lock VOLVO 960 1982 Service User Guide

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 960, Model: VOLVO 960 1982Pages: 168, PDF Size: 54.28 MB

Page 87 of 168

70019401960 Specifications

Section

2 B 28 Engine

Distributor

Eng ine type Ignit ion system Distributor

Volvo P IN Bosch No

B28A, B28E TSZ-4 1269191 0237402013

B28F TSZ-4 1269380 0237402017

B28A, E B28F

Bosch number ............... ............................... . 0237402013 0237402017

Volv o PIN ................................................... . 1

269 191 1 269380

Direction of rotat ion ............................ ... .......... . Clockwise

Clockwise

Resistance of impulse sender coil, [2 .........•................. 540-660

540-660

Air gap, rotor -stator , min ............. ...................... . 0.3 mm 0.3 mm

Centrifugal governor

Advance, total, degrees (distributor) ........ ................... .

Advance

begi ns at distrib. rev/sees ............................ .

distrib. rev/min

............................. .

Data:

5 ° at distr ib. rev/sees .............................. _ ... .

'III 13±1

11±1 '" III 7.fr-9.6 8.fr-10 ttl

(450-575)

(500-600) :':':': 12.fr-15.4 12.4-15.3 I'NI

(distrib. rev/min) ................................. . (750-925)

(740-920)

10° at distrib. rev/sees .................................. . 23.3-32.5 30-50

(distrib. rev/min)

................................. . (1400-1950)

(1800-3000)

Advance max at distrib . rev/sees ... .......................... . 40 33 .3

(distrib. rev/min)

............ ................. . (2400)

(2000)

Vacuum governor

Control direction ............................................ . Positive

Positive

Contro l, total

degrees (distributor) ............................. . 7,5±1 10±1

Control

commences at mm Hg ............................... . 160-210 10fr-135

Data: 2° at mm Hg ......................................... . . 200-240 11 fr-145

max control at mm Hg .................................. . 300 210

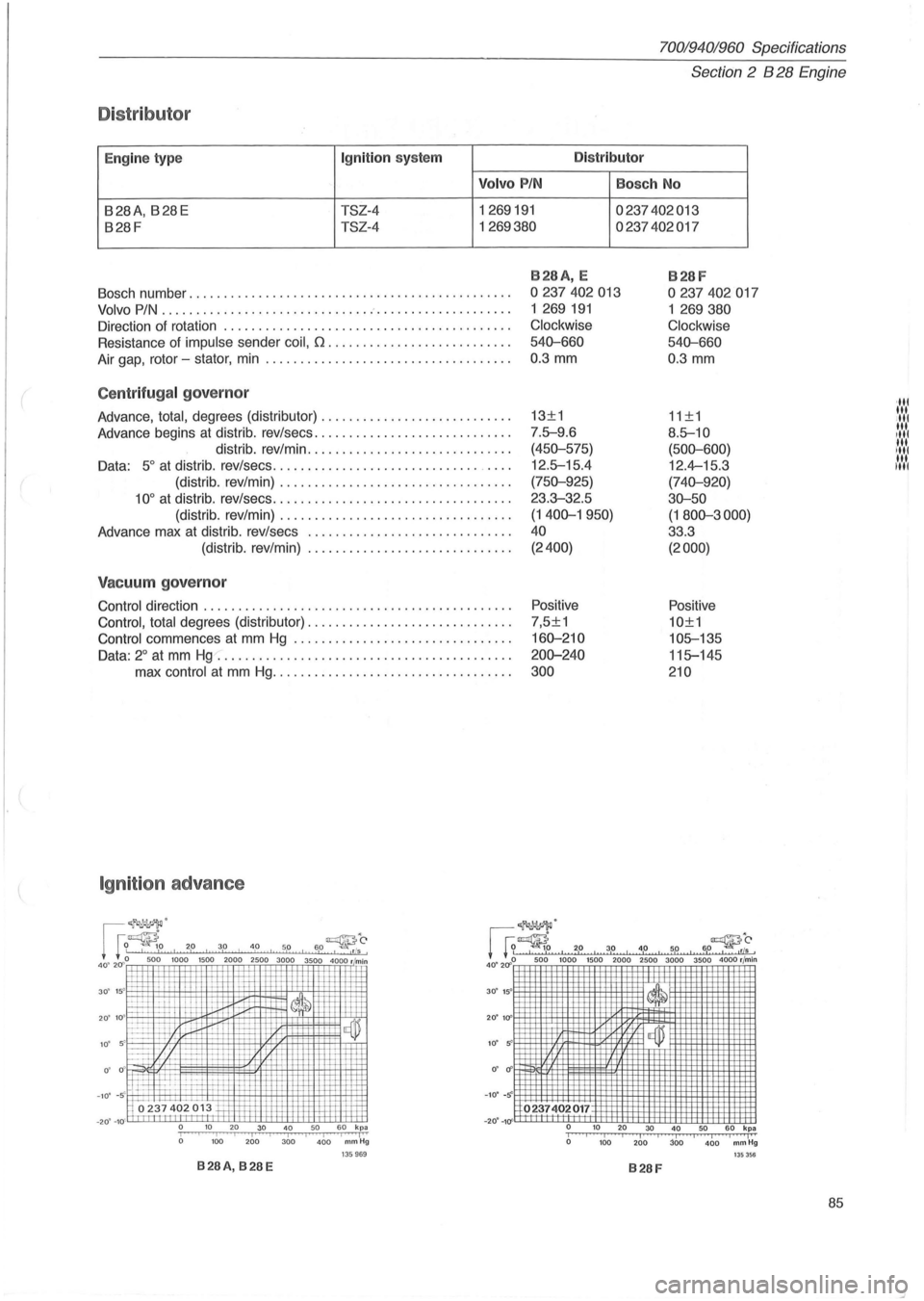

Ignition advance

60-~O , I

I I

I I I I ,. I

I I

I , .tls 0 500 1000 1500 2000 2500 3000 3500 4000 r min

~ !=ttl-It ~~ 30' 15'

.,r~'

1 G~ 2,0. 3.0 , 4,0 , 5,0 I 6,0~~, 40~ 2Cf~ 50~ l~OO 1500 2000 2500 3000 3500 4000 rjmin

20' 10 + ~ IT , 1{,llrD ,I=±' -~ --+;r -IT ~I -' I=l=l-~ I 1-

f:=:t 17/ 1-,+-1 ~ -+

ffi rtt~ . -I-t--

Mo237 402 013 +r

0 ' cf'

- 10 ' -s

0' if

-10' -s 0237402017 -20' -10

0 10 20 30 40 50 60 kpa I I

I I I I I I I I I 0 100 200 300 400 mmHg o 10 20 30 40 50 60 kpa iii i I Iii a 100 200 JOD 400 mm Hg 135969 135356 B28A, B28E B28F

85

Page 89 of 168

(

70019401960 Specifications

Section

2 B 280 Engine

Group 21 Engine block

Cylinder head

Max warp:

Maximum warp is 0.05 mm (0.002 in) per

100 mm (4 in) length.

I

[

Note: Do not level a warped cylinder head,

replace it!

n~Ql;J 129860

Cylinder liners

Bore liners marked 1 (A-marked piston) ........................ .

2 (B-marked piston) ....................... .

3 (C-marked piston) ....................... .

Liner height above

block face ................................. .

Shims for adjustment of liner height:

thickness, orange paint marking

............................ .

white paint marking

.............................. .

blue paint marking ............................... .

Pistons

Max weight difference between pistons in same engine .......... .

Piston

float ..................................... ............ .

Piston diameter, A-marked pistons

........ .

B-marked pistons .

....... .

C-marked pistons

........ .

91.00-91.01 mm

91.01-91.02 mm

91.02-91.03 mm

0.14-0.21 mm

0 .098-0.134 mm

0.118-0.154 mm

0.138-0.194 mm

6 grams

0.070-0.090 mm

90.920-90.930 mm

90.930-90.940 mm

90 .940-90.950 mm

(3.5826-3 .5830 in)

(3.5830-3.5835 in)

(3.5835-3.5838 in)

(0.0055-0.0083 in)

(0.0039-0.0053 in)

(0. 0046-0.0061 in)

(0.0054-0.0076 in)

(0.0028-0 .0035 in)

(3.5822-3.5826 in)

(3.5826-3.5830 in)

(3.5830-3.5834 in)

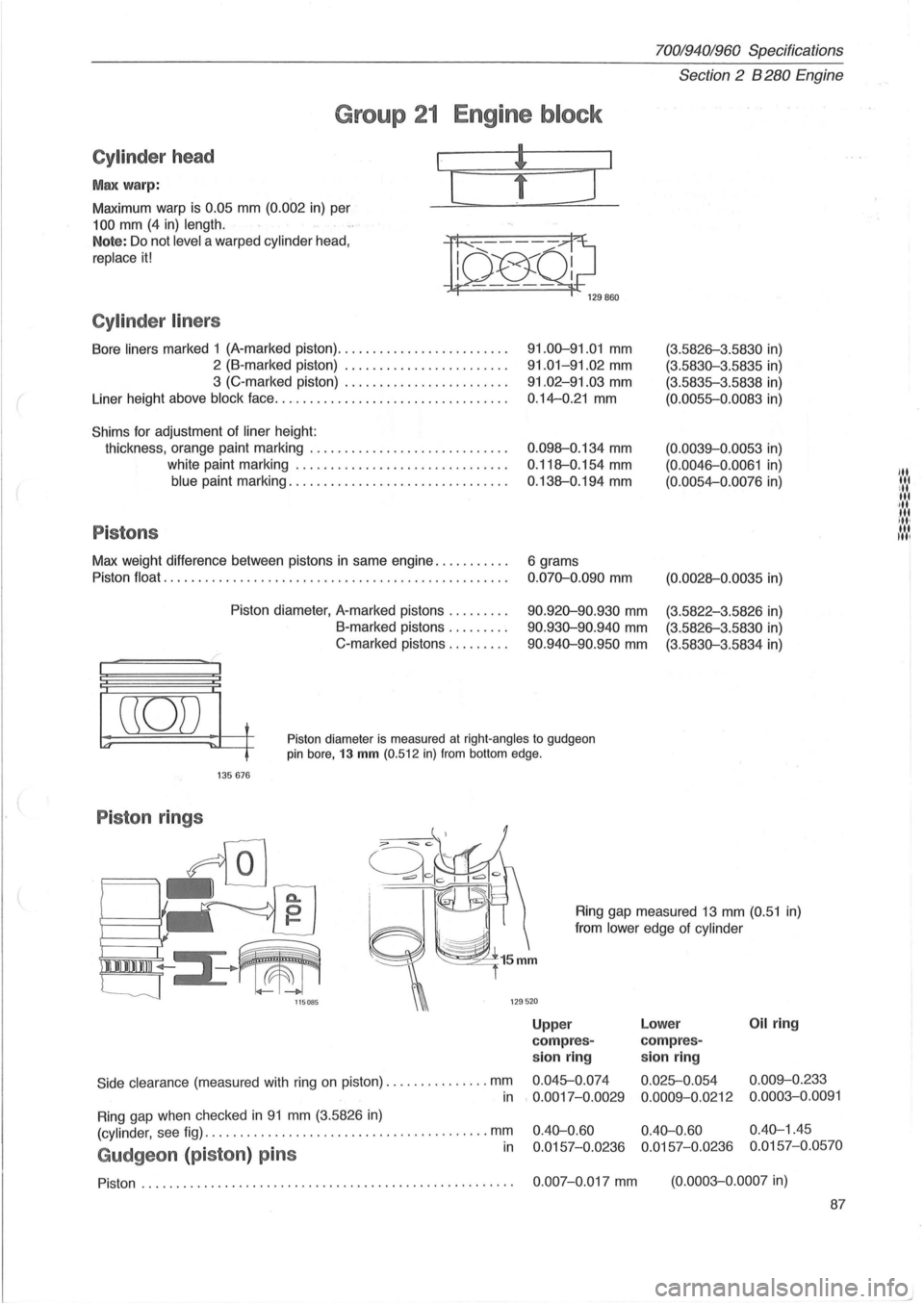

((0)) t

~ ~~ Piston diameter is measured at right-angles to gudgeon pin bore, 13 mm (0.512 in) from bottom edge.

135676

Piston rings

Side clearance (measured with ring on piston) .. ............ . mm

Ring gap measured 13 mm (0.51 in)

from

lower edge of cylinder

Upp er Lower Oil ring

com pres-compres-

sion ring sion ring

0.045-0.

074

0.025-0.054 0.009-0.233

in

Ring gap when checked in 91 mm (3.5826 in)

. 0.0017-0.0029

0.0009-0.0212 0.0003-0.0091

(cylinder,

see fig) ..................................... .... mm

Gudgeon (piston ) pins in

0.40-0.60 0.40-0.60 0.40-1.45

0.0157-0.0236 0.0157-0.0236 0.0157-0.0570

Piston. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.007-0.017 mm (0.0003-0.0007 in)

87

"' lit ill lit ·,11 tit ill, til Itil

Page 90 of 168

70019401960 Specifications

Section 2 B 280 Engine

Valve system

Valve clearance

Inlet valves, cold engine ..................................... .

warm engine

................................... . .

Exhaust valves, cold engine

.................................. .

warm engine

................................. .

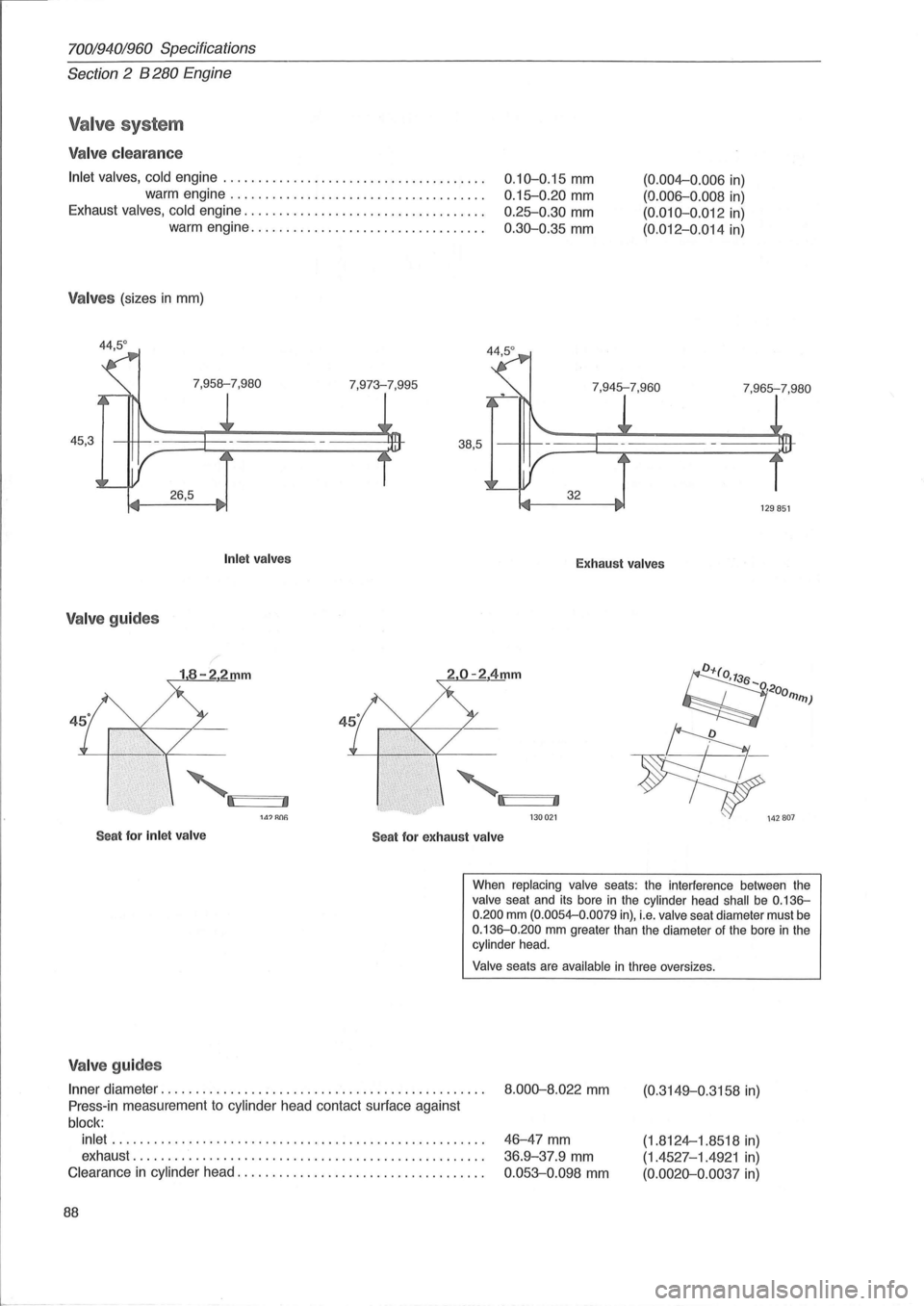

Valves (sizes in mm)

44,5°

0.10-0.15 mm

0.15-0.20 mm

0.25-0.30 mm

0.30-0.35 mm

(0.004-0.006 in)

(0.006-0.008 in)

(0.010-0.012 in)

(0.012-0.014 in)

7,973-7,995

7,965-7,980

45,3

129851

Inlet valves Exhaust valves

Valve guides

18-22mm 20-24mm

'·Il'I====JI, '·':1 ~:J' 141 RClfj 130021

Seat for Inlet valve

Seat for exhaust valve

When replacing valve seats: the interference between the valve seat and its bore in the cylinder head shall be 0.136-0.200 mm (0.0054-0.0079 in), i.e. valve seat diameter must be 0.136-0.200 mm greater than the diameter of the bore in the cylinder head .

Valve seats are available in three oversizes .

Valve guides

Inner diameter .............................................. .

Press-in measurement to cylinder head contact surface against

block: inlet .

.................................................... .

exhaust

........................... ....................... .

Clearance

in cylinder head ................................... .

88

8.000-8.022 mm

46-47 mm

36.9-37.9 mm

0.053-0.098 mm

(0.3149-0.3158 in)

(1.8124-1.8518 in)

(1.4527-1.4921 in)

(0.0020-0 .0037 in)

Page 93 of 168

(

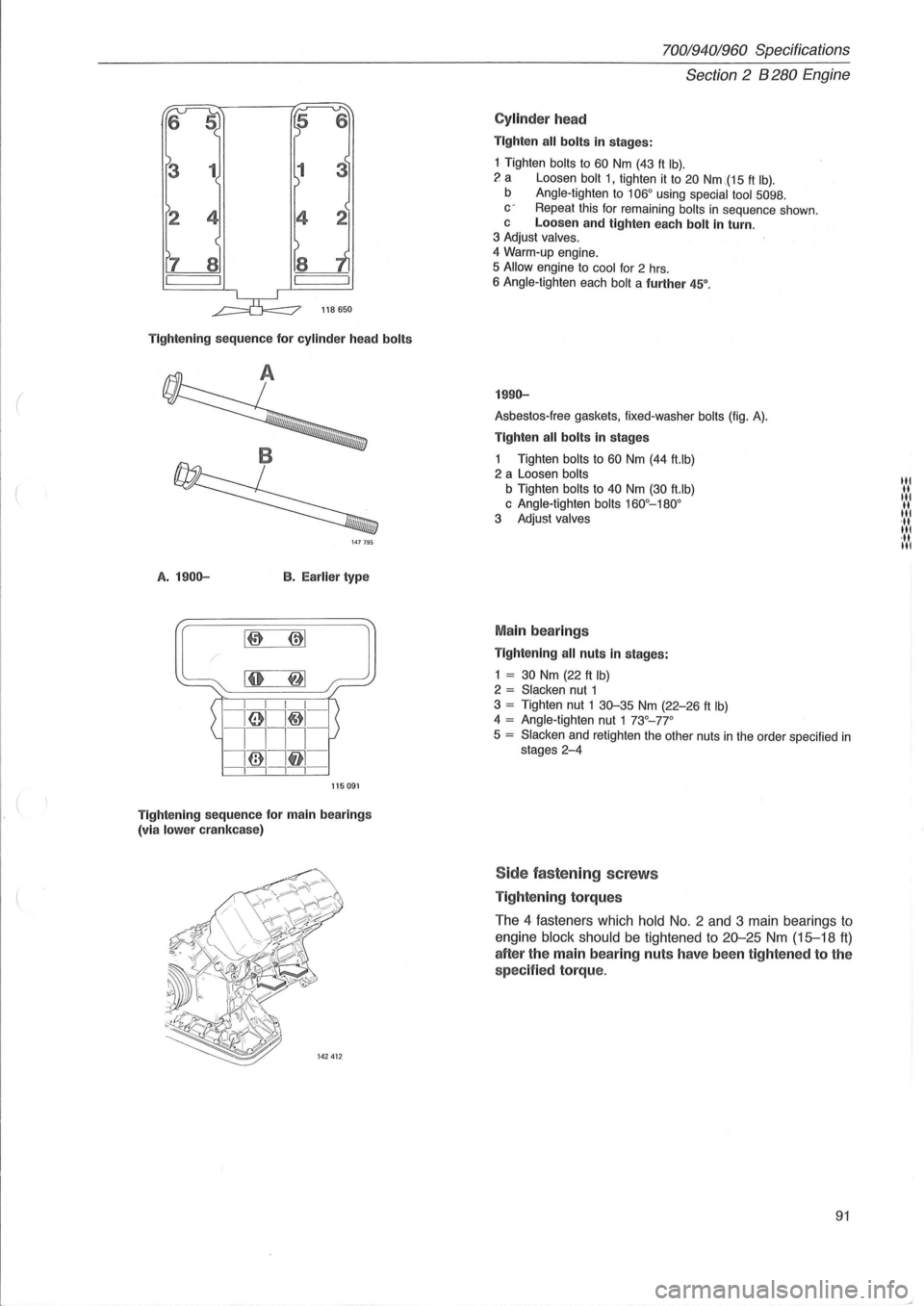

6

l1S 650

Tightening sequence for cylinder head bolts

147795

A. 1900-B. Ear lier type

115091

Tightening sequence for main bearings

(vi a lower crankcase)

7QOl9401960 Specifications

Section 2 B 280 Engine

Cylinder head

Tighten all bolts in stages:

1 Tighten bolts to 60 Nm (43 ft Ib). ? a Loosen bolt 1, tighten it to 20 Nm :(15 ft Ib). b Angle-tighten to 106° using special tool 5098. c' Repeat this for remaining bolts in sequence shown. c Loosen and tighte n each bolt in turn. 3 Adjust valves. 4 Warm-up engine.

5 Allow engine to cool for 2 hrs. 6 Angle-tighten each bolt a further 45°.

1990-

Asbestos-free gaskets, fixed-washer bolts (fig. A).

Tighten all bolts in stages

1 Tighten bolts to 60 Nm (44 ft.lb) 2 a Loosen bolts

b Tighten bolts to 40 Nm (30 ft.lb) c Angle-tighten bolts 160°-180° 3 Adjust valves

Main bearings

Tightening all nuts in stages:

1 = 30 Nm (22 ft Ib) 2 = Slacken nut 1 3 = Tighten nut 1 30-35 Nm (22-26 ft Ib) 4 = Angle-tighten nut 1 73°-77°

5 = Slacken and retighten the other nuts in the order specified in stages 2-4

Side fastening screws

Tightening torques

The 4 fasteners which hold No.2 and 3 main bearings to

engine block should be tightened to 20--25 Nm (15-18 tt)

after the main bearing nuts have been tightened to the

spec ified torque.

91

lit '\1 lit II lit .\1 lit ·11 III

Page 100 of 168

70019401960 Specifications

Section 2 B 6304 Engine

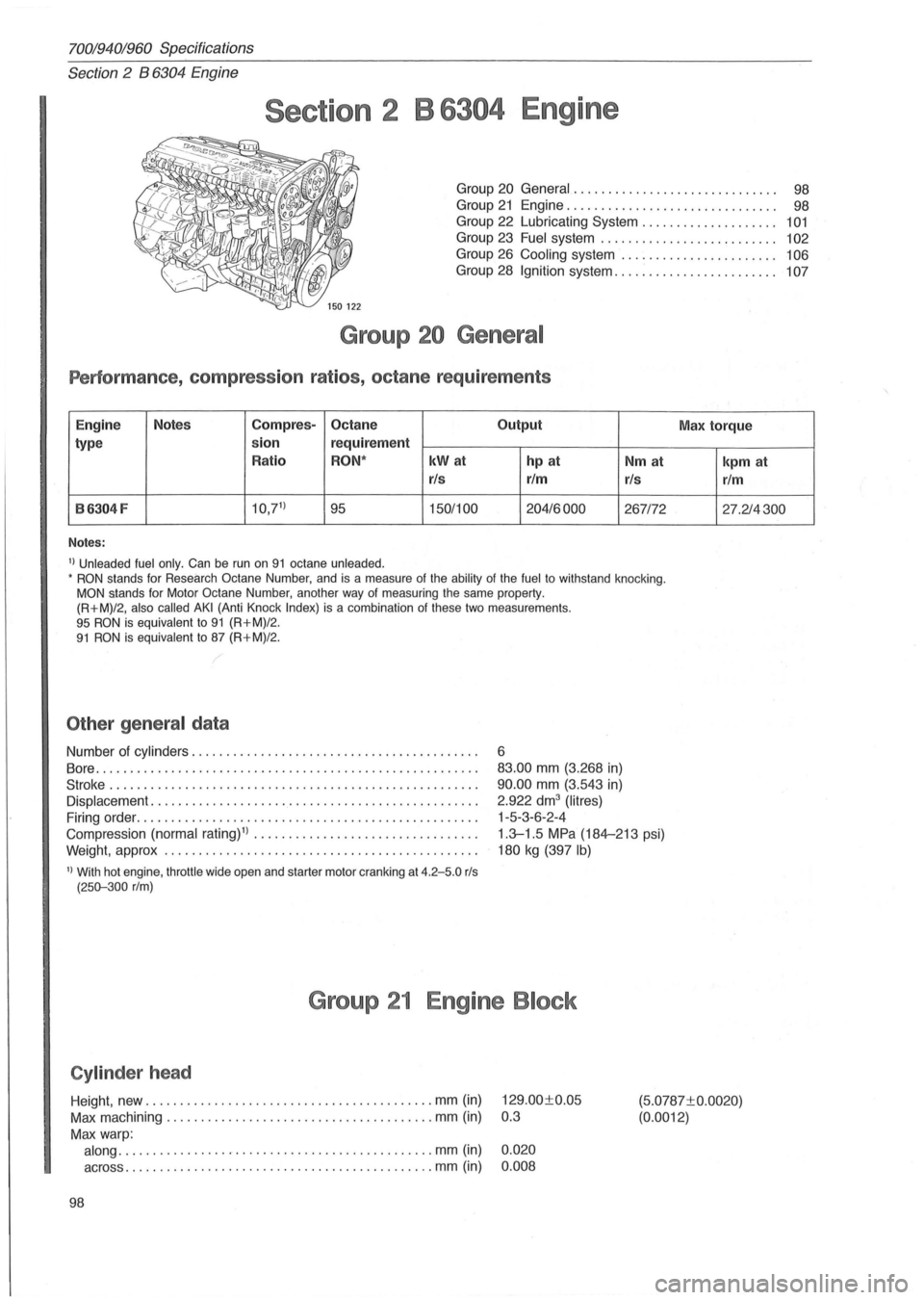

Section 2 B 6304 Engine

Group 20 General.... . . . . . . . . . . . . . . . . . . . . . . . . .. 98

Group 21 Engine............................... 98

Group

22 Lubricating System. . . . . . . . . . . . . . . . . . .. 101

Group 23 Fuel system . . . . . . . . . . . . . . . . . . . . . . . . .. 102

Group 26 Cooling system . . . . . . . . . . . . . . . . . . . . . .. 106

Group 28 Ignition system . . . . . . . . . . . . . . . . . . . . . . . . 107

Group 20 General

Performance , compression ratios, octane requirements

Engine Notes Compres-Octane

Output

type sion

requirement

Ratio

RON· kWat hp at Nm at

rls rim

rls

B6304F 10,71

) 95 150/100 204/6000 267172

Notes:

1) Unleaded fuel only. Can be run on 91 octane unleaded . • RON stands for Research Octane Number, and is a measure of the ability of the fuel to withstand knocking. MON stands for Motor Octane Number, another way of measuring the same property .

(R+M)/2, also called AKI (Anti Knock Index) is a combination of these two measurements . 95 RON is equivalent to 91 (R+M)/2. 91 RON is equivalent to 87 (R+M)/2 .

Other general data

Number of cylinders ......................................... .

Bore .

.................................................... .. .

Stroke .......................................... .......... . .

Displacement ......................... ................ ...... .

Firing order

............................................... .. .

Compression

(normal rating) 1) • ••••• ••••••••••••••••• •.••••••.•

Weight, approx ............................................. .

1) With hot engine, throttle wide open and starter motor cranking at 4.2-5.0 rls (250-300 rIm)

6

83.00 mm (3.268 in)

90 .00 mm (3.543 in)

2.922 dm3 (Iitres)

1-5 -3-6-2 -4

1 .3-1 .5 MPa (184-213 psi)

180 kg (397 Ib)

Group 21 Engine Block

Cylinder head

Max torque

kpm at

rim

27.214300

Height, new ............................... ........... mm (in) 129 .00±0.05

Max machining .............. ......................... mm (in) 0.3

(5.0787±0.0020)

(0.0012)

Max warp:

along ......... .... ................................. mm (in) 0.020

across .................................. ...... ..... mm (in) 0 .008

98

Page 101 of 168

(

Cylinder block

Bore

Standard (marked C)

........................... ....... mm (in)

(marked

D) ........... ....................... mm (in)

(marked

E) .................................. mm (in)

(marked

G) ................... . .............. mm (in)

Rebore if wear exceeds 0.1 mm and oil consumption is abnormally high.

Pistons

Piston diameter

Diameter to be measured at right

angles to gudgeon pin and

16 mm from bottom of piston.

Standard (marked C)

.................................. mm (in)

(marked

D): ................................ . mm (in)

(marked

E) .. , ........................ ....... mm (in)

(marked

G) ............ ...................... mm (in)

Piston weight

.......................................... g (oz)

Max weight difference between pistons in same engine

......... g

Piston rings

Axial clearance in piston groove ............................ mm

in

Ring gap (measured in cylinder, bore 83.00 mm) ............. mm ? in

Gudgeon (P iston ) pins

Fit in connecting rod ......................................... .

in piston

................................................ .

Valve system

Hydraulic

Valves

Length inlet ...... .................................... mm (in)

exhaust

.............. ......................... mm (in)

Matching surface

angle .................................. .... 0

Edge height, new valve ................................ mm (in)

min after machining .

...................... mm (in)

Max machining of

valve stem ................ ........... mm (in)

Valve Seats

Diameter standard .................................... mm (in)

oversize

.... ................................ mm (in)

Matching surface

angle .......................... ............ 0

Reduction angle, upper ...................................... 0

lower ................. ....... .............. 0

Width ...................................... ... ...... mm (in)

70019401960 Specifications

Section 2 B 6304 Engine

83.00-83.01

83.01-83 .02

83.02-83.03

83.04-83.05

82.98--82.99

82.99--83.00

83.00-83.01

83.02 -83.03

350

± 5

10

(3.2677-3 .2681 )

(3.2681-3.2685)

(3.2685-3 .2689)

(3.2693-3.2697)

(3.2669--3.26 7

3)

(3.2673-3.2677)

(3.2677-3.

2681 )

(3.2685-3.2689)

(12.5 ±

0.2)

(0.4)

Upper

camp. rings

0.05-0.085

0.0020-0.0033

0.2-0.4

0.008--0.016

Lower

camp. rings

0.03-0.065

0.0012-0.0026

0.2-0.4

0.008--0.016

Oil scraper

ring s

0.02-0.055

0.0008 -0.0022

0.25-0.5

0.009--0 .020

Light thumb pressure (close running fit)

Thumb pressure (push fit)

104.05±0.18

103.30±0.18

45.5

1.5

1.2

0 .4 (4

.

096±0.007)

(4.067±0. 007)

(0.059)

(0.047)

(0.016)

inl et exhaust

32.61 (1.284) 28.61 (1.126)

33.11

(1.304) 29 .11 (1.146)

45.25 45.25

20.25 15.25

60.25 60.25

1.4-1.8 (0.055-0.071) 1.8--2.2 (0.071-0.087)

99

Itl

It

Itl

.... 1 '11 Itl ... Itl

Page 103 of 168

(

Connecting rod bearing caps (stage 1) ................ Nm (ft Ib)

(stage 2) angle-tightening ......... 0

Crankshaft pulley (vibration damper), center bolt ........ Nm (ft Ib)

Flange bolts, vibration damper (stage 1) ............... Nm (ft Ib)

(stage 2) angle-tightening ........ 0

Driver plate (stage 1) ......................... ....... Nm (ft Ib)

(stage 2) angle-tightening ......................... 0

Camshaft wheel. .................................... Nm (ft Ib)

Tensi oning pulley, camshaft timing belt ................ Nm (ft Ib)

Damper unit, camshaft timing belt ..................... Nm (ft Ib)

Angle pulley, camshaft timing belt ..................... Nm (ft Ib)

Water pump ........................................ Nm (ft Ib)

Pin bolts, exhaust manifold (in cylinder head) ........... Nm (ft Ib)

(to front pipe) .............. Nm (ft Ib)

Oil sump pan ....................................... Nm (ft Ib)

Plug, oil sump ...................................... Nm (ft Ib)

Oil suction line ...................................... Nm (ft Ib)

Oil cooler, connector block ........................... Nm (ft Ib)

Oil trap ............................................ Nm (ft Ib)

Nipple, oil·filter ...................................... Nm (ft Ib)

Oil pressure switch .................................. Nrn (ft Ib)

Impulse sensor ..................................... ~~m (ft Ib)

Knock sensor ....................................... Nm (ft Ib)

Temperature sensor, rear edge of top cover ............ Nm (ft Ib)

Temperature sensor, thermostat ............... ....... Nm (ft Ib)

Plug, O-adjustment tool .............................. Nm (ft Ib)

Spark plugs ... ..................................... Nm (ft Ib)

20

90

300±30

35

60 45

50

20±2

39±5

24±4

24±6

17±3

20±3

35±5

17±3

38±5

17±3

17±3

15±2.5

40±2

40±5

8±2

20±2

20±2

10±2.5

38±6

25

Group 22 Lubricating System

Genera l

Oil fill volume and type, see p. 12.

Oil pressure with warm engine and new oil filter :

at 12,5 rls (750 rim), at least ....... ................ Mpa (psi) 0.1

at

50 rls (3 000 rim), at least ....................... Mpa (psi) 0.3

max

...................... ....................... Mpa (psi) 0.5

Lubricat ing oil pump

Relief valve spring, length under various loads

unloaded

.................... ....... mm (in)

loaded to 52±4 N (5.2 kp) ....... .... mm (in)

loaded to 85±8 N (8.5 kp) ........... mm (in)

82.13

56.1

39.9

70019401960 Specifications

Section 2 B 6304 Engine

(15)

(221 ±22)

(26)

(33)

(15±1.5)

(29±4)

(18±3)

(18±4)

(13±2)

(15±2)

(26±4)

(13±2)

(28±4)

(13±2)

(13±2)

(11 ±2)

(29±1.5)

(29±4)

(6±1.5)

(15±1.5)

(15±1.5)

(7±2)

(28±4)

(18)

(14)

(43)

(71 )

(3.233) (2.21)

(1.57)

101

I ..... ' '.','

"' ,III III ill u,1

Page 111 of 168

(

70019401960 Specifications

Sect ion

2 024, 024 T, 024 TIC Engines

Cylinder head

Max. warp .......................... , ... .

Cylinder head may not be machined.

It must be replaced if warp exceeds

maximum .

Cylinder head gasket

Group 21

129146

Three different gaskets are used depending on height of piston above cylinder block.

Notches

Height of piston above

cylinder block

mm

0.67-0.80

0.81-0.90

0.91-1.02

in

0.026-0.031

0.032-0.35

0.036-0.040

@.2 mrp = 0.008 in

!:, :' 1 ' . , • t ~I

129147

Gasket

number of thickness

notches mm

in

1 * 1.4 0.055

2 1.5 0.059

3 1.6 0.063

Piston height in same engine must not extend over more than

two classes .

Piston height is measured at the front and back of piston

(along the gudgeon (piston) pin) .

• Not D 24 TID 24 TIC

Cy lind er block

Bore Marking

(honing group)

Standard .

....... , . .. , ...... , .. .... , .. , ................. 651

652

653

Oversi ze 1 ............. , ... , .. , ... , .. , ... , . . , .. , ....... 676

(0.25 mm = 0.010 in) .... " .. , . . " .. , . . , ... , .. , . . , .. , .... 677

678

Oversize 2 ....... ......... , . ........................... 701

(0.50 mm = 0.020 in) .... , ...... , ...... , . ..... , .......... 702

703

Oversize 3 ................ , ... , .... .. , ... , ..... , ... .... 751

(1.00 mm = 0.040 in) ...................... , .. , .. , . , ..... 752

753

Max wear (compared with specified diameter) .... , ............. .

Pistons

Max . weight deviation between pistons in

same engine .............................. , .. .

Piston float, new .......... , ...... , .. , ........ . .

max

.................. ....... , .. , .. .

Piston diameter, see cylinder bore table

Max wear (compared with specified diameter) .....

Piston diameter is measured at right-angles to gudgeon

piston

lower edge .

12 grams

0.03-0.05 mm

0.13 mm

0.04 mm

Piston diameter

mm in

76.48 3.0110

76.49 3.0114

76.50 3.0118

76.73 3.0209

76.74 3.0213

76.75 3.0216

76.98 3.0307

76.99 3 .0311

77.00 3.0315

77.48 3.0504

77.49 3.0508

77.50 3.0512

0.04

mm (0.0016 in)

0.0012 -0.0019 in

0.0051 in

0.0016 in

Cylinder bore

mm in

76.51 3.0122

76.52 3.0125

76.53 3.0130

76 .76 3.0220

76.77 3.0224

76.78 3.0228

77.01 3.0318

77. 02 3.0322

77.03 3.0326

77.51 3.0515

77.52 3.0519

77

.53 3.0523

~ 0 • + .... I

t 129835

109

,III

.' .... 1

"' ·111

'" ·111

'" ·111

Page 114 of 168

70019401960 Specifications

Section

2 024, 024 T, 024 TIC Engines

Crankshaft

Max1

) runout, two centre bearings ............................. .

others

........................................ . .

Crankshaft, end

clearance, new ............................... .

max .

.............................. .

main bearing

clearance, new ....... ............... .

max

....................... .

Connecting

rod bearings, side clearance, max .................. .

bearing

clearance, max ............... .

new

............... .

l)Measured with two outer main bearings in V·blocks.

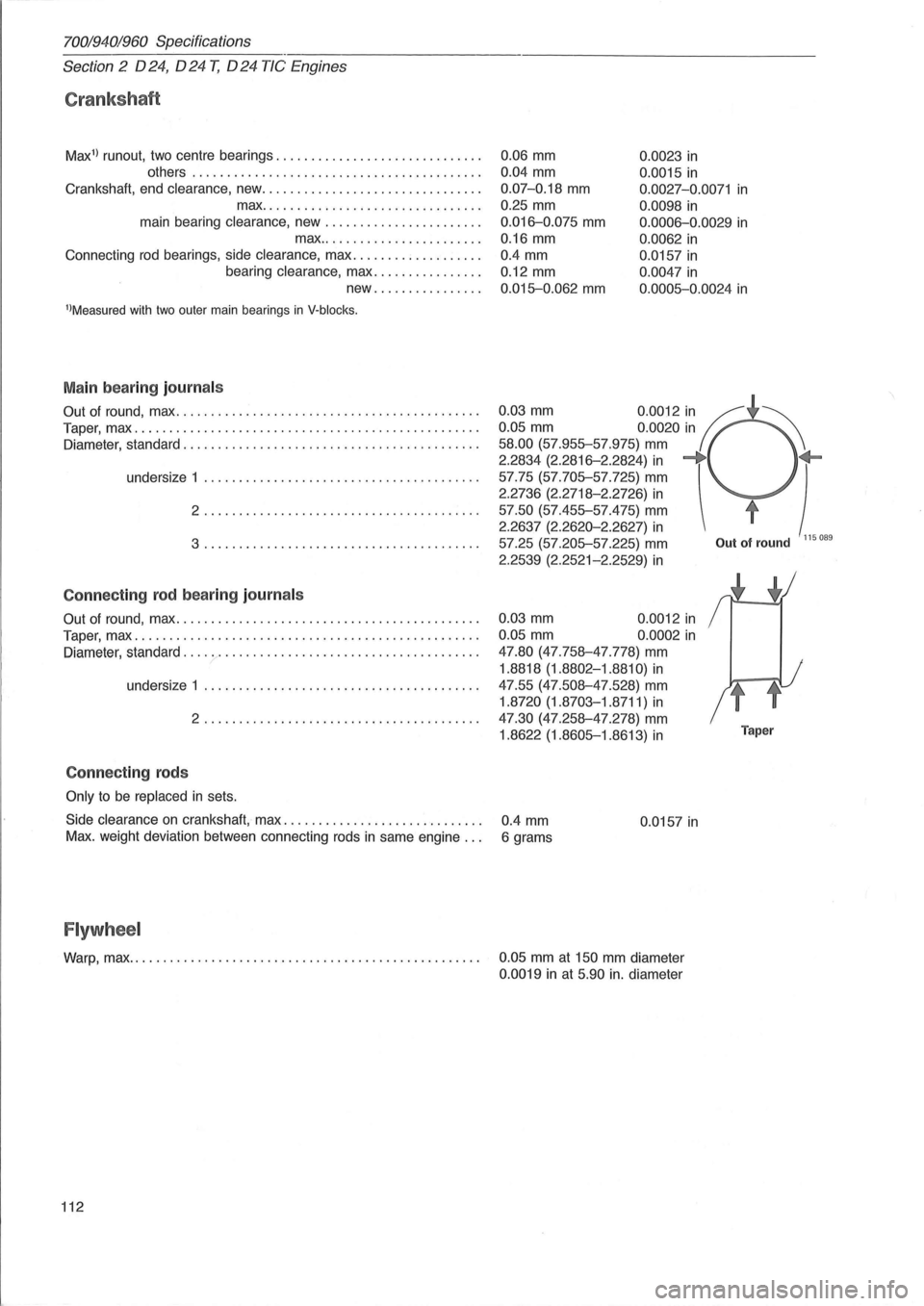

Main bearing journal s

Out of round, max ........................................... .

Taper, max

................................................. .

Diameter, standard .

.................................... ..... .

undersize 1 .

...................................... .

2 ....................................... .

3 ......................... .............. .

Con necting rod bearing journ als

Out of round, max ........................................... .

Taper, max

................................................. .

Diameter, standard

.......................................... .

undersize 1

....................................... .

2

....................................... .

Con necting rods

Only to be replaced in sets.

0.06 mm 0.0023 in

0.04 mm

0.07-0.18 mm

0.25 mm

0.016-0.075 mm

0.16 mm

0.0015 in

0.0027-0.0071 in

0 .0098 in

0.0006-0.0029 in

0.0062 in

0.4 mm 0.0157 in

0.12 mm

0.015-0.062 mm

0.0047 in

0 .0005-0.0024 in

0.03 mm 0.0012 in If ~ 0.05 mm 0.0020 in

58.00 (57.955-57.975) mm

2.2834 (2.2816-2.2824) in -+ +-) 57.75 (57.705-57.725) mm

2.2736 (2.2718-2.2726) in

57.50 (57.455-57.475) mm t

2.2637 (2.2620-2.2627) in 57.25 (57.205-57.225) mm Out of round 115089

2.2539 (2.2521-2.2529) in

0.03 mm 0.0012 in

0.05 mm 0.0002 in

47.80 (47.758-47.778) mm

1.8818 (1.8802-1.8810) in

47.55 (47.508-47.528) mm

1.8720 (1.8703-1.8711) in

47.30 (47.258-47 .278) mm

1.8622 (1.8605-1.8613) in Taper

Side clearance on crankshaft, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 mm 0.0157 in Max. weight deviation between connecting rods in same engine. . . 6 grams

Flywheel

Warp, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm at 150 mm diameter

0.0019 in at 5.90 in. diameter

112

Page 115 of 168

(

70019401960 Specifications

Section

2 024, 024 T, 024 TIC Engines

Tig ht enin g to rqu es

Tightening torques apply to oiled bolts and nuts. Oegreased (washed) parts should be oiled prior to assembly .

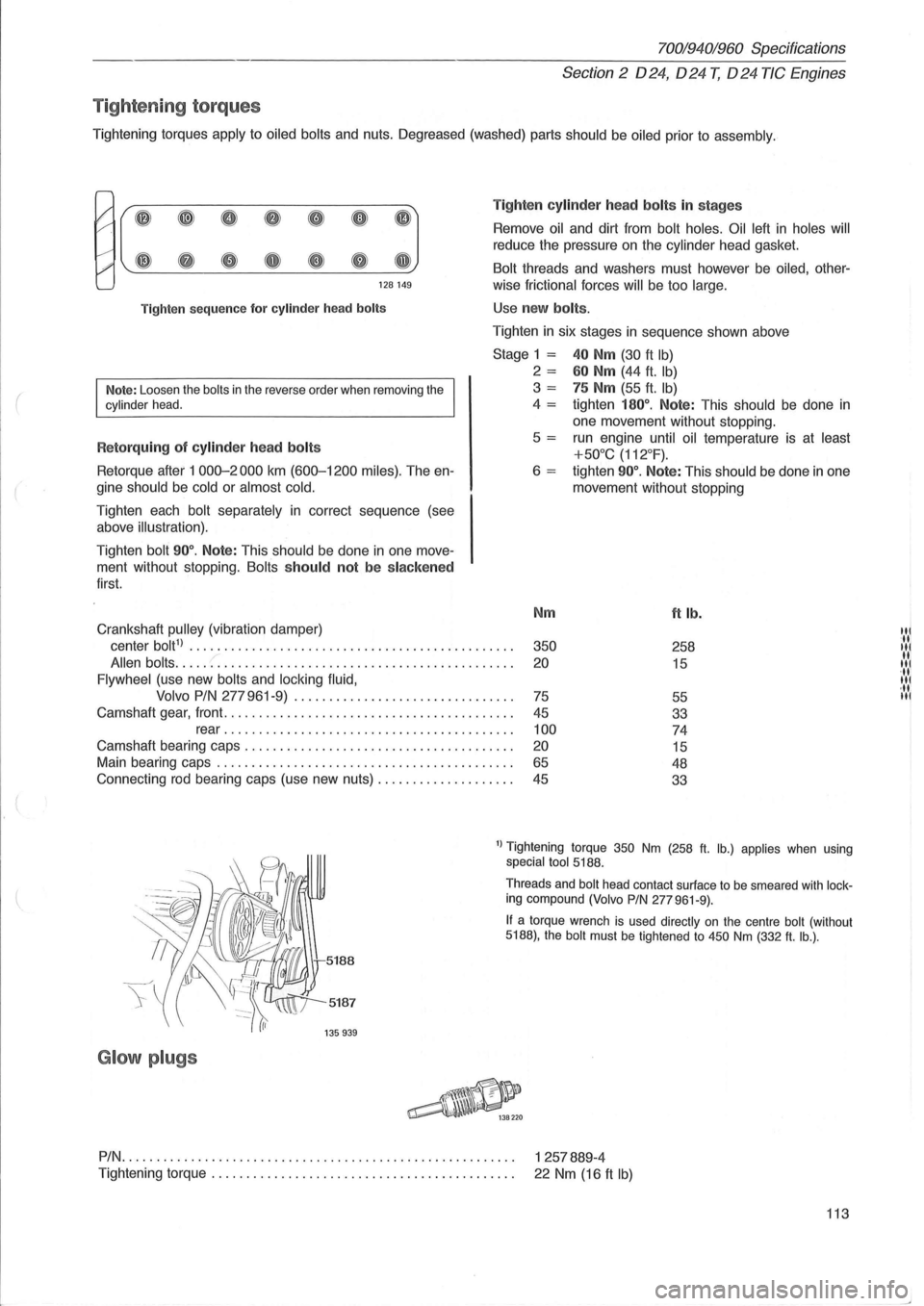

I' ~ ~ 0 8 CD 0 (IJ

#' ~ G e Q e Q GJ

128149

Tighten

sequence for cylinder head bolts

Note: Loosen the bolts in the reverse order when removing the cylinder head.

R etorquing of cylinder head bolts

Retorque after 1 000-2000 km (600-1200 miles). The en

gine

should be cold or almost cold.

Tighten each bolt separately in correct sequence (see

above

illustration).

Tighten bolt 90°. Note: This should be done in one move

ment without stopping.

Bolts should not be slacken ed

first.

Crankshaft

pulley (vibration damper) Ti

g

hten cylinde r h ea d bolts in stages

Remove oil and dirt from bolt holes. Oil left in holes will

reduce the pressure on the cylinder head gasket.

Bolt threads and washers must however be oiled, other-

wise

frictional forces will be too large.

Use new bolts .

Tighten in six stages in sequence shown above

Stage 1 = 40 Nm (30 ft Ib)

2 = 60 Nm (44 ft. Ib)

3 = 75 Nm (55 ft. Ib)

4 = tighten 180°. Note: This should be done in

one movement without stopping .

5

= run engine until oil temperature is at least

+50°C (112°F).

6 = tighten 90°. Note: This should be done in one

movement without stopping

Nm

ft lb.

center bolt1) ............................... ............... . 350 258

Allen bolts ..... :: ......................................... . 20 15

Flywheel (use new bolts and locking fluid,

Volvo PIN

277 961-9) ............................... .

75

55

Camshaft gear, front

......................................... .

45

33

rear

....................................... .. . 100 74

Camshaft bearing caps .................................... .. . 20 15

Main bearing caps .......................................... .

65 48

Connecting rod bearing caps (use new nuts)

................... .

45

33

1) Tightening torque 350 Nm (258 ft. lb.) applies when using special tool 5188.

5187

G lo w plugs

Threads and bolt head contact surface to be smeared with locking compound (Volvo PIN 277961-9).

If a torque wrench is used directly on the centre bolt (without 5188), the bolt must be tightened to 450 Nm (332 ft. lb.) .

PIN.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 257889-4

Tightening

torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Nm (16 ft Ib)

113

'il IN 11 '11 11

·11 III