ECU VOLVO C70 2013 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2013, Model line: C70, Model: VOLVO C70 2013Pages: 296, PDF Size: 7.18 MB

Page 163 of 296

06 Starting and driving

Towing

06

161

2. Insert the key into the ignition to unlock the

steering wheel. With the engine off and the

vehicle at a standstill, great effort will be

required to turn the steering wheel.

3.

Turn the ignition key to position II.

4. Place the gear selector in neutral. For vehi-

cles with automatic transmissions, follow

instruction on page 153, "Shiftlock over-

ride" to allow the gear selector to be moved

from the Park position.

5. Keep firm pressure on the brake pedal

while releasing the parking brake.

6. When towing has been completed, return

the gear selector to Park and apply the

parking brake.

The following points should also be

observed:

•Never exceed 50 mph (80 km/h). Never

exceed local towing speed limits and heed

all local towing restrictions.

•Never tow farther than 50 miles (80 km).

•Keep the tow rope taut at all times while the

vehicle is in motion.

•The disabled vehicle should be towed in

the forward direction only.

WARNING

•Never allow a vehicle to be towed with-

out a driver behind the wheel of the dis-

abled vehicle.

•When the engine is not running, steering

resistance and the effort needed to

apply the brakes will be great.

•Never attempt to tow a vehicle with a

dead battery at night.

CAUTION

•Check with state and local authorities

before attempting this type of towing,

as vehicles being towed are subject to

regulations regarding maximum towing

speed, length and type of towing

device, lighting, marker flags, etc.

•Never attempt to push- or tow-start a

vehicle with a dead battery. This would

inject unburned fuel into the three-way

catalytic converter(s), causing over-

heating, backfiring, and damage, see

page 163 for instructions on jump star-

ting the vehicle.

Towing vehicles with front wheel drive

Volvo recommends the use of flat bed equip-

ment for towing vehicles with front wheel drive.

If wheel lift equipment must be used, please

use extreme caution to help avoid damage to

the vehicle.

In this case, the vehicle should be towed with

the rear wheels on the ground if at all possible.

If it is absolutely necessary to tow the vehicle

with the front wheels on the ground, please

refer to the towing information on the previous

page.

•Sling-type equipment applied at the front

will damage radiator and air conditioning

lines.

•It is equally important not to use sling-type

equipment at the rear or apply lifting equip-

ment inside the rear wheels; serious dam-

age to the rear axle may result.

•If the vehicle is being towed on a flat bed

truck, the towing eyelets must not be used

to secure the vehicle on the flat bed. Con-

sult the tow truck operator.

Page 169 of 296

06 Starting and driving

Transporting loads

06

167 Loading the vehicle

Your vehicle's load-carrying capacity is affec-

ted by factors such as:

•the number of passengers

•tire inflation

•the amount of optional or accessory equip-

ment installed

•the amount of cargo.

See the chapter "Wheels and tires" for more

detailed information.

Before loading the car, turn off the engine, and

apply the parking brake when loading or

unloading long objects. The gear selector can

be inadvertently knocked out of position by

long cargo, causing the car to move.

Keep the following in mind when

loading the vehicle:

•Load objects in the trunk against the rear

seat backrest.

•Load heavy cargo as low as possible.

•Center wide loads.

•Secure all cargo with restraining straps

anchored to the load securing eyelets.

•Cover sharp edges on the load.

WARNING

•Remember that an object weighing

44 lbs (20 kg) produces a force of

2,200 lbs (1,000 kg) in a head-on colli-

sion at 30 mph (50 km/h)!

•When the rear backrest(s) are folded

down, the vehicle should not be loaded

to a level higher than 2 in. (5 cm) below

the upper edge of the rear side win-

dows. Objects placed higher than this

level could impede the function of the

Inflatable Curtain.

Page 193 of 296

07 Wheels and tires

Tire Sealing System*

07

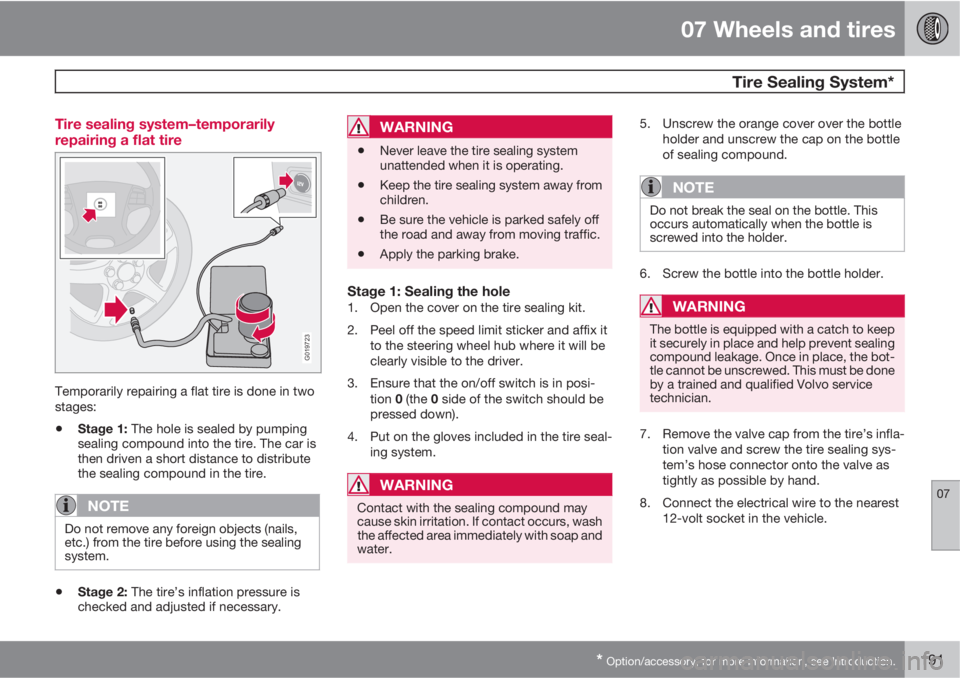

* Option/accessory, for more information, see Introduction.191 Tire sealing system–temporarily

repairing a flat tire

G019723

Temporarily repairing a flat tire is done in two

stages:

•Stage 1: The hole is sealed by pumping

sealing compound into the tire. The car is

then driven a short distance to distribute

the sealing compound in the tire.

NOTE

Do not remove any foreign objects (nails,

etc.) from the tire before using the sealing

system.

•Stage 2: The tire’s inflation pressure is

checked and adjusted if necessary.

WARNING

•Never leave the tire sealing system

unattended when it is operating.

•Keep the tire sealing system away from

children.

•Be sure the vehicle is parked safely off

the road and away from moving traffic.

•Apply the parking brake.

Stage 1: Sealing the hole1. Open the cover on the tire sealing kit.

2. Peel off the speed limit sticker and affix it

to the steering wheel hub where it will be

clearly visible to the driver.

3. Ensure that the on/off switch is in posi-

tion 0 (the 0 side of the switch should be

pressed down).

4. Put on the gloves included in the tire seal-

ing system.

WARNING

Contact with the sealing compound may

cause skin irritation. If contact occurs, wash

the affected area immediately with soap and

water.

5. Unscrew the orange cover over the bottle

holder and unscrew the cap on the bottle

of sealing compound.

NOTE

Do not break the seal on the bottle. This

occurs automatically when the bottle is

screwed into the holder.

6. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep

it securely in place and help prevent sealing

compound leakage. Once in place, the bot-

tle cannot be unscrewed. This must be done

by a trained and qualified Volvo service

technician.

7. Remove the valve cap from the tire’s infla-

tion valve and screw the tire sealing sys-

tem’s hose connector onto the valve as

tightly as possible by hand.

8. Connect the electrical wire to the nearest

12-volt socket in the vehicle.

Page 196 of 296

07 Wheels and tires

Tire Sealing System*

07

194* Option/accessory, for more information, see Introduction.

WARNING

•The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem. The parking brake should be

securely applied and the gear selector

should be in the P (park) position.

•Children should never be left unattended

in the vehicle when the engine is running.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation table for the cor-

rect inflation pressure. If the tire needs to

be inflated, start the tire sealing system’s

compressor (press the on/off switch to

position I). If necessary, release air from the

tire by turning the air release knob coun-

terclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

9. Turn off the compressor (press the on/off

switch to position 0) when the correct infla-

tion pressure has been reached.

10. Unscrew the hose from the tire’s inflation

valve and reinstall the valve cap.

11. Disconnect the electrical wire from the

12-volt socket.

Page 199 of 296

07 Wheels and tires

Spare tire and jack

07

197

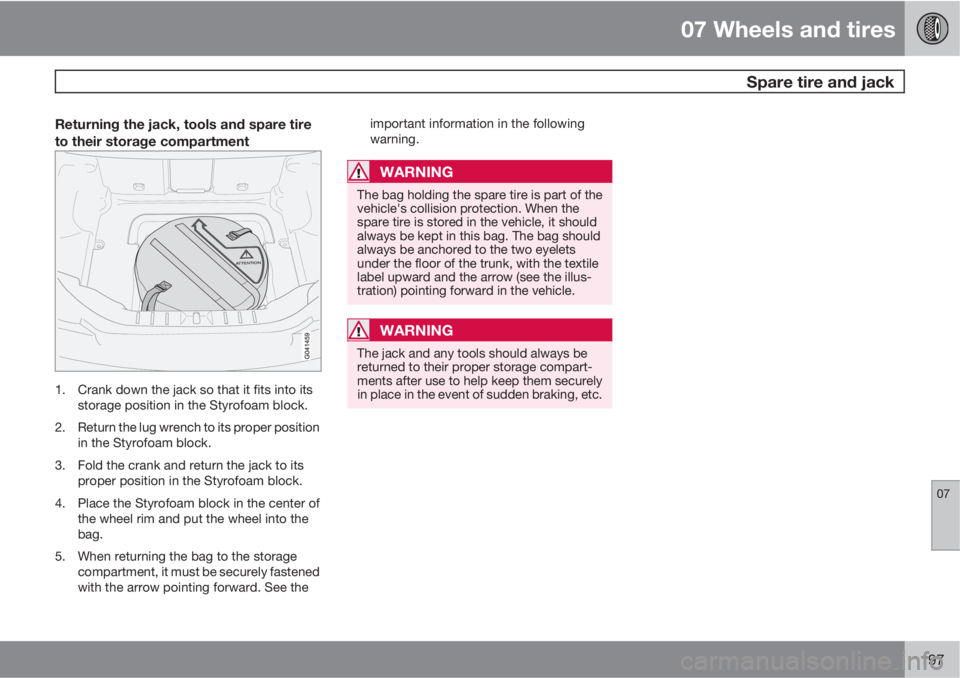

Returning the jack, tools and spare tire

to their storage compartment

1. Crank down the jack so that it fits into its

storage position in the Styrofoam block.

2. Return the lug wrench to its proper position

in the Styrofoam block.

3. Fold the crank and return the jack to its

proper position in the Styrofoam block.

4. Place the Styrofoam block in the center of

the wheel rim and put the wheel into the

bag.

5. When returning the bag to the storage

compartment, it must be securely fastened

with the arrow pointing forward. See theimportant information in the following

warning.

WARNING

The bag holding the spare tire is part of the

vehicle's collision protection. When the

spare tire is stored in the vehicle, it should

always be kept in this bag. The bag should

always be anchored to the two eyelets

under the floor of the trunk, with the textile

label upward and the arrow (see the illus-

tration) pointing forward in the vehicle.

WARNING

The jack and any tools should always be

returned to their proper storage compart-

ments after use to help keep them securely

in place in the event of sudden braking, etc.

Page 200 of 296

07 Wheels and tires

Wheel nuts

07

198

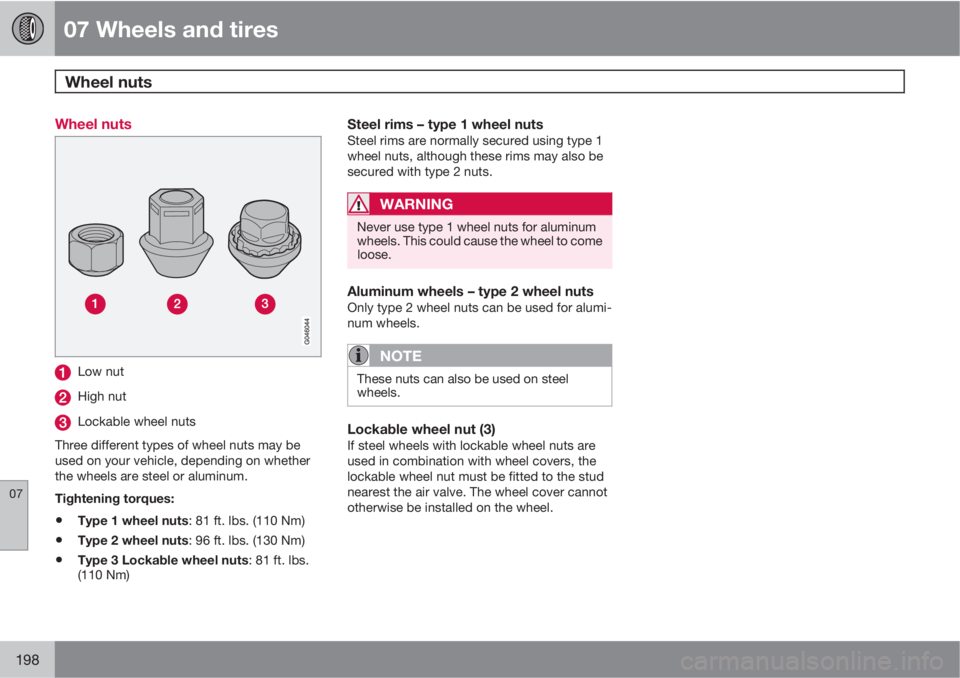

Wheel nuts

Low nut

High nut

Lockable wheel nuts

Three different types of wheel nuts may be

used on your vehicle, depending on whether

the wheels are steel or aluminum.

Tightening torques:

•Type 1 wheel nuts: 81 ft. lbs. (110 Nm)

•Type 2 wheel nuts: 96 ft. lbs. (130 Nm)

•Type 3 Lockable wheel nuts: 81 ft. lbs.

(110 Nm)

Steel rims – type 1 wheel nutsSteel rims are normally secured using type 1

wheel nuts, although these rims may also be

secured with type 2 nuts.

WARNING

Never use type 1 wheel nuts for aluminum

wheels. This could cause the wheel to come

loose.

Aluminum wheels – type 2 wheel nutsOnly type 2 wheel nuts can be used for alumi-

num wheels.

NOTE

These nuts can also be used on steel

wheels.

Lockable wheel nut (3)If steel wheels with lockable wheel nuts are

used in combination with wheel covers, the

lockable wheel nut must be fitted to the stud

nearest the air valve. The wheel cover cannot

otherwise be installed on the wheel.

Page 202 of 296

07 Wheels and tires

Changing a wheel

07

200

NOTE

The jack provided with your vehicle is

intended to be used only in temporary sit-

uations such as changing wheels in the

event of a flat tire. Only the jack that came

with your particular model should be used

to lift the vehicle. If the vehicle needs to be

lifted more frequently or for a prolonged

period, using a garage jack or hoist is rec-

ommended. Always follow this device’s

instructions for use.

Installing the wheel

1. Clean the contact surfaces between the

wheel and hub.

2. Lift the wheel and place it on the hub.

3. Install the wheel nuts and hand-tighten

them. Using the lug wrench, tighten cross-

wise until all nuts are snug.

4. Lower the vehicle to the ground and alter-

nately tighten the bolts crosswise to

81 ft. lbs. (110 Nm) or 96 ft. lbs. (130 Nm),

depending on the type of wheel/wheel nuts

used on your vehicle. See also 198 for

additional information.

5. Install the wheel cover (where applicable).

See page 196 for information on returning the

jack and tools to their proper storage positions.On vehicles equipped with the tire sealing sys-

tem, the jack should be cranked down as far as

possible and returned to its storage position in

the foam block.

WARNING

The jack and any tools should always be

returned to their proper storage compart-

ments after use to help keep them securely

in place in the event of sudden braking, etc.

Page 209 of 296

08 Car care

Washing and cleaning the car

08

207

tant, especially in the winter. Some automatic

washers do not have facilities for washing the

underbody.

CAUTION

•Remove the antenna on the right rear

fender. This antenna should never be

bent in any way. Doing so could result

in damage or malfunction. When the

antenna is put back in position, turn it

carefully to help avoid damaging the

threads on the antenna's mount.

•Before driving into an automatic car

wash, turn off the optional rain sensor to

avoid damaging the windshield wipers.

•Make sure that side view mirrors, auxil-

iary lamps, etc, are secure.

•Chromed wheels: Clean chrome-

plated wheels using the same deter-

gents used for the body of the vehicle.

Aggressive wheel-cleaning agents can

permanently stain chrome-plated

wheels.

WARNING

•When the car is driven immediately after

being washed, apply the brakes several

times in order to remove any moisture

from the brake linings.

•Engine cleaning agents should not be

used when the engine is warm. This

constitutes a fire risk.

Exterior lightingCondensation may form temporarily on the

inside of the lenses of exterior lights such as

headlights, fog lights, or taillights. This is nor-

mal and the lights are designed to withstand

moisture. Normally, condensation will dissi-

pate after the lights have been on for a short

time.

Polishing and Waxing

•Normally, polishing is not required during

the first year after delivery, however, wax-

ing may be beneficial.

•Before applying polish or wax the vehicle

must be washed and dried. Tar spots can

be removed with kerosene or tar remover.

Difficult spots may require a fine rubbing

compound.

•After polishing use liquid or paste wax.

•Several commercially available products

contain both polish and wax.

•Waxing alone does not substitute for pol-

ishing a dull surface.

•A wide range of polymer-based waxes can

be purchased today. These waxes are easy

to use and produce a long-lasting, high-

gloss finish that protects the bodywork

against oxidation, road dirt and fading.

•Do not polish or wax your vehicle in direct

sunlight (the surface of the vehicle should

not be warmer than 113 °F (45 °C).

CAUTION

Volvo does not recommend the use of long-

life or durable paint protection coatings,

some of which may claim to prevent pitting,

fading, oxidation, etc. These coatings have

not been tested by Volvo for compatibility

with your vehicle's clear coat. Some of them

may cause the clear coat to soften, crack,

or cloud. Damage caused by application of

paint protection coatings may not be cov-

ered under your vehicle's paint warranty.

Page 225 of 296

09 Maintenance and servicing

Wiper blades09

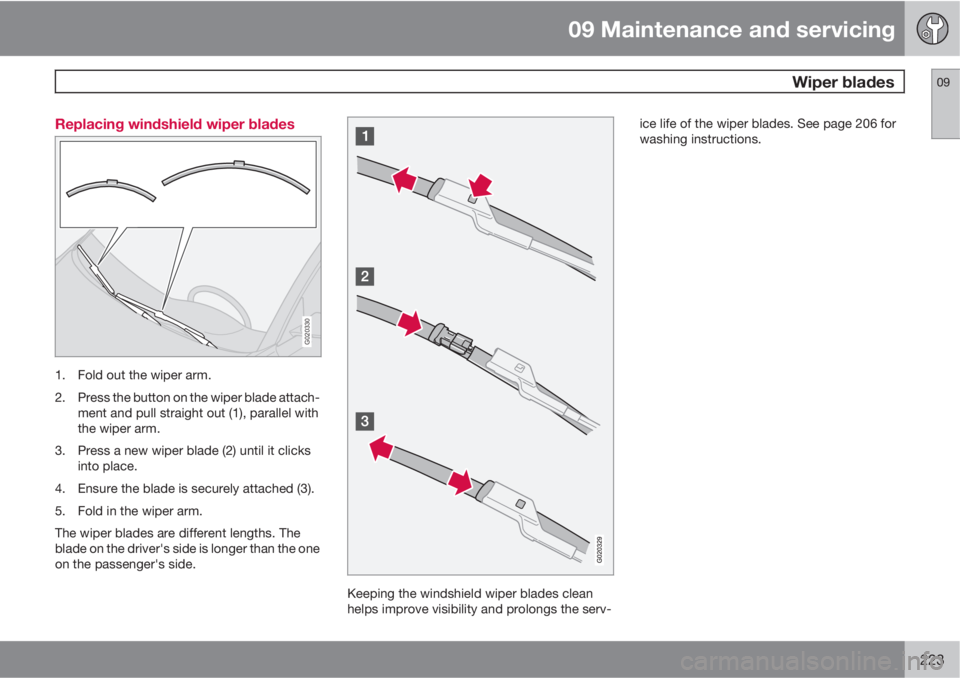

223 Replacing windshield wiper blades

G020330

1. Fold out the wiper arm.

2. Press the button on the wiper blade attach-

ment and pull straight out (1), parallel with

the wiper arm.

3. Press a new wiper blade (2) until it clicks

into place.

4. Ensure the blade is securely attached (3).

5. Fold in the wiper arm.

The wiper blades are different lengths. The

blade on the driver's side is longer than the one

on the passenger's side.

Keeping the windshield wiper blades clean

helps improve visibility and prolongs the serv-ice life of the wiper blades. See page 206 for

washing instructions.

Page 226 of 296

09 Maintenance and servicing

Battery 09

224

Battery maintenance

Driving habits and conditions, climate, the

number of starts, etc., all affect the service life

and function of the battery. In order for your

battery to perform satisfactorily, keep the fol-

lowing in mind:

Check the fluid level in each cell in the battery

every 24 months or every 15,000

1 miles

(24,000 km), whichever is sooner.

•Use a screw driver to open the caps or

cover and a flashlight to inspect the level.

•If necessary, add distilled water. The level

should never be above the indicator.

•The fluid level should be checked if the

battery has been recharged.

•After inspection, be sure the cap over each

battery cell or the cover is securely in

place.

•Check that the battery cables are correctly

connected and properly tightened.

•Never disconnect the battery when the

engine is running, or when the key is in the

ignition. This could damage the vehicle's

electrical system.

•The battery should be disconnected from

the vehicle when a battery charger is used

directly on the battery.

•To help keep the battery in good condition,

the vehicle should be driven for at least 15

minutes a week or connected to a charger

with an automatic charging function.

•If the battery is fully discharged a number

of times, this may shorten its service life.

Keeping the battery fully charged helps

prolong its service life.

•The service life of a battery is affected by

factors such as driving conditions and cli-

mate. Extreme cold may also further

decrease the battery’s starting capacity.

•Because the battery’s starting capacity

decreases with time, it may be necessary

to recharge it if the vehicle is not driven for

an extended period of time or if the vehicle

is usually only driven short distances.

•

WARNING

PROPOSITION 65 WARNING!

Battery posts, terminals, and related acces-

sories contain lead and lead compounds,

chemicals known to the state of California

to cause cancer and reproductive harm.

Wash hands after handling.

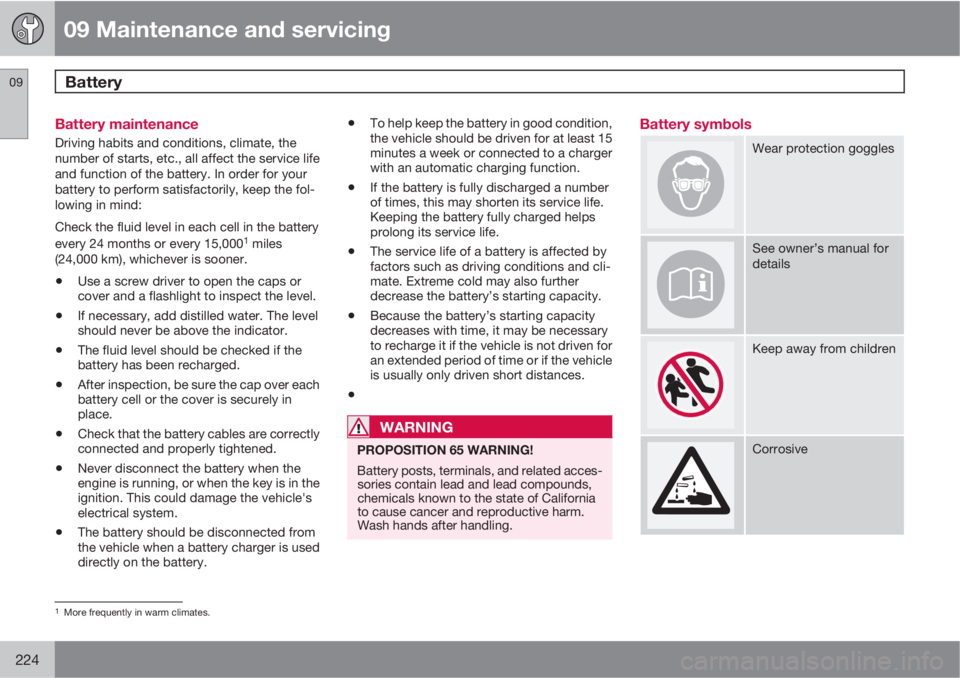

Battery symbols

Wear protection goggles

See owner’s manual for

details

Keep away from children

Corrosive

1More frequently in warm climates.