weight VOLVO 960 1982 Service Repair Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 960, Model: VOLVO 960 1982Pages: 168, PDF Size: 54.28 MB

Page 7 of 168

(

70019401960 Specifications

Section

0 General

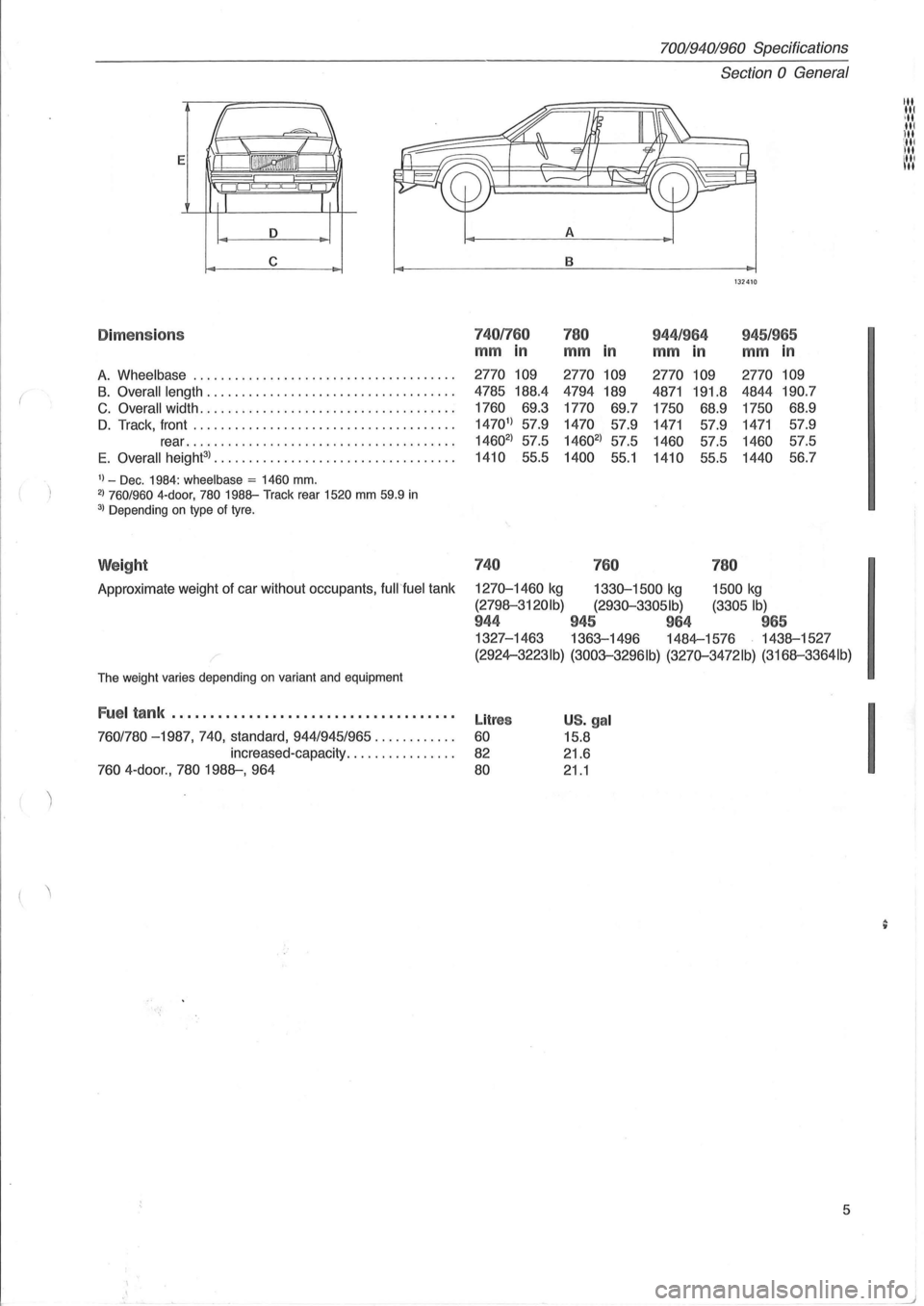

E

A

c B

132410

Dime ns io n s 7401760 780 944 /964 945/965

mm in mm in mm in mm in

A. Wheelbase .............................. . ...... . 2770 109 2770 109 2770

109 2770 109

B. Overall

length ................................... . 4785 188.4 4794

189 4871 191.8 4844 190.7

C. Overall width .................................... .

1760

69.3

1770 69.7

1750 68.9 1750 68.9

D. Track,

front ..................................... . 14701

) 57.9 1470 57.9 1471 57.9 1471 57.9

rear

................. ..................... . 14602

) 57.5 14602

) 57.5 1460 57.5 1460 57.5

E

. Overall height3

) ...... .........................•.•. 1410 55.5 1400 55.1 1410 55.5 1440 56.7

1) _ Dec. 1984: wheelbase = 1460 mm. 2) 760/960 4-door, 780 1988-Track

rear 1520 mm 59.9 in 3) Depending on type of tyre.

Weight 740

760 780

Approximate weight of car without occupants, fuWfuel tank 1270-1460 kg 1330-1500 kg 1500 kg

(2798-3120Ib) (2930-33051b) (3305 Ib)

944 945 964 965

1327-1463 1363-1496 1484-1576 1438-1527

,-(2924-3223Ib) (3003-3296Ib) (3270-3472lb) (3168-3364Ib)

The weight varies depending on variant and equipment

Fuel tank .................................... .

760/780 -1987,740, standard, 944/945/965 ........... .

increased-capacity

............... .

760 4 -door ., 780 1988-, 964

Litres

60

82

80

US. gal

15.8

21.6

21.1

5

I

Page 10 of 168

70019401960 Specifications

Section 0 General

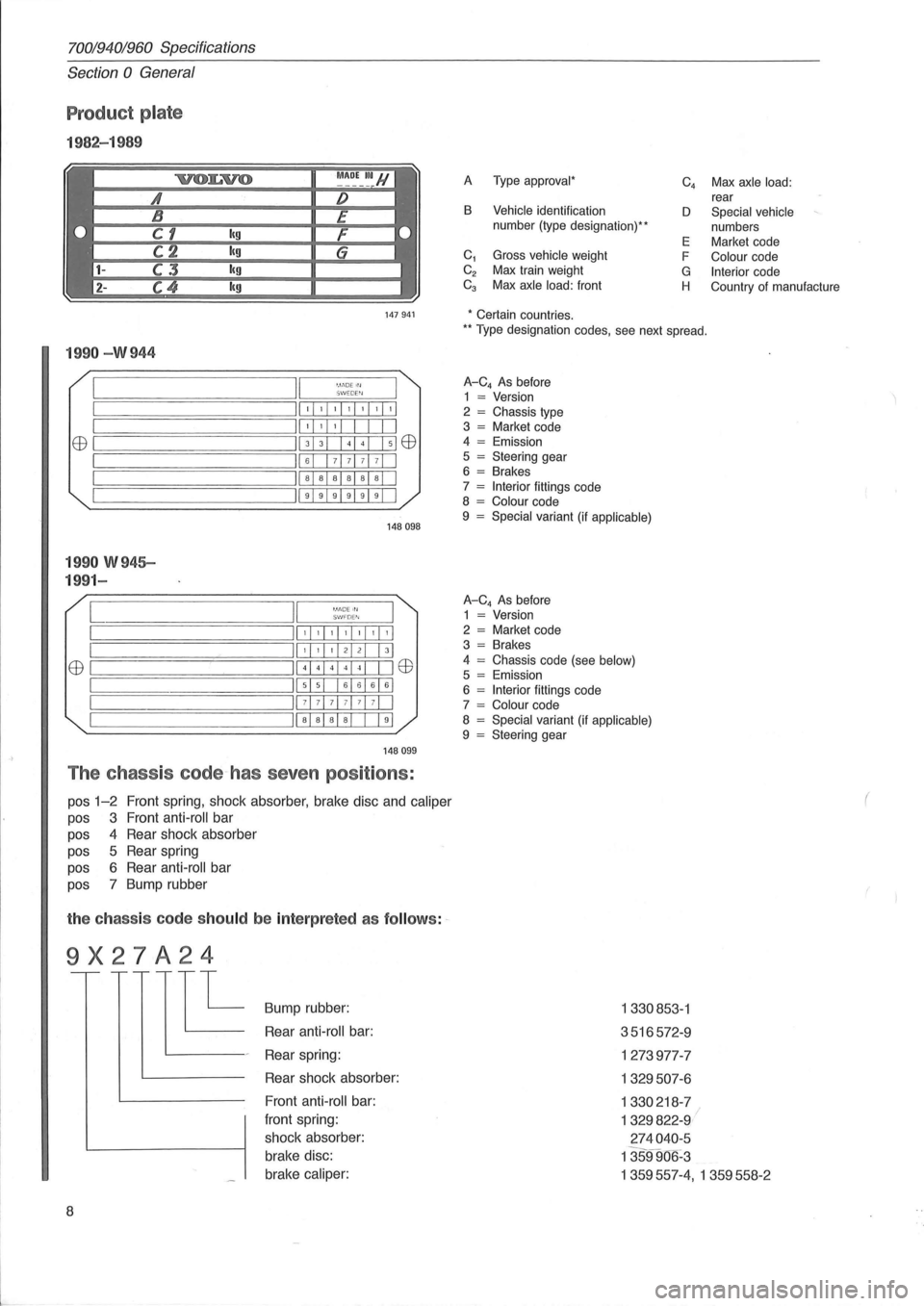

Product plate

1982-1 989

A Type approval *

B Vehicle identification

number (type designation) **

C

1 Gross vehicle weight

C

2 Max train weight Ca Max axle load: front C

4 Max axle

load: rear

D Special vehicle

numbers

E Market code

F

Colour code

G Interior code

H Country of manufacture

147941 * Certain countries.

199 0 -W 944

II '. 1.'DE Irl ~========:~===;:=:::;::;W::::,::::EW'::;:::::=r== ;==============ill, , , ,I, ,1'1 II' , , I I EEl ~===========;II 3 3 + El EEl

;==============ill 6 7 71 7 7 1 I II a a a al a al I ~===================; 11999919911

1 99 0 W 945-

199 1-

[ '.11'10E III S I.'/ FD E"I

148098

,I, ,1,1,1,1,1

EEl ~I ======== I

,I, ,I 21 21 I 31

41441414 1 I IEEl

515 161616161

71 7 7 1 71 71 71 I

Iiaia alai I 191

14 8099

The chass is code~has seven positions :

pos 1-2 Front spring, shock absorber, brake disc and caliper

pas 3 Front anti -roll bar

pas 4 Rear shock absorber

pas 5 Rear spring

pas 6 Rear anti -roll bar

pas 7 Bump rubber

the ch ass is code sh ould be inte rp reted as follow s: ~

9X27A24

E

8

Bump rubber:

Rear

anti -roll bar:

Rear spring:

Rear shock absorber:

Front

anti -roll bar:

front spring:

shock absorber:

brake disc:

brake

caliper:

** T ype designation codes, see next spread.

A-C4 As before

1 = Version

2 = Chassis type

3 = Market code

4 = Emission

5 = Steering gear

6 = Brakes

7 = Interior fittings code

8 = Colour code

9 = Special variant (if applicable)

A-C4 As before

1 = Version

2 = Market code

3 = Brakes

4

= Chassis code (see below) 5 = Emission

6 = Interior fittings code

7 = Colour code

8 = Special variant (if applicable) 9 = Steering gear

1330853 -1

3516572 -9

1273977-7

1329507 -6

1330218 -7

1329822-9 I

2 74040 -5

1359906 -3

1359557-4, 1359558- 2

(

Page 17 of 168

70019401960 Specifications

Section 2 B 19, B 23 Engines

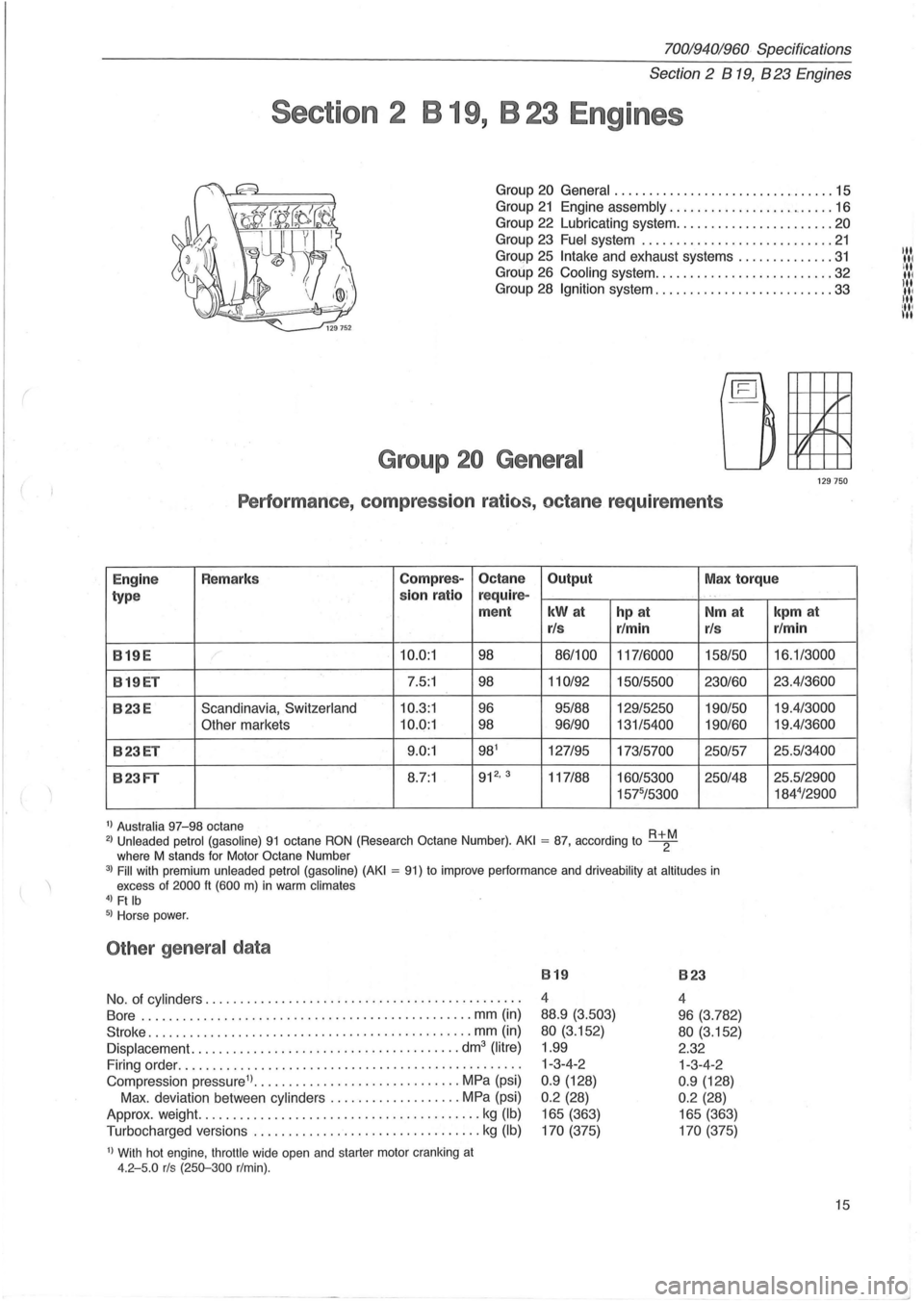

Section 2 B 19, B 23 Engines

Group 20 General ................................ 15

Group

21 Engine assembly ........................ 16

Group 22 Lubricating system

....................... 20

Group 23 Fuel system ............................ 21

Group 25 Intake and exhaust systems .............. 31

Group 26 Cooling system .......................... 32

Group 28

Ignition system .......................... 33

j'"

I.t

Group 20 General ~ :,

129750

Performance , compression ratios, octane requirements

Engine Remarks Compres-Octane

Output Max torque

type sion

ratio r

equire-

ment

kWat hp at

r/s r/min

819E 10.0:1 98 86/100

117/6000

819ET 7.5:1 98 110/92

150/5500

823E Scandinavia, Switzerland 10.3:1 96 95/88 129/5250

Other markets 10.0:1 98 96/90 131/5400

823ET 9.0:1 981 127/95 173/5700

823FT 8.7:1 912

• 3 117/88 160/5300

1575/5300

1) Australia 97-98 octane 2) Unleaded

petrol (gasoline) 91 octane RON (Research Octane Number). AKI = 87, according to R+2M where M stands for Motor Octane Number

. "

Nm at

r/s

158/50

230/60 190/50

190/60

250/57

250148

3) Fill with premium unleaded petrol (gasoline) (AKI = 91) to improve performance and driveability at altitudes in excess of 2000 It (600 m) in warm climates 4) Ft Ib 5) Horse power.

Other general data

No. of cylinders ............................................. .

Bore .

............................................. .. mm (in)

Stroke ..

.... ......................................... mm (in)

Displacement. ...................................... dm3 (litre)

Firing order ................................................. .

Compression pressure1) ..

............................ MPa (psi)

Max . deviation between

cylinders ................... MPa (psi)

Approx. weight.

............... ........... ..... ......... kg (Ib)

Turbocharged versions ................................. kg (Ib)

1) With hot engine, throttle wide open and starter motor cranking at 4.2-5.0 rls (250-300 r/min).

819

4

88.9

(3.503)

80 (3.152)

1.99

1-3-4-2

0.9 (128)

0 .2 (28)

165 (363)

170 (375)

823

4

96 (3.782)

80 (3.152)

2.32 1-3-4-2

0 .9 (128)

0 .2 (28)

165 (363)

170 (375)

kpm at

r/min

16.1/3000

23.4/3600

19.4/3000

19.4/3600

25.5/3400

25.5/2900 184

4/2900

15

Page 18 of 168

70019401960 Specifications

Section 2 B 19, 823 Engines

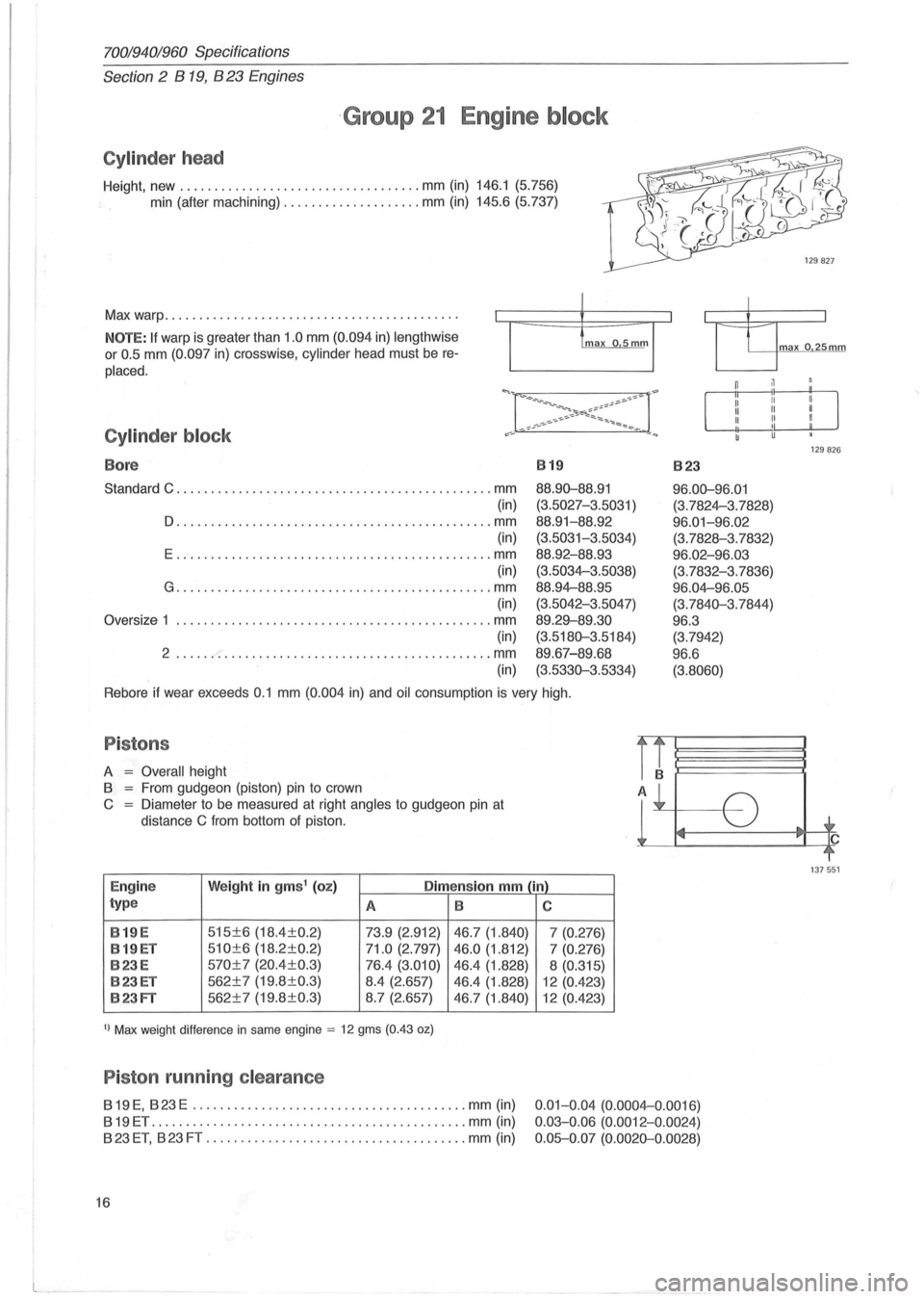

Group 21 Engine block

Cylinder head

Height, new ................................... mm (in) 146.1 (5.756)

min (after machining)

.................... mm (in) 145.6 (5.737)

Max warp ..

.. ..................................... . .

NOTE: If warp is greater than 1 .0 mm (0.094 in) lengthwise

or 0 .5 mm (0.097 in) crosswise, cylinder head must be re

placed.

Cylinder block

Bore 819 823

Standard C ............................................ .. mm

(in)

D .............................................. mm (in)

E .............................................. mm

(in)

G ........................................... . .. mm

(in)

Oversize 1

...................................... .... .... mm

(in)

2 ..... . -:-......................... ....... ....... mm

(in) 88.9D-88

.

91

(3.5027-3 .5031 )

88 .

91-88.92

(3.5031-3.5034)

88.92 -88.93

(3.5034-3.5038)

88.94-88.95

(3.5042-3.5047)

89 .29-89.30

(3.518D-3 .5184)

89.67-89.68

(3. 533D-3 .5334)

96 .0D-96.01

(3.7824-3. 7828)

96 .01-96.02

(3.7828-3.7832)

96 .02-96.03

(3.7832-3.7836)

96 .04-96.05

(3.7 84D-3 .7844)

96.3

(3.7 942)

96 .6

(3.8060)

Rebore if wear exceeds 0.1 mm (0.004 in) and oil consumption is very high.

Pistons

A = Overall height

8

= From gudgeon (piston) pin to crown

C = Diameter to be measured at right angles to gudgeon pin at

distance

C from bottom of piston.

Engine Weight in gms1 (oz) Dimension mm (in)

type A 8

8 19 E

515±6 (18.4±0.2)

73.9 (2.912) 46.7 (1.840)

8 19

ET 510±6 (18.2±0.2) 71.0 (2.797) 46.0 (1.812)

823E 570±7 (20.4±0.3) 76.4 (3.010) 46.4 (1.828)

823ET 562±7 (19.8 ±0.3) 8.4 (2.657)

46.4 (1.828)

823FT 562±7 (19.8±0.3) 8.7 (2.657)

46.7 (1.840)

1) Max weight difference in same engine = 12 gms (0.43 oz)

Piston running clearance

819 E, 823 E ........................................ mm (in)

819ET .............................................. mm (in)

823 ET, 823 FT ...................................... mm (in)

16

C

7 (0.276)

7 (0.276)

8 (0.315)

12 (0.423)

12 (0.423)

0.01- 0 .04 (0.0004-0.0016)

0 .03- 0.06 (0.0012-0 .0024)

0 .05-0.07 (0.002D-0 .0028)

J

ma x o 25mm

129826

137551

Page 21 of 168

(

70019401960 Specifications

Section 2 B 19, B 23 Engines

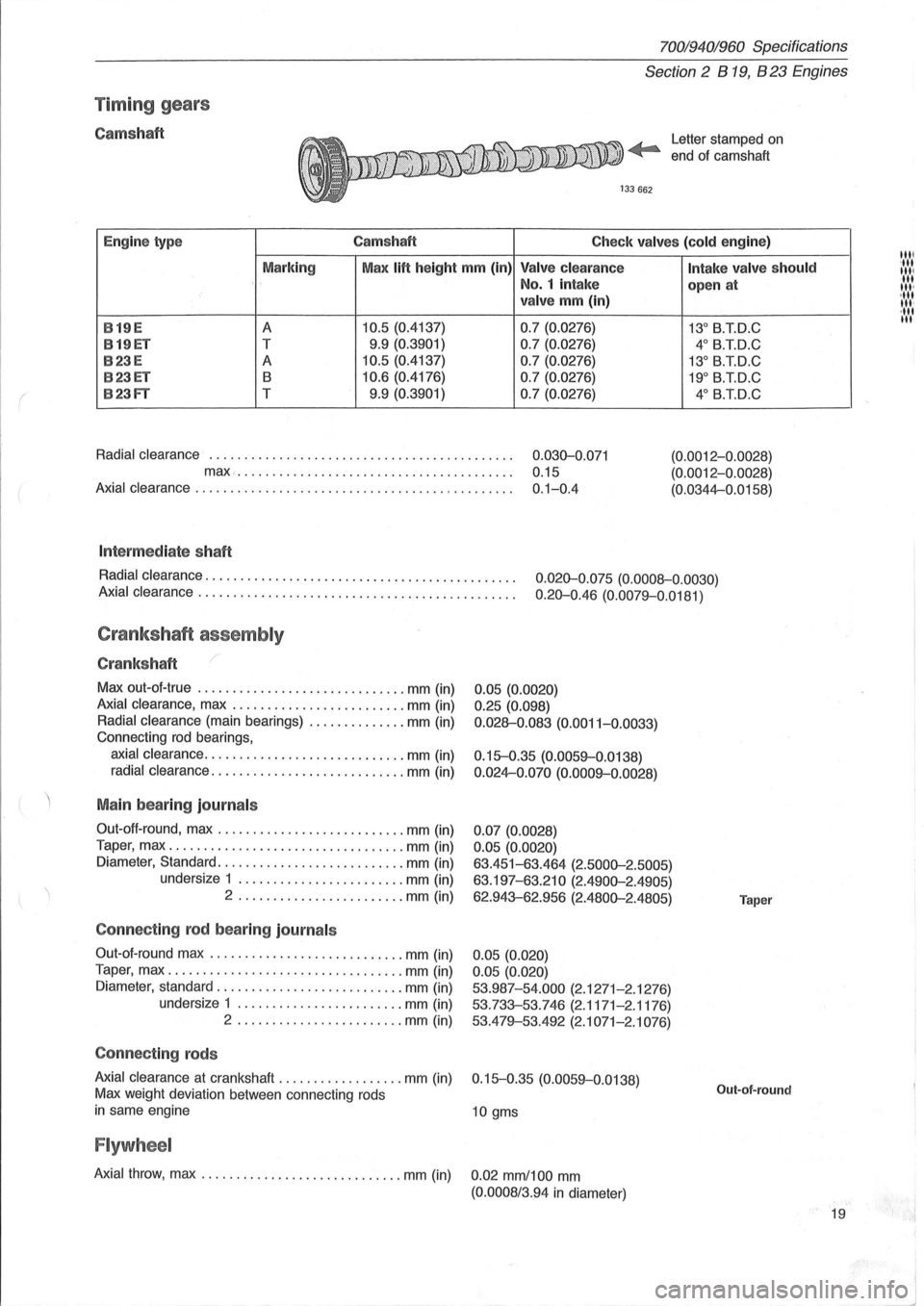

Timin g gears

Camshaft Letter stamped on

end ot camshaft

Engine type Camshaft

Check valves (cold engine)

Marking Max

lift height mm (in) Valve clearance

No.1 intake

valve mm (in)

B

19E A 10.5 (0.4137) 0.7 (0.0276)

B19ET T 9.9 (0.3901)

0.7 (0.0276)

B23E A 10.5 (0.4137) 0.7 (0.0276)

B23ET B 10.6 (0.4176) 0.7 (0.0276)

B23FT T 9.9 (0.3901)

0.7 (0.0276)

Radial clearance

............................................ 0.030-0 .071

max... . .... ... ............................... 0.15

Axial clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1-0.4

Int ermed iate shaft

Intake valve should

open at

13° B.T.D.C

4° B.T.D.C

13° B.TD.C

19° B.TD.C

4° B.iD.C

(0.0012-0 .0028)

(0.0012-0.0028)

(0.0344-0.0158)

Radial clearance.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.020-0.075 (0.0008-0.0030)

Axial clearance .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20-0.46 (0.0079-0.0181)

Crankshaft assembly

Crankshaft

Max out-ot-true .............................. mm (in)

Axial clearance, max ......................... mm (in)

Radial clearance (main bearings) .............. mm (in)

Connecting

rod bearings,

axial clearance ............................. mm (in)

radial clearance ............................ mm (in)

Main bearing journals

Out-oft-round, max ........................... mm (in)

Taper, max

.................................. mm (in)

Diameter, Standard .

.......................... mm (in)

undersize 1

........................ mm (in)

2 .

................ ....... mm (in)

Connecting rod bear ing journ als

Out-ot- round max ............................ mm (in)

Taper, max

.................................. mm (in)

Diameter, standard

........................... mm (in)

undersize 1

........................ mm (in)

2 ........................ mm (in)

Connecting rods

0.05 (0.0020)

0.25 (0.098)

0 :028-0.083 (0.0011-0.0033)

0.15-0.35 (0.0059-0.0138)

0 .024-0.070 (0.0009-0.0028)

0.07 (0.0028)

0.05 (0.0020)

63.451-63.464 (2.5000-2.5005)

63.197-63.210 (2.4900-2.4905)

62.943-62.956 (2.4800-2.4805)

0.05 (0.020)

0.05 (0.020)

53.987-54.000

(2.1271-2.1276)

53.733-53.746 (2.1171-2.1176)

53.479-53.492

(2.1071-2.1076)

Axial clearance

at crankshaft .................. mm (in) 0.15-0.35 (0.0059-0.0138)

Max weight deviation between connecting rods

in same engine 10 gms

Flywheel

Axial throw, max ............................. mm (in) 0.02 mm/100 mm

(0.0008/3.94 in diameter)

Taper

Out-of-round

19

1111 :111

111/ III III '

, III

III '

·111 III

"1

I

~J

Page 38 of 168

70019401960 Specifications

Section 2 B 200, B 230 Engines

Other General Data

Number of cylinders ......................................... .

80re .................................................... mm

Stroke .................................................. mm

Displacement. ..................................... dm3 (litres)

Firing order ................................................. .

Compression pressure

.............................. MPa (psi)

Max deviation between

cylinders ................... MPa (psi)

Weight

.................... ..................... .......... kg

(Ib)

B200

B204

4 88.9

80

B230

B234

4

96

80

2.32 1-3-4-2

0.9 (128)

0.2 (28)

140-150

(308-330)

with turbocharger .................................... kg

1.99

1-3-4-2

0.9 (128)

0.2 (28)

140-150

(308-330)

165 (363) 160-165 (352-363)

1) With hot engine throttle wide open and starter motor cranking at 4.2-5.0 rls (250-300 r/min).

Cylinder block

Bore

Group 21 Engine block

Standard, C ............................................. mm

(in)

o .... ............ ..................... ........ mm

(in)

E

.... ......................................... mm

(in)

G .

............................................ mm

(in)

Oversize

1 .......... . ........... ........................ mm

(in)

2 ............ -.................................. mm

(in)

B200

88.90-88.91

(3.5027-3.5031 )

88.91-88.92

(3.5031-3.5034)

88.92-88.93

(3.5034-3 .5038)

88.94-88.95

(3.5042-3.5047)

89.29-89.30

(3.5180-3.5184)

89 .

67-89.68

(3.5303)

Rebore if wear exceeds 0.1 mm (0.004 in) and oil consumption is very high.

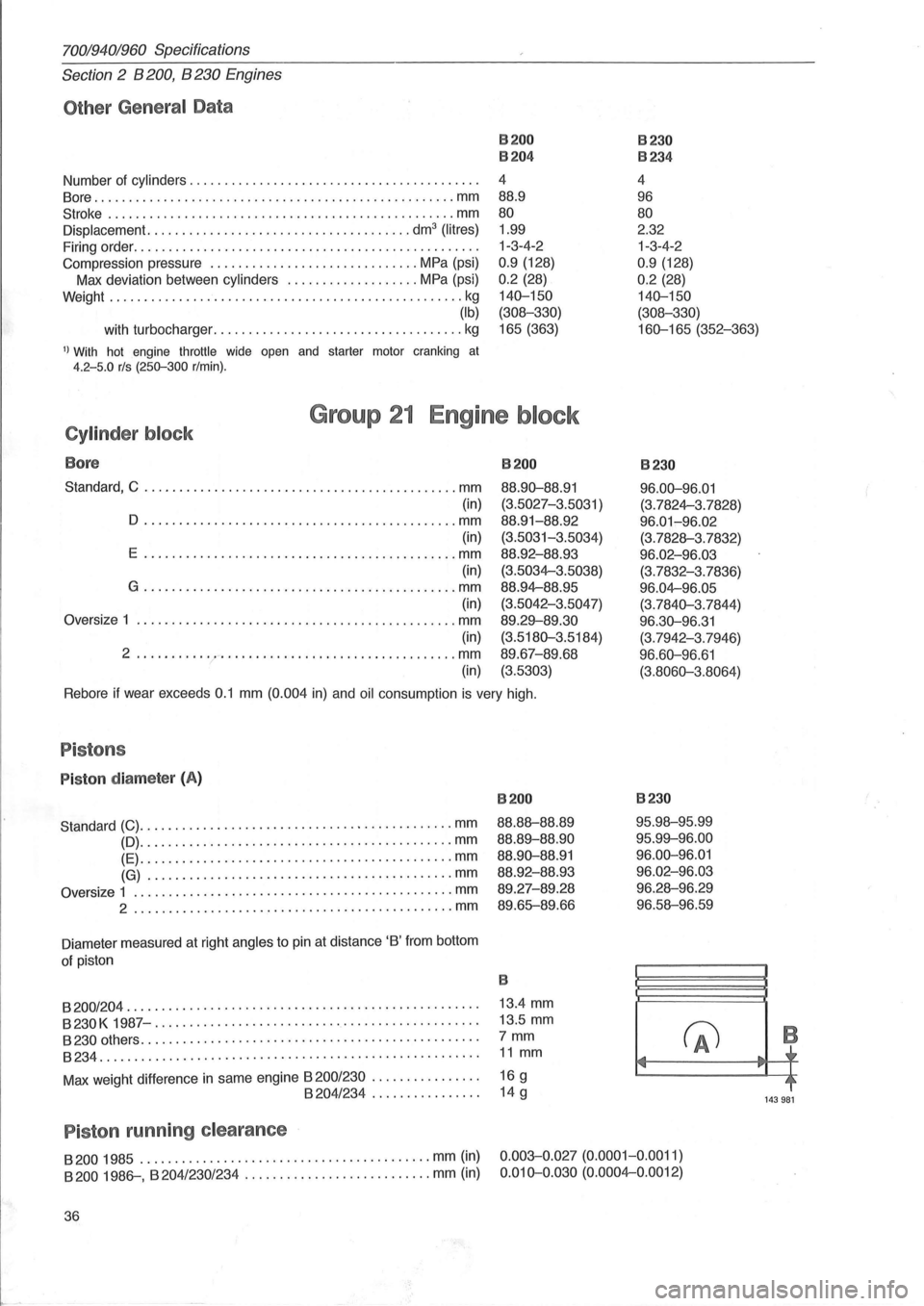

Pistons

Piston diamete r (A)

Standard (C) ............................................. mm

(D) ............................................. mm

(E)

....................................... ...... mm

(G) ........ .................................... mm

Oversize 1 .............................................. mm

2 ................................ ······· ·······mm

Diameter measured at right angles to pin at distance 'B' from bottom

of piston

B200

88.88-88.89

88.89-88.90

88.90-88.91

88.92-88.93

89.27-89.28

89.65--89 .66

B

8200/204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.4 mm

B230K 1987-..... ...... ................. ................... 13 .5 mm

8230 others. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 mm

8234....................................................... 11 mm

Max weight difference in same engine 8200/230 . . . . . . . . . . . . . . . . 16 g 8204/234 ................ 14 g

P iston running clearance

B230

96.00-96.01

(3.7824-3.7828)

96.01-96.02

(3.7828-3.7832)

96.02-96.03

(3.7832-3.7836)

96.04-96.05

(3.7840-3.7844)

96.30-96.31 (3.7942-3.7946)

96.60-96.61

(3.8060-3.8064)

B230

95.98-95.99

95.99-96.00

96.00-96.01 96.02-96.03

96.28-96.29

96.58-96.59

(fJ .... .,

8200 1985 .......................................... mm (in)

8200 1986--, B 204/230/234 ..... ...................... mm (in)

0.003-0.027 (0.0001-0.0011)

0.010-0.030 (0.0004-0.0012)

36

... -,.

B

~r

~~

143981

Page 43 of 168

(

70019401960 Specifications

Section

2 B 200, B 230 Engines

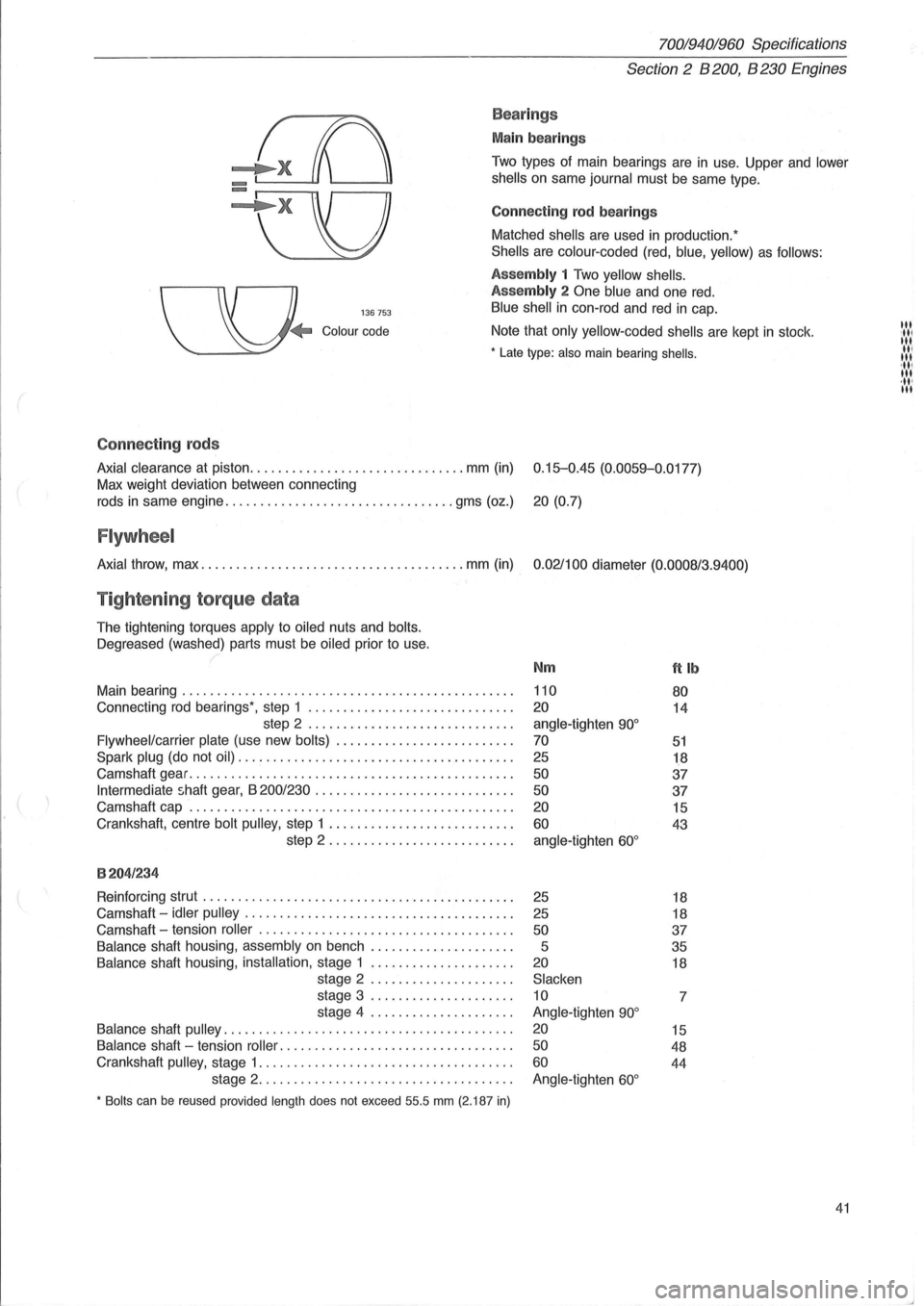

Bea rings

Main bearings

Two types of main bearings are in use. Upper and lower

shells

on same journal must be same type.

Connect

ing rod bearings

Matched

shells are used in production:

Shells are colour -coded (red, blue, yellow) as follows:

136753

Assembly 1 Two yellow shells.

Assembly

2 One blue and one red.

Blue shell in con-rod and red in cap.

Colour code Note that only yellow-coded shells are kept in stock .

• Late type: also main bearing shells .

Connect ing rods

Axial clearance at piston ............................... mm (in) 0.15-0.45 (0.0059-0.0177)

Max weight deviation between connecting

rods

in same engine ................................. gms (oz.) 20 (0.7)

Flywheel

Axial throw, max ...................................... mm (in) 0.021100 diameter (0.0008/3.9400)

Tightening torque data

The tightening torques apply to oiled nuts and bolts.

Oegreased

(washed) parts must be oiled prior to use.

Main bearing

............................................... .

Connecting

rod bearings', step 1 ............................. .

step 2

............................. .

Flywheel/carrier plate (use new bolts) ...................... ... .

Spark plug (do not oil) ....................................... .

Camshaft gear

.............................................. .

Intermediate shaft gear, B 200/230 ............................ .

Camshaft cap

.............................................. .

Crankshaft, centre

bolt pulley, step 1 .......................... .

step 2 .

.. ....................... .

8204/234

Reinforcing strut ............................................ .

Camshaft -

idler pulley ...................................... .

Camshaft -tension

roller .................................... .

Balance shaft housing, assembly on bench .................... .

Balance shaft housing, installation, stage 1 .................... .

stage 2

.................... .

stage 3

.................... .

stage 4

.................... .

Balance shaft pulley ......................................... .

Balance shaft -tension roller .. ............................... .

Crankshaft

pulley, stage 1 .................................... .

stage 2

.................................... .

• Bolts can be reused provided length does not exceed 55.5 mm (2.187 in)

Nm

110

20

angle-tighten 90°

70

25

50

50

20

60

angle-tighten 60°

25

25

50

5

20

Slacken

10

Angle-tighten

90°

20

50

60

Angle-tighten 60°

ftlb

80

14

51

18

37

37

15

43

18

18

37

35

18

7

15

48

44

41

III :11' III II, III 'III III ,11' III

Page 71 of 168

70019401960 Specifications

Section

2 B 28 Engine

Section 2 B 28 Engine

Group 20 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 69

Group 21 Engine................................ 70

Group 22 Lubricating system ...................... 74

Group 23 Fuel system ............ . . . . . . . . . . . . . .. 75

Group 25

Intake and exhaust systems ............. 82

Group 26 Cooling system ......................... 83

Group 28

Ignition system. . . . . . . . . . . . . . . . . . . . . . . .. 84

129756

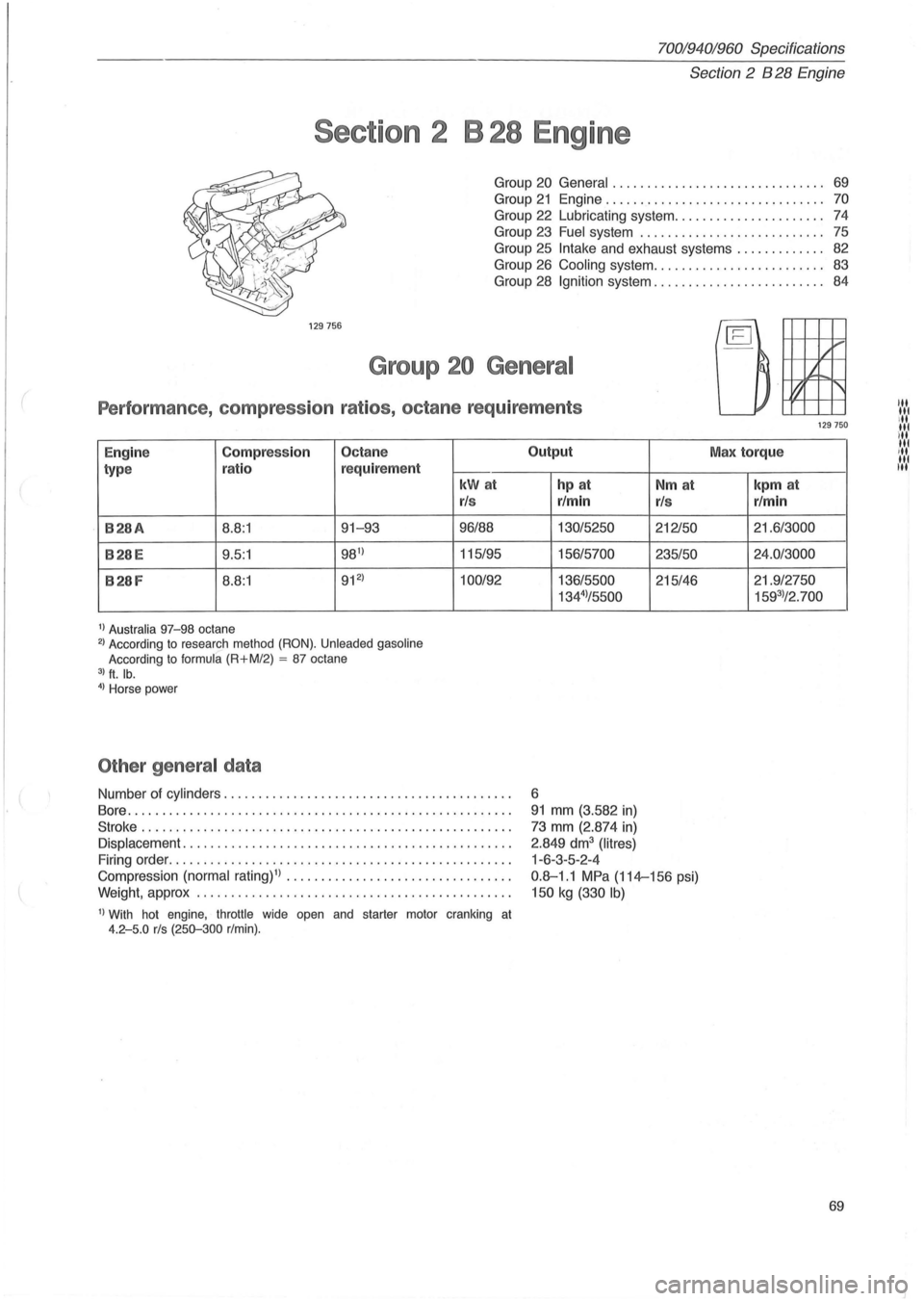

Group 20 General

Performance, compression ratios, octane requirements

E ngine Compression Octane

type ratio r

eq

uirement

B28A 8.8:1 91-93

B28E 9 .5 :1 981

)

B28F 8.8 :1 912

)

1) Australia 97-98 octane 2) According to research method (RON). Unleaded gasoline

According to formula (R+M/2) = 87 octane 3) ft. lb. 4) Horse power

Other general data

kWat

rl s

96/88

115/95

100/92

Number of cylinders ......................................... .

Bore

.............. ......................................... .

Stroke ................ " ................................... .

Displacement ............................................... .

Firing order

................................................. .

Compression

(normal rating)l) ........................... ..... .

Weight, approx

................ ............................. .

I) With hot engine, throttle wide open and starter motor cranking at 4.2-5.0 rls (250-300 r/min).

Output

hp at

r/min

130/5250

156/5700

136/5500

134

4)/5500

6

91 mm (3.582 in)

73 mm (2.874 in)

2 .849 dm3 (Iitres)

1-6-3-5 -2-4

Nm at

rl s

212150

235/50

215/46

0.8-1 .1 MPa (114-156 psi)

150 kg (330 Ib)

/ ......

l.t

~ '

129750

Max torque

kpm at

r/min

21.6/3000

24.0/3000

21. 9/2750

1593)/2. 700

69

"' '" ill

,' ....

N,'

'" III

Page 72 of 168

70019401960 Specifications

Section'-2" B 28 Engine

Group 21 Engine block

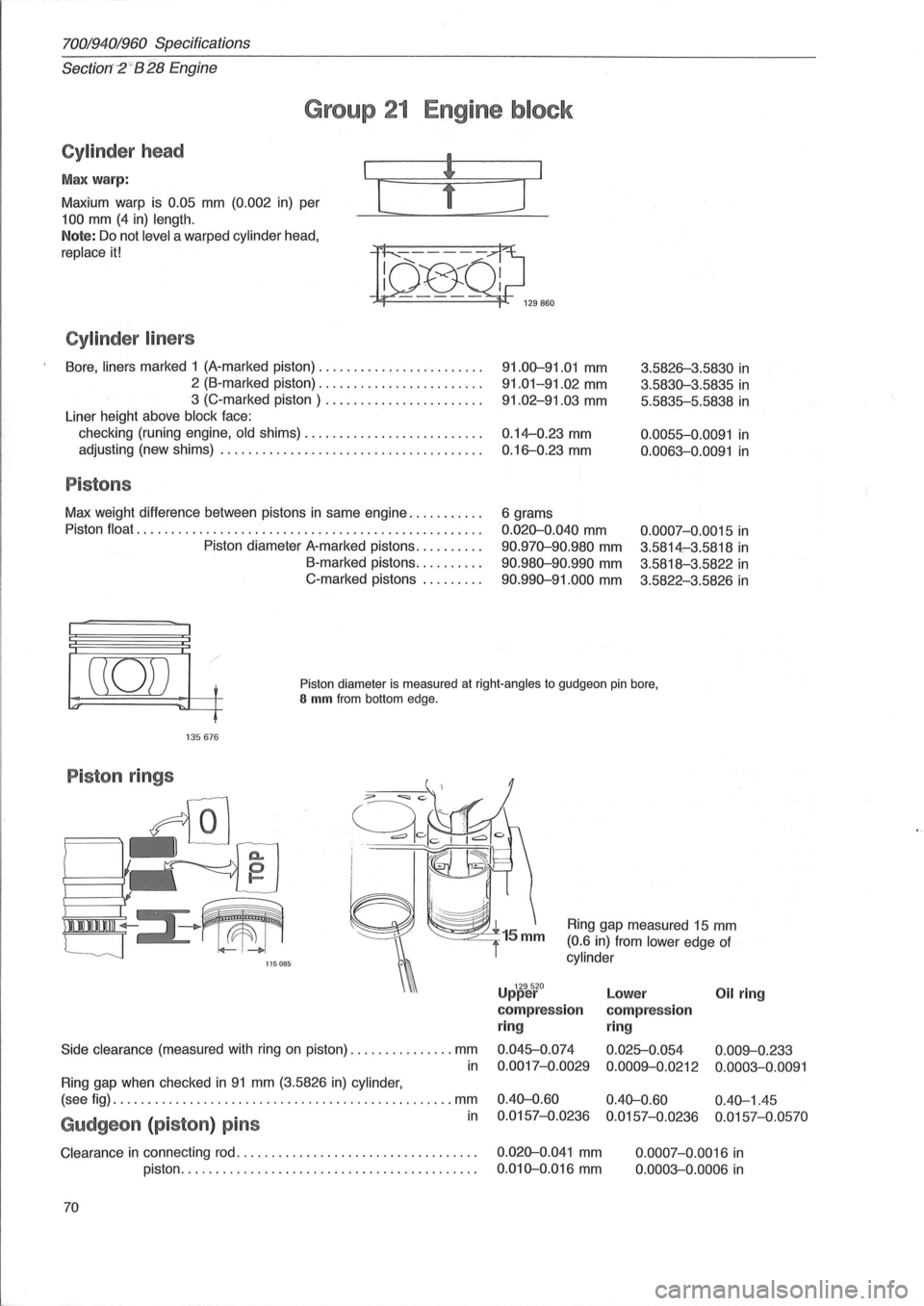

Cylinder head

Max warp:

Maxium warp is

0.05 mm (0.002 in) per

100 mm (4 in) length.

Note: Do not level a warped cylinder head,

replace it!

Cylinder liners

[

Bore, liners marked 1 (A-marked piston) ....................... .

2 (B-marked piston) ....................... .

3 (C-marked piston) ...................... .

Liner height above

block face:

checking (runing engine,

old shims) ....................... .. .

adjusting (new shims)

..................................... .

Pistons

Max weight difference between pistons in same engine .......... .

Piston

float ................................................. .

Piston diameter A-marked pistons

......... .

B-marked pistons

......... .

C-marked pistons

........ .

]

91.00-91.01 mm

91.01-91.02 mm

91.02-91.03 mm

0.14--0.23 mm

0.16-0.23 mm

6 grams

0.020-0.040 mm

90.970-90.980 mm

90.980-90.990 mm

90.990-91.000 mm

3.5826-3.5830 in

3.5830-3.5835 in

5.5835-5.5838 in

0.0055-0.0091 in

0.0063-0.0091 in

0.0007-0. 0015 in

3.5814-:3.5818 in

3.5818-3.5822 in

3.5822-3.5826 in

((0)) t

'" ~L-f

Piston diameter is measured at right-angles to gudgeon pin bore, S mm from bottom edge.

135676

Piston rings

/,

I 111111111 ~III

'--J 115085

Side clearance (measured with ring on piston) ............... mm

in

Ring gap when checked in 91 mm (3.5826 in) cylinder,

Ring gap measured 15 mm

(0.6 in) from lower edge of

cylinder

U 129520 pper

compression

ring

0.045-0.074

0.0017-0.0029

Lower Oil ring

compression

ring

0.025-0.054 0.009--0.233

0.0009--0.0212 0.0003-0.0091

(see fig) ................................................. mm 0.40-0.60 0.40-0.60 0.40-1.45

in 0.0157-0.0236 0.0157-0.0236 0.0157-0.0570 Gudgeon (piston) pins

Clearance in connecting rod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.020-0.041 mm

piston. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.010-0.016 mm

70 0.0007-0.0016

in

0.0003-0.0006 in

Page 75 of 168

{

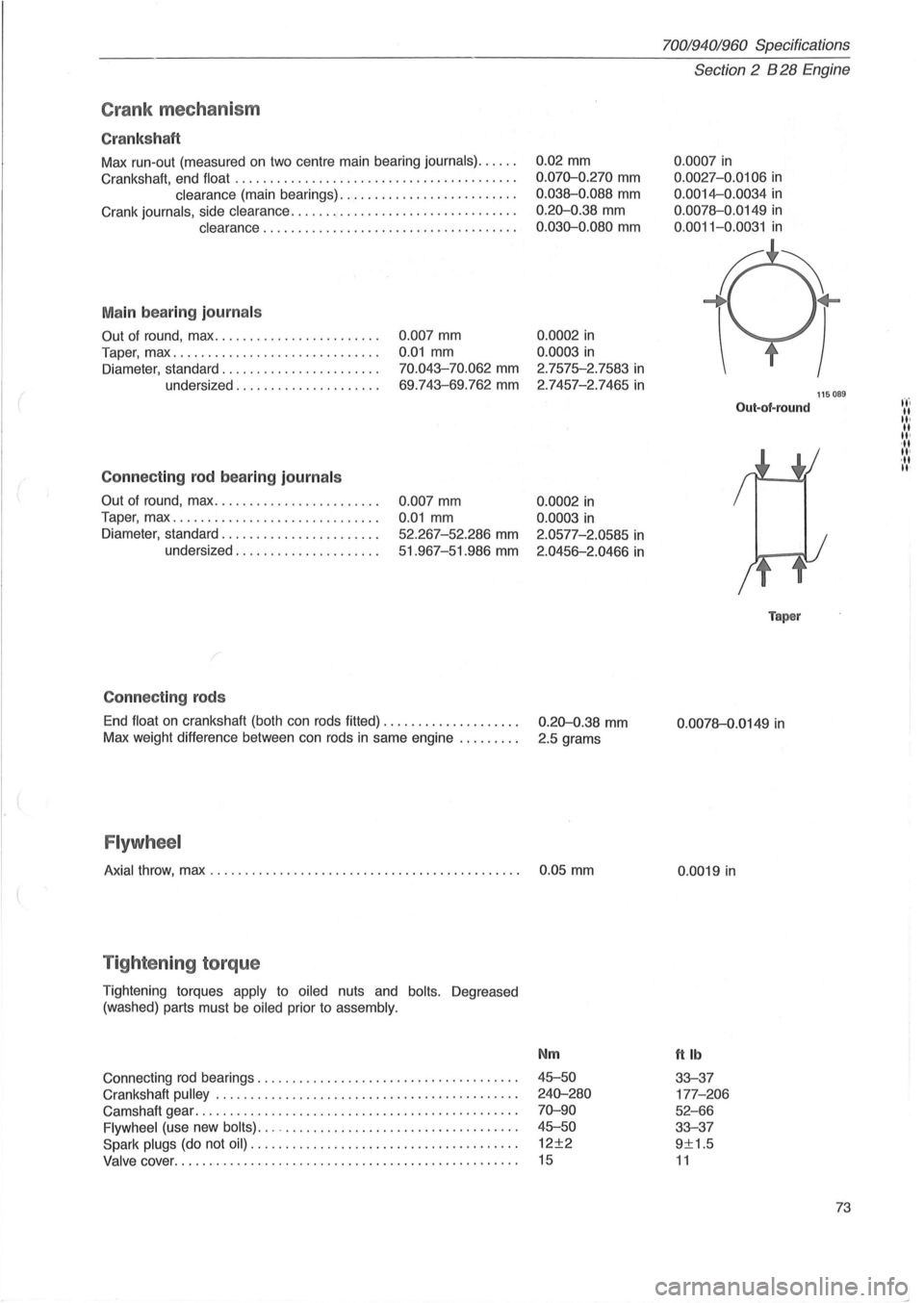

Crank mec ha ni sm

Cr ank sh aft

Max run-out (measured on two centre main bearing journals) ..... .

Crankshaft, end float

........................................ .

clearance (main bearings) ......................... .

Crank

journals, side clearance ...........•.................... .

clearance .................................... .

M ain bea rin g journ als

Out of round, max ....................... .

Taper, max

...... ....................... .

Diameter, standard ...

................... .

undersized

.................... .

Conne cting rod b ea ring journ als

Out of round, max ....................... .

Taper, max

............................. .

Diameter, standard

...................... .

undersized

.................... .

C onnec tin g rods

0 .007 mm

0.01 mm

70.043-70.062 mm

69 .743-69.762 mm

0.007 mm

0.01 mm

52.267-52 .286 mm

51.967-51.986 mm

End

float on crankshaft (both can rods fitted) ................... .

Max weight difference between can rods

in same engine ........ .

Flywh eel

0.02 mm

0 .070-0.270 mm

0.038-0.088 mm

0.20-0.38 mm

0 .030-0.080 mm

0.0002 in

0.0003 in

2.7575-2.7583 in

2 .7457-2.7465 in

0.0002 in

0.0003 in

2.0577-2.0585 in

2.0456-2.0466 in

0.20-0.38 mm

2.5 grams

Axial throw, max . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 .05 mm

T ig hte nin g torq ue

Tightening torques apply to oiled nuts and bolts. Degreased

(washed) parts must be

oiled prior to assembly.

Connecting rod bearings ................. .......... ..... ..... .

Crankshaft

pulley . ........ .......... ........................ .

Camshaft gear

................................. ............. .

Flywheel (use new bolts) ... -................................. .

Spark plugs (do not oil) ...................................... .

Valve cover ......... .................................... .... .

Nm

45-50

240-280

70-90

45-50

12±2

15

70019401960 Specifications

Section 2 B 28 Engine

0 .0007 in

0.0027 -0.0106 in

0.0014-0.0034 in

0.0078-0 .0149 in

0 .0011-0.0031 in

Out-of-round

Taper

0 .0078-0.0149 in

0.0019 in

ttlb

33-37

177 -206

52-66

33-37

9±1.5

11

115089

73

t't'. -II II· II II' ,II II'

,II II'