wheel size VOLVO 960 1982 Service Repair Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 1982, Model line: 960, Model: VOLVO 960 1982Pages: 168, PDF Size: 54.28 MB

Page 21 of 168

(

70019401960 Specifications

Section 2 B 19, B 23 Engines

Timin g gears

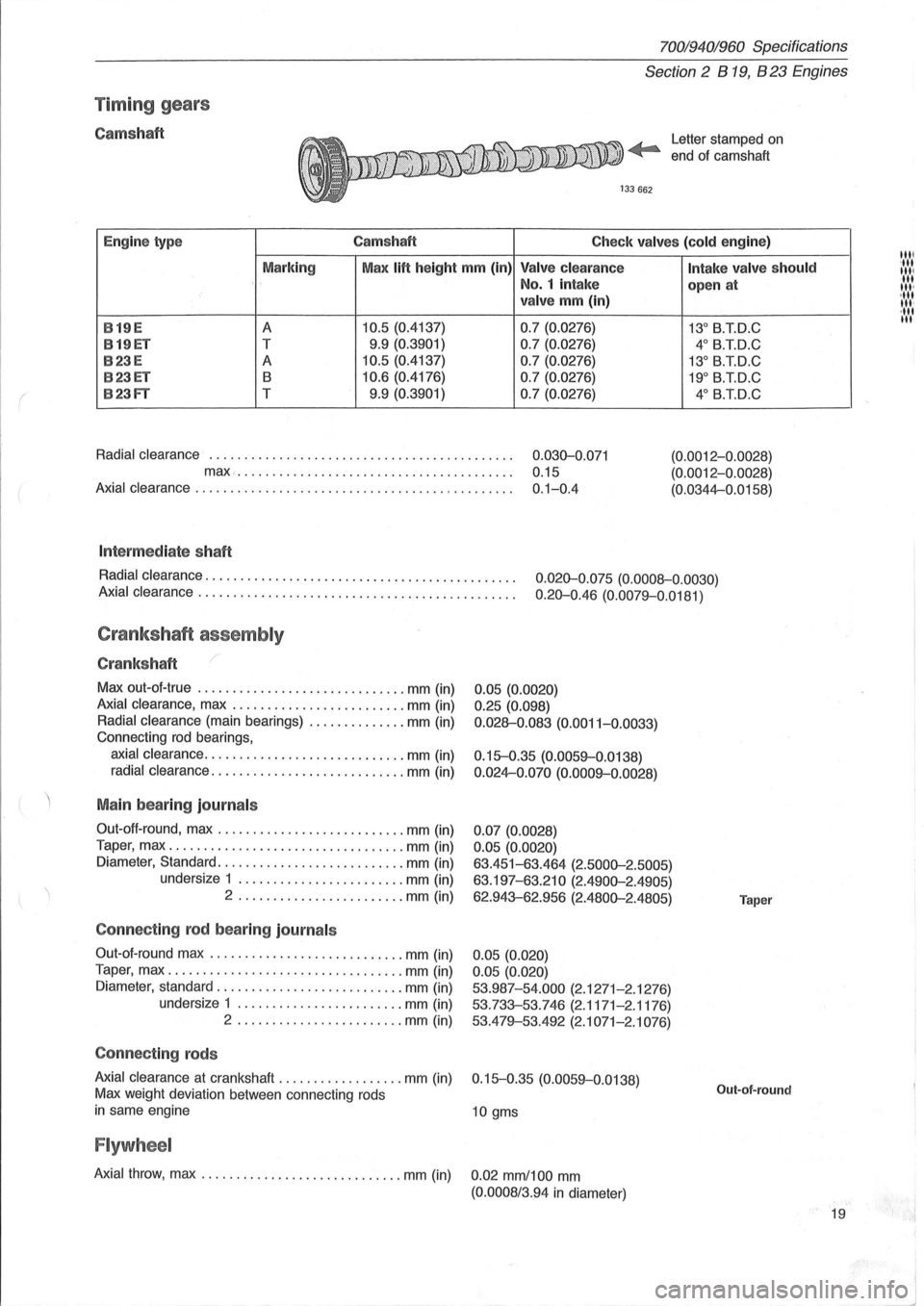

Camshaft Letter stamped on

end ot camshaft

Engine type Camshaft

Check valves (cold engine)

Marking Max

lift height mm (in) Valve clearance

No.1 intake

valve mm (in)

B

19E A 10.5 (0.4137) 0.7 (0.0276)

B19ET T 9.9 (0.3901)

0.7 (0.0276)

B23E A 10.5 (0.4137) 0.7 (0.0276)

B23ET B 10.6 (0.4176) 0.7 (0.0276)

B23FT T 9.9 (0.3901)

0.7 (0.0276)

Radial clearance

............................................ 0.030-0 .071

max... . .... ... ............................... 0.15

Axial clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1-0.4

Int ermed iate shaft

Intake valve should

open at

13° B.T.D.C

4° B.T.D.C

13° B.TD.C

19° B.TD.C

4° B.iD.C

(0.0012-0 .0028)

(0.0012-0.0028)

(0.0344-0.0158)

Radial clearance.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.020-0.075 (0.0008-0.0030)

Axial clearance .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20-0.46 (0.0079-0.0181)

Crankshaft assembly

Crankshaft

Max out-ot-true .............................. mm (in)

Axial clearance, max ......................... mm (in)

Radial clearance (main bearings) .............. mm (in)

Connecting

rod bearings,

axial clearance ............................. mm (in)

radial clearance ............................ mm (in)

Main bearing journals

Out-oft-round, max ........................... mm (in)

Taper, max

.................................. mm (in)

Diameter, Standard .

.......................... mm (in)

undersize 1

........................ mm (in)

2 .

................ ....... mm (in)

Connecting rod bear ing journ als

Out-ot- round max ............................ mm (in)

Taper, max

.................................. mm (in)

Diameter, standard

........................... mm (in)

undersize 1

........................ mm (in)

2 ........................ mm (in)

Connecting rods

0.05 (0.0020)

0.25 (0.098)

0 :028-0.083 (0.0011-0.0033)

0.15-0.35 (0.0059-0.0138)

0 .024-0.070 (0.0009-0.0028)

0.07 (0.0028)

0.05 (0.0020)

63.451-63.464 (2.5000-2.5005)

63.197-63.210 (2.4900-2.4905)

62.943-62.956 (2.4800-2.4805)

0.05 (0.020)

0.05 (0.020)

53.987-54.000

(2.1271-2.1276)

53.733-53.746 (2.1171-2.1176)

53.479-53.492

(2.1071-2.1076)

Axial clearance

at crankshaft .................. mm (in) 0.15-0.35 (0.0059-0.0138)

Max weight deviation between connecting rods

in same engine 10 gms

Flywheel

Axial throw, max ............................. mm (in) 0.02 mm/100 mm

(0.0008/3.94 in diameter)

Taper

Out-of-round

19

1111 :111

111/ III III '

, III

III '

·111 III

"1

I

~J

Page 75 of 168

{

Crank mec ha ni sm

Cr ank sh aft

Max run-out (measured on two centre main bearing journals) ..... .

Crankshaft, end float

........................................ .

clearance (main bearings) ......................... .

Crank

journals, side clearance ...........•.................... .

clearance .................................... .

M ain bea rin g journ als

Out of round, max ....................... .

Taper, max

...... ....................... .

Diameter, standard ...

................... .

undersized

.................... .

Conne cting rod b ea ring journ als

Out of round, max ....................... .

Taper, max

............................. .

Diameter, standard

...................... .

undersized

.................... .

C onnec tin g rods

0 .007 mm

0.01 mm

70.043-70.062 mm

69 .743-69.762 mm

0.007 mm

0.01 mm

52.267-52 .286 mm

51.967-51.986 mm

End

float on crankshaft (both can rods fitted) ................... .

Max weight difference between can rods

in same engine ........ .

Flywh eel

0.02 mm

0 .070-0.270 mm

0.038-0.088 mm

0.20-0.38 mm

0 .030-0.080 mm

0.0002 in

0.0003 in

2.7575-2.7583 in

2 .7457-2.7465 in

0.0002 in

0.0003 in

2.0577-2.0585 in

2.0456-2.0466 in

0.20-0.38 mm

2.5 grams

Axial throw, max . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 .05 mm

T ig hte nin g torq ue

Tightening torques apply to oiled nuts and bolts. Degreased

(washed) parts must be

oiled prior to assembly.

Connecting rod bearings ................. .......... ..... ..... .

Crankshaft

pulley . ........ .......... ........................ .

Camshaft gear

................................. ............. .

Flywheel (use new bolts) ... -................................. .

Spark plugs (do not oil) ...................................... .

Valve cover ......... .................................... .... .

Nm

45-50

240-280

70-90

45-50

12±2

15

70019401960 Specifications

Section 2 B 28 Engine

0 .0007 in

0.0027 -0.0106 in

0.0014-0.0034 in

0.0078-0 .0149 in

0 .0011-0.0031 in

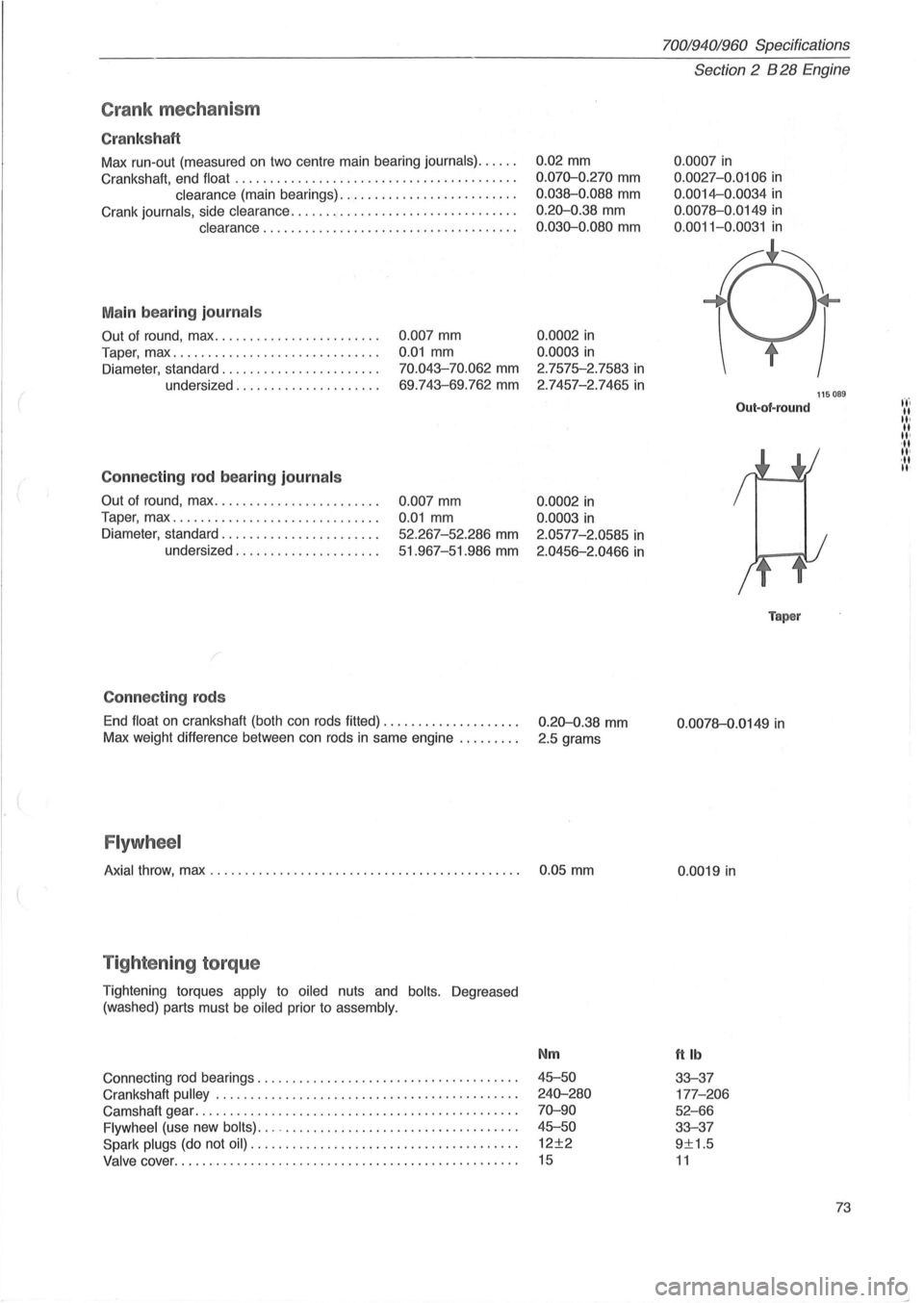

Out-of-round

Taper

0 .0078-0.0149 in

0.0019 in

ttlb

33-37

177 -206

52-66

33-37

9±1.5

11

115089

73

t't'. -II II· II II' ,II II'

,II II'

Page 114 of 168

70019401960 Specifications

Section

2 024, 024 T, 024 TIC Engines

Crankshaft

Max1

) runout, two centre bearings ............................. .

others

........................................ . .

Crankshaft, end

clearance, new ............................... .

max .

.............................. .

main bearing

clearance, new ....... ............... .

max

....................... .

Connecting

rod bearings, side clearance, max .................. .

bearing

clearance, max ............... .

new

............... .

l)Measured with two outer main bearings in V·blocks.

Main bearing journal s

Out of round, max ........................................... .

Taper, max

................................................. .

Diameter, standard .

.................................... ..... .

undersize 1 .

...................................... .

2 ....................................... .

3 ......................... .............. .

Con necting rod bearing journ als

Out of round, max ........................................... .

Taper, max

................................................. .

Diameter, standard

.......................................... .

undersize 1

....................................... .

2

....................................... .

Con necting rods

Only to be replaced in sets.

0.06 mm 0.0023 in

0.04 mm

0.07-0.18 mm

0.25 mm

0.016-0.075 mm

0.16 mm

0.0015 in

0.0027-0.0071 in

0 .0098 in

0.0006-0.0029 in

0.0062 in

0.4 mm 0.0157 in

0.12 mm

0.015-0.062 mm

0.0047 in

0 .0005-0.0024 in

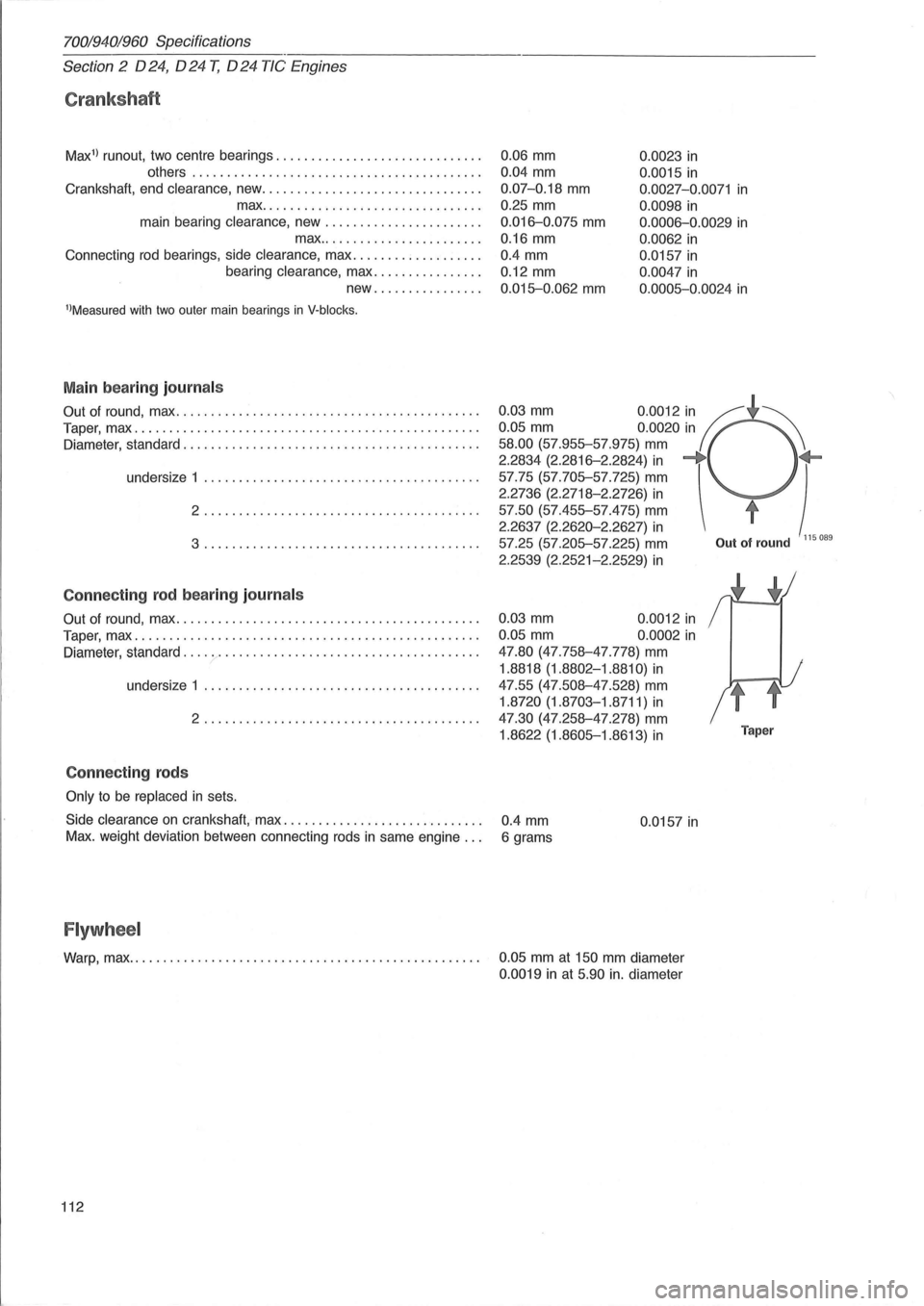

0.03 mm 0.0012 in If ~ 0.05 mm 0.0020 in

58.00 (57.955-57.975) mm

2.2834 (2.2816-2.2824) in -+ +-) 57.75 (57.705-57.725) mm

2.2736 (2.2718-2.2726) in

57.50 (57.455-57.475) mm t

2.2637 (2.2620-2.2627) in 57.25 (57.205-57.225) mm Out of round 115089

2.2539 (2.2521-2.2529) in

0.03 mm 0.0012 in

0.05 mm 0.0002 in

47.80 (47.758-47.778) mm

1.8818 (1.8802-1.8810) in

47.55 (47.508-47.528) mm

1.8720 (1.8703-1.8711) in

47.30 (47.258-47 .278) mm

1.8622 (1.8605-1.8613) in Taper

Side clearance on crankshaft, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.4 mm 0.0157 in Max. weight deviation between connecting rods in same engine. . . 6 grams

Flywheel

Warp, max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 mm at 150 mm diameter

0.0019 in at 5.90 in. diameter

112

Page 161 of 168

(

700194019fiO Specifications

Section

7 Springs, dampers and wheels

Section 7 Springs, shock absorbers, wheels

Group 77 Wheels, tires, hubs

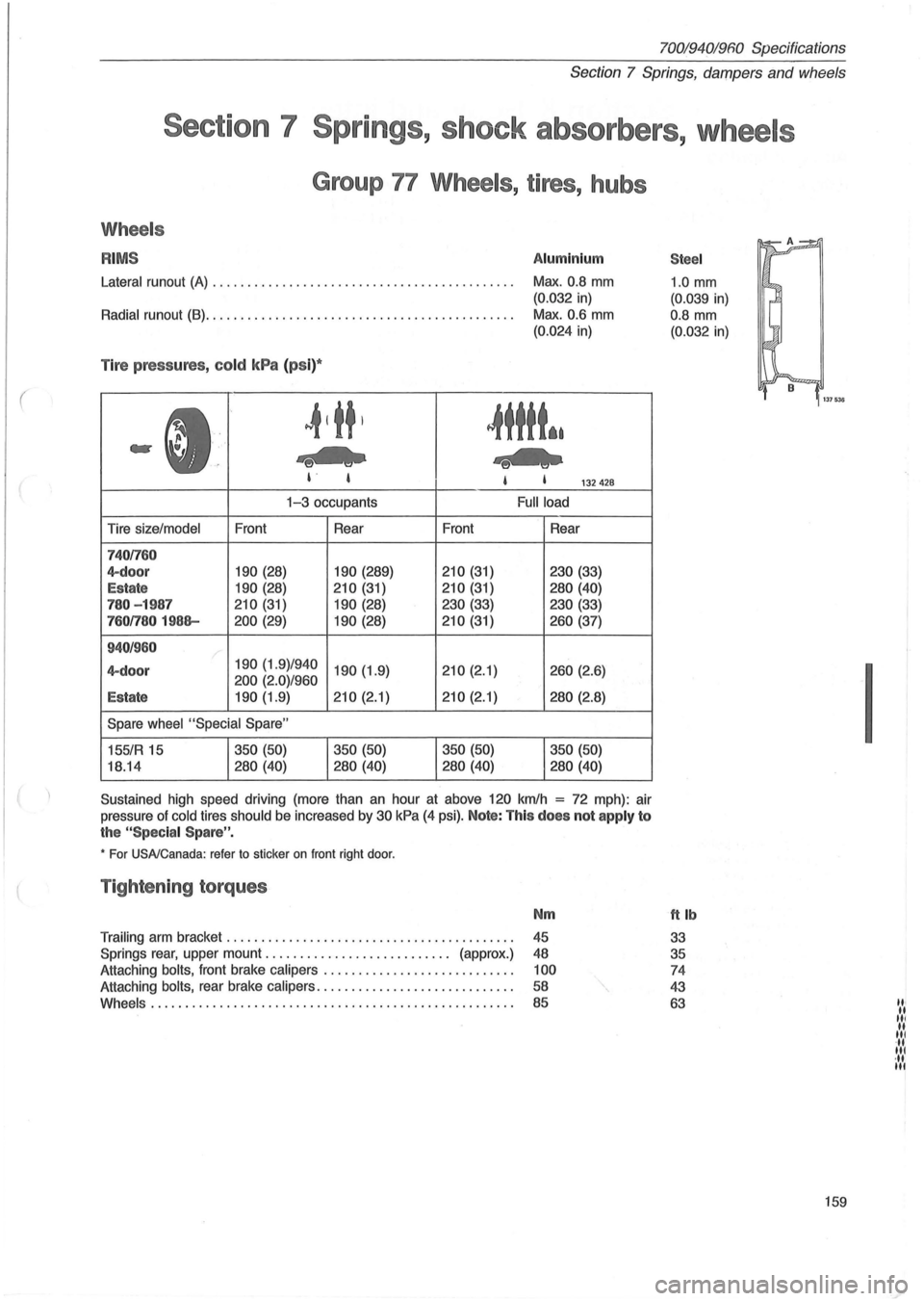

Wheels

RIMS Aluminium

Lateral runout (A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Max. 0.8 mm

(0.032 in)

Radial runout (8). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Max. 0.6 mm

(0.024 in)

Tire pressures , cold kPa (ps i)*

~tttt*.

-e-US , I 132428

Tire size/model

7401760

4-door

Estate

780 - 1987

7601780 1988-

940/960

4-doo r

Estate

Front

190 (28)

190 (28)

210 (31)

200 (29)

1-3 occupants

Rear

190 (289)

210 (31)

190 (28)

190 (28)

190 (1.9)/940 190 (1.9)

200 (2.0)/960

190 (1.9) 210 (2.1)

Spare wheel "Special Spare"

155/R 15

18.14 350

(50)

280 (40) 350

(50)

280 (40) Front

210 (31)

210 (31)

230 (33)

210 (31)

210 (2.1)

210 (2.1)

350 (50)

280 (40)

Full load

Rear

230 (33)

280 (40)

230 (33)

260 (37)

260 (2.6)

280 (2.8)

350 (50)

280 (40)

Sustained high speed driving (more than an hour at above 120 kmlh

= 72 mph) : air

pressure of

cold tires should be increased by 30 kPa (4 psi). Note: This does not apply to

the "Spec ia l Spare " .

• For USA/Canada: refer to sticker on front right door.

Tightening torques

Nm

Trailing arm bracket ......................................... .

45

Springs

rear, upper mount. . . . . . . . . . . . . . . . . . . . . . . . . .. (approx.) 48

Attaching

bolts, front brake calipers ............. .............. . 100

Attaching bolts, rear brake calipers ............................ . 58

Whe e

ls .................................................... .

85

Stee l

1.0 mm

(0.039 in)

0.8

mm

(0.032 in)

ttlb

33

35

74

43

63

159

I

III .. III II III ... III ·11 III