red warning light VOLKSWAGEN TRANSPORTER 2021 Owners Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 2021, Model line: TRANSPORTER, Model: VOLKSWAGEN TRANSPORTER 2021Pages: 486, PDF Size: 69.28 MB

Page 409 of 486

• Use unleaded petrol only.

• Do not allow the fuel tank to run empty.

• Do not overfill engine oil 353.

• Do not tow-start the vehicle. Use jump leads 443.

If you notice misfiring, uneven running or loss of power when the vehicle is moving, reduce speed Immediately. The vehicle should be inspected at

Diesel particulate filter

r-f'n First read and observe the Introductory L-J,:,.IJ Information and safety warnings & on page 407.

The diesel particulate filter filters out soot particles in the exhaust gas. The soot particles gather in the filter and are burnt under high temperatures peri-odically (regeneration). Heat produced can warm the engine.

Regeneration can cause noises, light smells and delay in radiator fan irrespective of the outside temperature, even after the engine is switched off.

To assist the regeneration of diesel particle filter, Volkswagen recommends that you avoid making only short journeys. In vehicles with a DSG® dual clutch gearbox the engine speed can increase while the vehicle is being driven. However, the indi-cator lamp • will not light up.

Observe the following points to ensure that the ex-haust system and the diesel particulate filter will work properly for a long time:

the nearest qualified workshop. If this happens, un-bumt fuel can enter the exhaust system and es-cape into the atmosphere. The catalytic converter can also be damaged by overheating.

Even when the exhaust purification system is W working perfectly, there may be a smell of sulphur from the exhaust in some conditions. This depends on the sulphur content of the fuel being used. <1

• Only use diesel with low sulphur levels 343.

• Never use biodiesel, petrol or heating oil.

• Do not allow the fuel tank to run empty.

• Do not overfill engine oil 353.

• Do not tow-start the vehicle. Use jump leads =page 443.

Even when the exhaust purification system is W working perfectly, there may be a smell of sulphur from the exhaust in some conditions. This depends on the sulphur content of the fuel being used.

m Note for courier vehicles: vehicles with diesel l!J particulate filter are identified accordingly with

Vehicle care and maintenance 409

Page 420 of 486

Changing a wheel

CllJ Introduction

This chapter contains information on the following subjects:

Preparations for changing a wheel . . . . . . . . . 420

Wheel bolts . . . . . . . . . . . . . . . . . . . 421

Lifting the vehicle with the jack . . . . . . . . . . . . 423

Changing a wheel . . . . . . . . . . . . . . . . . . . . . . . 424

After changing a wheel . . . . . . . . . . . . . 425

Some models are delivered without a factory-fitted jack or box spanner. If this is the case, the wheel should be changed by a qualified workshop.

The vehicle jack supplied with the vehicle is only designed for changing a wheel when one vehicle tyre is damaged and has to be replaced. Seek ex-pert assistance if both tyres on one side of the ve-hicle, both tyres on one axle, or all tyres are dam-aged.

Only change the wheel yourself when the car is parked in a safe place, you are familiar with the necessary steps and safety procedures and you have access to all the correct tools. Seek expert assistance if this is not the case.

Additional information and warnings:

• Exterior views =>page 5

• Vehicle key set =>page 36

• Tyre monitoring system =>page 318

• Wheels and tyres =>page 367

• In an emergency =>page 411

• Vehicle tool kit =>page 416

• Hubcaps =>page 417

Preparations for changing a wheel

1"1'11 First read and observe the introductory L-1o:.U information and safety warnings & on page 420.

Checklist

The following actions must always be carried out in the given order in preparation for changing the wheel=>&:

1. In the event of a flat tyre, park your vehicle on a firm and level surface at a safe dis-tance from the flow of traffic.

2. Apply the handbrake =>page 269.

420 I If and when

A wARNING

Changing a wheel can be dangerous, espe-cially when carried out at the side of a road. Please note the following steps in order to re-duce the risk of serious injuries:

• Stop the vehicle as soon as possible and when safe to do so. Park the vehicle at a safe distance from moving traffic in order to carry out the wheel change.

• All passengers and children in particular must be at a safe distance and away from your area of work during the wheel change.

• Switch on the hazard warning lights to warn other road users.

• Check that the surface the vehicle Is parked on Is level and firm. If necessary use a large, strong board or similar support for the vehicle jack.

• Only change the wheel yourself if you feel confident carrying out the procedure. If not, seek expert assistance.

• Always use suitable and undamaged tools to change the wheel.

• Always switch off the engine, apply the handbrake and move the selector lever to the position P or select a gear on a manual gear-box in order to reduce the risk of unintended vehicle movement.

• The wheel bolt tightening torque should be checked with a torque wrench immediately after changing a wheel.

4. Stop the engine and remove the key from the ignition =>page 257.

5. Manual gearbox: select a gear =>page 260.

6. Make sure all vehicle occupants exit the ve-hicle and move to safety, for instance be-hind the safety barrier.

7. Chock the wheel diagonally opposite the wheel being worked on with a stone or a similar object. ""

Page 425 of 486

• Clean the area around the fastening holes of the spare wheel.

• Position the spare wheel.

• Insert the anti-theft wheel bolt using the adapter at position 298 @or® and tighten it slight-ly.

• Screw in all the other wheel bolts in a clockwise direction and use the box spanner to tighten them gently.

• Lower the vehicle with the jack.

• Use the box spanner to tighten all the wheel bolts securely in a clockwise direction &. Do not tighten the bolts in clockwise or anticlockwise se-quence. Tighten them in diagonal sequence.

• Fit the cover caps, centre covers or wheel cov-ers 417.

After changing a wheel

rl'l1 First read and observe the Introductory L-.lo:.ll Information and safety warnings & on page 420.

• If necessary, clean the vehicle tools and stow them safely in the vehicle 416.

• Stow the spare wheel or the removed wheel safely under the vehicle.

Breakdown set

CQJ Introduction

This chapter contains information on the following subjects:

Storing . . . . . . . . . . . . . . . . . . . . 426

Contents of the breakdown set . . . . . . . . . . . . 427 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Sealing and inflating tyres . . . . • . . . . . . . 428

Test after driving for 10 minutes . . . . 429

You can use the breakdown set (tyre mobility set) to safely seal any tyre damage caused by foreign bodies or punctures (up to 4 mm (0.16 Inches) in diameter). Do not remove foreign objects (e.g. screws or nails) from the tyrel

Once the sealant has been added to the tyre, the tyre pressure must be checked again after approxi-mately 10 minutes of driving.

,A WARNING

Incorrect torque or incorrect use of wheel bolts can lead to a loss of control of the vehi-cle, cause accidents and serious Injuries.

• Always keep all wheel bolts and threads In the wheel hubs clean and free from oil and grease. The wheel bolts must be easy to turn and be tightened to the specified torque.

• The hexagonal socket In the screwdriver handle should only be used for turning wheel bolts, not use for loosening or tightening them.

• The damaged wheel should be replaced as soon as possible.

m In vehicles with a tyre monitoring system, the L!..J system may have to "re-learn" if new tyres are fitted 318.

Only use the breakdown set if the car is parked in a safe place, you are familiar with the required ac-tions and safety procedures, and you have access to the correct breakdown set. Seek expert assis-tance if this is not the case.

The tyre sealant must not be used:

• If the rim is damaged.

• If the outside temperature is below -2o•c (-4 ·F).

• If there are cuts or punctures in the tyre that are larger than 4 mm. .,.

Practical tips 425

Page 426 of 486

• If the tyre pressure is very low or the tyres are flat.

• If the use-by date on the tyre filler bottle has ex-pired.

Additional information and warnings:

• Vehicle key set 36

• Seat functions, front 69

• Stowage 150

• Braking, stopping and parking =>page 269

• Wheels and tyres 367

• In an emergency 411

• Hubcaps 417

A WARNING

Using the breakdown set can be dangerous, especially if the tyres are inflated at the road-side. Please note the following points In or-der to reduce the risk of serious injuries:

• Stop the vehicle as soon as possible and when safe to do so. Park the vehicle at a safe distance from moving traffic in order to fill the tyre.

• Check that the surface the vehicle is parked on is level and firm.

• All passengers, and children in particular, must be at a safe distance and away from your area of work.

• Switch on the hazard warning lights to warn other road users.

• The breakdown set should only be used if you feel confident with carrying out the pro-cedure. If not, seek expert assistance.

Storing

rT'n First read and observe the introductory L-W.I information and safety warnings & on page 425.

Model

Multivan

California

426 I If and when

A WARNING (Continued)

• Tyres repaired with the breakdown set are intended for temporary, emergency use only. They should only be used until you can reach the nearest qualified workshop.

• Tyres that have been repaired using the breakdown set should be replaced as soon as possible.

• Sealant Is hazardous to health and must be washed off Immediately if it gets onto the skin.

• The breakdown set must be stored out of the reach of children.

• Never use a vehicle jack, even If it Is ap-proved for the vehicle.

• Always switch off the engine, apply the handbrake and move the selector lever to the position P or select a gear on a manual gear-box In order to reduce the risk of unintended vehicle movement.

A WARNING

Tyres that have been filled with sealant will not handle In the same way as a standard tyre.

• Never drive faster than 80 km/h (50 mph).

• Avoid full acceleration, sudden braking and fast driving through bends In the road.

• Drive for just 10 minutes at no more than 80 km/h (50 m ph) and then check the tyre.

Dispose of used or out-of-date sealant in ac-W cordance with legal requirements.

m You can get a new tyre filler bottle from a L!:J Volkswagen Commercial Vehicles dealership.

m Observe the separate instructions from the l!:J manufacturer of the breakdown set. <1

The breakdown set can be located in different pla-ces depending on the model.

Stowage

In the drawer in the 3-seat bench or in the drawer of the rear left single seat.

Behind the load-through hatch cover on the side of the bench seat/bed. <1

Page 427 of 486

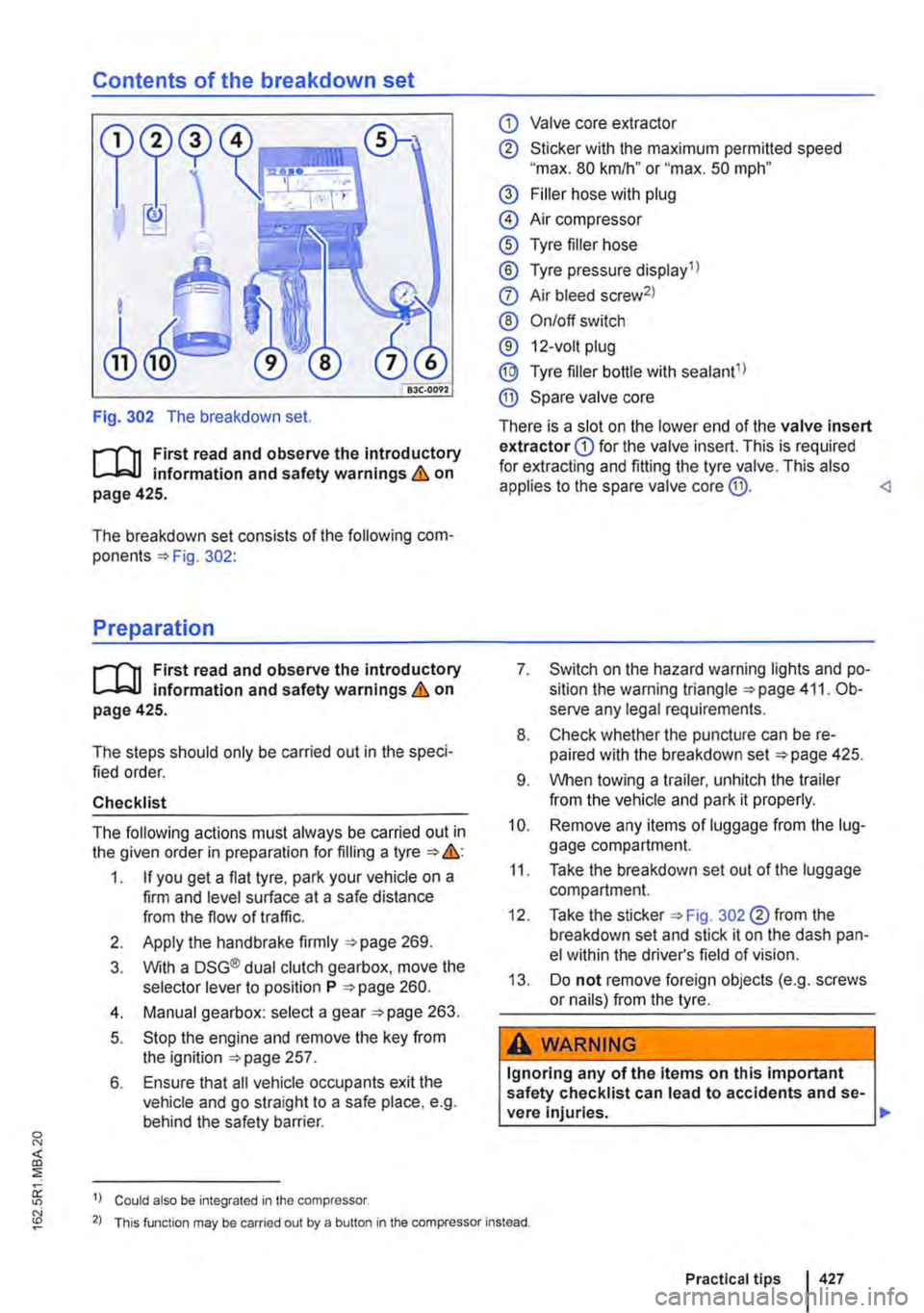

Contents of the breakdown set

Fig. 302 The breakdown set.

r--T'n First read and observe the introductory L-L::.U information and safety warnings & on page 425.

The breakdown set consists of the following com-ponents 302:

Preparation

r--T'n First read and observe the introductory L-L::.U information and safety warnings & on page 425.

The steps should only be carried out in the speci-fied order.

Checklist

The following actions must always be carried out in the given order in preparation for filling a tyre &:

1. If you get a flat tyre, park your vehicle on a firm and level surface at a safe distance from the flow of traffic.

2. Apply the handbrake firmly 269.

3. With a DSG® dual clutch gearbox, move the selector lever to position P 260.

4. Manual gearbox: select a gear 263.

5. Stop the engine and remove the key from the ignition 257.

6. Ensure that all vehicle occupants exit the vehicle and go straight to a safe place, e.g. behind the safety barrier.

1) Could also be integrated in the compressor.

CD Valve core extractor

® Sticker with the maximum permitted speed "max. 80 km/h" or "max. 50 mph"

@ Filler hose with plug

@ Air compressor

® Tyre filler hose

® Tyre pressure display 1 l

0 Air bleed screw2l

® On/off switch

® 12-volt plug

@ Tyre filler bottle with sealant1l

® Spare valve core

There is a slot on the lower end of the valve insert extractor CD for the valve insert. This is required for extracting and fitting the tyre valve. This also applies to the spare valve core @.

8. Check whether the puncture can be re-paired with the breakdown set 425.

9. When towing a trailer, unhitch the trailer from the vehicle and park it properly.

10. Remove any items of luggage from the lug-gage compartment.

11. Take the breakdown set out of the luggage compartment.

12. Take the sticker 302 ®from the breakdown set and stick it on the dash pan-el within the driver's field of vision.

13. Do not remove foreign objects (e.g. screws or nails) from the tyre.

A WARNING

Ignoring any of the items on this important safety checklist can lead to accidents and se-vere Injuries. ,..

2) This function may be carried out by a button in the compressor instead.

Practical tips 427

Page 445 of 486

r'l11 First read and observe the Introductory L-J,:.,U Information and safety warnings & on page 443.

CD Vehicle with discharged battery that is being jump-started.

@ Vehicle with vehicle battery that is supplying power and jump-starting the other vehicle.

@ Suitable earth connection. A solid metal part that is firmly bolted to the engine block, or the engine block itself.

The discharged vehicle battery must be properly connected to the vehicle's electrical system.

The vehicles must not touch. Otherwise electricity could flow as soon as the positive terminals are connected.

Ensure that the battery clamps have good metal-to-metal contact with the battery terminals.

If the engine does not start immediately, switch off the starter after about 10 seconds and try again af-ter about half a minute.

The steps should only be carried out in the speci-fied order.

Attaching the jump leads

• Switch off the ignitions In both vehicles 257.

• If necessary, open the battery cover in the en-gine compartment 362.

• Connect one end of the red jump lead to the positive terminal 318 E) or 319 E) of the vehicle with the discharged battery CD &.

• Connect the other end of the red jump lead to the positive terminal E) In the vehicle providing as-sistance@.

• In vehicles without start/stop system: con-nect one end of the black jump lead to the negative terminal 0 in the vehicle providing assistance @ 318.

• In vehicles with start/stop system: connect one end of the black jump lead @to a suitable earth connection, to a solid metal part which is se-curely bolted onto the cylinder or to the cylinder block itself =:-Fig. 319.

• Connect the other end of the black jump lead @ to a solid metal component that is bolted firmly to the engine block of the vehicle with the flat bat-tery, to the engine block itself or, if necessary, to the screwed-in towing eye at the front. Do not con-nect it to a point near the battery CD &.

• Position the leads in such a way that they can-not come into contact with any moving parts in the engine compartment.

Starting the engine

• Start the engine of the vehicle which is provid-ing assistance and let it run at idle.

• Start the engine of the car with the discharged vehicle battery and wait two or three minutes until the engine is running "smoothly".

Removing the jump leads

• Before disconnecting the jump leads, switch off the dipped beam headlights If they are switched on.

• Turn on the heater blower and rear window heater in the vehicle battery with the discharged battery. This helps minimise the voltage peaks generated when the leads are disconnected.

• With the engines running, disconnect the jump leads in the exact reverse order to the instructions given above.

A WARNING

Jump starting the vehicle Incorrectly can cause the battery to explode, which can lead to serious injuries. Please note the following In order to reduce the risk of the battery ex-ploding:

• All work on the vehicle battery and the electrical system can cause serious chemical burns, fire or electric shocks. Always read the warnings and safety Information before carrying out any kind of work on the vehicle battery 362, Vehicle battery.

• Always wear suitable eye protection and never lean over the vehicle battery.

• Attach the connector cables In the correct order-the positive cable first, followed by the negative.

• Never connect the negative cable to parts of the fuel system or to the brake lines.

• The non-insulated parts of the battery clamps must not be allowed to touch. The jump lead attached to the positive vehicle battery terminal must not touch metal parts of the vehicle.

• Check the battery window using a torch If necessary. If the display Is light yellow or col-ourless, do not jump start the vehicle. Seek expert assistance.

• Avoid electrostatic discharge In the vicini-ty of the vehicle battery. The gas emitted from the vehicle battery could be Ignited by sparks.

• Do not use jump leads to start the engine If the vehicle battery Is damaged or if it is or has ever been frozen.

Page 446 of 486

Tow-starting and towing

0::0 Introduction

This chapter contains information on the following subjects:

Notes on tow-starting . . . . . . . . . . . . . . . . . . . . 446

Notes on towing . . . . . . . . . . . . . . . . . . . . . . . . . 447

Fitting the towing eye at front . . . . . . . . . . . . 448 Notes on driving while towing . . . . . . . . . . . . . . 448

Observe any legal requirements when towing.

For technical reasons, vehicles with a dis-charged battery must not be tow-started.

Towing a vehicle when the engine is switched off and the ignition is switched on discharges the vehi-cle battery. Depending on the vehicle battery charge level, the drop in voltage can be large enough after just a few minutes that electrical con-sumers in the vehicle will no longer function, e.g. the hazard warning lights.

Additional information and warnings:

• Exterior views =>page 5

• Changing gear =>page 257

• Engine management system and exhaust puri-fication system =>page 407

• Jump starting =>page 443

A wARNING

Never tow a vehicle that has no power sup-ply.

• Never remove the key from the ignition. The steering lock may be activated and you will no longer be able to steer the vehicle. This can lead to a loss of control of the vehi-cle, accidents and serious injuries.

Notes on tow-starting

t""""("'n First read and observe the introductory L-.lc:.JJ information and safety warnings & on page 446.

Vehicles should not be tow-started wherever possible. Use jump leads to start the engine in· stead =>page 443.

For technical reasons, the following vehicles can-not be tow-started:

4461 If and when

A WARNING (Continued)

• If the power supply to the towed vehicle is disconnected, stop towing immediately and seek expert assistance.

A WARNING

If a vehicle is being towed, the vehicle han-dling and braking effect will change signifi-cantly. Please note the following in order to reduce the risk of an accident or serious inju-ries:

• Notes for the driver of the towed vehicle:

-You will need to depress the brake ped-al more vigorously than normal as the brake servo is not working. Always be careful not to drive Into the vehicle that is pulling your vehicle.

-You will need to turn the steering wheel more vigorously as the power-assisted steering function Is not working.

• Notes for the driver of the towing vehicle

-Accelerate carefully and gently.

-Avoid sudden braking and driving ma· noeuvres.

-Brake earlier than normal by pressing lightly on the brake pedal.

CD

• Remove and install the cover and the tow-ing eye carefully so as to avoid damage to the vehicle, e.g. the palntwork.

• Unburnt fuel can enter the catalytic convert· er and damage it while the vehicle Is being tow-ed.

• If the vehicle battery has discharged, the en-gine control units will not function properly.

However, if the vehicle still has to be tow-started (manual gearbox):

• Engage second or third gear.

• Keep the clutch pressed down.

Page 447 of 486

• Switch on the ignition and the hazard warning lights.

• Once both vehicles are in motion, release the clutch.

• As soon as the engine starts, press the clutch and put the gear into neutral. This helps to prevent driving into the towing vehicle.

Notes on towing

i"""fl1 First read and observe the introductory L-W! information and safety warnings & on page 446.

Fixed towing eye at rear

On vehicles without a towing bracket there is a fixed towing eye under the bumper at the rear right.

Towing bracket instead of a fixed towing eye

If the vehicle has a factory-fitted towing bracket, it should also be used for towing other vehicles.

Tow rope or tow bar

lt is easier and safer to tow a vehicle with a tow bar. Only use a tow rope if you do not have a tow bar.

The tow rope should be slightly elastic to reduce the strain on both vehicles. lt is advisable to use a tow rope made of synthetic fibre or similarly elastic material.

Only attach the tow rope or tow bar to the specially provided towing eyes or to the towing bracket.

Vehicles with a factory-fitted towing bracket must be towed only with a tow bar that is specially designed for fitting to a ball coupling 139.

When your vehicle has to be towed:

• Switch on the ignition.

• Select the neutral position or move the selector lever to N 257.

• Release the handbrake. if necessary.

CD

When tow-starting, unburnt fuel can enter the catalytic converter and damage it. <1

• Do not allow the vehicle to be towed at speeds faster than 50 km/h (30 mph).

• Do not allow the vehicle to be towed further than 50 km.

• Vehicles with a DSG® dual clutch gearbox may only be towed by the breakdown truck with the front wheels raised.

Towing vehicles with four-wheel drive (4MOTION)

Vehicles with four-wheel drive (4MOTION) may be towed with a tow bar or tow rope. If the vehicle is towed with the rear or front axle raised, the engine must be switched off otherwise the drive train could be damaged.

When should your vehicle not be towed?

• If, due to damage, the vehicle gearbox no lon-ger contains any lubricant.

• If the vehicle battery is discharged.

• If the distance to be towed is further than 50 km -applies only to vehicles with the DSG® dual clutch gearbox.

• If the steering function or the operating clear-ance of the wheels cannot be ensured, e.g. after an accident.

Please comply with the following when towing another vehicle:

• Comply with legal regulations.

• Comply with the information on towing con-tained in the owner's manual for the other vehicle. <1

Practical tips

Page 448 of 486

Fitting the towing eye at front

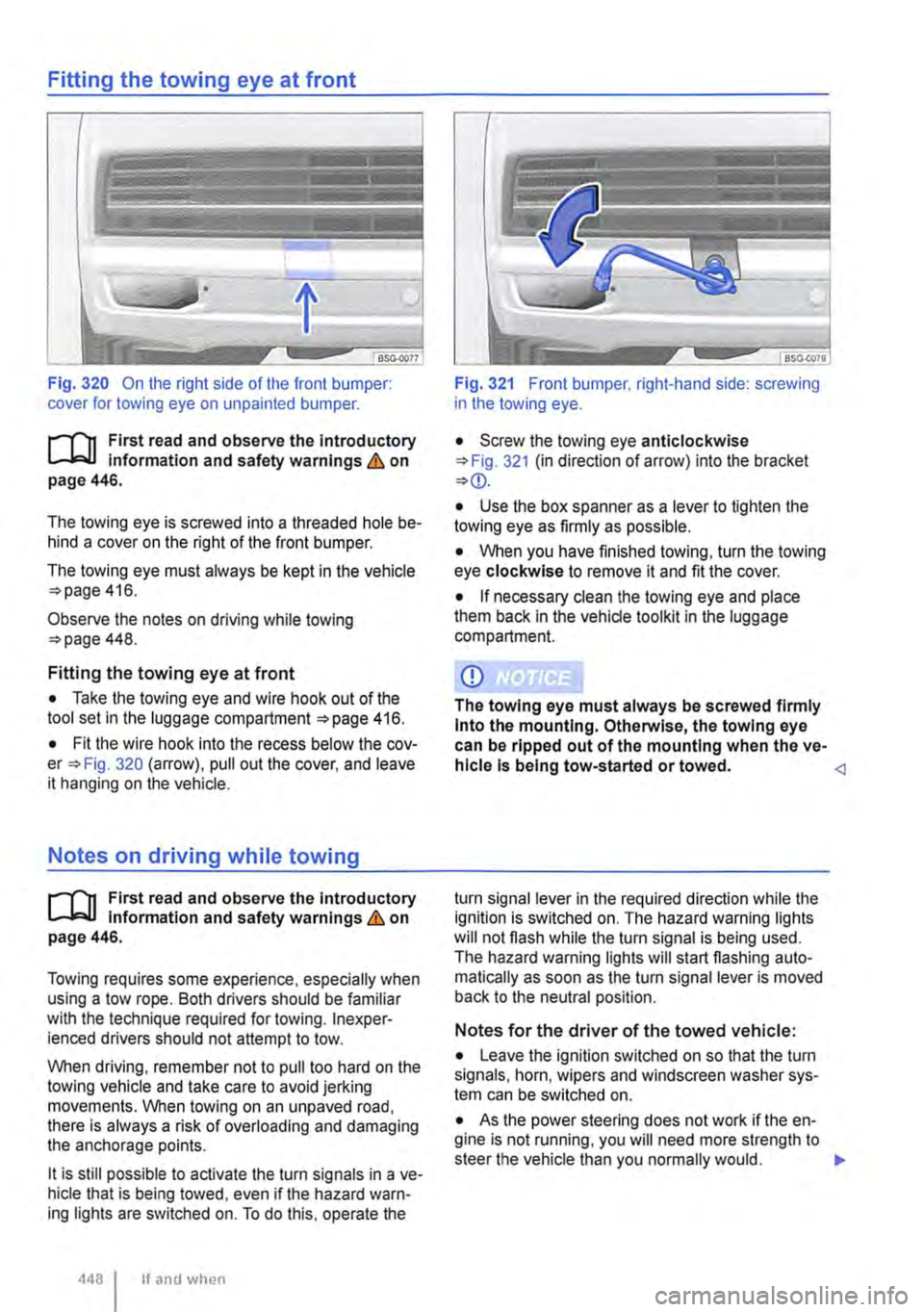

Fig. 320 On the right side of the front bumper: cover for towing eye on unpainted bumper.

l"""('n First read and observe the Introductory L-Jo:.U Information and safety warnings & on page 446.

The towing eye is screwed into a threaded hole be-hind a cover on the right of the front bumper.

The towing eye must always be kept in the vehicle 416.

Observe the notes on driving while towing 448.

Fitting the towing eye at front

• Take the towing eye and wire hook out of the tool set in the luggage compartment 416.

• Fit the wire hook into the recess below the cov-Fig. 320 (arrow). pull out the cover, and leave it hanging on the vehicle.

Notes on driving while towing

l"""('n First read and observe the introductory L-Jo:.U Information and safety warnings & on page 446.

Towing requires some experience, especially when using a tow rope. Both drivers should be familiar with the technique required for towing. lnexper· ienced drivers should not attempt to tow.

When driving, remember not to pull too hard on the towing vehicle and take care to avoid jerking movements. When towing on an unpaved road, there is always a risk of overloading and damaging the anchorage points.

lt is still possible to activate the turn signals in a ve-hicle that is being towed, even if the hazard warn-ing lights are switched on. To do this, operate the

4481 If and when

Fig. 321 Front bumper. right-hand side: screwing in the towing eye.

• Screw the towing eye anticlockwise 321 (in direction of arrow) into the bracket

• Use the box spanner as a lever to tighten the towing eye as firmly as possible.

• When you have finished towing, turn the towing eye clockwise to remove it and fit the cover.

• If necessary clean the towing eye and place them back in the vehide toolkit in the luggage compartment.

CD

The towing eye must always be screwed firmly Into the mounting. Otherwise, the towing eye can be ripped out of the mounting when the ve-hicle Is being tow-started or towed.

Notes for the driver of the towed vehicle:

• Leave the ignition switched on so that the turn signals, horn, wipers and windscreen washer sys-tem can be switched on.

• As the power steering does not work if the en-gine is not running, you will need more strength to steer the vehicle than you normally would. .,.

Page 473 of 486

Gear-change Indicator . . . . . . . . . . • . . . . . 268

Glasses compartent . . . . . . . . . . . . . . . . . . 152

Glove compartment Lights ............................. 114 see Stowage areas . . . . . . . . . . . . . . . . . 151

Gross vehicle weight rating . . . . . . . . . . . . 450

Guide rail system In the rear vehicle floor Business . . . . . . . . . . . . . . . . . . . . . . . . . 133 California . . . . . . . . . . . . . . . . . . . . . . . . . 133 Multivan . . . . . . . . . . . . . . . . . . . . . . . . . . 133

H

Handbrake

Hands-free system in the passenger com· partment

271

See Rear-seat telephony . . . . . . . . . . . . . 187 Hazard warning lights . . . . . . . . . . . . . . . . . 412

Headlight range control ............. 11,113 Dynamic headlight range control . . . . . . . . 113

Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . 108 Cleaning system . . • . . . . . . . . . . . . . . . . . 118 Driving abroad . . . . . . . . . . . . . . . . . . . . . . 111 Headlight (LED) . . . . . . . . . . . . . . . . . . . . . . 434

Head restraints . . . . . . . . . . . . . . . . . . . . . . . 67

Heat-insulating glass windscreen . . . . . . . . . . . . . . . . . . . . . . . . . 116

Heated seats . . . . . . . . . . . . . . . . . . . . . . . . . 69

Heating and fresh air system Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 327

High-pressure cleaner . . . . . . . . . . . . . . . . 382

High-visibility waistcoat . . . . . . . . . . . . . . . 413

Hill Descent Assist . . . . . . . . . . • . . • . . . . . 285

Hill Hold Assist . . . . . . . . . . . . . . . . . . . . . . 284

Horn ................•................ 11

Hubcaps . . . . . . . . . . . . . . . . . . . . . . . . 417, 420 Centre cover . . . . . . . . . . . . . . . . . . . . . . 418 Wheel bolt caps . . . . . . . . . . . . . . • . . . . . 419 Wheel cover . . . . . . . . . . . . . . . . . . . . . . . 419

ICC 173

Identification number . . . . . . . . . . . . . . . . . 451

If and when.......................... 410

Ignition see Engine and ignition . . . . . . . . . . . . . . 257

Ignition key see Key . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Ignition lock . . . . . . . . . . . . . . . . . . . . 258 Non-authorised vehicle key . . . . . . . . . . . 258 Withdrawal lock . . . . . . . . . . . . . . . . . . . . 258

Immobilizer . . . . . . . . . . . . . . . . . . . . . . . . . . 260 Fault ............................. 257 In-car communication system . . . . . 173

Indicator lamp Adaptive chassis control (DCC) 317 Adaptive cruise control (ACC) . . . . • . . . . 300 AdBiue . . . . . . ............. 347 Airbag system . . . . . . . . . . . . . . . . . . . . . . 89 Brake pad wear indicator . . . . . . . . . . . . . 270 Brake system . . . . . . . . . . . . . . . . . . . . . . 270 Catalytic converter . . . . . . . . . . . . . . . . . . 407 Changing bulbs . . . . . . . . . . . . . . . . . . . . 433 Changing gear . . . . . . . . . . . . . . . . . . . . . 261 Checking the oil level . . . . . . • . . . . . . . . . 354 Coolant . . . . . . . . . . . . . . . . . • . . . . . . . . . 359 Cruise control system . . . . . . . . . . . . . . . 296 Depress brake . . . . . . . . . . . . . . . . . . . . . 270 Diesel particulate filter . . . . . . . . . . . . . . . 407 Engine management system . . . . . . . . . . 407 Engine oil sensor . . . . . . . . . . . . . . . . . . . 354 ESC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270 Exhaust purification system . . . . . . . . . . . 407 Filling the tank . . . . . . . . . . . . . . . . . . . . . 341 Fuel level . . . . . . . . . . . . . . . . . . . . . . . . . 341 In the driver door . . . . . . . . . . . . . . . . . . . . 43 Lane change assist system . . . . . . . . . . . 313 Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Remote control key . . . . . . . . . . . . . . . . . . 38 Seat belt . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Tyre monitoring system . . . . . . . . . . . . . . 319 Windscreen washer fluid level . . . . . . . . . . 117

Indirect ventilation . . . . . . . . . . . . . . . . . . . . 329

Information stored in the control units . . . 398 Infrared-reflecting windscreen . . . . . . . . . . . 116

Instrument cluster . . . . . . . . . . . . . . . . . . . . . 16 Displays . . . . . . . . . . . . . . . . . . . . . 20, 21, 25 Indicator lamps . . . . . . . . . . . . . . . . . . . . . . 16 Instruments . . . . . . . . . . . . . . . . . . . . . . . . 20 Menu structure . . . . . . . . . . . . . . . . . . . . . . 25 Service interval display . . . . . . . . . . . . . . . 22 Symbols ........................... 16 Using menus . . . . . . . . . . . . . . . . . . . . . . . 27 Warning lamps . . . . . . . . . . . . . . . . . . . . . . 16 Instruments . . . . . . . . . . . . . . . . . • . . . . . . . . 20

Integrated child seat . . . . . . . . . . . . . . . . . . 102 Seat belt routing . . . . . . . . . . . . . . . . . . . . 1 05

Interior lights ................ , ........ 114

Interior lights, California . . . . . . . . . . . . . . . 208 Living area . . . . . . . . . . . . . . . . . . . . . . . . 209 Pop-up roof . . . . . . . . . . . • . . . . . . . . • . . 21 0 Interior mirror . . . . . . . . . . . . . . . . . . . . . . . . 122

Interior monitoring system . . . . . . . . . . . . . . 44 ISOFIX.............................. 100 see Child seat . . . . . . . . . . . . . . . . . . • . . . 96

Index 473