length VOLVO 940 1982 Service User Guide

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 940, Model: VOLVO 940 1982Pages: 168, PDF Size: 54.28 MB

Page 66 of 168

700/940/960 Specifications

Section 2' 8200,8230 Engines

Group 25 Intake and exhaust systems

Turbo engines

'-198~

Engine type .... ; ......... . , ............ .. .............

Charg~ pressure, at full load and ................... r/min

checking

.. ................... kPa (psi)

setting. . . . . . . . . . . . . . . . . . . . .

.. kPa (psi)

Charge air overpressure, switch opens at ....... kPa

(psi)

Charge air pressure, switch closes at ........... kPa (psi)

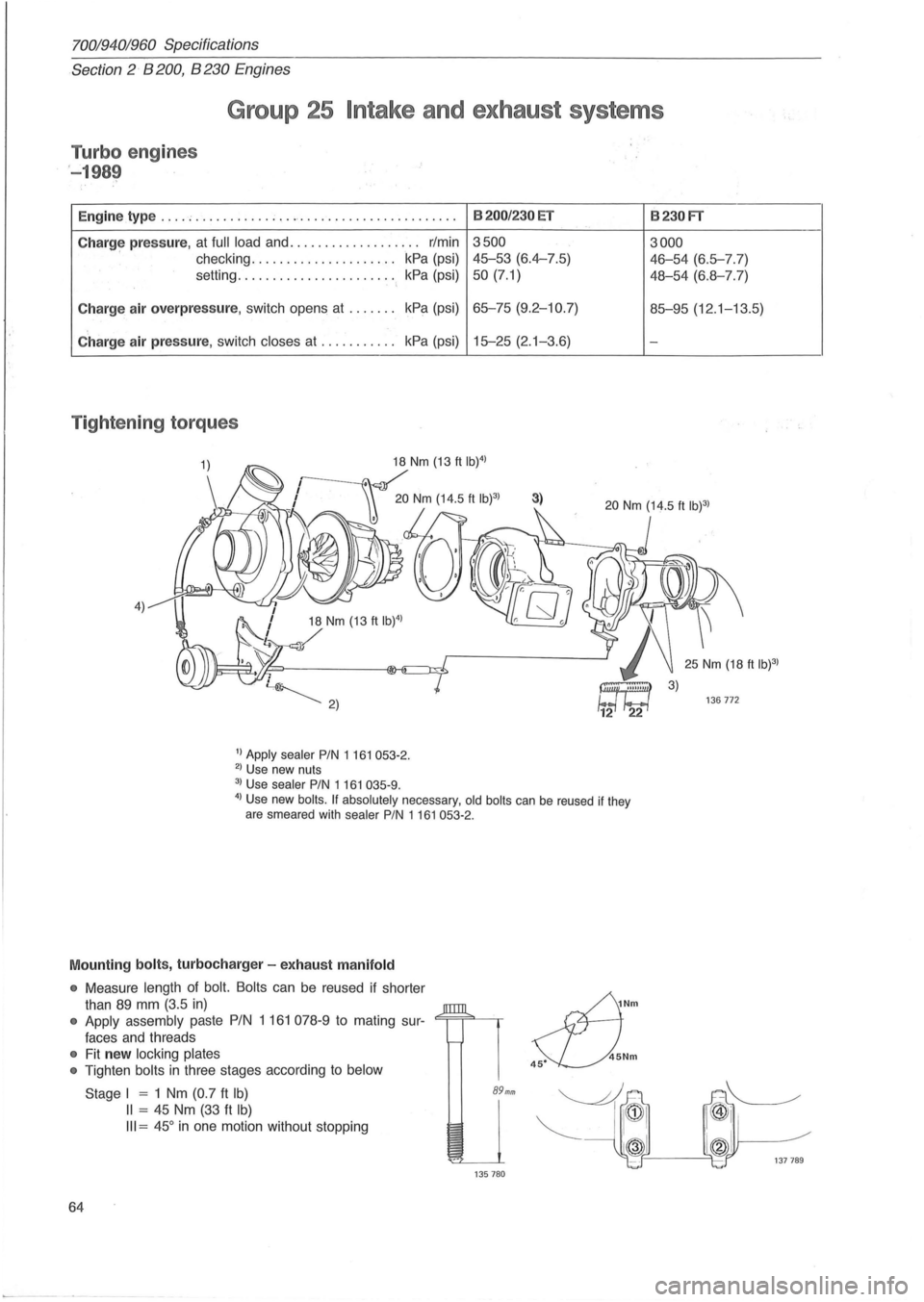

Tightening torques

4) 18 Nm (13 ft IW)

/

1) Apply sealer PIN 1 161 053-2. 2) Use new nuts

3) Use sealer PIN 1161 035-9.

8200/230 ET

3500

45-53 (6.4-7.5)

50 (7.1)

65-75 (9.2-10.7)

15-25 (2. 1-3.6)

3)

4) Use new boils. If absolutely necessary, old boils can be reused if they

are smeared with sealer PIN 1161053-2.

Mounting bolts, turbocharger -exhaust manifold

• Measure length of bolt. Bolts can be reused if shorter

than

89 mm (3.5 in)

• Apply assembly paste PIN 1 161 078-9 to mating sur-<=;==;=""-~

faces and threads

• Fit new locking plates

•

Tighten bolts in three stages according to below

64

Stage I = 1 Nm (0.7 ft Ib)

II = 45 Nm (33 ft Ib)

III = 45° in one motion without stopping

89mm

135780

~Nm

s::L).Nm

8230FT

3000

46-54 (6.5-7.7)

48-54 (6.8-7.7)

85-95 (12 .1-13.5)

-

136772

Page 72 of 168

70019401960 Specifications

Section'-2" B 28 Engine

Group 21 Engine block

Cylinder head

Max warp:

Maxium warp is

0.05 mm (0.002 in) per

100 mm (4 in) length.

Note: Do not level a warped cylinder head,

replace it!

Cylinder liners

[

Bore, liners marked 1 (A-marked piston) ....................... .

2 (B-marked piston) ....................... .

3 (C-marked piston) ...................... .

Liner height above

block face:

checking (runing engine,

old shims) ....................... .. .

adjusting (new shims)

..................................... .

Pistons

Max weight difference between pistons in same engine .......... .

Piston

float ................................................. .

Piston diameter A-marked pistons

......... .

B-marked pistons

......... .

C-marked pistons

........ .

]

91.00-91.01 mm

91.01-91.02 mm

91.02-91.03 mm

0.14--0.23 mm

0.16-0.23 mm

6 grams

0.020-0.040 mm

90.970-90.980 mm

90.980-90.990 mm

90.990-91.000 mm

3.5826-3.5830 in

3.5830-3.5835 in

5.5835-5.5838 in

0.0055-0.0091 in

0.0063-0.0091 in

0.0007-0. 0015 in

3.5814-:3.5818 in

3.5818-3.5822 in

3.5822-3.5826 in

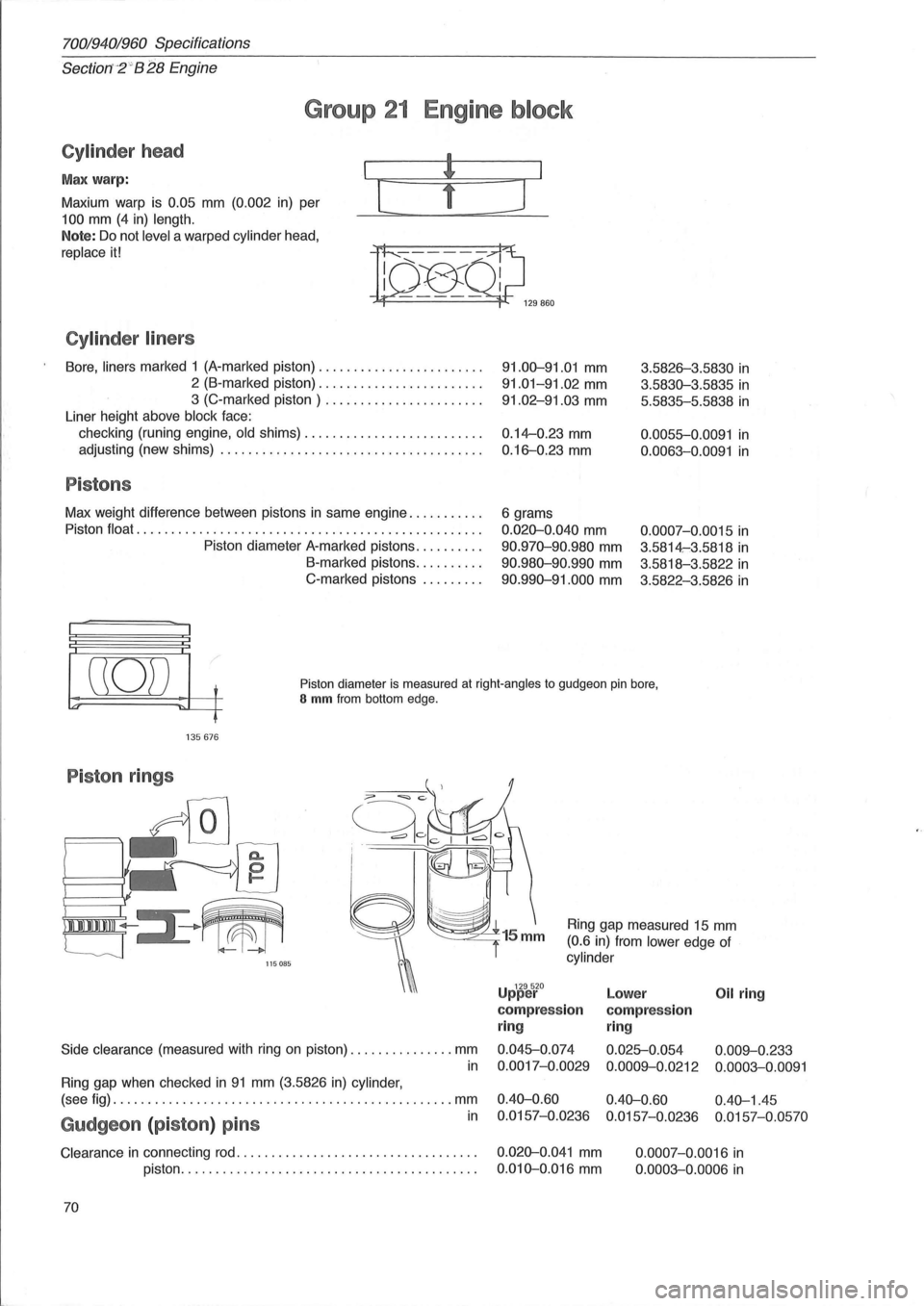

((0)) t

'" ~L-f

Piston diameter is measured at right-angles to gudgeon pin bore, S mm from bottom edge.

135676

Piston rings

/,

I 111111111 ~III

'--J 115085

Side clearance (measured with ring on piston) ............... mm

in

Ring gap when checked in 91 mm (3.5826 in) cylinder,

Ring gap measured 15 mm

(0.6 in) from lower edge of

cylinder

U 129520 pper

compression

ring

0.045-0.074

0.0017-0.0029

Lower Oil ring

compression

ring

0.025-0.054 0.009--0.233

0.0009--0.0212 0.0003-0.0091

(see fig) ................................................. mm 0.40-0.60 0.40-0.60 0.40-1.45

in 0.0157-0.0236 0.0157-0.0236 0.0157-0.0570 Gudgeon (piston) pins

Clearance in connecting rod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.020-0.041 mm

piston. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.010-0.016 mm

70 0.0007-0.0016

in

0.0003-0.0006 in

Page 74 of 168

70019401960 Specifications

Section

2 B 28 Engine

.. Valve guides are available in three oversizes and are

marked with grooves.

Standard

Oversize 1

Oversize 2

Oversize 3

129865

Valve springs

115083

Rocker arm mechanism

Marking Reamer

No groove

1 groove 5166

2 grooves 5167

3 grooves 5168

Springs marked green

Length

mm

in

47.1 1.85

40.0 1.57

30.0 1 .18

Load

N

o

230-266

613-689

The rocker arm tips are surface hardened and must not

be

ground.

lb.

o

52-60

137-154

Clearance. shaft-rocker arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.012-0 .054 mm (0.0005-0.0021 in)

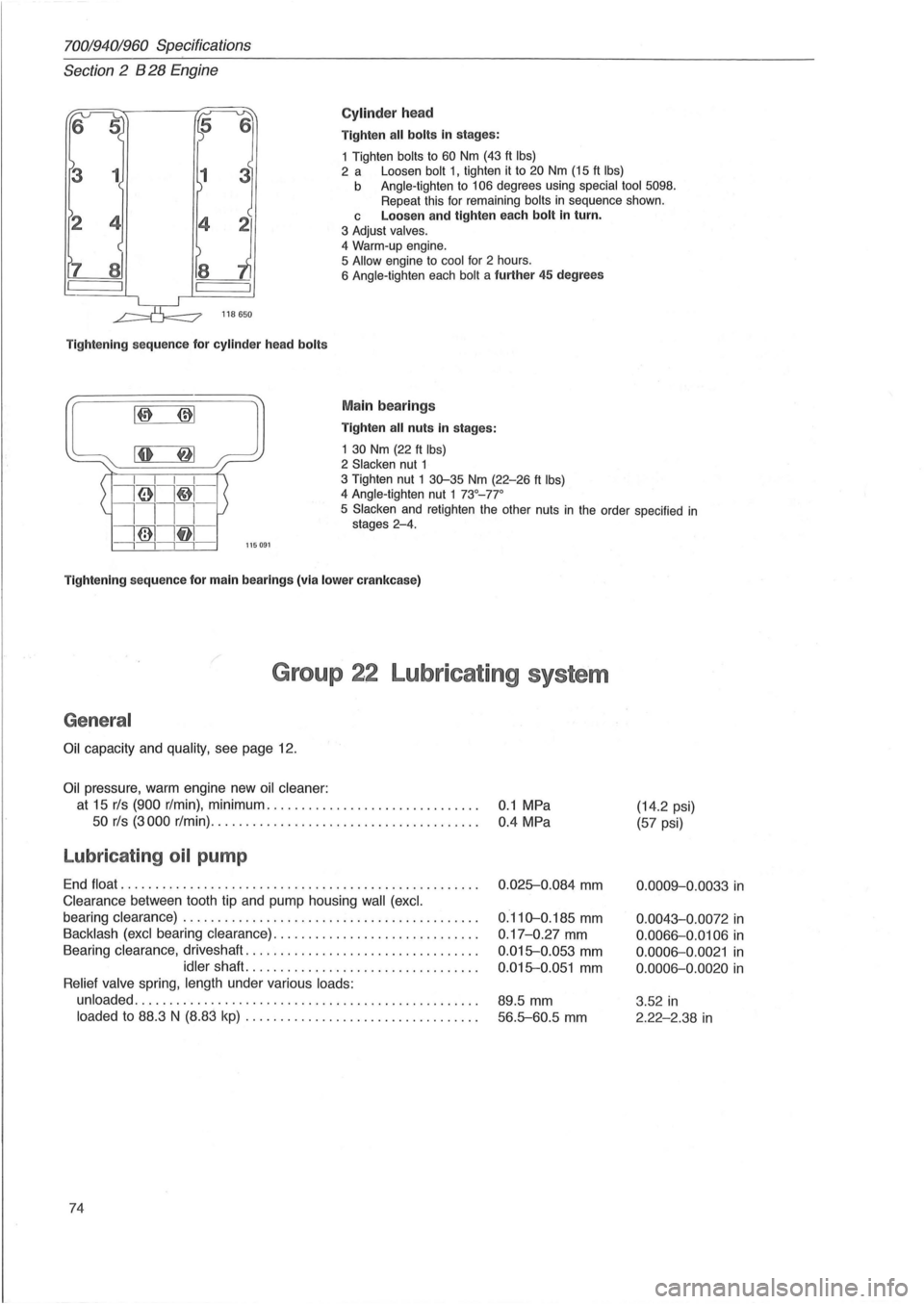

Timing gears

Camshaft

Engine type ............................. B28A, E B28F

Left

Right

Marking ................................. F

F

Part number

(last three digits).

early type ............................... .. .615 . . .616

late type ................................ . .. 977 .. .978

740~

Letter

B28A, E B28F

Max lobe lifting height. left and right. inlet ...................... .

exhaust. .

................ "

5.96 mm (0.2348 in) 5.44 mm

5.96 mm (0.2348 in) 5.94 mm

Checking camshaft settings (cold engine):

adjust

valve clearance on 1 st and 6th inlet valves to .......... . 0.7 mm (0.0275 in) 0.7 mm

The inlet valves should then open at:

Left

G

... 486

. . .979

1 st .................................................... . 8±3° B.T.D.C. 1 ±3° B.T.D.C.

6th .. ,

................................................. . 8±3° B.T.D.C. 1 ±3° B.T.D.C.

Journal clearance ........................................... . 0.035-0.085 mm

(0.0013-0.0033 in)

End play, new .............................................. . 0.070-0.144 mm

(0.0027-0.0056 in)

max .............................................. . 0.5 mm

(0.0196 in)

72

Right

G

... 487

... 980

(0.2142

in)

(0.2339 in)

(0. 0275 in)

Page 76 of 168

70019401960 Specifications

Section

2 B 28 Engine

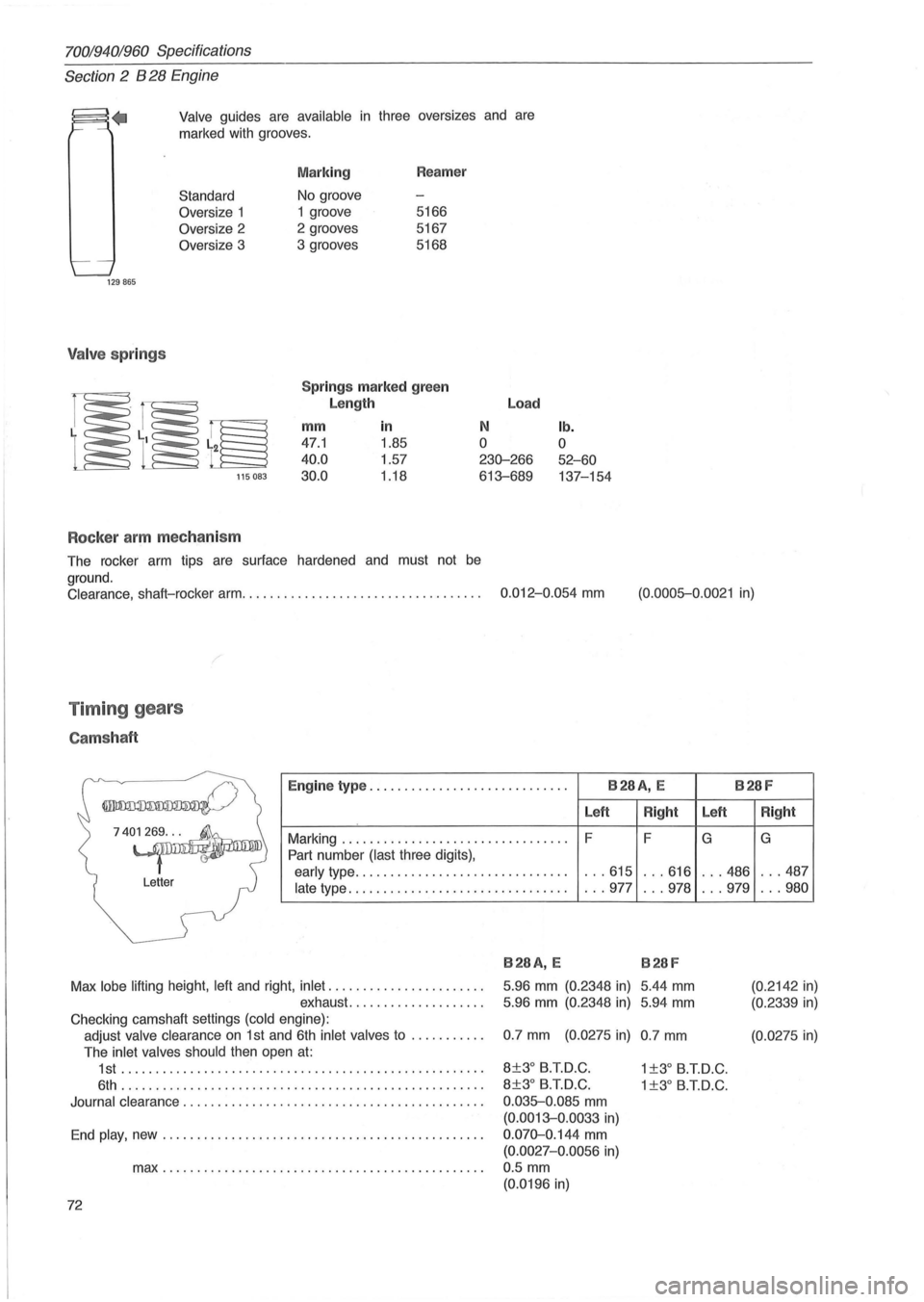

Cylinder head

Tighten all bolts in stages:

1 Tighten

bolts to 60 Nm (43 ft Ibs) 2 a Loosen bolt 1, tighten it to 20 Nm (15 ft Ibs) b Angle-tighten to 106 degrees using special tool 5098. Repeat this for remaining bolts in sequence shown.

118650

Tightening sequence for cylinder head bolts

L~~::~:~' ~I ~: I I I I

i61I~-

c Loosen and tighten each bolt in turn.

3 Adjust valves.

4

Warm-up engine.

5 Allow engine to cool for 2 hours.

6 Angle-tighten each bolt a further 45 degrees

Main bearings

Tighten all nuts in stages:

1

30 Nm (22 ft Ibs) 2 Slacken nut 1 3 Tighten nut 1 30-35 Nm (22-26 ft Ibs) 4 Angle-tighten nut 1 73°_77 °

1111-

i@1lf11 -

5 Slacken and retighten the other nuts in the order specified in stages 2-4.

---,---,---,---,-115091

Tightening sequence for main bearings (via lower crankcase)

Group 22 Lubricating system

General

Oil capacity and quality, see page 12.

Oil pressure, warm engine new oil cleaner:

at 15 rls (900 r/min), minimum .............................. .

50 rls (3000 r/min) .......... ....... ......... ............ .

Lubricating oil pump

End float ................................................... .

Clearance between tooth tip and pump housing wall (excl.

bearing clearance) .......................................... .

Backlash (excl bearing clearance) ................ ............. .

Bearing

clearance, driveshaft ................................. .

idler shaft. ................................ .

Relief valve spring, length under various loads:

unloaded

................................................. .

loaded to 88.3 N (8.83 kp) ............ ... .... .............. .

74

0.1 MPa

0.4 MPa

0 .

025-0.084 mm

0.110-0.185 mm

0 .17-0.27 mm

0.015-0.053 mm

0.015-0.051 mm

89.5 mm

56.5-60.5 mm

(14.2 psi)

(57 psi)

0.0009-0.0033 in

0.0043-0.0072 in

0.0066-0.0106 in

0 .0006-0.0021 in

0.0006-0.0020 in

3 .52 in

2.22-2.38 in

Page 84 of 168

70019401960 Specifications

Section

2 B 28 Engine

Group 25 Intake and exhaust systems

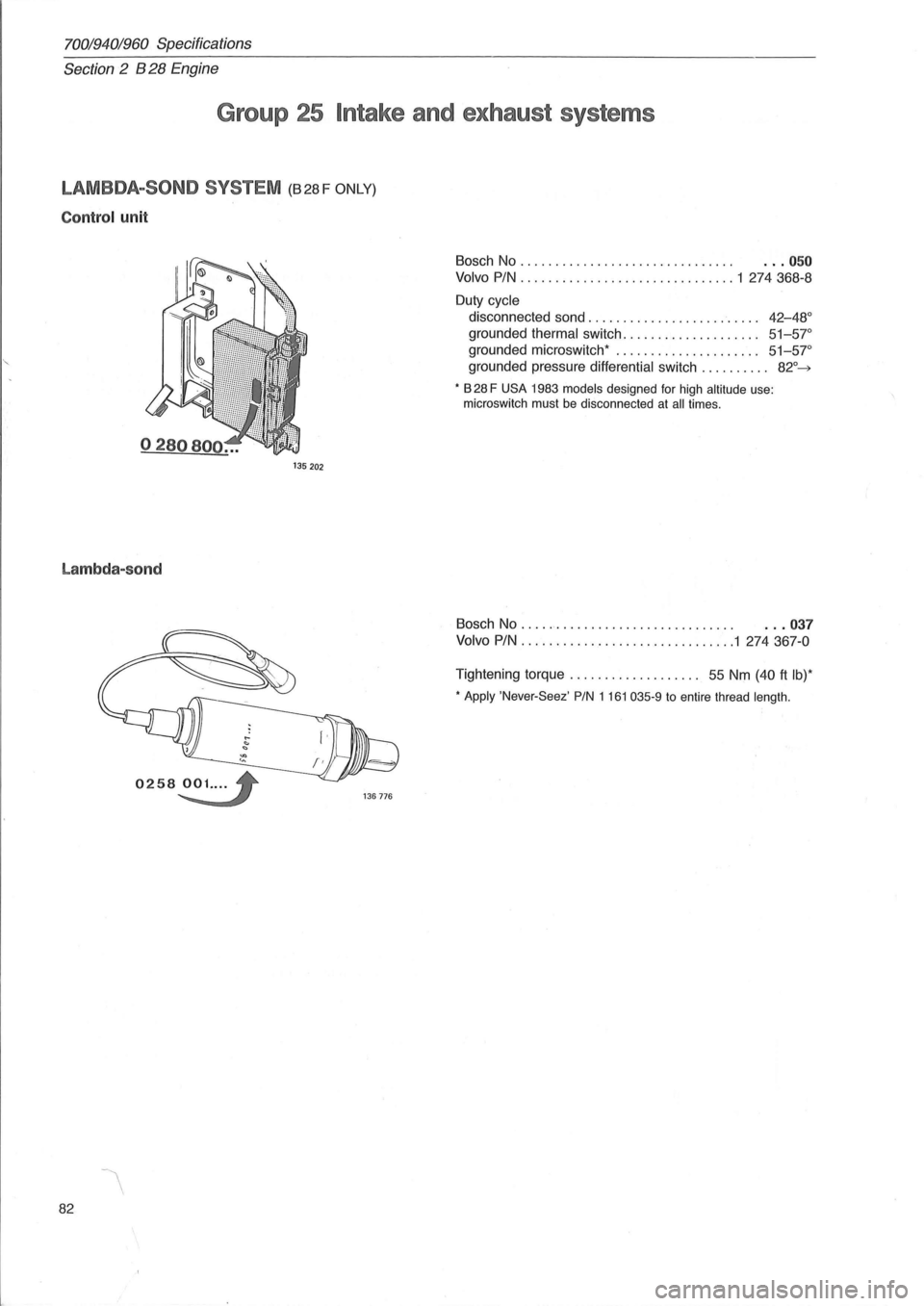

LAMBDA-SOND SYSTEM (B28F ONLY)

Control unit

135 202

Lambda-sond

82

Bosch No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 050

Volvo PIN ............................... 1 274368-8

Duty cycle

disconnected sand. . . . . . . . . . . . . . . . . . . . . . . . .

42-48°

grounded thermal switch . . . . . . . . . . . . . . . . . . .. 51-57°

grounded microswitch* ..................... 51-57"

grounded pressure differential switch .......... 82°~

* B 28 F USA 1983 models designed for high altitude use:

microswitch must be disconnected at all times.

Bosch No . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .. 037

Volvo PIN ..................... .......... 1 274367-0

Tightening torque. . . . . . . . . . . . . . . . . .. 55 Nm (40 ft Ib)*

* Apply 'Never-Seez' PIN 1 161 035-9 to entire thread length.

Page 89 of 168

(

70019401960 Specifications

Section

2 B 280 Engine

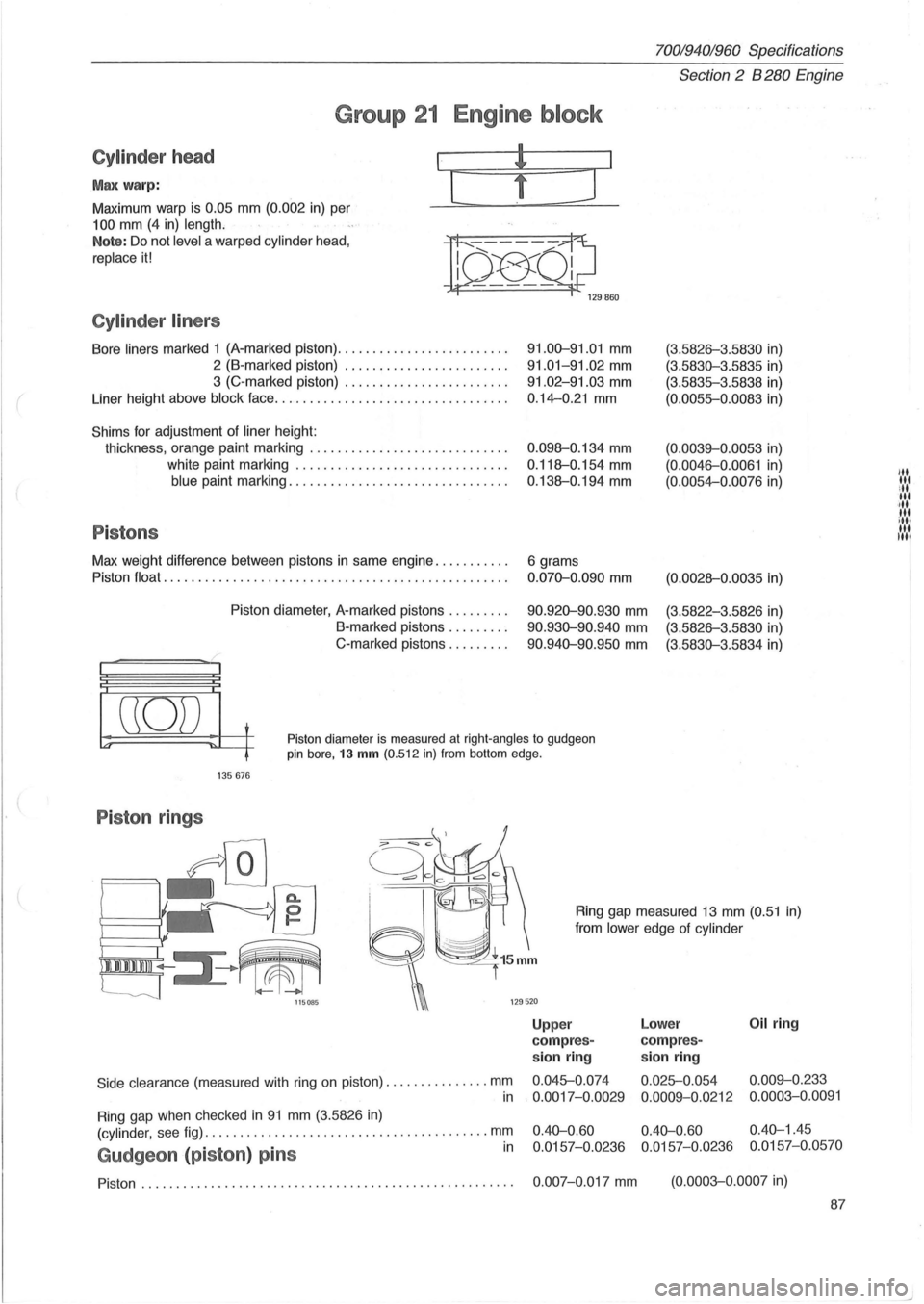

Group 21 Engine block

Cylinder head

Max warp:

Maximum warp is 0.05 mm (0.002 in) per

100 mm (4 in) length.

I

[

Note: Do not level a warped cylinder head,

replace it!

n~Ql;J 129860

Cylinder liners

Bore liners marked 1 (A-marked piston) ........................ .

2 (B-marked piston) ....................... .

3 (C-marked piston) ....................... .

Liner height above

block face ................................. .

Shims for adjustment of liner height:

thickness, orange paint marking

............................ .

white paint marking

.............................. .

blue paint marking ............................... .

Pistons

Max weight difference between pistons in same engine .......... .

Piston

float ..................................... ............ .

Piston diameter, A-marked pistons

........ .

B-marked pistons .

....... .

C-marked pistons

........ .

91.00-91.01 mm

91.01-91.02 mm

91.02-91.03 mm

0.14-0.21 mm

0 .098-0.134 mm

0.118-0.154 mm

0.138-0.194 mm

6 grams

0.070-0.090 mm

90.920-90.930 mm

90.930-90.940 mm

90 .940-90.950 mm

(3.5826-3 .5830 in)

(3.5830-3.5835 in)

(3.5835-3.5838 in)

(0.0055-0.0083 in)

(0.0039-0.0053 in)

(0. 0046-0.0061 in)

(0.0054-0.0076 in)

(0.0028-0 .0035 in)

(3.5822-3.5826 in)

(3.5826-3.5830 in)

(3.5830-3.5834 in)

((0)) t

~ ~~ Piston diameter is measured at right-angles to gudgeon pin bore, 13 mm (0.512 in) from bottom edge.

135676

Piston rings

Side clearance (measured with ring on piston) .. ............ . mm

Ring gap measured 13 mm (0.51 in)

from

lower edge of cylinder

Upp er Lower Oil ring

com pres-compres-

sion ring sion ring

0.045-0.

074

0.025-0.054 0.009-0.233

in

Ring gap when checked in 91 mm (3.5826 in)

. 0.0017-0.0029

0.0009-0.0212 0.0003-0.0091

(cylinder,

see fig) ..................................... .... mm

Gudgeon (piston ) pins in

0.40-0.60 0.40-0.60 0.40-1.45

0.0157-0.0236 0.0157-0.0236 0.0157-0.0570

Piston. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.007-0.017 mm (0.0003-0.0007 in)

87

"' lit ill lit ·,11 tit ill, til Itil

Page 91 of 168

(

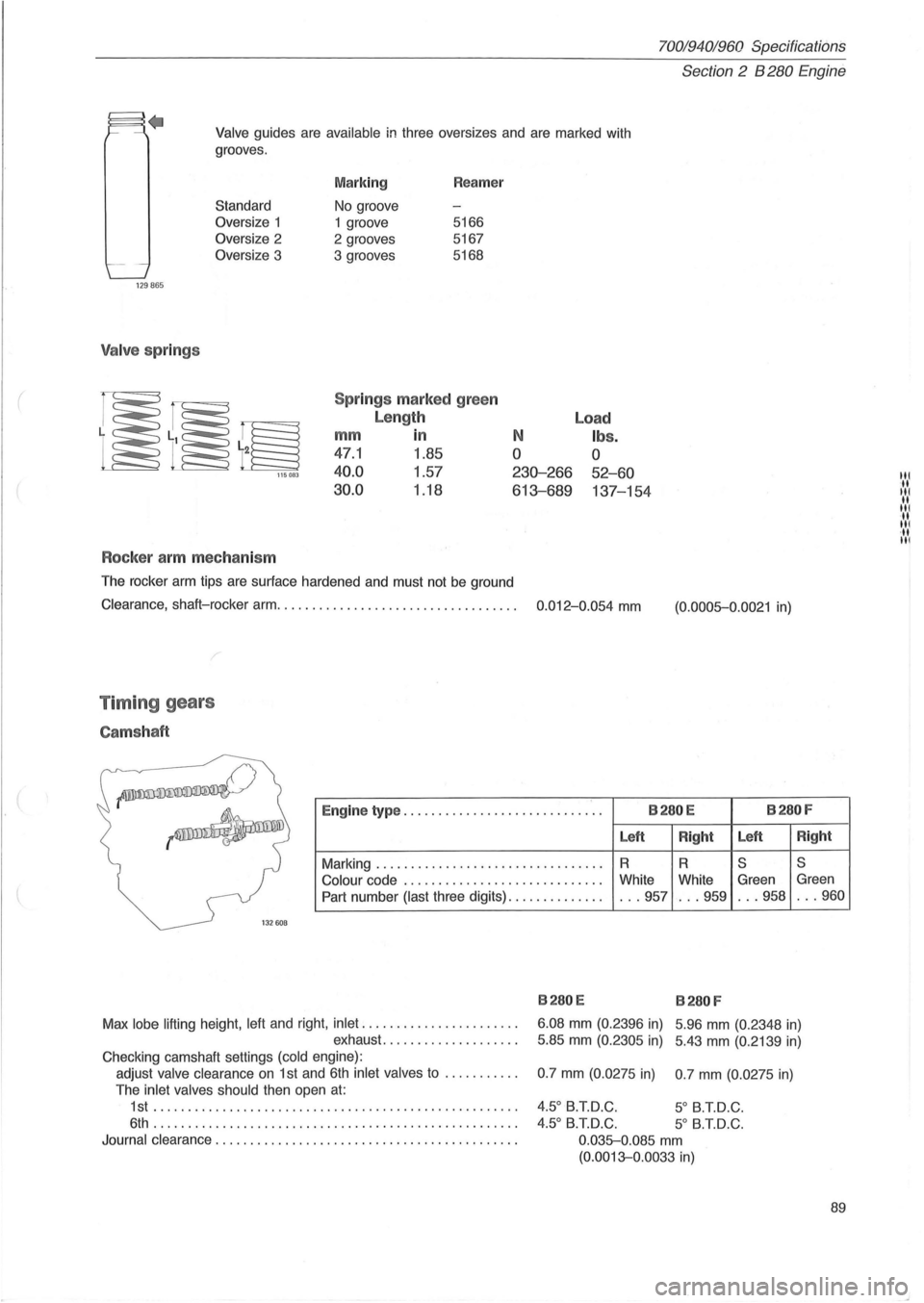

70019401960 Specifications

Section

2 B 280 Engine

Valve guides are available in three oversizes and are marked with

grooves .

129865

Valve springs

Standard

Oversize 1

Oversize 2

Oversize 3

115083

Rocker arm mechanism

Marking

No groove

1 groove

2 grooves

3 grooves Reamer

5166

5167

5168

Spr ings marked green

Length

mm in

47.1 1.85

40.0 1.57

30.0 1.18

N

o

230-266

613-689

The rocker arm tips are surface hardened and must not be ground

Load

Ibs.

o

52-60

137-154

Clearance, shaft-rocker arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.012-0.054 mm

Timing gears

Camshaft

(0.0005-0.0021 in)

~

--~

Engine type ............................. B280E B280F

Left

Right Left

Right

Marking

........................... ...... R R S S

Colour

code ...... ... .................... White

White Green Green

Part number (last three digits)

.............. ... 957 ... 959 . .. 958 . .. 960

1

32608

B280E B280 F

Max lobe lifting height . left and right. inlet

...................... .

exhaust

........... ' " ... .. . 6.08

mm (0.

2396 in) 5 .96 mm (0.2348 in)

5.85 mm (0.2305 in) 5.43 mm (0.2139 in)

Checking camshaft settings (cold engine) :

adjust valve clearance

on 1 st and 6th inlet valves to .......... .

The inlet valves should then open

at:

1st ...... .................... .......................... .

6th . ................................................... .

Journal clearance

............................... ............ . 0.7

mm (0.0275 in) 0.7 mm (0.

0275 in)

4.50 B.T.D.C. 5 0 B.T.D.C .

4.50 B.T.D.C. 5

0 B.T.D.C.

0 .035-0.085

mm

(0.0013-0.0033 in)

89

III .. III .. III ... III ·11 III

Page 94 of 168

70019401960 Specifications

Section 2 B 280 Engine

Group 22 Lubricating system

General

Oil capacity and quality, see page 12.

Oil pressure, warm engine , new oil cleaner:

at 15 rls (900 r/min), minimum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1 MPa

50 rls (3000 r/min). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 MPa

Lubricating oil pump

End float ...... ........................ ..................... .

Clearance between tooth tip and pump housing wall (excl.

bearing clearance) .

......................................... .

Backlash (excl. bearing clearance) ............................ .

Bearing clearance , driveshaft ....

............................. .

idler shaft ................................. .

Relief valve spring, length under various loads:

unloaded

..................... ................. ........... .

loaded to 90 N (9.0 kp) .................................... .

92

0.025-0.084 mm

0.020-0.095 mm

0.17 -0.27 mm

0.015-0.053 mm

0.015-0.051 mm

89.5 mm

56.5-60.5 mm

(14.2 psi)

(57 psi)

(0.0010-0 .0033 in)

(0.0008-0 .0037 in)

(0.0066-0 .0106 in)

(0.0006-0 .0021 in)

(0.0006-0.0020 in)

(3.52 in)

(2.22-2.38 in)

Page 101 of 168

(

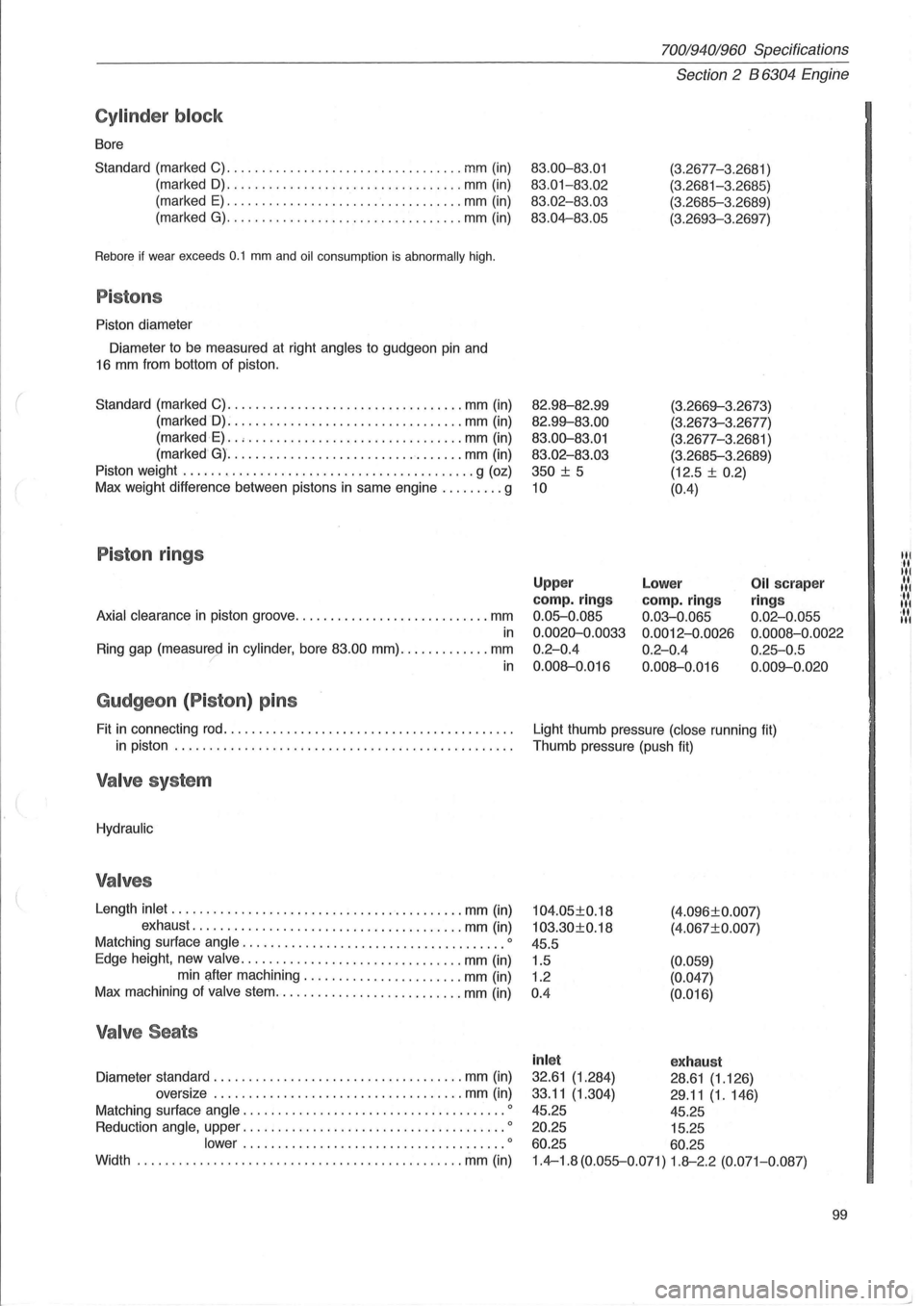

Cylinder block

Bore

Standard (marked C)

........................... ....... mm (in)

(marked

D) ........... ....................... mm (in)

(marked

E) .................................. mm (in)

(marked

G) ................... . .............. mm (in)

Rebore if wear exceeds 0.1 mm and oil consumption is abnormally high.

Pistons

Piston diameter

Diameter to be measured at right

angles to gudgeon pin and

16 mm from bottom of piston.

Standard (marked C)

.................................. mm (in)

(marked

D): ................................ . mm (in)

(marked

E) .. , ........................ ....... mm (in)

(marked

G) ............ ...................... mm (in)

Piston weight

.......................................... g (oz)

Max weight difference between pistons in same engine

......... g

Piston rings

Axial clearance in piston groove ............................ mm

in

Ring gap (measured in cylinder, bore 83.00 mm) ............. mm ? in

Gudgeon (P iston ) pins

Fit in connecting rod ......................................... .

in piston

................................................ .

Valve system

Hydraulic

Valves

Length inlet ...... .................................... mm (in)

exhaust

.............. ......................... mm (in)

Matching surface

angle .................................. .... 0

Edge height, new valve ................................ mm (in)

min after machining .

...................... mm (in)

Max machining of

valve stem ................ ........... mm (in)

Valve Seats

Diameter standard .................................... mm (in)

oversize

.... ................................ mm (in)

Matching surface

angle .......................... ............ 0

Reduction angle, upper ...................................... 0

lower ................. ....... .............. 0

Width ...................................... ... ...... mm (in)

70019401960 Specifications

Section 2 B 6304 Engine

83.00-83.01

83.01-83 .02

83.02-83.03

83.04-83.05

82.98--82.99

82.99--83.00

83.00-83.01

83.02 -83.03

350

± 5

10

(3.2677-3 .2681 )

(3.2681-3.2685)

(3.2685-3 .2689)

(3.2693-3.2697)

(3.2669--3.26 7

3)

(3.2673-3.2677)

(3.2677-3.

2681 )

(3.2685-3.2689)

(12.5 ±

0.2)

(0.4)

Upper

camp. rings

0.05-0.085

0.0020-0.0033

0.2-0.4

0.008--0.016

Lower

camp. rings

0.03-0.065

0.0012-0.0026

0.2-0.4

0.008--0.016

Oil scraper

ring s

0.02-0.055

0.0008 -0.0022

0.25-0.5

0.009--0 .020

Light thumb pressure (close running fit)

Thumb pressure (push fit)

104.05±0.18

103.30±0.18

45.5

1.5

1.2

0 .4 (4

.

096±0.007)

(4.067±0. 007)

(0.059)

(0.047)

(0.016)

inl et exhaust

32.61 (1.284) 28.61 (1.126)

33.11

(1.304) 29 .11 (1.146)

45.25 45.25

20.25 15.25

60.25 60.25

1.4-1.8 (0.055-0.071) 1.8--2.2 (0.071-0.087)

99

Itl

It

Itl

.... 1 '11 Itl ... Itl

Page 102 of 168

70019401960 Specifications

Section 2 B 6304 Engine

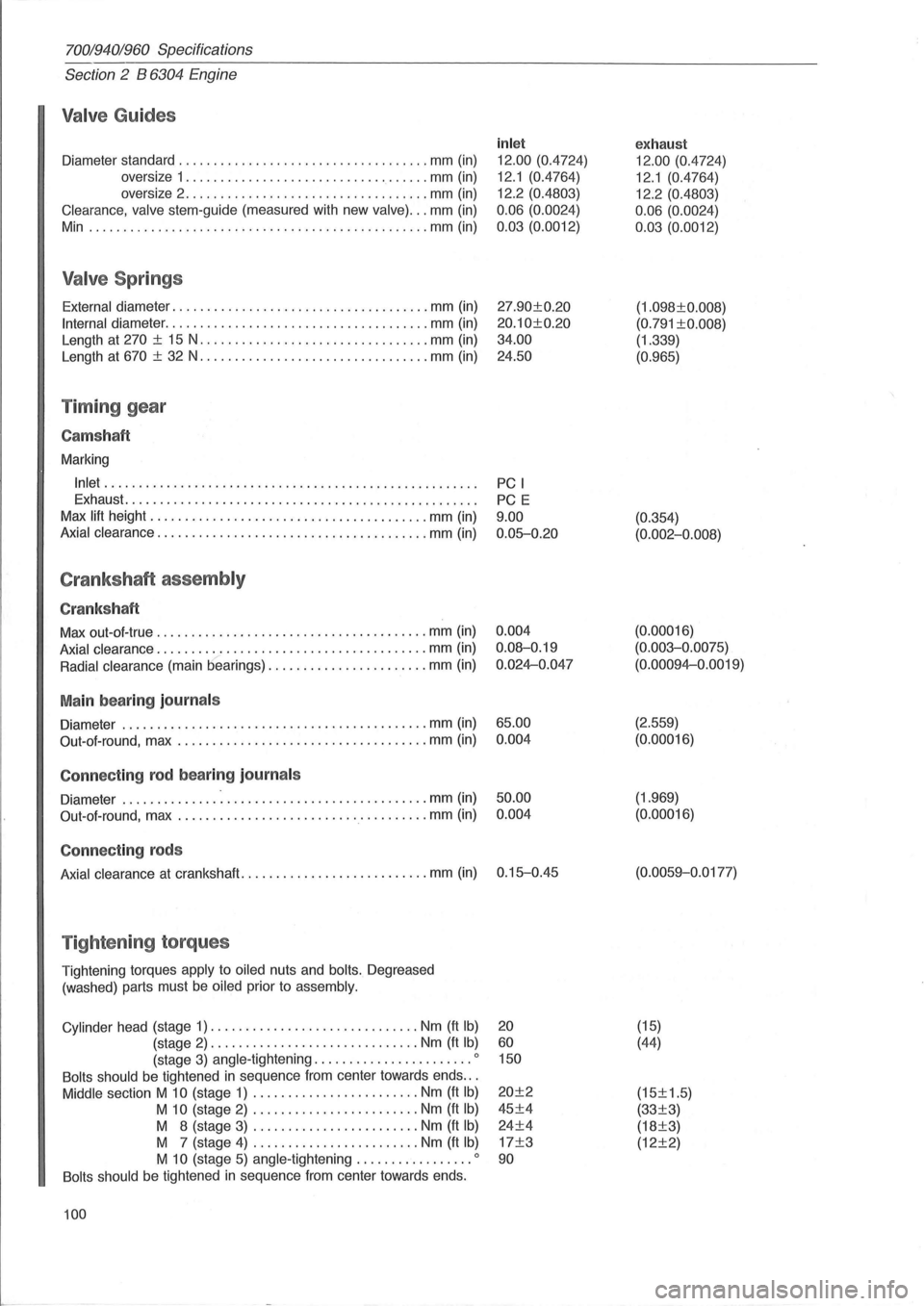

Valve Guides

Diameter standard .................................... mm (in)

oversize 1

................................... mm (in)

oversize 2

...................... ............. mm (in)

Clearance, valve stem-guide (measured with new valve) ... mm (in)

Min .

................................................ mm (in)

Valve Springs

External diameter ..................................... mm (in)

Internal diameter ...................................... mm (in)

Length at

270 ± 15 N ................................. mm (in)

Length at

670 ± 32 N ................................. mm (in)

Timing gear

Cams haft

Marking

Inlet ..................................................... .

Exhaust

.................................................. .

Max

lift height ................... ..................... mm (in)

Axial clearance ....................................... mm (in)

Crankshaft assembly

Crankshaft

Max out-ol-true ...................................... . mm (in)

Axial clearance ....................................... mm (in)

Radial clearance (main bearings) ....................... mm (in)

Main bearing journals

Diameter ............................................ mm (in)

Out-ol-round, max

.................................... mm (in)

Connecting rod bearing journ als

Diameter ................................... ......... mm (in)

Out-aI-round, max

.................................... mm (in)

Connecting rods

Axial clearance at crankshaft ........................... mm (in)

Tightening torques

Tightening torques apply to oiled nuts and bolts. Degreased

(washed) parts must

be oiled prior to assembly.

Cylinder

head (stage 1) .............................. Nm (ft Ib)

(stage 2) .............................. Nm (ft Ib)

(stage 3) angle -tightening ....................... 0

Bolts should be tightened in sequence Irom center towards ends .. .

Middle section M 10 (stage 1) ........................ Nm (ft Ib)

M 10 (stage 2) ........................ Nm (ft Ib)

M 8 (stage 3) ........................ Nm (It Ib)

M 7 (stage 4) ........................ Nm (It Ib)

M 10 (stage 5) angle -tightening ................. 0

Bolts should be tightened in sequence Irom center towards ends.

100

inlet

12.00 (0.4724)

12.1 (0.4764)

12.2 (0.4803)

0.06 (0.0024)

0.03 (0.0012)

27.90±0.20

20.10±0.20

34.00

24.50

PC I

PC E

9.00 0.05-0.20

0.004

0.08-0.19

0.024-0.047

65.00 0.004

50.00 0.004

0.15-0.45

20

60 150

20±2

45±4

24±4

17±3

90

exhaust

12.00 (0.4724)

12.1 (0.4764)

12.2 (0.4803)

0.06 (0.0024)

0.03 (0.0012)

(1.098±0.008)

(0.791 ±0.008)

(1.339)

(0.965)

(0.354)

(0.002-0.008)

(0. 00016)

(0.003-0.0075)

(0.00094-0.0019)

(2.559)

(0.00016)

(1.969)

(0.00016)

(0.0059-0 .0177)

(15)

(44)

(15±1.5)

(33±3)

(18±3)

(12±2)