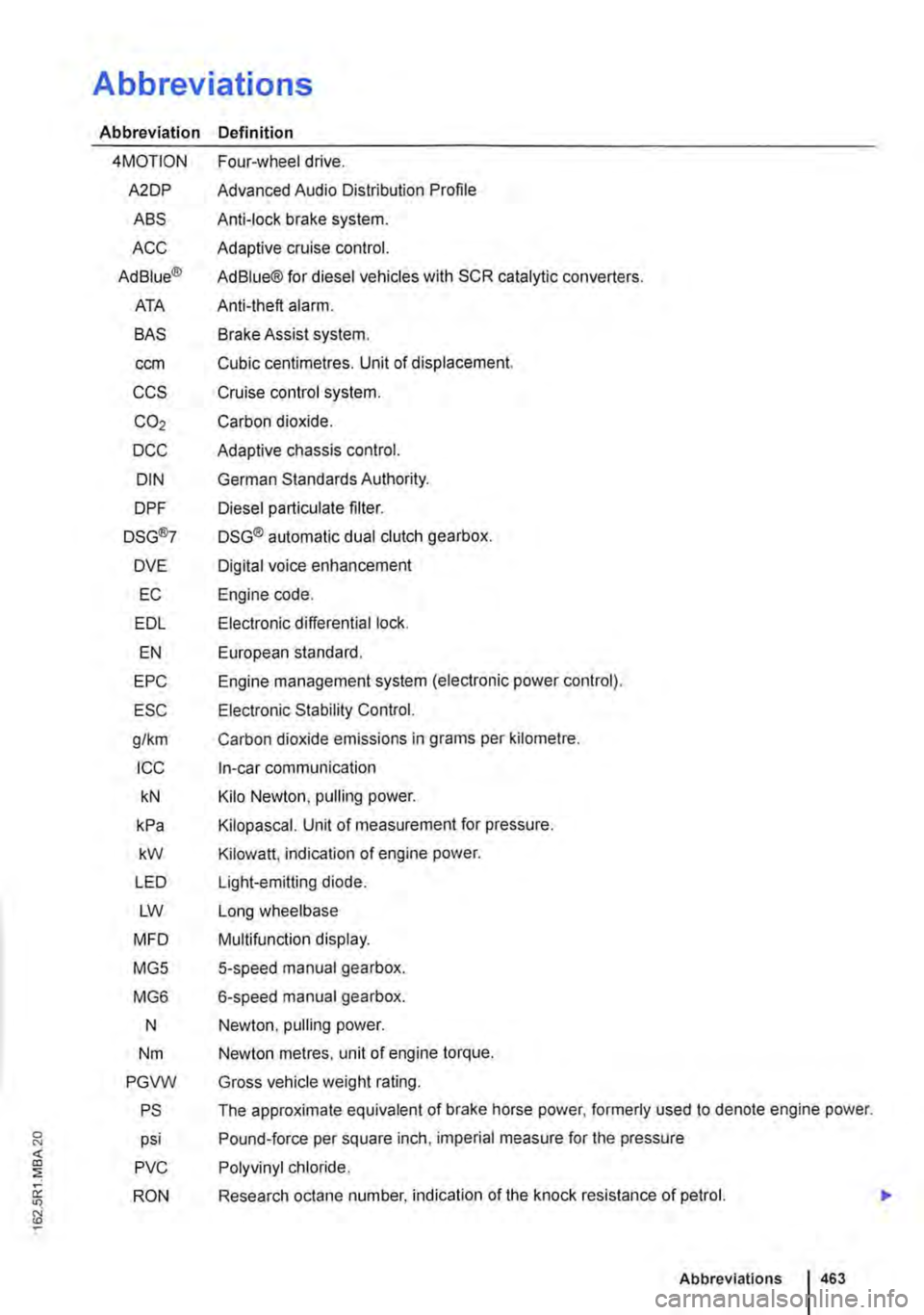

Abbreviations

Abbreviation Definition

4MOTION

A2DP

ABS

ACC

Ad Blue®

ATA

SAS

ccm

ccs

C02

DCC

DIN

DPF

DSG®7

DVE

EC

EDL

EN

EPC

ESC

g/km

ICC

kN

kPa

kW

LED

LW

MFD

MG5

MG6

N

Nm

PGVW

PS

psi

PVC

RON

Four-wheel drive.

Advanced Audio Distribution Profile

Anti-lock brake system.

Adaptive cruise control.

Ad Blue® for diesel vehicles with SCR catalytic converters.

Anti-theft alarm.

Brake Assist system.

Cubic centimetres. Unit of displacement.

Cruise control system.

Carbon dioxide.

Adaptive chassis control.

German Standards Authority.

Diesel particulate filter.

DSG® automatic dual clutch gearbox.

Digital voice enhancement

Engine code.

Electronic differential lock.

European standard.

Engine management system (electronic power control).

Electronic Stability Control.

Carbon dioxide emissions in grams per kilometre.

In-car communication

Kilo Newton, pulling power.

Kilopascal. Unit of measurement for pressure.

Kilowatt, indication of engine power.

Light-emitting diode.

Long wheelbase

Multifunction display.

5-speed manual gearbox.

6-speed manual gearbox.

Newton, pulling power.

Newton metres, unit of engine torque.

Gross vehicle weight rating.

The approximate equivalent of brake horse power. formerly used to denote engine power.

Pound-force per square inch, imperial measure for the pressure

Polyvinyl chloride.

Research octane number, indication of the knock resistance of petrol.

Abbreviations I 463