torque VOLVO 940 1982 Service Owner's Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 940, Model: VOLVO 940 1982Pages: 168, PDF Size: 54.28 MB

Page 92 of 168

70019401960 Specifications

Section

2 B 280 Engine

Crank mechanism

Cranks haft

Max run-out (measured on two centre main bearing journals) ..... .

Crankshaft, end

float ........................................ .

Crank

journals, side clearance ................................ .

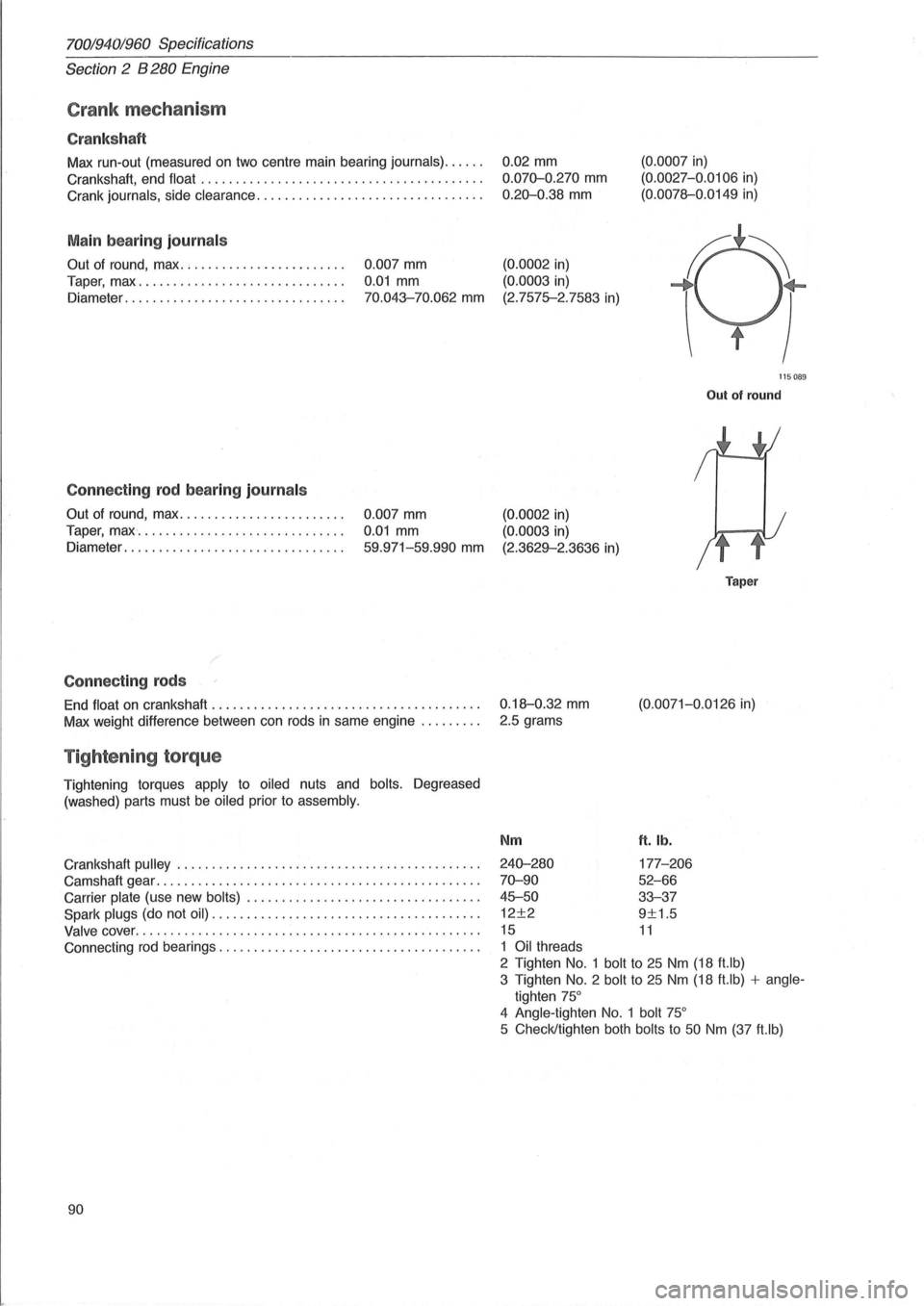

Main bearing journal s

Out of round, max. ; ..................... .

Taper, max

............................. .

Diameter

............................... .

Connecting rod bearing journal s

Out of round, max ....................... .

Taper,

max " ............................. .

Diameter

............................ ... .

Connecting rods

0.007 mm

0.01 mm

70.043-70.062 mm

0.007 mm

0.01 mm

59.971-59.990 mm

End float on crankshaft ...................................... .

Max weight difference between can rods

in same engine ........ .

Tightening torque

Tightening torques apply to oiled nuts and bolts. Degreased

(washed) parts must

be oiled prior to assembly.

Crankshaft pulley ........................ ................... .

Camshaft gear

.............................................. .

Carrier

plate (use new bolts) ................................. .

Spark

plugs (do not oil) .. .................................... .

Valve cover ........................................... ...... .

Connecting

rod bearings ..................................... .

90 0.02

mm

0.070-0.270 mm

0.20-0.38 mm

(0.0002 in)

(0.0003

in)

(2.7575-2.7583

in)

(0.0007 in)

(0. 0027-0.0106 in)

(0.0078--0.0149

in)

115089

Out of round

(0.0002 in)

(0.0003 in)

(2.3629--2.3636 in)

0.18--0.32

mm

2.5 grams

Nm

240-280

70-90

45-50

12±2

15

1 Oil threads

Taper

(0.0071-0.0126 in)

ft. lb.

177-206

52-66

33-37

9±1.5

11

2 Tighten No.1 bolt to 25 Nm (18 ft.lb)

3 Tighten

No.2 bolt to 25 Nm (18 ft.lb) + angle

tighten 75°

4 Angle -tighten No. 1 bolt 75°

5 Check/tighten both bolts to 50 Nm (37 ft.lb)

Page 93 of 168

(

6

l1S 650

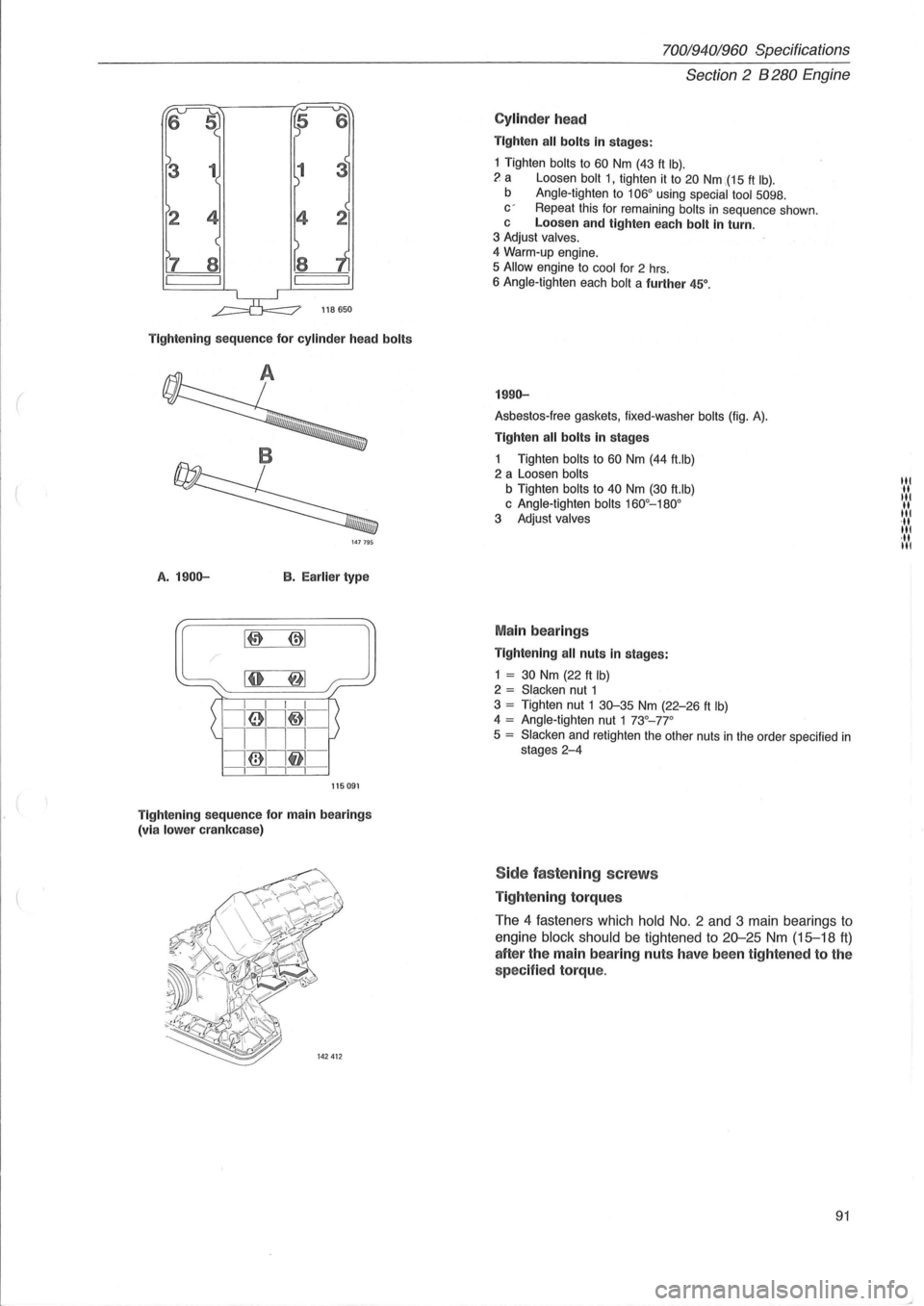

Tightening sequence for cylinder head bolts

147795

A. 1900-B. Ear lier type

115091

Tightening sequence for main bearings

(vi a lower crankcase)

7QOl9401960 Specifications

Section 2 B 280 Engine

Cylinder head

Tighten all bolts in stages:

1 Tighten bolts to 60 Nm (43 ft Ib). ? a Loosen bolt 1, tighten it to 20 Nm :(15 ft Ib). b Angle-tighten to 106° using special tool 5098. c' Repeat this for remaining bolts in sequence shown. c Loosen and tighte n each bolt in turn. 3 Adjust valves. 4 Warm-up engine.

5 Allow engine to cool for 2 hrs. 6 Angle-tighten each bolt a further 45°.

1990-

Asbestos-free gaskets, fixed-washer bolts (fig. A).

Tighten all bolts in stages

1 Tighten bolts to 60 Nm (44 ft.lb) 2 a Loosen bolts

b Tighten bolts to 40 Nm (30 ft.lb) c Angle-tighten bolts 160°-180° 3 Adjust valves

Main bearings

Tightening all nuts in stages:

1 = 30 Nm (22 ft Ib) 2 = Slacken nut 1 3 = Tighten nut 1 30-35 Nm (22-26 ft Ib) 4 = Angle-tighten nut 1 73°-77°

5 = Slacken and retighten the other nuts in the order specified in stages 2-4

Side fastening screws

Tightening torques

The 4 fasteners which hold No.2 and 3 main bearings to

engine block should be tightened to 20--25 Nm (15-18 tt)

after the main bearing nuts have been tightened to the

spec ified torque.

91

lit '\1 lit II lit .\1 lit ·11 III

Page 97 of 168

( ,

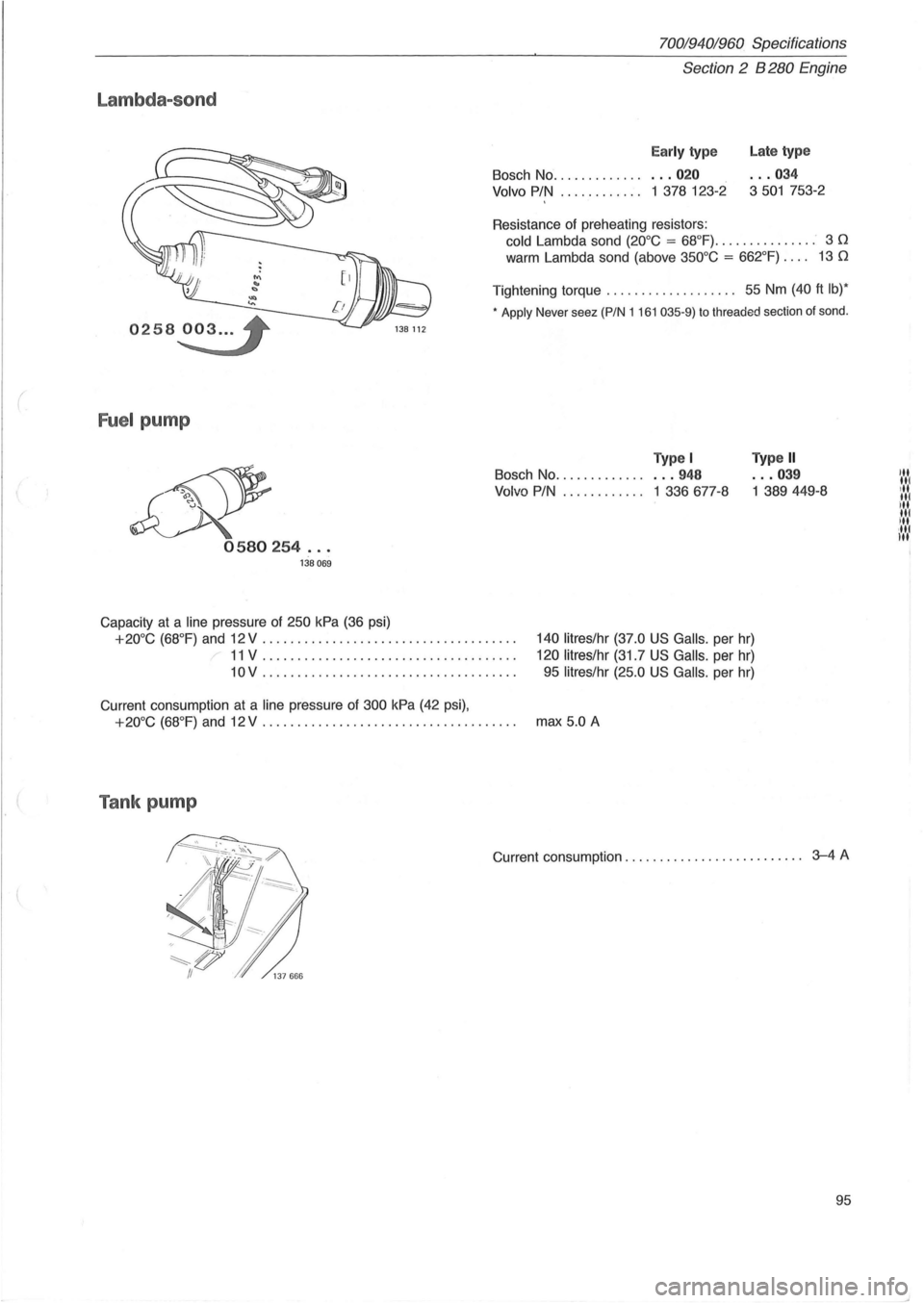

Lambda-sond

0258~ 138 112

Fuel pump

&' 0580254 ... 138069

Capacity at a line pressure of 250 kPa (36 psi)

70019401960 Specifications

Section 2 B 280 Engine

Early type

Bosch No ................ 020

Volvo PIN ............ 1 378 123-2

Resistance

of preheating resistors:

Late type

... 034

3501 753-2

cold Lambda sand (20°C = 68°F) ............... 3 n

warm Lambda sand (above 350°C = 662°F) . . .. 13 n

Tightening torque ....... ............ 55 Nm (40 ft Ib)*

* Apply Never seez (PIN 1 161 035-9) to threaded section of sond .

Type I

Bosch No ................ 948

Volvo PIN ............ 1 336 677-8

Type II

... 039

1 389449-8

+20°C (68°F) and 12 V .................................... . 140 litres/hr (37.0 US Galls. per hr)

120 litres/hr (31.7 US Galls . per hr)

95

litres/hr (25.0 US Galls. per hr)

11 V ........•............................

10V .. .................................. .

Current consumption

at a line pressure of 300 kPa (42 psi),

+20°C (68°F) and 12 V .................................... . max 5.0 A

Tank pump

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . .. 3-4 A

95

'" III , II

NI' III ill ,II'

'"

)

Page 99 of 168

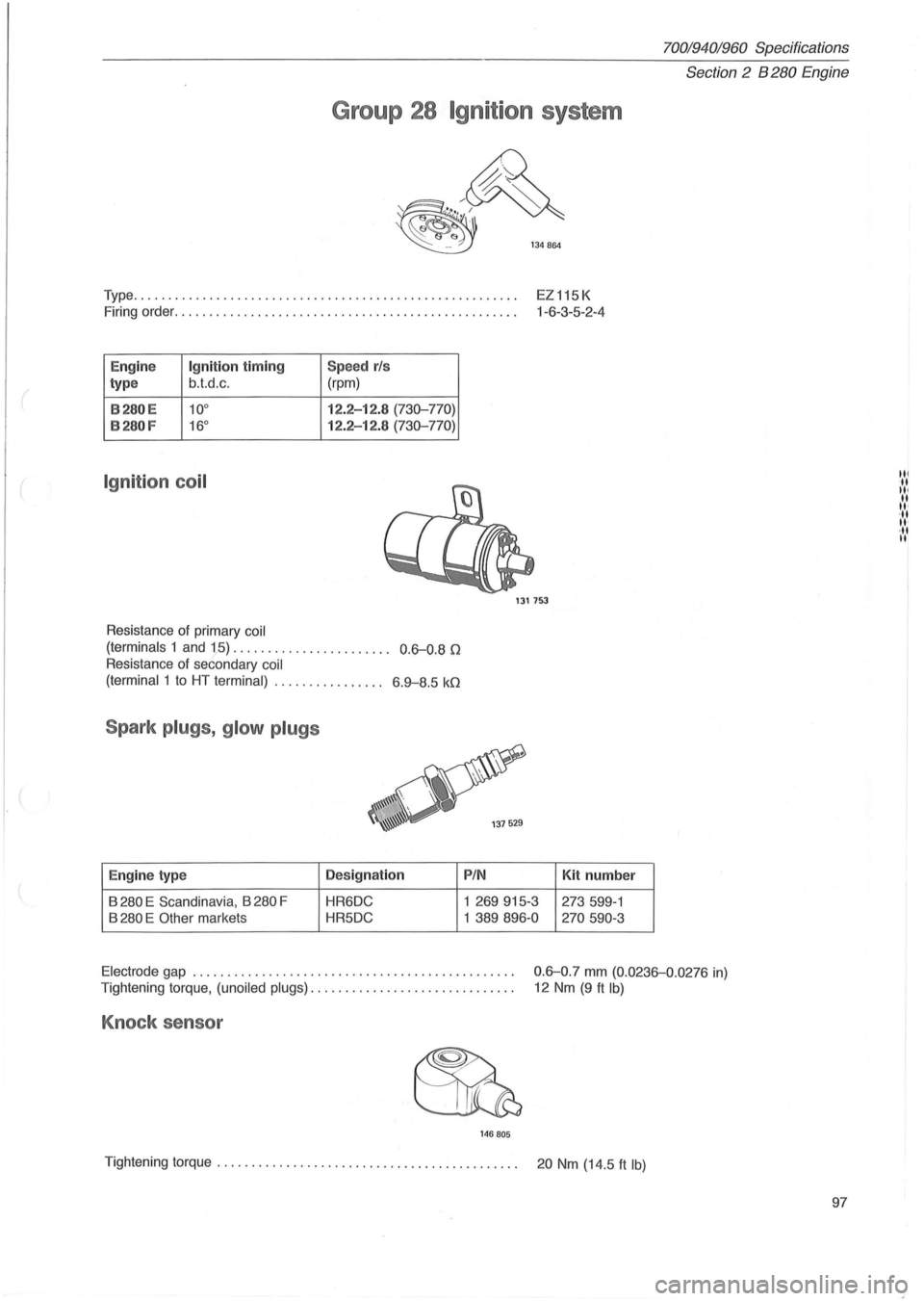

Group 28 Ignition system

~

~~ ~ 134864

Type ....................................................... .

EZ115K

1-6 -3-5 -2 -4

Firing

order ................................................. .

E ng in e

Ig niti on tim ing Speed rls

type b.t.d

.c. (rpm)

B280E 10° 12 .2-12 .8 (730-770)

B280 F 16° 12 .2-12.8 ( 7 30-770)

Ignit ion coil

Resistance of primary coil

(terminals

1 and 15) . . . . . . . . . . . . . . . . . . . . . . . 0.6-0.8 n

Resistance of secondary coil

(terminal

1 to HT terminal) ..... . . . . . . . . . .. 6 .9-8.5 kn

Spark plugs, glow plugs

Eng in e type Des

ig nation

B

280 E Scandinav ia , B 280 F HR6DC

B

280 E Other markets HR5DC

1317~

PIN

1 269915-3

1

389896-0

Kit num ber

273599-1

270590-3

70019401960 Specifications

Section

2 B 280 E ngine

Electrode gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.6-0.7 mm (0.0236-0.0276 in)

Tightening torque, (unoiled plugs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Nm (9 ft Ib)

Knock sensor

14 6 805

Tightening torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Nm (14.5 ft Ib)

97

III ... III II

II' ... II' ·11 II

Page 100 of 168

70019401960 Specifications

Section 2 B 6304 Engine

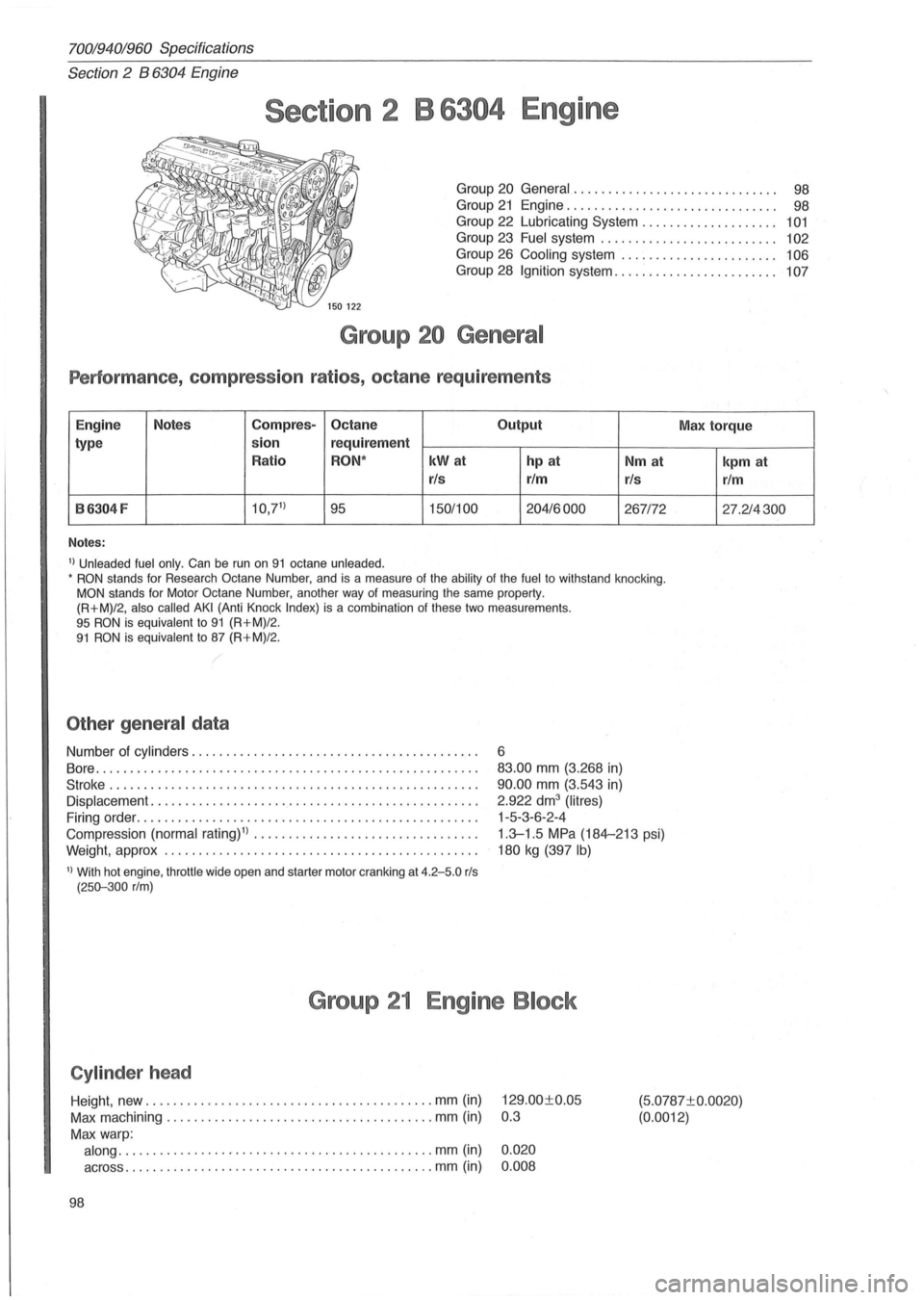

Section 2 B 6304 Engine

Group 20 General.... . . . . . . . . . . . . . . . . . . . . . . . . .. 98

Group 21 Engine............................... 98

Group

22 Lubricating System. . . . . . . . . . . . . . . . . . .. 101

Group 23 Fuel system . . . . . . . . . . . . . . . . . . . . . . . . .. 102

Group 26 Cooling system . . . . . . . . . . . . . . . . . . . . . .. 106

Group 28 Ignition system . . . . . . . . . . . . . . . . . . . . . . . . 107

Group 20 General

Performance , compression ratios, octane requirements

Engine Notes Compres-Octane

Output

type sion

requirement

Ratio

RON· kWat hp at Nm at

rls rim

rls

B6304F 10,71

) 95 150/100 204/6000 267172

Notes:

1) Unleaded fuel only. Can be run on 91 octane unleaded . • RON stands for Research Octane Number, and is a measure of the ability of the fuel to withstand knocking. MON stands for Motor Octane Number, another way of measuring the same property .

(R+M)/2, also called AKI (Anti Knock Index) is a combination of these two measurements . 95 RON is equivalent to 91 (R+M)/2. 91 RON is equivalent to 87 (R+M)/2 .

Other general data

Number of cylinders ......................................... .

Bore .

.................................................... .. .

Stroke .......................................... .......... . .

Displacement ......................... ................ ...... .

Firing order

............................................... .. .

Compression

(normal rating) 1) • ••••• ••••••••••••••••• •.••••••.•

Weight, approx ............................................. .

1) With hot engine, throttle wide open and starter motor cranking at 4.2-5.0 rls (250-300 rIm)

6

83.00 mm (3.268 in)

90 .00 mm (3.543 in)

2.922 dm3 (Iitres)

1-5 -3-6-2 -4

1 .3-1 .5 MPa (184-213 psi)

180 kg (397 Ib)

Group 21 Engine Block

Cylinder head

Max torque

kpm at

rim

27.214300

Height, new ............................... ........... mm (in) 129 .00±0.05

Max machining .............. ......................... mm (in) 0.3

(5.0787±0.0020)

(0.0012)

Max warp:

along ......... .... ................................. mm (in) 0.020

across .................................. ...... ..... mm (in) 0 .008

98

Page 102 of 168

70019401960 Specifications

Section 2 B 6304 Engine

Valve Guides

Diameter standard .................................... mm (in)

oversize 1

................................... mm (in)

oversize 2

...................... ............. mm (in)

Clearance, valve stem-guide (measured with new valve) ... mm (in)

Min .

................................................ mm (in)

Valve Springs

External diameter ..................................... mm (in)

Internal diameter ...................................... mm (in)

Length at

270 ± 15 N ................................. mm (in)

Length at

670 ± 32 N ................................. mm (in)

Timing gear

Cams haft

Marking

Inlet ..................................................... .

Exhaust

.................................................. .

Max

lift height ................... ..................... mm (in)

Axial clearance ....................................... mm (in)

Crankshaft assembly

Crankshaft

Max out-ol-true ...................................... . mm (in)

Axial clearance ....................................... mm (in)

Radial clearance (main bearings) ....................... mm (in)

Main bearing journals

Diameter ............................................ mm (in)

Out-ol-round, max

.................................... mm (in)

Connecting rod bearing journ als

Diameter ................................... ......... mm (in)

Out-aI-round, max

.................................... mm (in)

Connecting rods

Axial clearance at crankshaft ........................... mm (in)

Tightening torques

Tightening torques apply to oiled nuts and bolts. Degreased

(washed) parts must

be oiled prior to assembly.

Cylinder

head (stage 1) .............................. Nm (ft Ib)

(stage 2) .............................. Nm (ft Ib)

(stage 3) angle -tightening ....................... 0

Bolts should be tightened in sequence Irom center towards ends .. .

Middle section M 10 (stage 1) ........................ Nm (ft Ib)

M 10 (stage 2) ........................ Nm (ft Ib)

M 8 (stage 3) ........................ Nm (It Ib)

M 7 (stage 4) ........................ Nm (It Ib)

M 10 (stage 5) angle -tightening ................. 0

Bolts should be tightened in sequence Irom center towards ends.

100

inlet

12.00 (0.4724)

12.1 (0.4764)

12.2 (0.4803)

0.06 (0.0024)

0.03 (0.0012)

27.90±0.20

20.10±0.20

34.00

24.50

PC I

PC E

9.00 0.05-0.20

0.004

0.08-0.19

0.024-0.047

65.00 0.004

50.00 0.004

0.15-0.45

20

60 150

20±2

45±4

24±4

17±3

90

exhaust

12.00 (0.4724)

12.1 (0.4764)

12.2 (0.4803)

0.06 (0.0024)

0.03 (0.0012)

(1.098±0.008)

(0.791 ±0.008)

(1.339)

(0.965)

(0.354)

(0.002-0.008)

(0. 00016)

(0.003-0.0075)

(0.00094-0.0019)

(2.559)

(0.00016)

(1.969)

(0.00016)

(0.0059-0 .0177)

(15)

(44)

(15±1.5)

(33±3)

(18±3)

(12±2)

Page 106 of 168

70019401960 Specifications

Section

2 B 6304 Engine

I

150425

o 580 464 ...

145791

145792

Sil

104

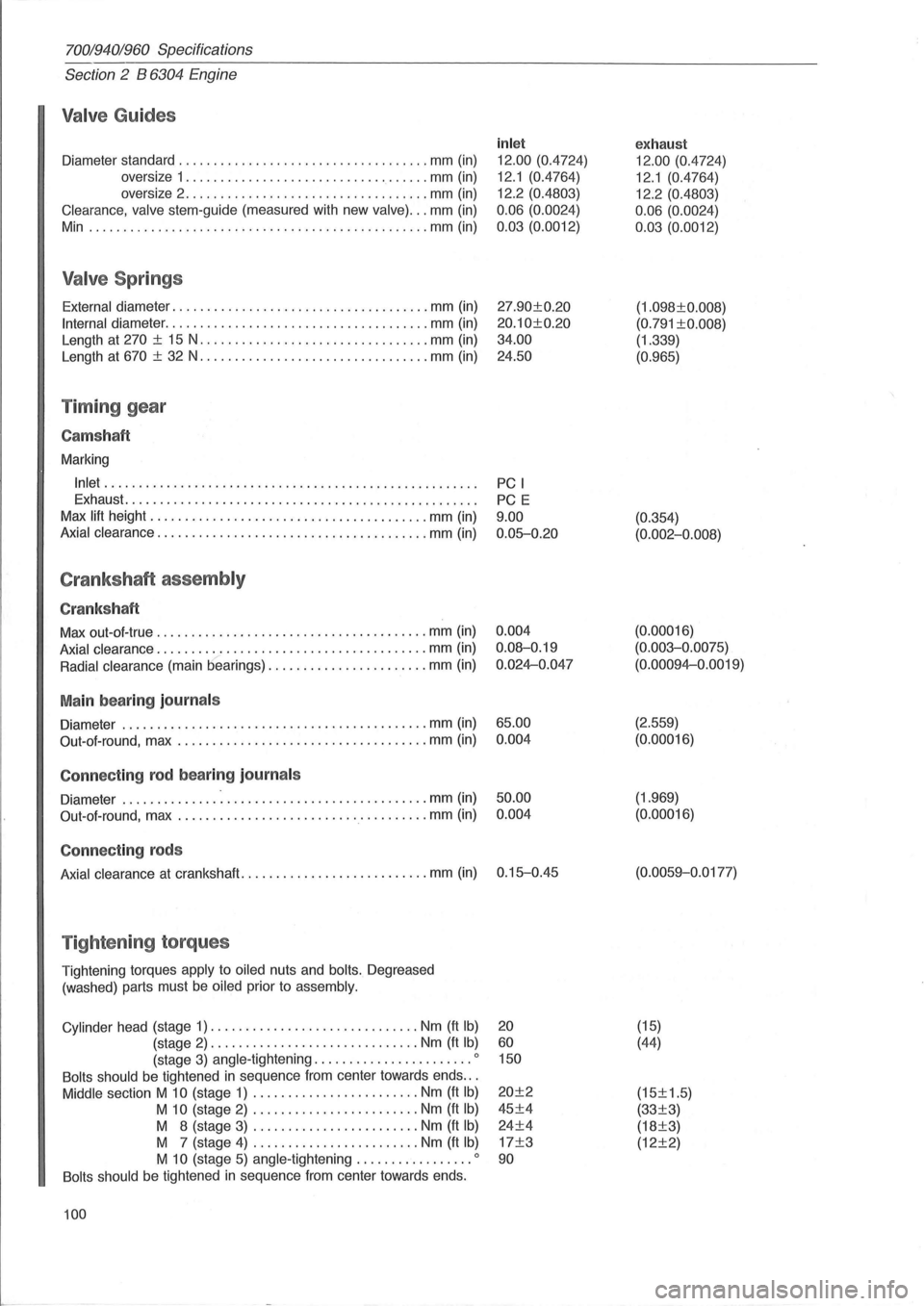

Temperature sensor, coolant

SWF number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 601.605

Volvo part number ....................... 1 362643-7

Resistance

at:

O°C (32°F) . . . . . . . . . . . . . . . . . . . . . . . . . .. 7 300 0

+ 20°C (68°F) . . . . . . . . . . . . . . . . . . . . . . . . . .. 2 800 0

+ 40°C (104°F) . . . .. . . .. . .. . .. . . . . . . . . . .. 1 200 0

+ 80°C (176°F) . . . . . . . . . . . . . . . . . . . .. . . . . . .. 300 0

+100°C (212°F)

............................ 1500

See diagram for other values

Lambda-sond

Bosch number. . . . . . . . . . . . . . . . . . . . . . .. 0 280 003 119

Volvo part number ....................... 3531 251-1

Resistance

in preheating resistor:

cold sand, 20°C (68°F) . . . . . . . . . . . . . . . . . . . . . . . . .. 3 0

hot sand, above 350°C (660°F). . . . . . . . . . . . . . . . .. 13 0

Tightening torque . . . . . . . . . . . . . . . . . . . . . . . . . . .. 55 Nm

(40 ft Ib) Apply 'Never-Seez', Volvo part number 1 161 035-9, to

entire thread

length.

Fuel pump

Bosch number. . . . . . . . . . . . . . . . . . . . . . .. 0 580 464 039

Volvo part number. . . . . . . . . . . . . . . . . . . . . .. 1 389449-8

Pump capacity at 300 kPa

(43 psi) and +20°C (68°F):

-12 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 130 lit res/hour

(1.1 litres/30 secs)

-11 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 108 litres/hour

(0.9 Iitres/30

secs)

-10 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 86 litres/hour

(0.7 litres/30

secs)

Current consumption

at line pressure

300 kPa (43 psi), +20°C (68°F) and 12 V:

max ................................ ....... 6.5 amp

Tank pump

VDO number. . . . . . . . . . . . . . . . . . . . . . . . . . . .. 92151034

Volvo

part number ....................... 3501 928-0

Current consumption . . . . . . . . . . . . . . . . . . . . . .. 3-4 amp

Fuel filter

Bosch number. . . . . . . . . . . . . . . . . . . . . . .. a 450 905 601

Volvo part number. . . . . . . . . . . . . . . . . . . . . .. 1 389 450-6

Filters particles

down to . . . . . . .. 0.002 mm (0.00008 in)

Tightening torque . . . . . . . . . . . . . . . . . . . . . .

.. 20-35 Nm

(15-26 ft Ib)

Page 109 of 168

(

70019401960 Specifications

Section

2 B 6304 Engine

Group 28 Ignition System

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Motronic 1.8

Firing sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-3-6-2-4

Ignition timing at 12.5 rls (750 rim). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 °

Made in Germany @

150365

150431

148680

COMPONENTS

Power stage

Bosch number. . . . . . . . . . . . . . . . . . . . . . . .. 0 227 100 203

Volvo part number. . . . . . . . . . . . . . . . . . . . . .. 1 367 776-0

Ign ition coil

Nippon Denso number . . . . . . . . . . . . . . . .. 029 700-7260

Volvo

part number . . . . . . . . . . . . . . . . . . . . . .. 1 531 300-6

Resistance of primary coil

(between terminals 1 and 15). . . . . . . . . . . . . . . . . .. 0 .5 [2

Spark plugs

Designation, Bosch ......................... FR 6 DC

Champion. . . . . . . . . . . . . . . . . . .

.. RC 7 YC

Volvo part number. . . . . . . . . . . . . . . . . . . . . .. 1 517629-6

kit number .......................... 271 427-7

Electrode gap. . . . . . . . . . . . . . . . . . . . . . . . . . 0.7-0.8 mm

(0.0276-0.0315 in)

Tightening torque,

unoiled threads . . . . . . . . . . . . . 25 Nm

(18 ft Ib)

Relay, ignition

Volvo part number. . . . . . . . . . . . . . . . . . . . . .. 3 323 592-4

Knock senso r

Bosch number ........................ 0261 231 006

Volvo part number . . . . . . . . . . . . . . . . . . . . . .. 1 367644-0

107

III 'IIt III II' III 'III III ,III III

Page 110 of 168

70019401960 Specifications

Section 2 024, 024 T, 024 TIC Engines

Section 2 D 24, D 24 T, D 24 TIC Engines

Group 20 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 108

Group 21 Engine..... ...................... .... 109

Group 22 Lubricating system . . . . . . . . . . . . . . . . . . . . 114

Group 23

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Group 25

Intake and exhaust systems. . . . . . . . . . .. 116

Group 26

Cooling system .. . . . . . . . . . . . . . . . . . . . .. 117

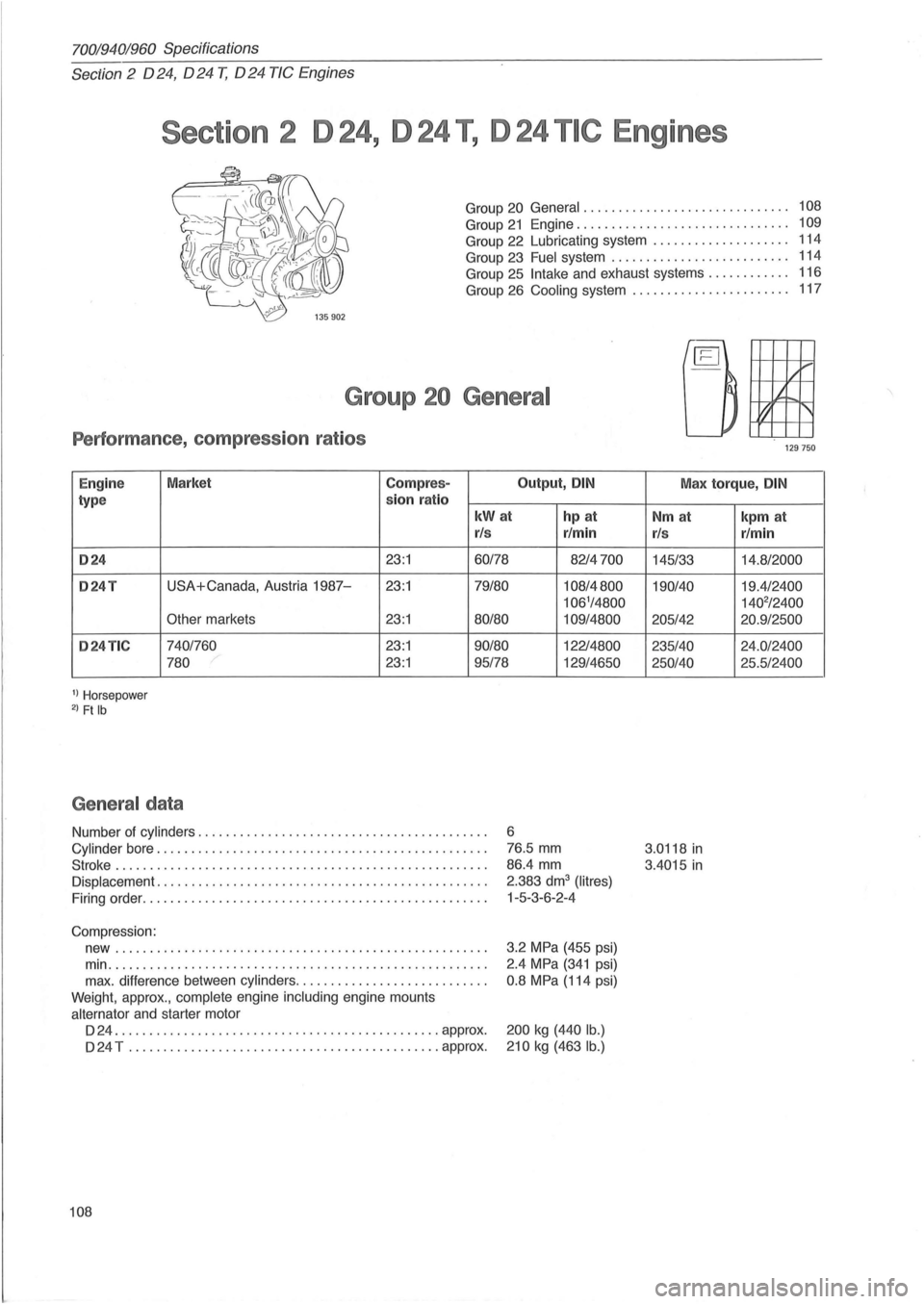

Group 20 Genera l

Performance , co mpress io n r atios

Engine Market Compre

s-Output, DIN

type sion

ra tio

kWat hp at

r/s r/min

024 23:1 60/78 8214700

024T USA+Canada, Austria 1987-23:1 79/80 108/4800

106'/4800

Other

markets 23:1 80/80 109/4800

024TIC 740/760 23:1 90/80 12214800

780

23:1 95/78 129/4650

1) Horsepower 2) Ft Ib

Ge ne ra l da ta

Number of cylinders .. ............... ........................ .

Cylinder bore .................... ...................... ..... .

Stroke ..

............................ ............. ... ....... .

Displacement ........ ....................................... .

Firing order ..

............................................... .

Compression: new

..................................................... .

min

....................... ............................... .

max. difference between

cylinders ........................... .

Weight, approx.,

complete engine including engine mounts

alternator and starter motor

D 24 ....

.............. ... ............ ... ........... approx .

D 24 T

............................................. approx.

108

6

76.5 mm

86.4 mm

2.383 dm

3 (Iitres)

1-5-3-6-2 -4

3.2

MPa (455 psi)

2.4

MPa (341 psi)

0.8 MPa (114 psi)

200 kg (440 lb.)

210

kg (463 lb .)

,/1-'"

It

t1 '

'29750

Max torque, DIN

Nm at

r/s

145/33

190/40

205/42

235/40

250/40

3.0118

in

3.4015 in

kpm at

r/min

14.8/2000

19.4/2400

140

2/2400

20.9/2500

24 .0/2400

25 .5/2400

Page 115 of 168

(

70019401960 Specifications

Section

2 024, 024 T, 024 TIC Engines

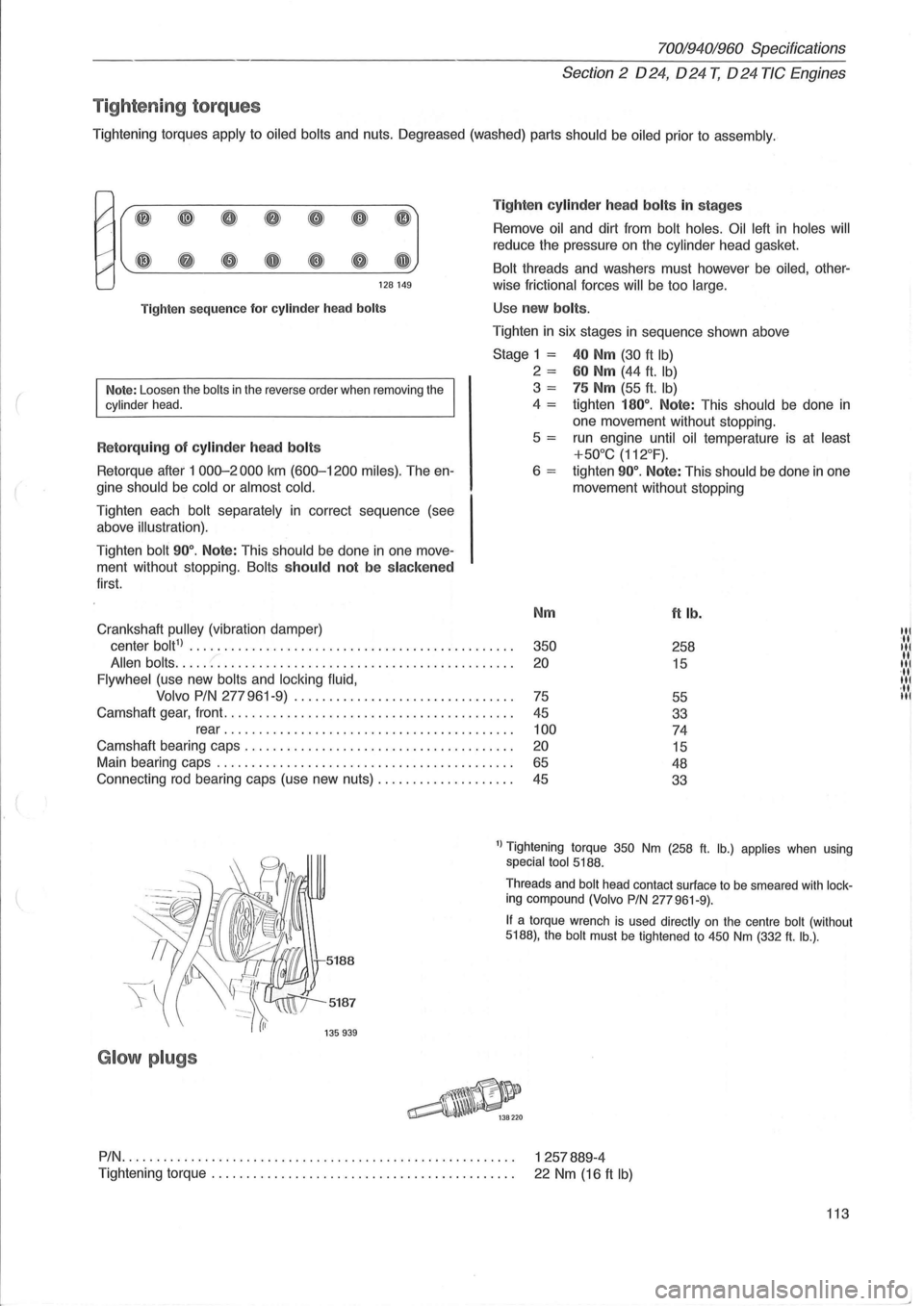

Tig ht enin g to rqu es

Tightening torques apply to oiled bolts and nuts. Oegreased (washed) parts should be oiled prior to assembly .

I' ~ ~ 0 8 CD 0 (IJ

#' ~ G e Q e Q GJ

128149

Tighten

sequence for cylinder head bolts

Note: Loosen the bolts in the reverse order when removing the cylinder head.

R etorquing of cylinder head bolts

Retorque after 1 000-2000 km (600-1200 miles). The en

gine

should be cold or almost cold.

Tighten each bolt separately in correct sequence (see

above

illustration).

Tighten bolt 90°. Note: This should be done in one move

ment without stopping.

Bolts should not be slacken ed

first.

Crankshaft

pulley (vibration damper) Ti

g

hten cylinde r h ea d bolts in stages

Remove oil and dirt from bolt holes. Oil left in holes will

reduce the pressure on the cylinder head gasket.

Bolt threads and washers must however be oiled, other-

wise

frictional forces will be too large.

Use new bolts .

Tighten in six stages in sequence shown above

Stage 1 = 40 Nm (30 ft Ib)

2 = 60 Nm (44 ft. Ib)

3 = 75 Nm (55 ft. Ib)

4 = tighten 180°. Note: This should be done in

one movement without stopping .

5

= run engine until oil temperature is at least

+50°C (112°F).

6 = tighten 90°. Note: This should be done in one

movement without stopping

Nm

ft lb.

center bolt1) ............................... ............... . 350 258

Allen bolts ..... :: ......................................... . 20 15

Flywheel (use new bolts and locking fluid,

Volvo PIN

277 961-9) ............................... .

75

55

Camshaft gear, front

......................................... .

45

33

rear

....................................... .. . 100 74

Camshaft bearing caps .................................... .. . 20 15

Main bearing caps .......................................... .

65 48

Connecting rod bearing caps (use new nuts)

................... .

45

33

1) Tightening torque 350 Nm (258 ft. lb.) applies when using special tool 5188.

5187

G lo w plugs

Threads and bolt head contact surface to be smeared with locking compound (Volvo PIN 277961-9).

If a torque wrench is used directly on the centre bolt (without 5188), the bolt must be tightened to 450 Nm (332 ft. lb.) .

PIN.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 257889-4

Tightening

torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Nm (16 ft Ib)

113

'il IN 11 '11 11

·11 III