low oil pressure VOLVO 960 1982 Service Repair Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 960, Model: VOLVO 960 1982Pages: 168, PDF Size: 54.28 MB

Page 19 of 168

(

70019401960 Specifications

Section

2 B 19, B 23 Engines

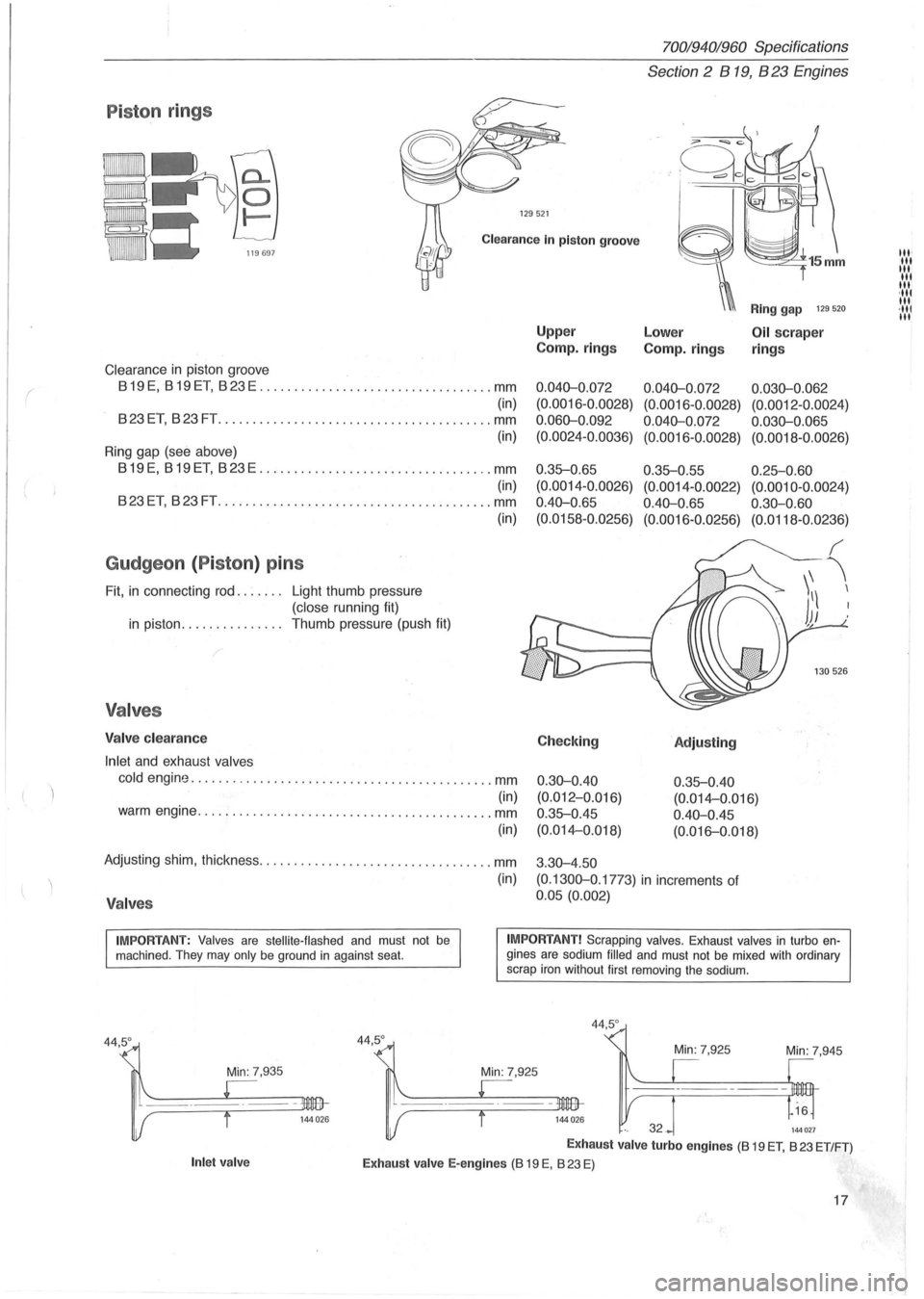

P iston rings

129521

Clearance In piston groove

Clearance in piston groove

819 E, 819 ET, 823 E .................................. mm

(in)

823ET, 823FT .............. .......................... mm

(in)

Ring gap (see above)

819E, 819ET, 823E .................................. mm

(in)

823ET, 823FT ................ .......... .............. mm

Gudgeon (Piston ) pins

Fit, in connecting rod. . . . . .. Light thumb pressure

(close running fit)

in piston. . . . . . . . . . . . . .. Thumb pressure (push fit)

Valves

Valve clearance

Inlet

and exhaust valves

(in)

cold engine ............................................ mm

(in) warm engine ........................................... mm

(in)

Adjusting shim, thickness .................................. mm

(in)

Valves

Upper

Camp.

rings

0.040-0 .072

(0. 0016-0.0028)

0.060-0 .092

(0.0024-0.0036)

0 .35-0.65

(0.0014 -0 .0026)

0.40-0 .

65

(0.0158-0.0256)

Checking

0.30-0.40

(0.012-0.Q16)

0.35-0.45

(0.014-0.018)

3 .

30-4.50

Ring gap 129 520

Lower Oil scraper

Camp.

rings rings

0.040-0.072 0.030-0.062

(0.0016 -0 .0028) (0.0012 -0.0024)

0.040-0.072 0.030-0.065

(0.0016-0.0028) (0.0018-0.0026)

0.35-0.55 0.25-0.60

(0.0014-0.0022) (0.0010-0.0024)

0.40-0.65 0.30-0.60

(0.0016-0.0256) (0.0118-0.0236)

'Adjusting

0.35-0.40

(0. 014-0 .016)

0.40-0.45

(0. 016-0.018)

(0.1300-0 .1773)

in increments of

0.05 (0.002)

IMPORTANT: Valves are stellite-flashed and must not be machined . They may only be ground in against seat. IMPORTANT! Scrapping valves. Exhaust valves in turbo engines are sodium filled and must not be mixed with ordinary

scrap iron without first removing the sodium.

Min: 7,935

Inlet valve

44,5°

44,5 °

Min: 7,945

144027

Exhaust valve turbo engines (8 19 ET, 823 ET/FT)

Exhaust valve E-engines (8 19 E, 823 E)

17

III' III III

III

III ,111 III ·111 III

Page 39 of 168

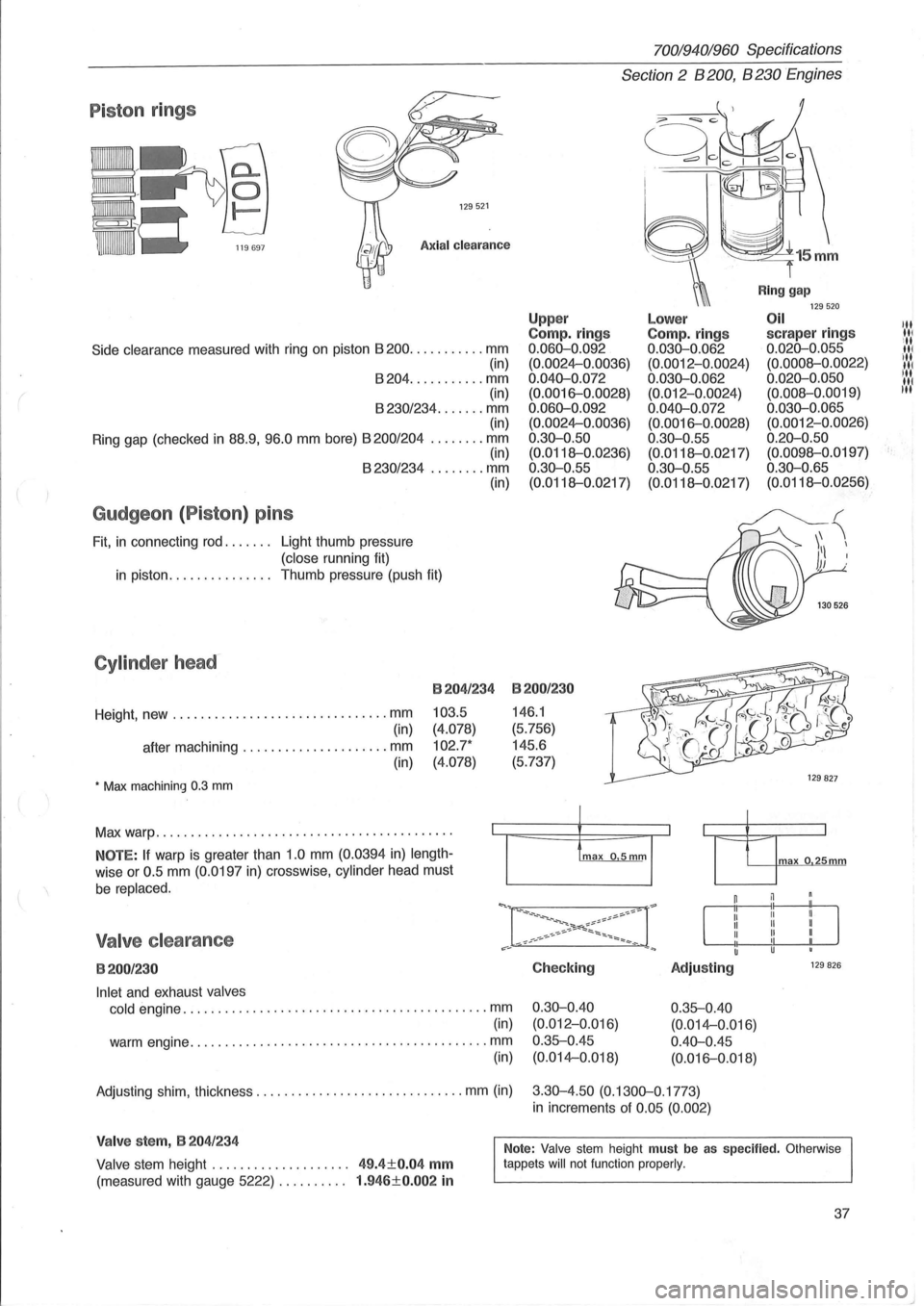

Piston rings

129521

Axial clearance

Side clearance measured with ring on piston 8200 ........... mm

(in)

8204 ........... mm

(in)

8230/234 ....... mm (in)

Ring gap (checked

in 88.9, 96.0 mm bore) 8200/204 ........ mm (in) 8230/234 ........ mm

Gudgeon (Piston) pins

Fit, in connecting rod. . . . . .. Light thumb pressure

(close running fit) (in)

in piston.

. . . . . . . . . . . . .. Thumb pressure (push fit)

Cylinder head-

Height, new ............................... mm

(in)

after machining

..................... mm

(in)

• Max machining 0.3 mm

B204/234

103.5

(4.078)

102.7*

(4.078)

Max warp .......................................... .

NOTE: If warp is greater than 1.0 mm (0.0394 in) length

wise or 0.5 mm (0.0197 in) crosswise, cylinder head must

be replaced.

Valve clearance

B200/230

Inlet and exhaust valves

cold

engine ............................................ mm

(in)

warm engine

........................................... mm

(in)

70019401960 Specifications

Section 2 B 200, B 230 Engines

Upp er Compo rings 0.060-0.092

(0.0024-0.0036)

0.040-0.072 (0.0016-0.0028)

0.060-0.092 (0.0024-0.0036)

0.30-0.50

(0.0118--0.0236)

0.30-0.55

(0.0118--0.0217)

B200/230

146.1

(5.756)

145.6

(5.737)

Checking

0.30-0.40 (0.012-0.Q16)

0.35--0.45 (0.014-0.018)

Lower Compo rings 0.030-0.062 (0.0012-0.0024)

0.030-0.062 (0.012-0.0024)

0.040-0.072 (0.0016-0.0028)

0 .30-0.55

(0.0118--0.0217)

0.30-0.55

(0.0118--0.0217)

Adjusting

0.35--0.40

(0.014-0.016)

0.40-0.45 (0.016-0.018)

Ring gap 129520 Oil scraper rings 0.020-0.055

(0.0008--0.0022)

0.020-0.050 (0.008--0.0019)

0.030-0.065 (0.0012-0.0026)

0.20-0.50 (0.0098--0.0197)

0.30-0.65 (0.0118--0.0256)

max o 25mm

129 826

Adjusting shim, thickness .............................. mm (in) 3.30-4.50 (0.1300-0.1773)

in increments of 0.05 (0.002)

Valve stem, B 204/234

Valve stem height . . . . . . . . . . . . . . . . . . .. 49.4±0.04 mm

(measured with gauge 5222) . . . . . . . . .. 1.946±0.002 in

Note: Valve stem height must be as specified. Otherwise

tappets will not function properly.

37

III III

ill III ill

IN liN

t·

Page 66 of 168

700/940/960 Specifications

Section 2' 8200,8230 Engines

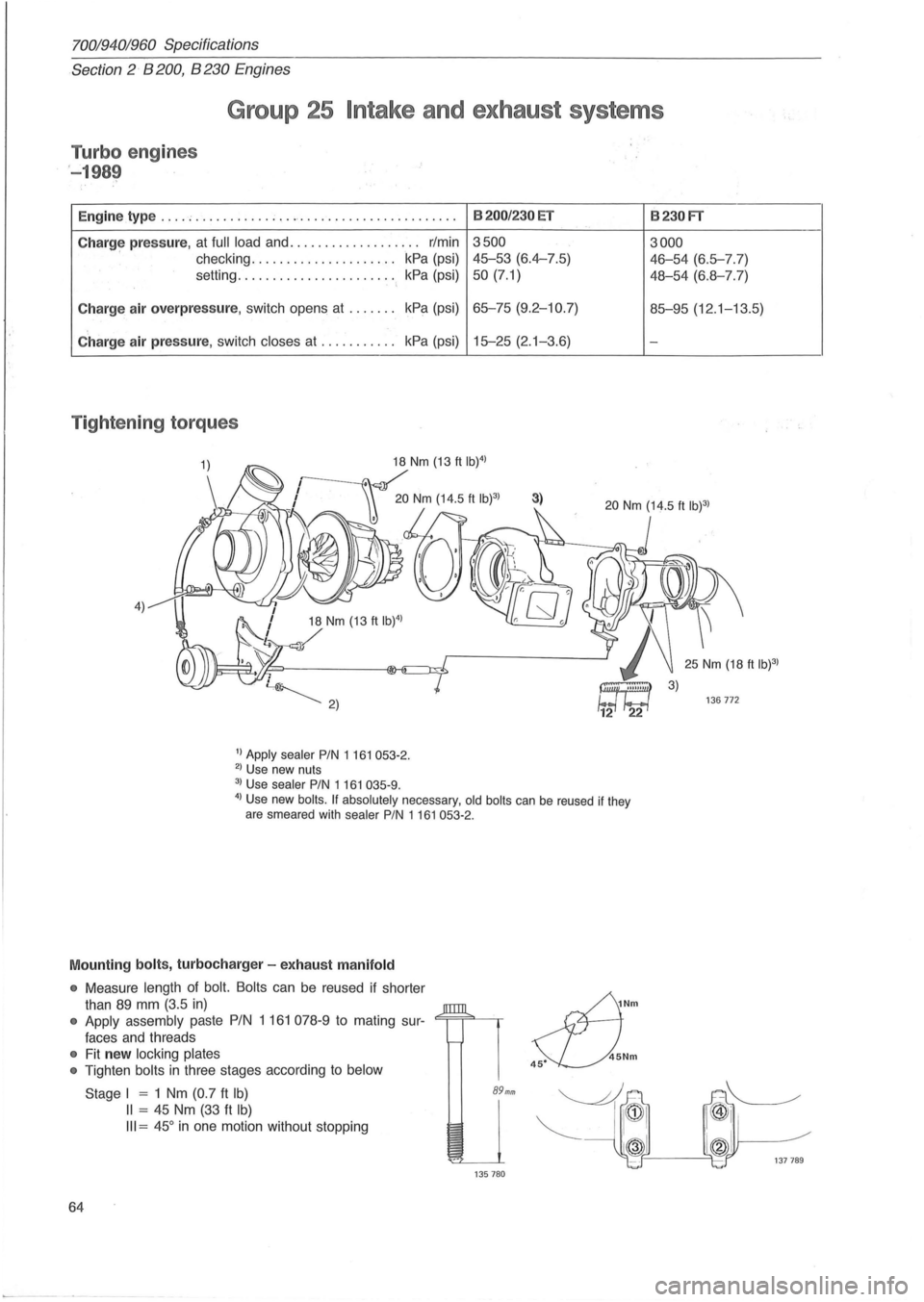

Group 25 Intake and exhaust systems

Turbo engines

'-198~

Engine type .... ; ......... . , ............ .. .............

Charg~ pressure, at full load and ................... r/min

checking

.. ................... kPa (psi)

setting. . . . . . . . . . . . . . . . . . . . .

.. kPa (psi)

Charge air overpressure, switch opens at ....... kPa

(psi)

Charge air pressure, switch closes at ........... kPa (psi)

Tightening torques

4) 18 Nm (13 ft IW)

/

1) Apply sealer PIN 1 161 053-2. 2) Use new nuts

3) Use sealer PIN 1161 035-9.

8200/230 ET

3500

45-53 (6.4-7.5)

50 (7.1)

65-75 (9.2-10.7)

15-25 (2. 1-3.6)

3)

4) Use new boils. If absolutely necessary, old boils can be reused if they

are smeared with sealer PIN 1161053-2.

Mounting bolts, turbocharger -exhaust manifold

• Measure length of bolt. Bolts can be reused if shorter

than

89 mm (3.5 in)

• Apply assembly paste PIN 1 161 078-9 to mating sur-<=;==;=""-~

faces and threads

• Fit new locking plates

•

Tighten bolts in three stages according to below

64

Stage I = 1 Nm (0.7 ft Ib)

II = 45 Nm (33 ft Ib)

III = 45° in one motion without stopping

89mm

135780

~Nm

s::L).Nm

8230FT

3000

46-54 (6.5-7.7)

48-54 (6.8-7.7)

85-95 (12 .1-13.5)

-

136772

Page 76 of 168

70019401960 Specifications

Section

2 B 28 Engine

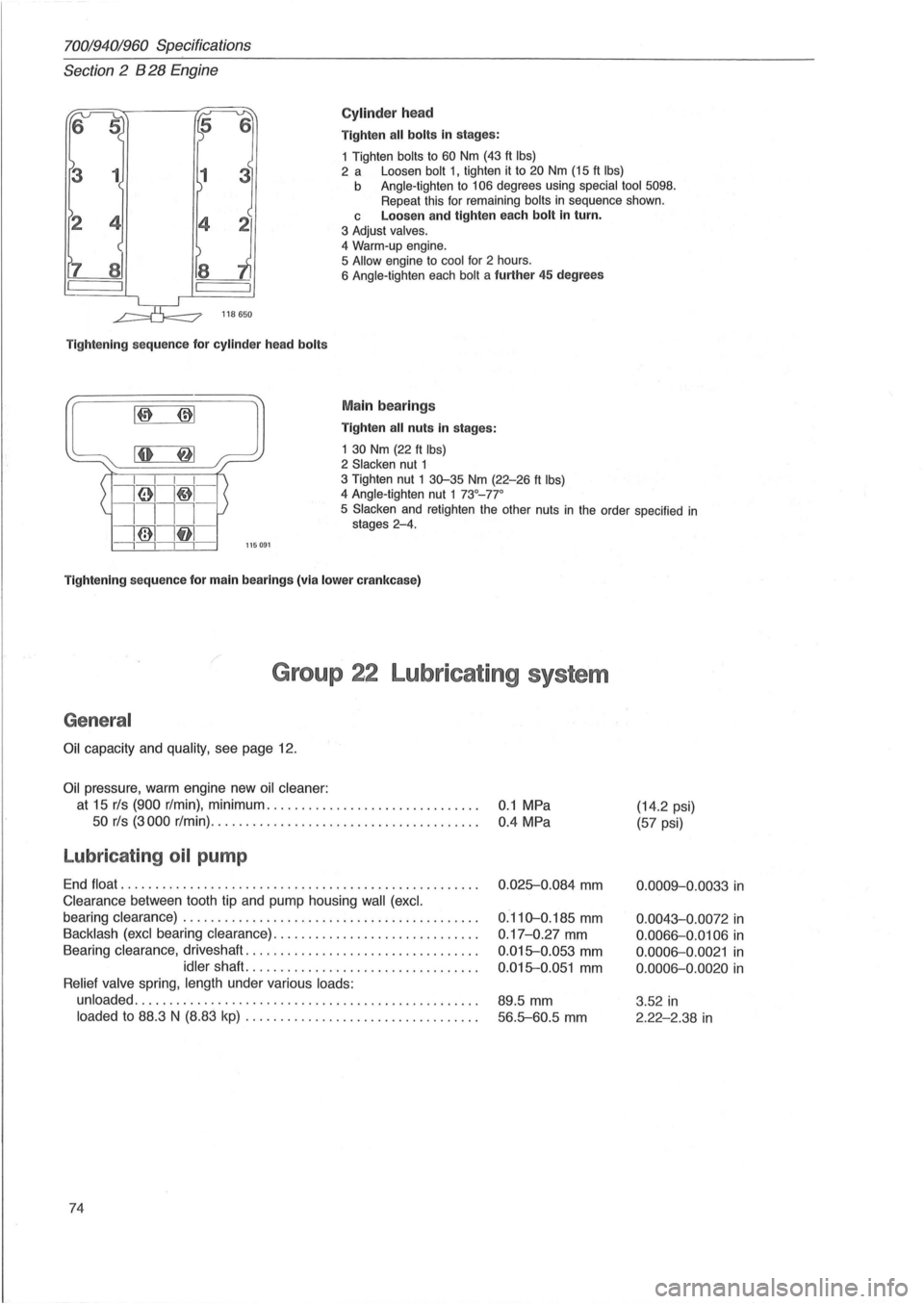

Cylinder head

Tighten all bolts in stages:

1 Tighten

bolts to 60 Nm (43 ft Ibs) 2 a Loosen bolt 1, tighten it to 20 Nm (15 ft Ibs) b Angle-tighten to 106 degrees using special tool 5098. Repeat this for remaining bolts in sequence shown.

118650

Tightening sequence for cylinder head bolts

L~~::~:~' ~I ~: I I I I

i61I~-

c Loosen and tighten each bolt in turn.

3 Adjust valves.

4

Warm-up engine.

5 Allow engine to cool for 2 hours.

6 Angle-tighten each bolt a further 45 degrees

Main bearings

Tighten all nuts in stages:

1

30 Nm (22 ft Ibs) 2 Slacken nut 1 3 Tighten nut 1 30-35 Nm (22-26 ft Ibs) 4 Angle-tighten nut 1 73°_77 °

1111-

i@1lf11 -

5 Slacken and retighten the other nuts in the order specified in stages 2-4.

---,---,---,---,-115091

Tightening sequence for main bearings (via lower crankcase)

Group 22 Lubricating system

General

Oil capacity and quality, see page 12.

Oil pressure, warm engine new oil cleaner:

at 15 rls (900 r/min), minimum .............................. .

50 rls (3000 r/min) .......... ....... ......... ............ .

Lubricating oil pump

End float ................................................... .

Clearance between tooth tip and pump housing wall (excl.

bearing clearance) .......................................... .

Backlash (excl bearing clearance) ................ ............. .

Bearing

clearance, driveshaft ................................. .

idler shaft. ................................ .

Relief valve spring, length under various loads:

unloaded

................................................. .

loaded to 88.3 N (8.83 kp) ............ ... .... .............. .

74

0.1 MPa

0.4 MPa

0 .

025-0.084 mm

0.110-0.185 mm

0 .17-0.27 mm

0.015-0.053 mm

0.015-0.051 mm

89.5 mm

56.5-60.5 mm

(14.2 psi)

(57 psi)

0.0009-0.0033 in

0.0043-0.0072 in

0.0066-0.0106 in

0 .0006-0.0021 in

0.0006-0.0020 in

3 .52 in

2.22-2.38 in

Page 101 of 168

(

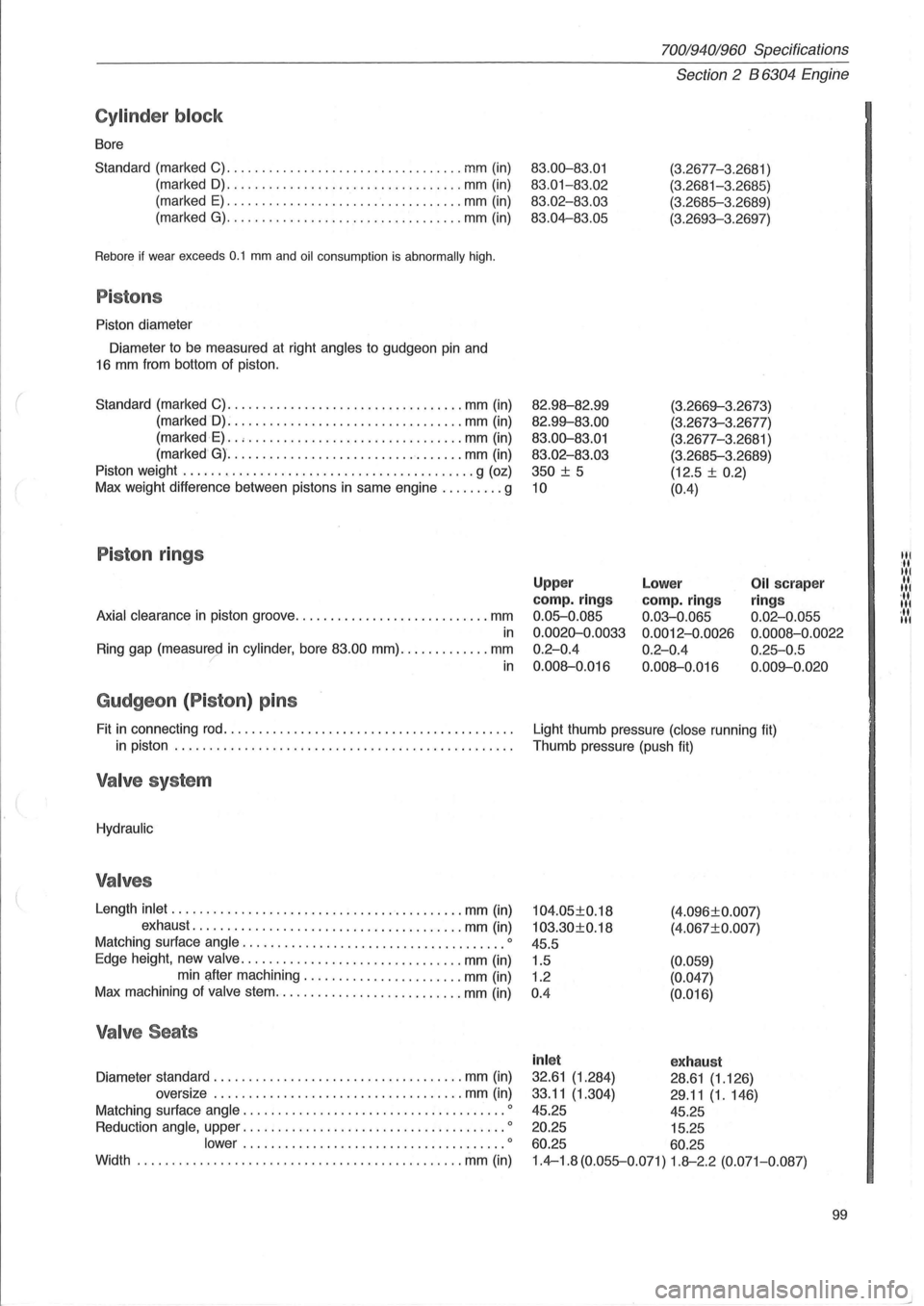

Cylinder block

Bore

Standard (marked C)

........................... ....... mm (in)

(marked

D) ........... ....................... mm (in)

(marked

E) .................................. mm (in)

(marked

G) ................... . .............. mm (in)

Rebore if wear exceeds 0.1 mm and oil consumption is abnormally high.

Pistons

Piston diameter

Diameter to be measured at right

angles to gudgeon pin and

16 mm from bottom of piston.

Standard (marked C)

.................................. mm (in)

(marked

D): ................................ . mm (in)

(marked

E) .. , ........................ ....... mm (in)

(marked

G) ............ ...................... mm (in)

Piston weight

.......................................... g (oz)

Max weight difference between pistons in same engine

......... g

Piston rings

Axial clearance in piston groove ............................ mm

in

Ring gap (measured in cylinder, bore 83.00 mm) ............. mm ? in

Gudgeon (P iston ) pins

Fit in connecting rod ......................................... .

in piston

................................................ .

Valve system

Hydraulic

Valves

Length inlet ...... .................................... mm (in)

exhaust

.............. ......................... mm (in)

Matching surface

angle .................................. .... 0

Edge height, new valve ................................ mm (in)

min after machining .

...................... mm (in)

Max machining of

valve stem ................ ........... mm (in)

Valve Seats

Diameter standard .................................... mm (in)

oversize

.... ................................ mm (in)

Matching surface

angle .......................... ............ 0

Reduction angle, upper ...................................... 0

lower ................. ....... .............. 0

Width ...................................... ... ...... mm (in)

70019401960 Specifications

Section 2 B 6304 Engine

83.00-83.01

83.01-83 .02

83.02-83.03

83.04-83.05

82.98--82.99

82.99--83.00

83.00-83.01

83.02 -83.03

350

± 5

10

(3.2677-3 .2681 )

(3.2681-3.2685)

(3.2685-3 .2689)

(3.2693-3.2697)

(3.2669--3.26 7

3)

(3.2673-3.2677)

(3.2677-3.

2681 )

(3.2685-3.2689)

(12.5 ±

0.2)

(0.4)

Upper

camp. rings

0.05-0.085

0.0020-0.0033

0.2-0.4

0.008--0.016

Lower

camp. rings

0.03-0.065

0.0012-0.0026

0.2-0.4

0.008--0.016

Oil scraper

ring s

0.02-0.055

0.0008 -0.0022

0.25-0.5

0.009--0 .020

Light thumb pressure (close running fit)

Thumb pressure (push fit)

104.05±0.18

103.30±0.18

45.5

1.5

1.2

0 .4 (4

.

096±0.007)

(4.067±0. 007)

(0.059)

(0.047)

(0.016)

inl et exhaust

32.61 (1.284) 28.61 (1.126)

33.11

(1.304) 29 .11 (1.146)

45.25 45.25

20.25 15.25

60.25 60.25

1.4-1.8 (0.055-0.071) 1.8--2.2 (0.071-0.087)

99

Itl

It

Itl

.... 1 '11 Itl ... Itl

Page 141 of 168

70019401960 Specifications -------------------------------------------------------------

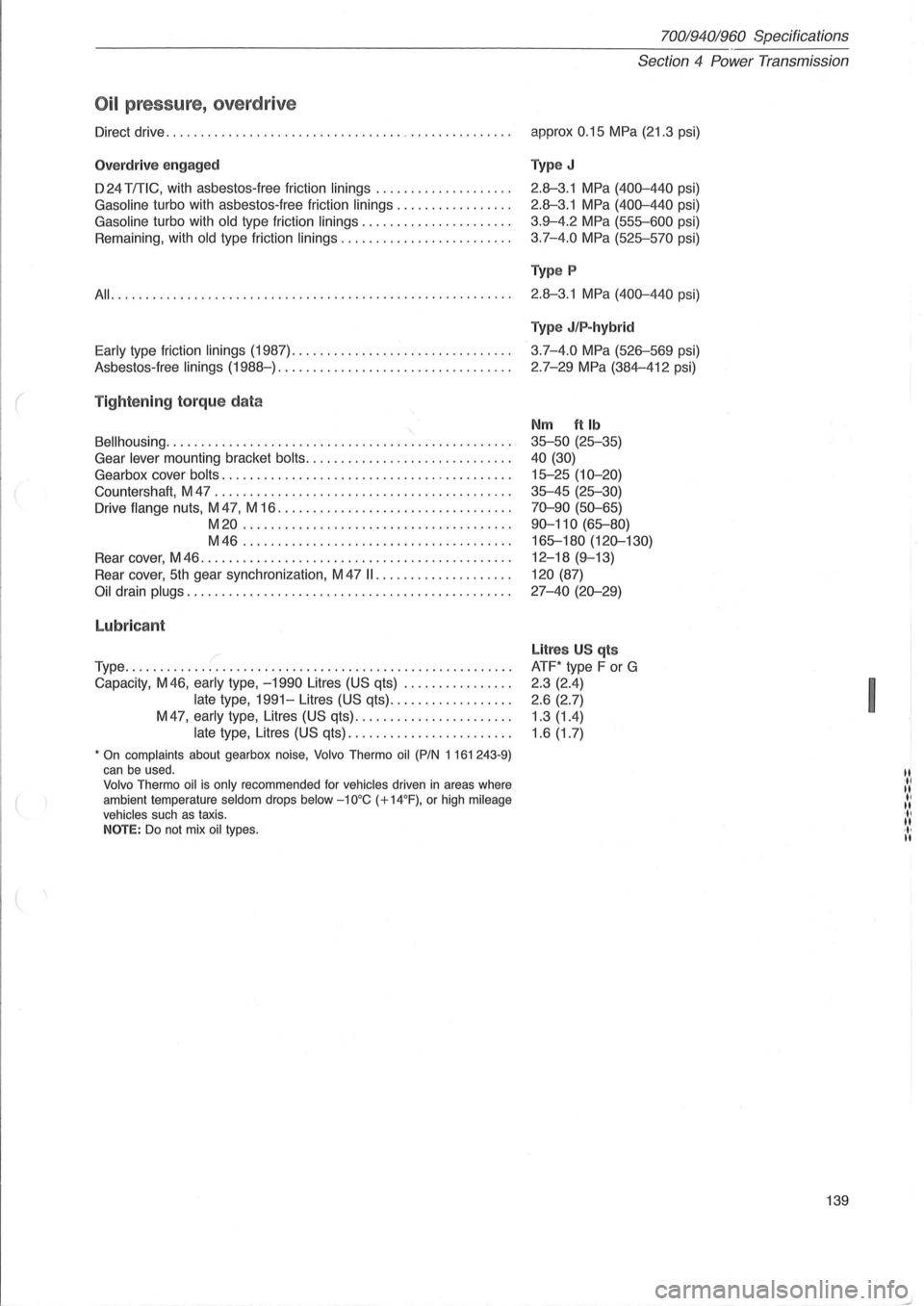

Oil pressure, overdrive

Direct drive .............................................. .. . .

Overdr ive engaged

D 24 TmC, with asbestos-free friction linings ................... .

Gasoline turbo with asbestos-free friction linings ................ .

Gasoline turbo with old type friction linings ..................... .

Remaining, with

old type friction linings ........................ .

All ......................................................... .

Early type friction linings (1987) ............................... .

Asbestos -

free linings (1988-) ................................. .

( Tightening torque data

8ellhousing ................................................. .

Gear

lever mounting bracket bolts ............................. .

Gearbox cover

bolts ......................................... .

Countershaft, M 47

.......................................... .

Drive

flange nuts, M 47, M 16 ................................. .

M20 ...................................... .

M46 ...................................... .

Rear cover, M 46

............................................ .

Rear cover,

5th gear synchronization, M 47 II ................... .

Oil drain plugs .............................................. .

Lubricant

/ Type ....................................................... .

Capacity, M46,

early type, -1990 Litres (US qts) ............... .

late type, 1991-Litres (US qts) ................. .

M

47, early type, Litres (US qts) ...................... .

late type, Litres (US qts) ....................... .

• On complaints about gearbox noise, Volvo Thermo oil (PIN 1161 243-9) can be used. Volvo Thermo oil is only recommended for vehicles driven in areas where

ambient temperature seldom drops below -10°C (+14°F), or high mileage vehicles such as taxis. NOTE: Do not mix oil types.

Section 4 Power Transmission

approx 0.15 MPa (21.3 psi)

Type J

2.8--3.1 MPa (400-440 psi)

2.8--3.1 MPa (400-440 psi)

3.9-4.2

MPa (555-600 psi)

3.7-4.0

MPa (525-570 psi)

Type P

2.8--3.1 MPa (400-440 psi)

Type J/P-hybrid

3.7-4.0 MPa (526-569 psi)

2.7-29

MPa (384-412 psi)

Nm ft Ib

35-50 (25-35)

40 (30)

15-25 (10-20)

35-45 (25-30)

70-90 (50-65)

90-110

(65-80)

165-180

(120-130)

12-18 (9-13)

120 (87)

27-40 (20-29)

Litres U S qts

ATF* type F or G

2 .3 (2.4)

2.6 (2.7)

1.3 (1.4)

1.6 (1.7)

139

I

.til I! II I! II I! ·1 , I!

Page 143 of 168

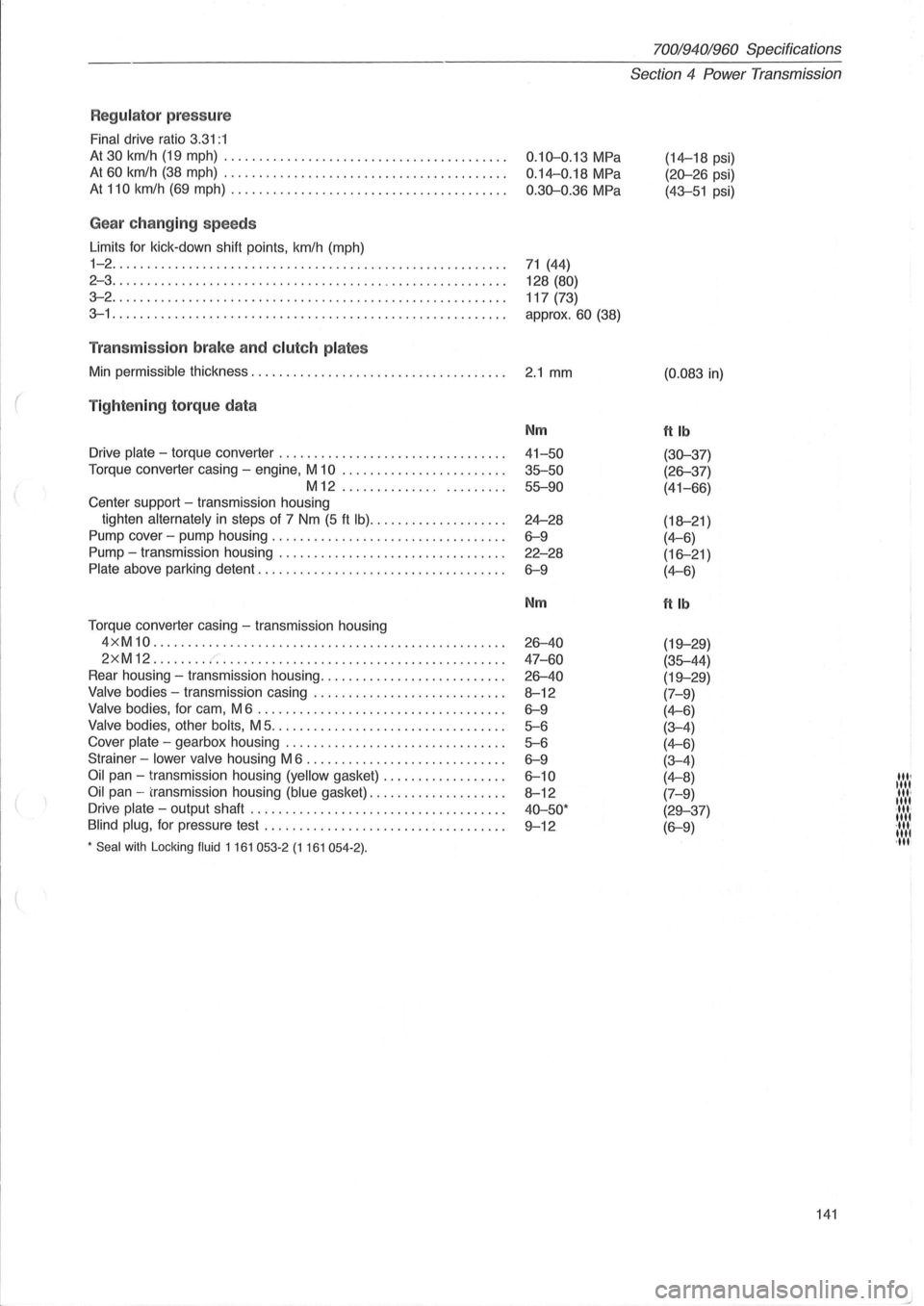

Regulator press ure

Final drive ratio 3.31:1

At 30 km/h (19 mph) ........................................ .

At 60 km/h (38 mph) ....... ................................. .

At 110 km/h (69 mph) ....................................... .

Gea r ch anging speeds

Limits for kick -down shift points , km/h (mph)

1-2 ........................................................ .

2 - 3

......... ............................................... .

3-2 ............................. ........................... .

3-1 ...................................................... .. .

Tran smiss io n brake an d clut ch pla tes

Min permissible thickness .................................. .. .

( Tig ht enin g to rq ue da ta

Drive plate - torque converter ....................... ......... .

Torque converter casing -engine, M

10 ....................... .

M12 ..................... ..

Center support -transmission housing

tighten

alternately in steps of 7 Nm (5 ft Ib) ................... .

Pump cover -pump housing

.................. ............... .

Pump -transmission housing ...

............................. .

Plate above parking detent ............................ .... ... .

Torque converter casing -transmission housing

4 x M

10 .................................................. .

2xM12 ....... . r. ............... ......................... .

Rear housing -transmission housing .......................... .

Valve bodies -transmission casing ........................... .

Valve bodies, for cam, M 6 ................................... .

Valve bodies, other bolis, M 5 ................................. .

Cover

plate - gearbox housing ............................... .

Strainer -

lower valve housing M 6 ......................... ... .

Oil pan - transmission housing (yellow gasket) ................. .

Oil pan -transmission housing (blue gasket) ................... .

Drive

plate - output shaft .... ............................. ... .

Blind plug, for pressure test ....................... .. ......... .

* Seal with Locking fluid 1 161 053-2 (1 161 054-2) .

0.10-0.13 MPa

0.14-0.18 MPa

0.30-0.36 MPa

71 (44)

128

(80)

117 (73)

approx.

60 (38)

2.1 mm

Nm

41-50

35-50 55-90

24-28

6-9

22-28

6-9

Nm

26-40

47 -60

26-40

8-12

6-9

5-6

5-6

6-9

6-10

8-12

40-50·

9-12

70019401960 Specifications

Section 4 Power Transmission

(14-18 psi)

(20-26 psi)

(43-51 psi)

(0.083 in)

ftlb

(30-37)

(26-37)

(41-66)

(18-21 )

(4-6)

(16-21)

(4-6)

ftlb

(19-29)

(35-44)

(19-29)

(7-9)

(4-6)

(3-4)

(4-6)

(3-4)

(4-8)

(7-9)

(29-37)

(6-9)

141

'", "" '", "" ·11"

"" ·11.· 1111 ,11'

Page 147 of 168

(

(

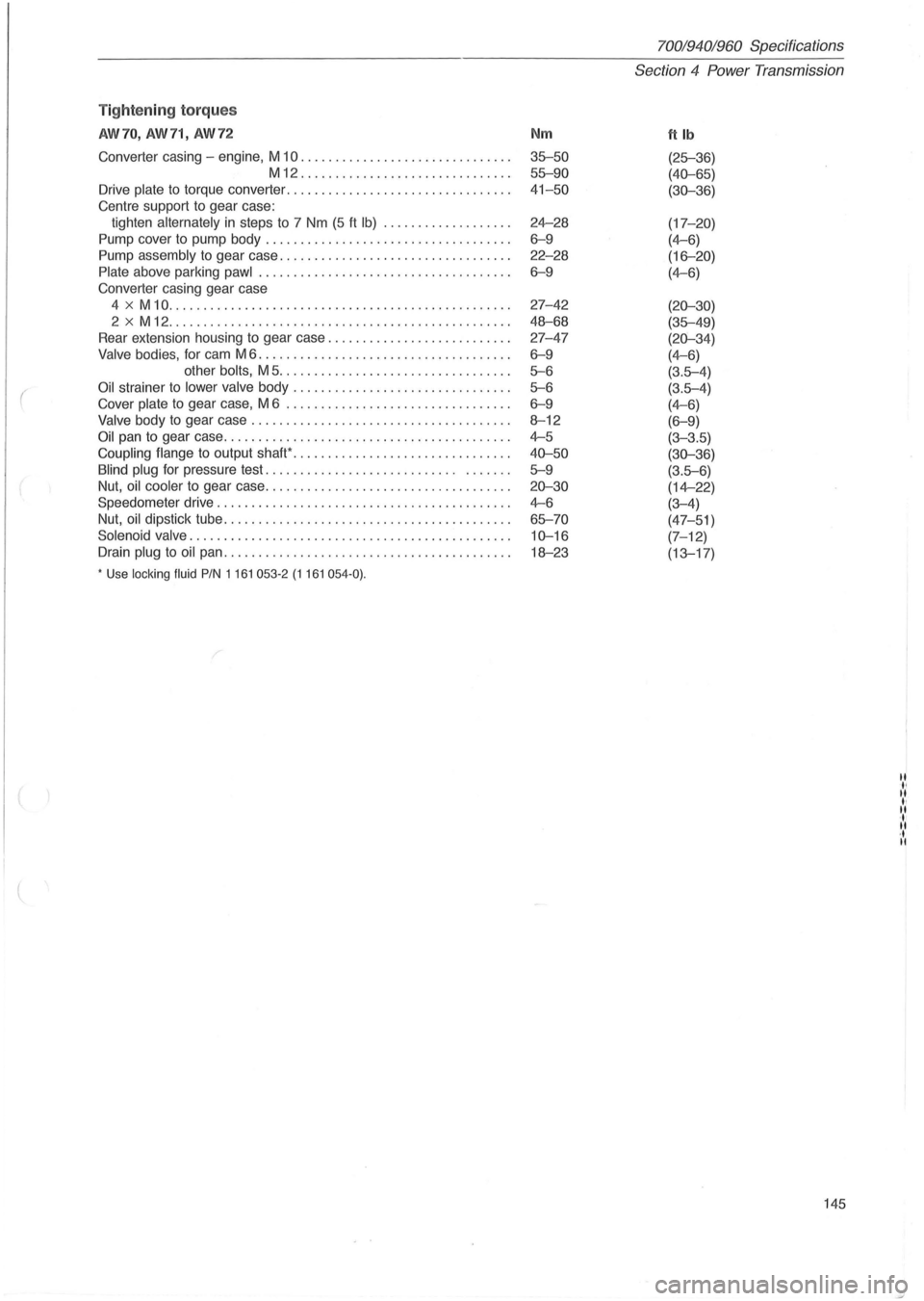

Tightening torques

AW70, AW71, AW72

Converter casing -engine, M 10 ...................... .. ...... .

M12 .................. ......... .. . .

Drive plate

to torque converter ................... ............. .

Centre support to gear case:

tighten alternately

in steps to 7 Nm (5 ft Ib) ............... ... .

Pump cover to pump body .......................... ......... .

Pump assembly to gear case .............. ................... .

Plate above parking pawl ............................. ....... .

Converter casing gear case

4

x M 10 ................................ ................. .

2 x M 12 ..

.............. ................................. .

Rear extension housing to gear case

.......................... .

Valve bodies, for cam M 6 .................................... .

other bolts, M 5 ...

.............................. .

Oil strainer to lower valve body ........... .. ............ ...... .

Cover plate

to gear case, M 6 ................................ .

Valve body to gear case ..................... .......... ..... . .

Oil pan to gear case .......... ........ ..................... .. .

Coupling flange

to output shaW .................... ........... .

Blind plug for pressure test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

... .

Nut, oil cooler to gear case .

.................................. .

Speedometer drive

................... .................. ..... .

Nut, oil dipstick tube

........ ................................. .

Solenoid valve

.................... .. ........................ .

Drain plug

to oil pan ........................................ . .

• Use locking fluid PIN 1161 053-2 (1161 054-0) .

Nm

35-50

55-90

41-50

24-28

6-9

22-28

6-9

27-42

48-68

27-47

6-9

5-6

5-6

6-9

8-12

4-5

40-50

5-9

20-30

4-6

65-70

10-16

18-23

70019401960 Specif ications

Section

4 Power Transmission

ftlb

(25-36)

(40-65)

(30-36)

(17-20)

(4-6)

(16-20)

(4-6)

(20-30)

(35-49)

(20-34)

(4-6)

(3.5-4)

(3.5-4)

(4-6)

(6-9)

(3-3.5)

(30-36)

(3.5-6)

(14-22)

(3-4)

(47-51)

(7-12)

(13-17)

145

II

" II ., II ' . .. • • ..

Page 163 of 168

(

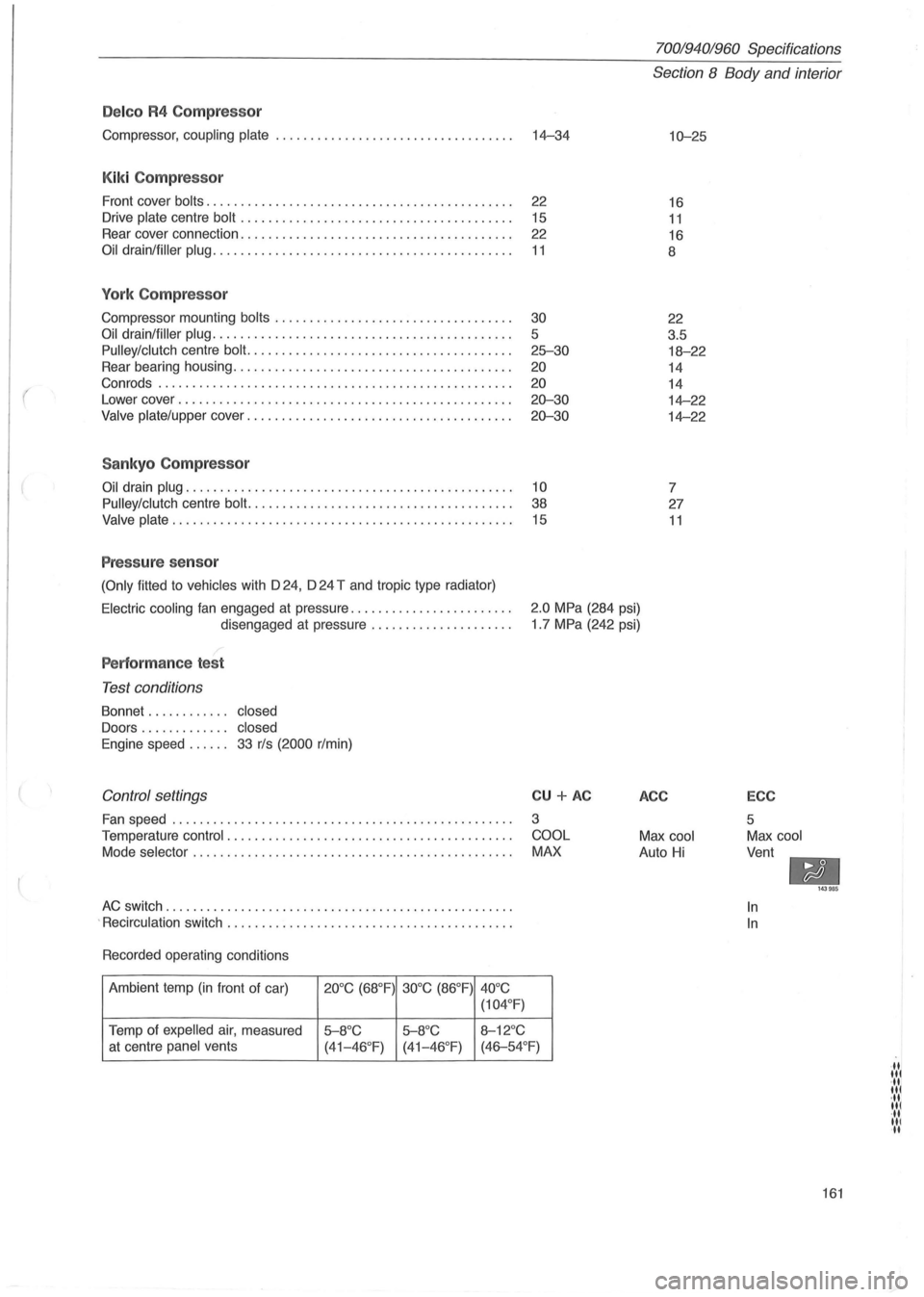

Delco R4 Compressor

Compressor, coupling plate ................................... 14-34

Kiki Compressor

Front cover bolts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Drive

plate centre bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rear cover connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

Oil drain/filler plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

York Compressor

Compressor mounting bolts ........................ .......... .

Oil drain/filler plug ........................................... .

Pulley/clutch centre bolt. ..................................... .

Rear bearing housing

.................................. ...... .

Con rods .

.................................................. .

Lower cover

........................................ .. ...... .

Valve plate/upper cover ...................................... .

Sankyo Compressor

30

5

25-30

20

20

20-30

20-30

Oil drain plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pulley/clutch

centre bolt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Valve plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure sensor

(Only fitted to vehicles with D 24, D 24 T and tropic type radiator)

70019401960 Specifications

Section 8 Body and interior

10-25

16

11

16

8

22

3.5

18-22

14

14

14-22

14-22

7

27

11

Electric cooling fan engaged at pressure ....................... .

disengaged at pressure

.................... .

2.0 MPa (284 psi)

1 .7 MPa (242 psi)

Performance test

Test conditions

Bonnet . . . . . . . . . . .. closed

Doors . . . . . . . . . . . .. closed

Engine

speed. . . . .. 33 r/s (2000 r/min)

Control settings

Fan speed ........................... ...................... .

Temperature

control . ................................. ....... .

Mode

selector . ............................................. .

AC switch ............. ..................................... .

.

Recirculation switch ......................................... .

Recorded operating conditions

Ambient temp

(in front of car) 20°C (68°F) 30°C (86°F)

40°C

(104 °

F)

Temp of expelled air, measured 5-8°C 5-8°C 8-12°C

CU + AC

3

COOL

MAX

at centre panel vents

(41-46°F) (41-46 °F) (46-54°F)

ACC

Max cool

Auto Hi

ECC

5

Max cool

Vent

-In

In

143985

161

·11 lit ·11 lit ·11 lit ·11 III II