wheel VOLVO 960 1982 Service Repair Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 960, Model: VOLVO 960 1982Pages: 168, PDF Size: 54.28 MB

Page 3 of 168

(

)

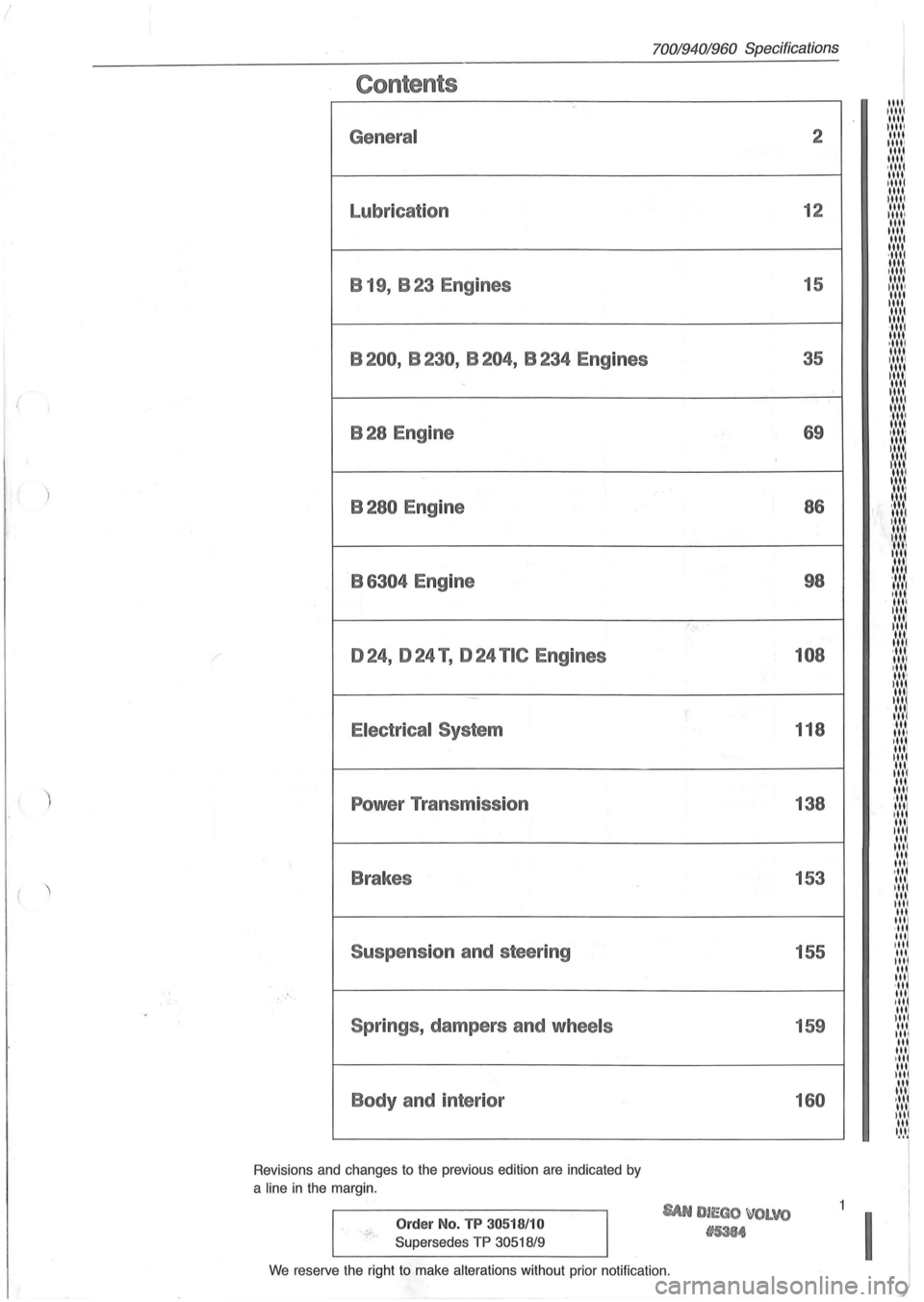

Contents

General

Lubrication B 19, B 23 Engines

B200, B230, B204, B234 Engines

B28 Engine

B280 Engine

B

6304 Engine

024, 024 T , 024 TIC Engines

Electrical System

Power Transmission

Brakes

Suspension and steering

Springs , dampers and

wheels

Body and interior

Revisions and changes to the previous edition are indicated by

a

line in the margin.

Order No. TP 30518/10

Supersedes TP 30518/9

70019401960 Specifications

'., ..

SAN DIEGO ~OLVO

tI5384

2

12

15

35

69 86

98

108

118

138

153 155

159

160

We reserve the right to make alterations without prior notification.

11111 1 1111 1111 IIII! 1111

11111 1111 1111 ·1111 1111 11111 1111 11111 1111 11111 1111 1111 1111

;::::::: 1111 1,1 ..... 1111 II,' ....

~:,:,:,: 1111 , ...... 1

1,' .... 1

1 ...... 1 1111 ·11" 1111 ,II', 1111 III'

I:':':':

'"' '"' ~ .... ,'. 1111 , .... " 1 III' 1111

:I:':',~ ·11 11,1

,"' 1111 III'

'" 1111 ...... 1 ,11' "'1 ,II'

"" I .... I~ III

"' "' ·111 1111 ,III

"' I II I

'" 1111

"' 1111

·11' 1111 I II 1 III III 11 .... 1 III 111/ ,II til. '"I III 1111 .'.'111 ,III 111/ ,II

11.'.'1

Itt'.'1

' llt

lit 'II It.'I'1 It.'.'1 III IItl 'II~ III III til "'1 " " , .... 11

'~I~'~

Page 7 of 168

(

70019401960 Specifications

Section

0 General

E

A

c B

132410

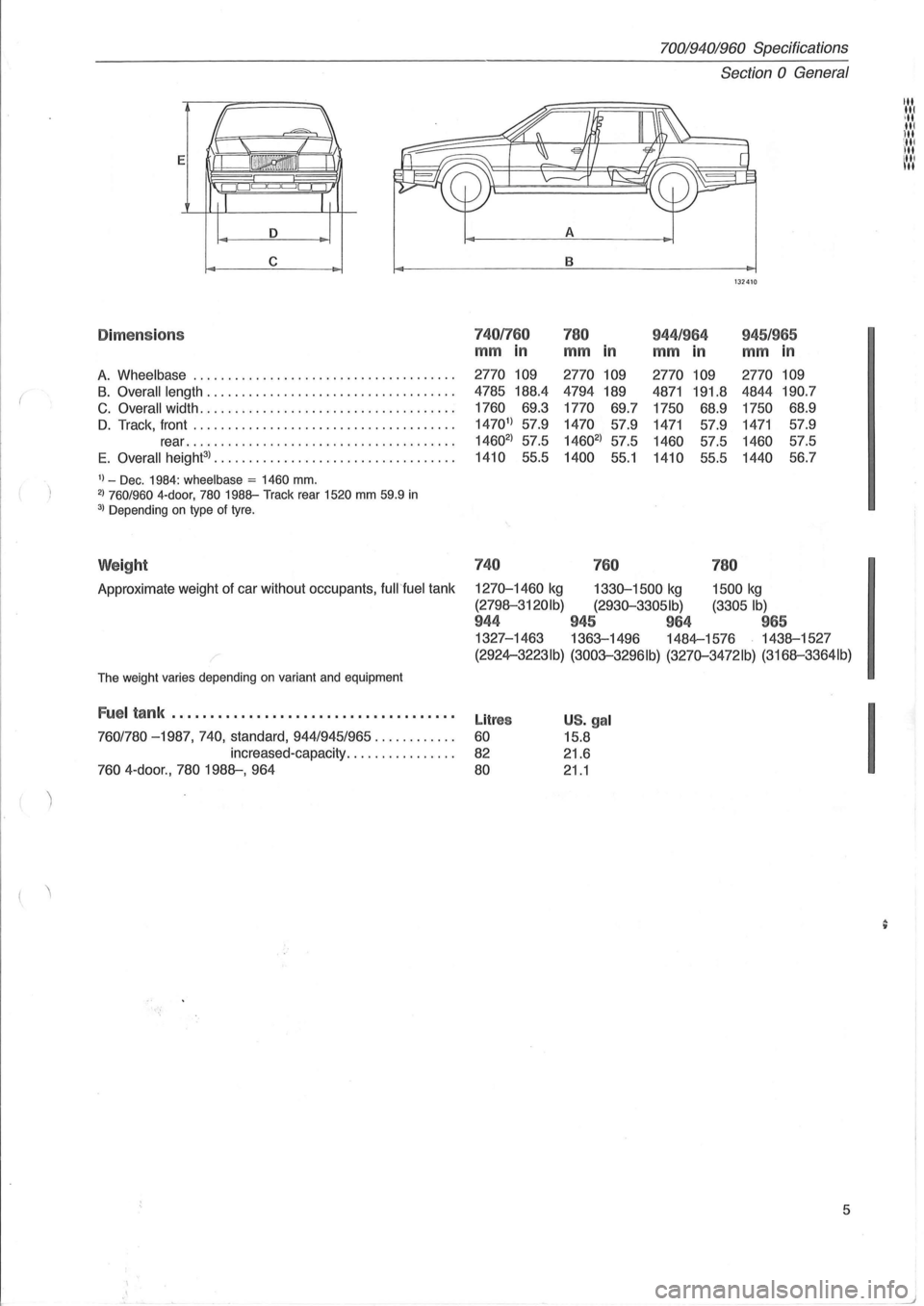

Dime ns io n s 7401760 780 944 /964 945/965

mm in mm in mm in mm in

A. Wheelbase .............................. . ...... . 2770 109 2770 109 2770

109 2770 109

B. Overall

length ................................... . 4785 188.4 4794

189 4871 191.8 4844 190.7

C. Overall width .................................... .

1760

69.3

1770 69.7

1750 68.9 1750 68.9

D. Track,

front ..................................... . 14701

) 57.9 1470 57.9 1471 57.9 1471 57.9

rear

................. ..................... . 14602

) 57.5 14602

) 57.5 1460 57.5 1460 57.5

E

. Overall height3

) ...... .........................•.•. 1410 55.5 1400 55.1 1410 55.5 1440 56.7

1) _ Dec. 1984: wheelbase = 1460 mm. 2) 760/960 4-door, 780 1988-Track

rear 1520 mm 59.9 in 3) Depending on type of tyre.

Weight 740

760 780

Approximate weight of car without occupants, fuWfuel tank 1270-1460 kg 1330-1500 kg 1500 kg

(2798-3120Ib) (2930-33051b) (3305 Ib)

944 945 964 965

1327-1463 1363-1496 1484-1576 1438-1527

,-(2924-3223Ib) (3003-3296Ib) (3270-3472lb) (3168-3364Ib)

The weight varies depending on variant and equipment

Fuel tank .................................... .

760/780 -1987,740, standard, 944/945/965 ........... .

increased-capacity

............... .

760 4 -door ., 780 1988-, 964

Litres

60

82

80

US. gal

15.8

21.6

21.1

5

I

Page 8 of 168

I

70019401960 Specifications

Section 0 General

1

~-

'''''~''''.' .. ~. . . , .... -. . .~. ," _. , . ..... ,. . . . . VOLV o . '

VOLVO _._N

C I, c , ,. .. , . I

4 C 3

r--8280 9A 150 873

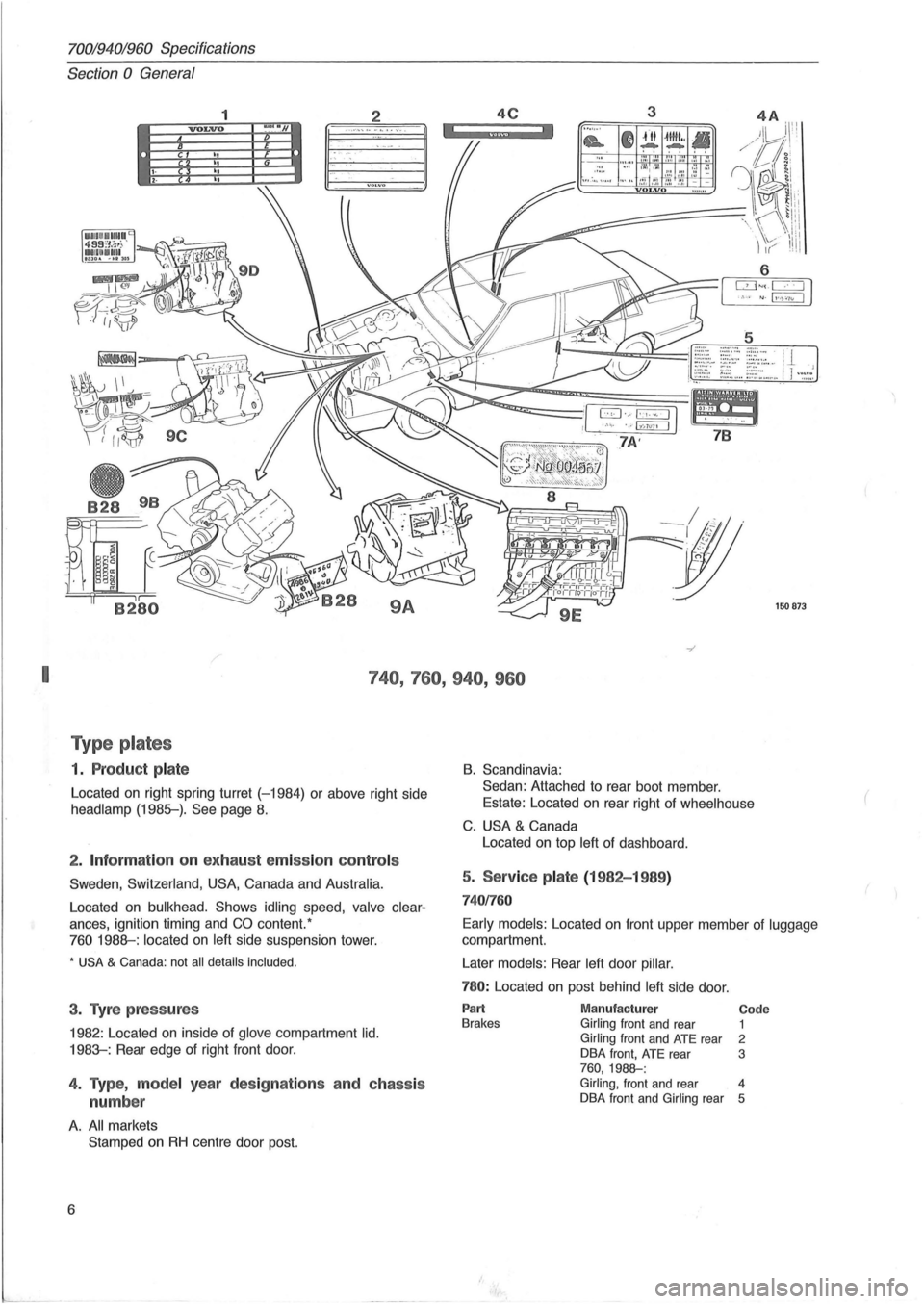

740,760 ,940 ,960

T ype p lates

1. P roduc t p la te

Located on right spring turret (-1984) or above right side

headlamp (1985-). See page 8.

2 . Inf ormation on exhau st emissio n co ntr ols

Sweden , Switzerland, USA, Canada and Australia.

Located on bulkhead. Shows idling speed, valve clear

ances, ignition timing and CO content. '

760 1988-: located on left side suspension tower.

* USA & Canada: not all details included .

3. Tyre p ress ures

1982 : Located on inside of glove compartment lid.

1983-: Rear edge of right front door.

4. Type, m ode l year des ig nat io ns a nd c hass is

numbe r

A. All markets

Stamped

on RH centre door post.

6

B. Scandinavia:

Sedan: Attached to rear boot member .

Estate: Located on rear right of

wheelhouse

C. USA & Canada

Located on top

left of dashboard.

5. Service pla te (1982-1 989 )

74 01760

Early models : Located on front upper member of luggage

compartment.

Later

models: Rear left door pillar.

780: Located on post behind left side door.

Part Brakes Manufactur er Girling front and rear Girling front and ATE rear

DBA front, ATE rear 760,1988-:

Code 1 2 3

Girling, front and rear 4

DBA front and Girling rear 5

(

Page 21 of 168

(

70019401960 Specifications

Section 2 B 19, B 23 Engines

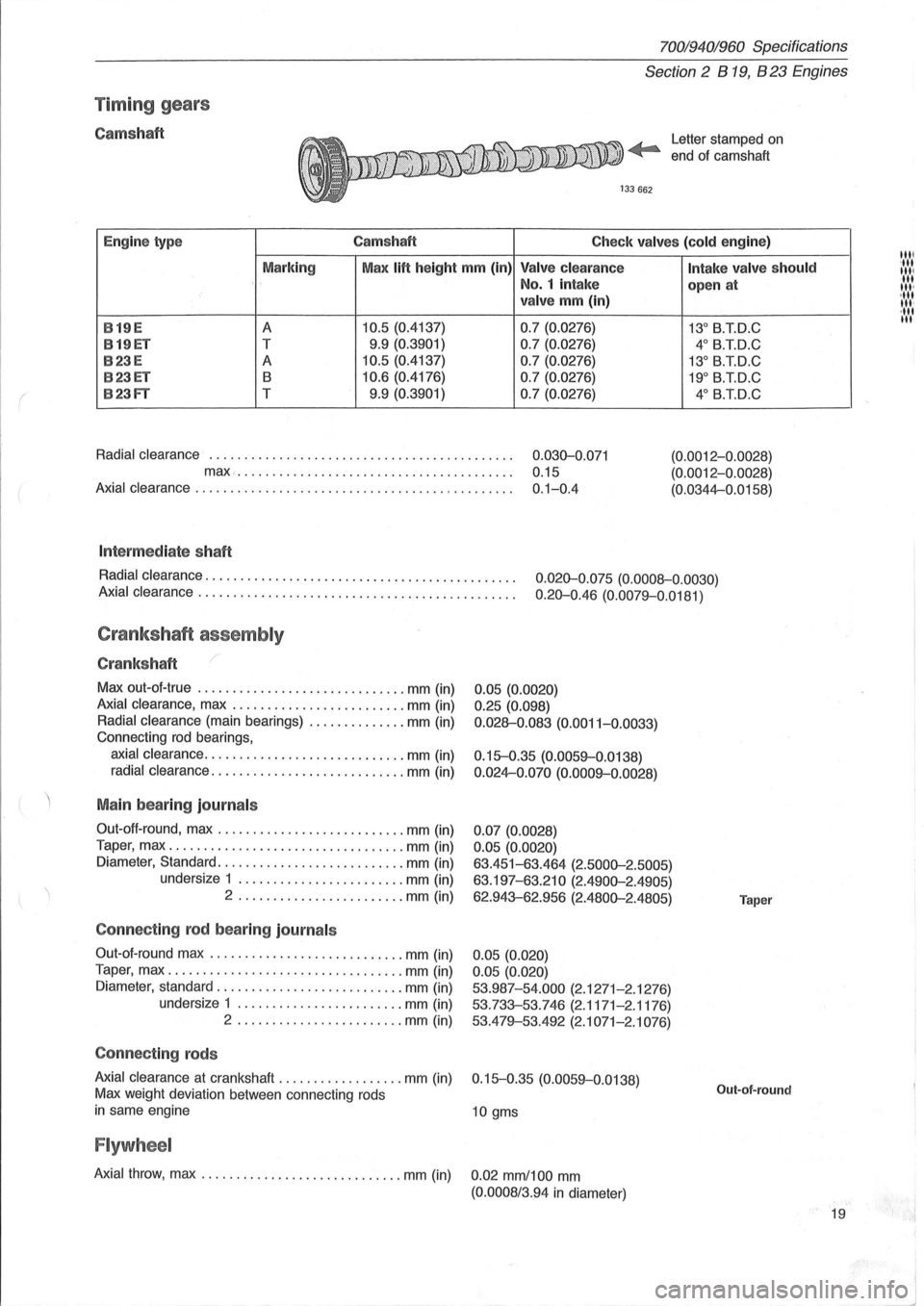

Timin g gears

Camshaft Letter stamped on

end ot camshaft

Engine type Camshaft

Check valves (cold engine)

Marking Max

lift height mm (in) Valve clearance

No.1 intake

valve mm (in)

B

19E A 10.5 (0.4137) 0.7 (0.0276)

B19ET T 9.9 (0.3901)

0.7 (0.0276)

B23E A 10.5 (0.4137) 0.7 (0.0276)

B23ET B 10.6 (0.4176) 0.7 (0.0276)

B23FT T 9.9 (0.3901)

0.7 (0.0276)

Radial clearance

............................................ 0.030-0 .071

max... . .... ... ............................... 0.15

Axial clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1-0.4

Int ermed iate shaft

Intake valve should

open at

13° B.T.D.C

4° B.T.D.C

13° B.TD.C

19° B.TD.C

4° B.iD.C

(0.0012-0 .0028)

(0.0012-0.0028)

(0.0344-0.0158)

Radial clearance.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.020-0.075 (0.0008-0.0030)

Axial clearance .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20-0.46 (0.0079-0.0181)

Crankshaft assembly

Crankshaft

Max out-ot-true .............................. mm (in)

Axial clearance, max ......................... mm (in)

Radial clearance (main bearings) .............. mm (in)

Connecting

rod bearings,

axial clearance ............................. mm (in)

radial clearance ............................ mm (in)

Main bearing journals

Out-oft-round, max ........................... mm (in)

Taper, max

.................................. mm (in)

Diameter, Standard .

.......................... mm (in)

undersize 1

........................ mm (in)

2 .

................ ....... mm (in)

Connecting rod bear ing journ als

Out-ot- round max ............................ mm (in)

Taper, max

.................................. mm (in)

Diameter, standard

........................... mm (in)

undersize 1

........................ mm (in)

2 ........................ mm (in)

Connecting rods

0.05 (0.0020)

0.25 (0.098)

0 :028-0.083 (0.0011-0.0033)

0.15-0.35 (0.0059-0.0138)

0 .024-0.070 (0.0009-0.0028)

0.07 (0.0028)

0.05 (0.0020)

63.451-63.464 (2.5000-2.5005)

63.197-63.210 (2.4900-2.4905)

62.943-62.956 (2.4800-2.4805)

0.05 (0.020)

0.05 (0.020)

53.987-54.000

(2.1271-2.1276)

53.733-53.746 (2.1171-2.1176)

53.479-53.492

(2.1071-2.1076)

Axial clearance

at crankshaft .................. mm (in) 0.15-0.35 (0.0059-0.0138)

Max weight deviation between connecting rods

in same engine 10 gms

Flywheel

Axial throw, max ............................. mm (in) 0.02 mm/100 mm

(0.0008/3.94 in diameter)

Taper

Out-of-round

19

1111 :111

111/ III III '

, III

III '

·111 III

"1

I

~J

Page 22 of 168

70019401960 Specifications

Section 2 B

19, B 23 Engines

Tightening torques

Apply to oiled nuts and bolts.

Oegreased (washed) parts must be oiled prior to assembly.

Main bearings ....................... ' ....................... .

Connecting rod bearings,

old bolts ............................ .

new

bolts ......... .................. .

Flywheel (use new bolts) ..................................... .

Spark

plugs (unoiled) .............. ; ......................... .

Camshaft sprocket

............... ........................... .

Intermediate shaft sprocket ................................. .. .

Camshaft bearing caps .

............................ ......... .

Crankshaft center

bolt ....................................... .

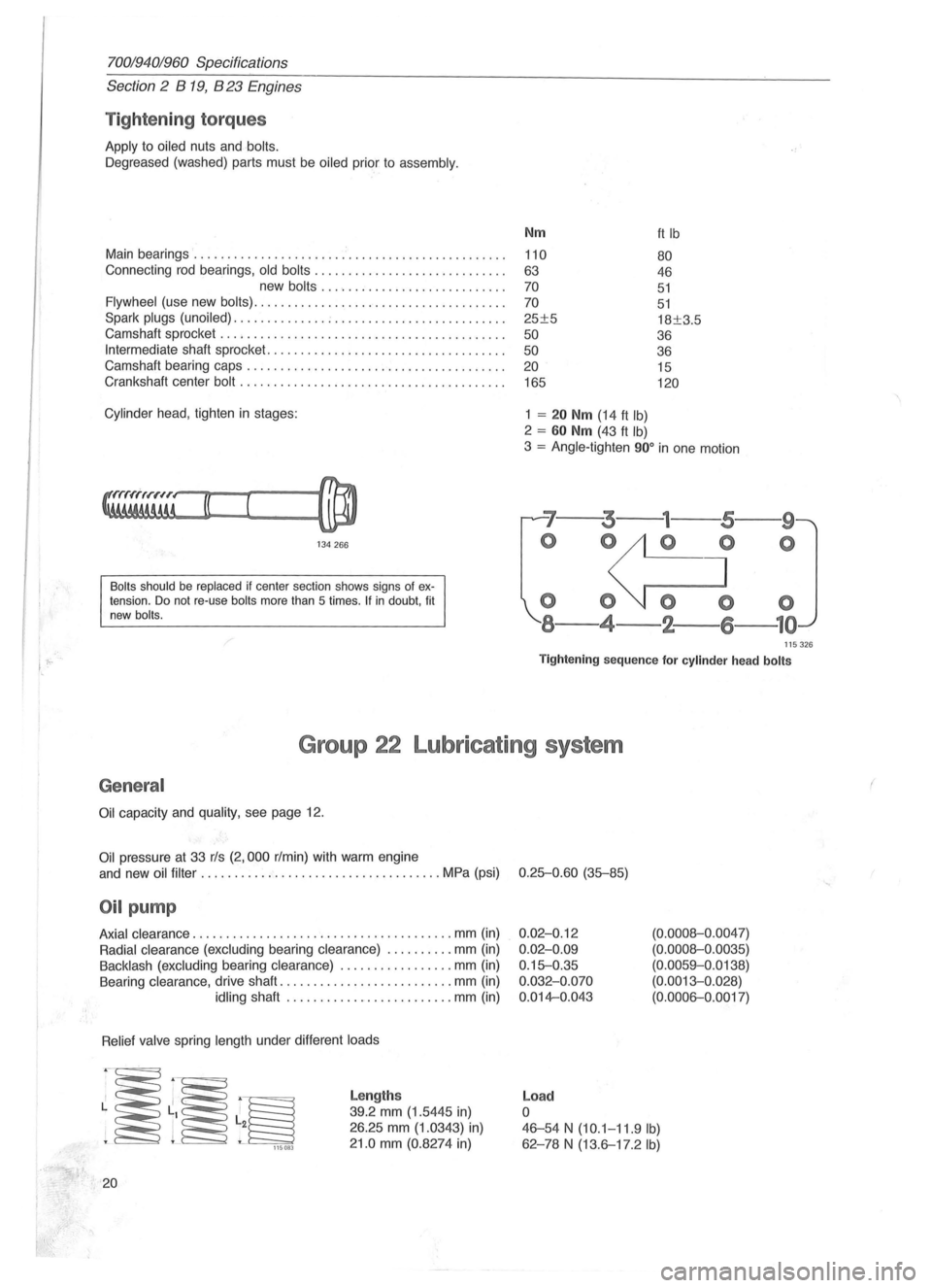

Cylinder head , tighten in stages:

134266

Bolts should be replaced if center section shows signs of extension. Do not re-use bolts more than 5 times . If in doubt, fit

new bolts.

Nm

110

63

70

70

25±5

50

50 20

165

1 = 20 Nm (14 ft Ib)

2 = 60 Nm (43 ft Ib)

ft Ib

80

46

51

51

18±3.5

36

36 15

120

3 = Angle-tighten 900 in one motion

'7--3---

o 0

000

8-4-2-

--9

o

115326

Tightening sequence for cylinder head bolts

Group 22 Lubricating system

General

Oil capacity and quality, see page 12.

Oil pressure at 33 rls (2,000 r/min) with warm engine

and new

oil filter ...... .............................. MPa (psi) 0.25-0.60 (35-85)

Oil pump

Axial clearance .................. ..................... mm (in)

Radial clearance (excluding bearing clearance) .......... mm (in)

Backlash (excluding bearing clearance) ................. mm (in)

Bearing clearance, drive shaft

.......................... mm (in)

idling shaft ..... ........... .......... mm (in)

Relief valve spring length under different loads

~~~ 115083

20

Lengths

39.2 mm (1.5445 in)

26.25 mm (1.0343) in)

21.0 mm (0.8274 in)

0.02-0.12

0.02-0.09

0.15-0.35

0.032-0.070

0.014-0.043

Load

o

(0.0008-0 .0047)

(0.0008-0.0035)

(0.0059-0.0138)

(0.0013-0. 028)

(0.0006-0.0017)

46-54 N (10.1-11.9 Ib)

62 -78 N (13.6-17.2 Ib)

(

Page 43 of 168

(

70019401960 Specifications

Section

2 B 200, B 230 Engines

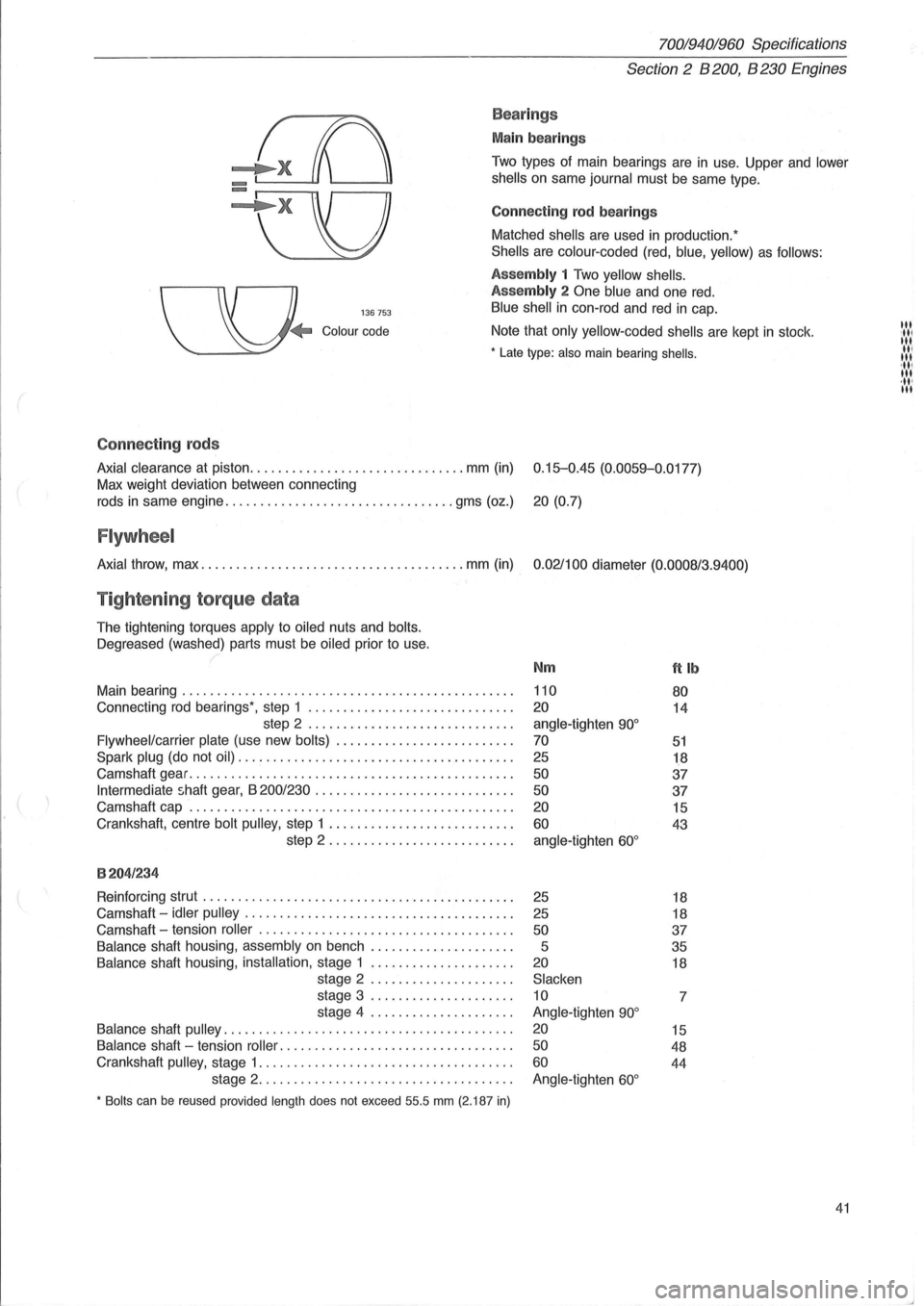

Bea rings

Main bearings

Two types of main bearings are in use. Upper and lower

shells

on same journal must be same type.

Connect

ing rod bearings

Matched

shells are used in production:

Shells are colour -coded (red, blue, yellow) as follows:

136753

Assembly 1 Two yellow shells.

Assembly

2 One blue and one red.

Blue shell in con-rod and red in cap.

Colour code Note that only yellow-coded shells are kept in stock .

• Late type: also main bearing shells .

Connect ing rods

Axial clearance at piston ............................... mm (in) 0.15-0.45 (0.0059-0.0177)

Max weight deviation between connecting

rods

in same engine ................................. gms (oz.) 20 (0.7)

Flywheel

Axial throw, max ...................................... mm (in) 0.021100 diameter (0.0008/3.9400)

Tightening torque data

The tightening torques apply to oiled nuts and bolts.

Oegreased

(washed) parts must be oiled prior to use.

Main bearing

............................................... .

Connecting

rod bearings', step 1 ............................. .

step 2

............................. .

Flywheel/carrier plate (use new bolts) ...................... ... .

Spark plug (do not oil) ....................................... .

Camshaft gear

.............................................. .

Intermediate shaft gear, B 200/230 ............................ .

Camshaft cap

.............................................. .

Crankshaft, centre

bolt pulley, step 1 .......................... .

step 2 .

.. ....................... .

8204/234

Reinforcing strut ............................................ .

Camshaft -

idler pulley ...................................... .

Camshaft -tension

roller .................................... .

Balance shaft housing, assembly on bench .................... .

Balance shaft housing, installation, stage 1 .................... .

stage 2

.................... .

stage 3

.................... .

stage 4

.................... .

Balance shaft pulley ......................................... .

Balance shaft -tension roller .. ............................... .

Crankshaft

pulley, stage 1 .................................... .

stage 2

.................................... .

• Bolts can be reused provided length does not exceed 55.5 mm (2.187 in)

Nm

110

20

angle-tighten 90°

70

25

50

50

20

60

angle-tighten 60°

25

25

50

5

20

Slacken

10

Angle-tighten

90°

20

50

60

Angle-tighten 60°

ftlb

80

14

51

18

37

37

15

43

18

18

37

35

18

7

15

48

44

41

III :11' III II, III 'III III ,11' III

Page 75 of 168

{

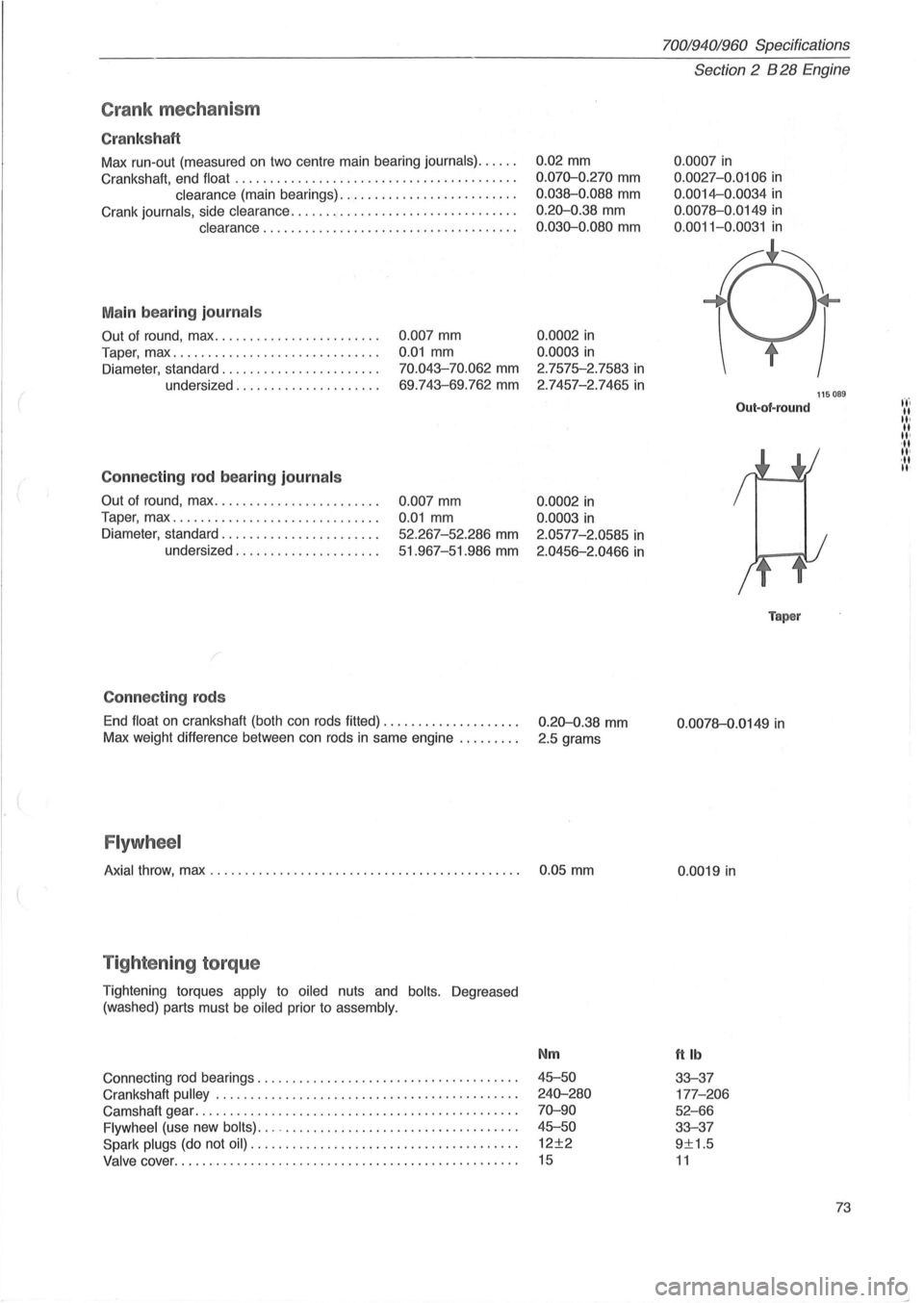

Crank mec ha ni sm

Cr ank sh aft

Max run-out (measured on two centre main bearing journals) ..... .

Crankshaft, end float

........................................ .

clearance (main bearings) ......................... .

Crank

journals, side clearance ...........•.................... .

clearance .................................... .

M ain bea rin g journ als

Out of round, max ....................... .

Taper, max

...... ....................... .

Diameter, standard ...

................... .

undersized

.................... .

Conne cting rod b ea ring journ als

Out of round, max ....................... .

Taper, max

............................. .

Diameter, standard

...................... .

undersized

.................... .

C onnec tin g rods

0 .007 mm

0.01 mm

70.043-70.062 mm

69 .743-69.762 mm

0.007 mm

0.01 mm

52.267-52 .286 mm

51.967-51.986 mm

End

float on crankshaft (both can rods fitted) ................... .

Max weight difference between can rods

in same engine ........ .

Flywh eel

0.02 mm

0 .070-0.270 mm

0.038-0.088 mm

0.20-0.38 mm

0 .030-0.080 mm

0.0002 in

0.0003 in

2.7575-2.7583 in

2 .7457-2.7465 in

0.0002 in

0.0003 in

2.0577-2.0585 in

2.0456-2.0466 in

0.20-0.38 mm

2.5 grams

Axial throw, max . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 .05 mm

T ig hte nin g torq ue

Tightening torques apply to oiled nuts and bolts. Degreased

(washed) parts must be

oiled prior to assembly.

Connecting rod bearings ................. .......... ..... ..... .

Crankshaft

pulley . ........ .......... ........................ .

Camshaft gear

................................. ............. .

Flywheel (use new bolts) ... -................................. .

Spark plugs (do not oil) ...................................... .

Valve cover ......... .................................... .... .

Nm

45-50

240-280

70-90

45-50

12±2

15

70019401960 Specifications

Section 2 B 28 Engine

0 .0007 in

0.0027 -0.0106 in

0.0014-0.0034 in

0.0078-0 .0149 in

0 .0011-0.0031 in

Out-of-round

Taper

0 .0078-0.0149 in

0.0019 in

ttlb

33-37

177 -206

52-66

33-37

9±1.5

11

115089

73

t't'. -II II· II II' ,II II'

,II II'

Page 103 of 168

(

Connecting rod bearing caps (stage 1) ................ Nm (ft Ib)

(stage 2) angle-tightening ......... 0

Crankshaft pulley (vibration damper), center bolt ........ Nm (ft Ib)

Flange bolts, vibration damper (stage 1) ............... Nm (ft Ib)

(stage 2) angle-tightening ........ 0

Driver plate (stage 1) ......................... ....... Nm (ft Ib)

(stage 2) angle-tightening ......................... 0

Camshaft wheel. .................................... Nm (ft Ib)

Tensi oning pulley, camshaft timing belt ................ Nm (ft Ib)

Damper unit, camshaft timing belt ..................... Nm (ft Ib)

Angle pulley, camshaft timing belt ..................... Nm (ft Ib)

Water pump ........................................ Nm (ft Ib)

Pin bolts, exhaust manifold (in cylinder head) ........... Nm (ft Ib)

(to front pipe) .............. Nm (ft Ib)

Oil sump pan ....................................... Nm (ft Ib)

Plug, oil sump ...................................... Nm (ft Ib)

Oil suction line ...................................... Nm (ft Ib)

Oil cooler, connector block ........................... Nm (ft Ib)

Oil trap ............................................ Nm (ft Ib)

Nipple, oil·filter ...................................... Nm (ft Ib)

Oil pressure switch .................................. Nrn (ft Ib)

Impulse sensor ..................................... ~~m (ft Ib)

Knock sensor ....................................... Nm (ft Ib)

Temperature sensor, rear edge of top cover ............ Nm (ft Ib)

Temperature sensor, thermostat ............... ....... Nm (ft Ib)

Plug, O-adjustment tool .............................. Nm (ft Ib)

Spark plugs ... ..................................... Nm (ft Ib)

20

90

300±30

35

60 45

50

20±2

39±5

24±4

24±6

17±3

20±3

35±5

17±3

38±5

17±3

17±3

15±2.5

40±2

40±5

8±2

20±2

20±2

10±2.5

38±6

25

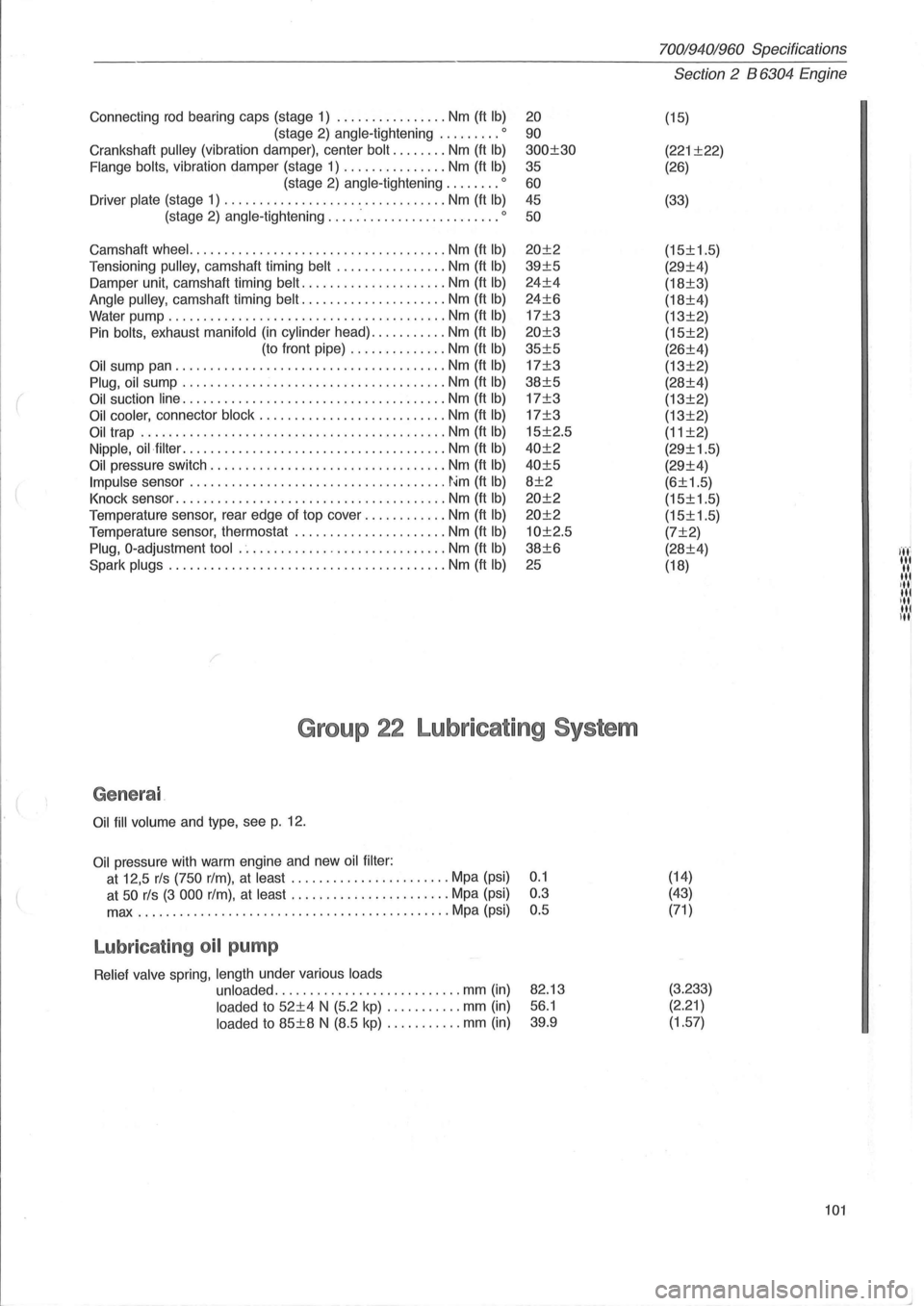

Group 22 Lubricating System

Genera l

Oil fill volume and type, see p. 12.

Oil pressure with warm engine and new oil filter :

at 12,5 rls (750 rim), at least ....... ................ Mpa (psi) 0.1

at

50 rls (3 000 rim), at least ....................... Mpa (psi) 0.3

max

...................... ....................... Mpa (psi) 0.5

Lubricat ing oil pump

Relief valve spring, length under various loads

unloaded

.................... ....... mm (in)

loaded to 52±4 N (5.2 kp) ....... .... mm (in)

loaded to 85±8 N (8.5 kp) ........... mm (in)

82.13

56.1

39.9

70019401960 Specifications

Section 2 B 6304 Engine

(15)

(221 ±22)

(26)

(33)

(15±1.5)

(29±4)

(18±3)

(18±4)

(13±2)

(15±2)

(26±4)

(13±2)

(28±4)

(13±2)

(13±2)

(11 ±2)

(29±1.5)

(29±4)

(6±1.5)

(15±1.5)

(15±1.5)

(7±2)

(28±4)

(18)

(14)

(43)

(71 )

(3.233) (2.21)

(1.57)

101

I ..... ' '.','

"' ,III III ill u,1

Page 114 of 168

70019401960 Specifications

Section

2 024, 024 T, 024 TIC Engines

Crankshaft

Max1

) runout, two centre bearings ............................. .

others

........................................ . .

Crankshaft, end

clearance, new ............................... .

max .

.............................. .

main bearing

clearance, new ....... ............... .

max

....................... .

Connecting

rod bearings, side clearance, max .................. .

bearing

clearance, max ............... .

new

............... .

l)Measured with two outer main bearings in V·blocks.

Main bearing journal s

Out of round, max ........................................... .

Taper, max

................................................. .

Diameter, standard .

.................................... ..... .

undersize 1 .

...................................... .

2 ....................................... .

3 ......................... .............. .

Con necting rod bearing journ als

Out of round, max ........................................... .

Taper, max

................................................. .

Diameter, standard

.......................................... .

undersize 1

....................................... .

2

....................................... .

Con necting rods

Only to be replaced in sets.

0.06 mm 0.0023 in

0.04 mm

0.07-0.18 mm

0.25 mm

0.016-0.075 mm

0.16 mm

0.0015 in

0.0027-0.0071 in

0 .0098 in

0.0006-0.0029 in

0.0062 in

0.4 mm 0.0157 in

0.12 mm

0.015-0.062 mm

0.0047 in

0 .0005-0.0024 in

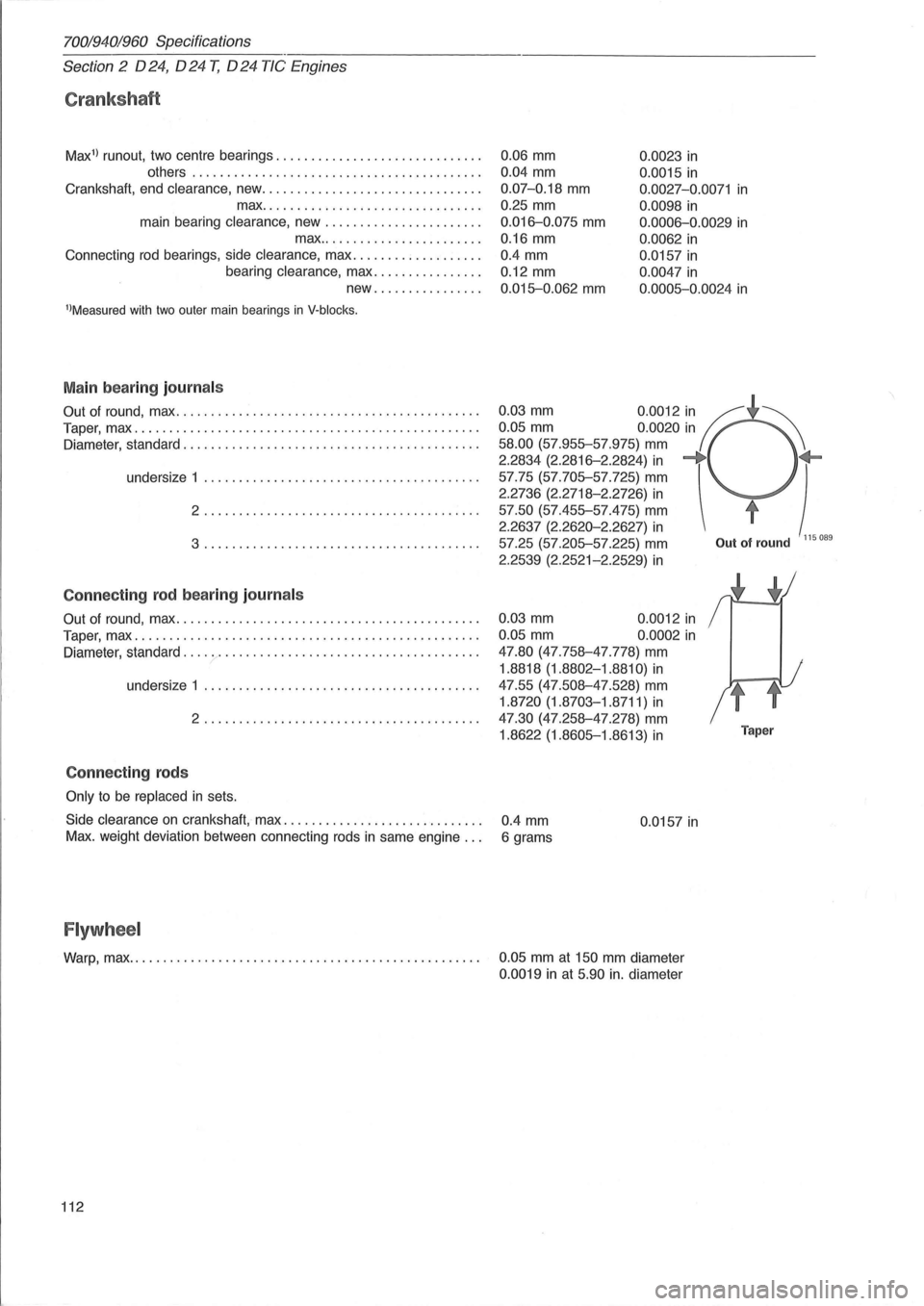

0.03 mm 0.0012 in If ~ 0.05 mm 0.0020 in

58.00 (57.955-57.975) mm

2.2834 (2.2816-2.2824) in -+ +-) 57.75 (57.705-57.725) mm

2.2736 (2.2718-2.2726) in

57.50 (57.455-57.475) mm t

2.2637 (2.2620-2.2627) in 57.25 (57.205-57.225) mm Out of round 115089

2.2539 (2.2521-2.2529) in

0.03 mm 0.0012 in

0.05 mm 0.0002 in

47.80 (47.758-47.778) mm

1.8818 (1.8802-1.8810) in

47.55 (47.508-47.528) mm

1.8720 (1.8703-1.8711) in

47.30 (47.258-47 .278) mm

1.8622 (1.8605-1.8613) in Taper

Side clearance on crankshaft, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 mm 0.0157 in Max. weight deviation between connecting rods in same engine. . . 6 grams

Flywheel

Warp, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm at 150 mm diameter

0.0019 in at 5.90 in. diameter

112

Page 115 of 168

(

70019401960 Specifications

Section

2 024, 024 T, 024 TIC Engines

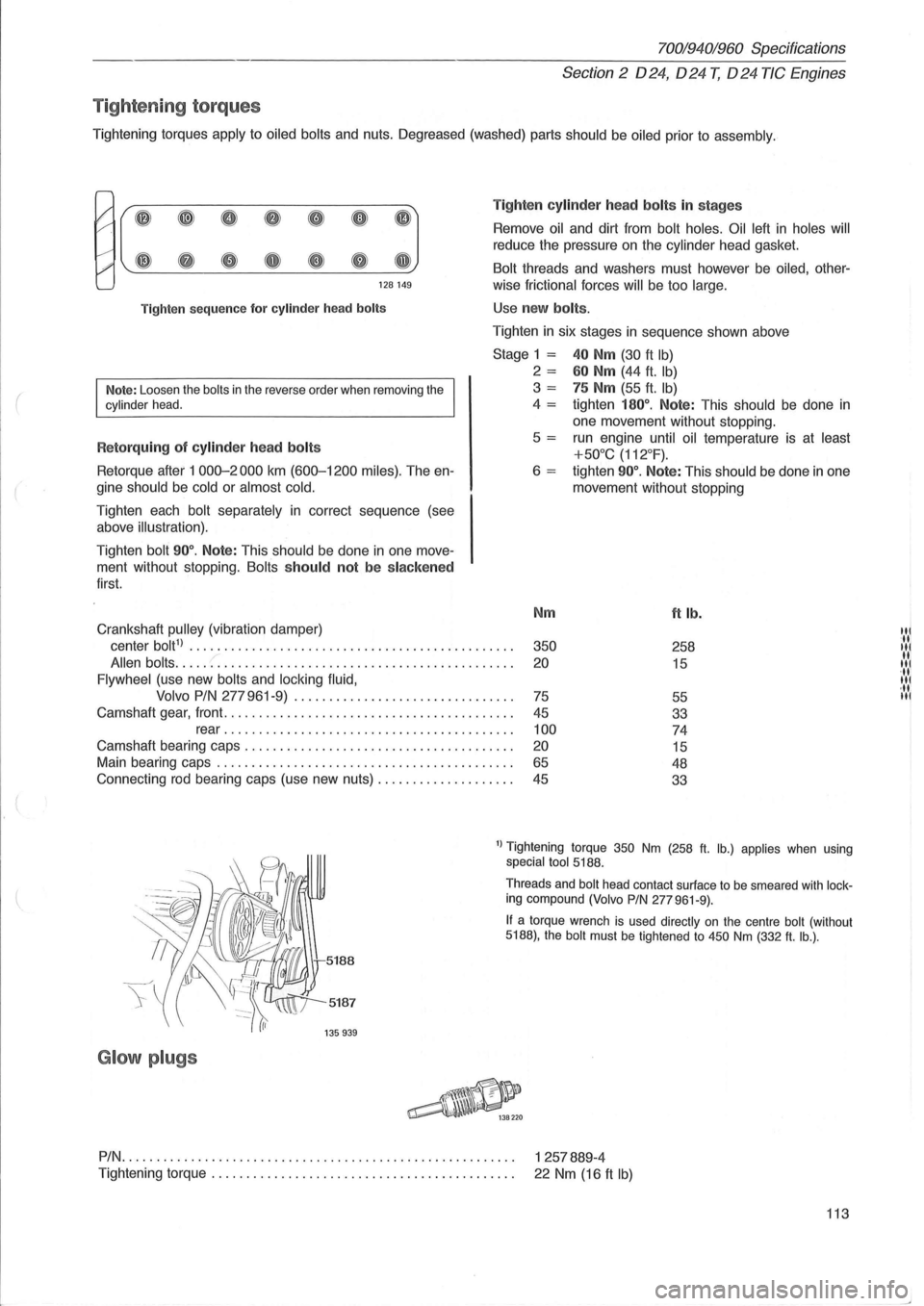

Tig ht enin g to rqu es

Tightening torques apply to oiled bolts and nuts. Oegreased (washed) parts should be oiled prior to assembly .

I' ~ ~ 0 8 CD 0 (IJ

#' ~ G e Q e Q GJ

128149

Tighten

sequence for cylinder head bolts

Note: Loosen the bolts in the reverse order when removing the cylinder head.

R etorquing of cylinder head bolts

Retorque after 1 000-2000 km (600-1200 miles). The en

gine

should be cold or almost cold.

Tighten each bolt separately in correct sequence (see

above

illustration).

Tighten bolt 90°. Note: This should be done in one move

ment without stopping.

Bolts should not be slacken ed

first.

Crankshaft

pulley (vibration damper) Ti

g

hten cylinde r h ea d bolts in stages

Remove oil and dirt from bolt holes. Oil left in holes will

reduce the pressure on the cylinder head gasket.

Bolt threads and washers must however be oiled, other-

wise

frictional forces will be too large.

Use new bolts .

Tighten in six stages in sequence shown above

Stage 1 = 40 Nm (30 ft Ib)

2 = 60 Nm (44 ft. Ib)

3 = 75 Nm (55 ft. Ib)

4 = tighten 180°. Note: This should be done in

one movement without stopping .

5

= run engine until oil temperature is at least

+50°C (112°F).

6 = tighten 90°. Note: This should be done in one

movement without stopping

Nm

ft lb.

center bolt1) ............................... ............... . 350 258

Allen bolts ..... :: ......................................... . 20 15

Flywheel (use new bolts and locking fluid,

Volvo PIN

277 961-9) ............................... .

75

55

Camshaft gear, front

......................................... .

45

33

rear

....................................... .. . 100 74

Camshaft bearing caps .................................... .. . 20 15

Main bearing caps .......................................... .

65 48

Connecting rod bearing caps (use new nuts)

................... .

45

33

1) Tightening torque 350 Nm (258 ft. lb.) applies when using special tool 5188.

5187

G lo w plugs

Threads and bolt head contact surface to be smeared with locking compound (Volvo PIN 277961-9).

If a torque wrench is used directly on the centre bolt (without 5188), the bolt must be tightened to 450 Nm (332 ft. lb.) .

PIN.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 257889-4

Tightening

torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Nm (16 ft Ib)

113

'il IN 11 '11 11

·11 III