lock VOLVO S40 2009 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2009, Model line: S40, Model: VOLVO S40 2009Pages: 286, PDF Size: 7.08 MB

Page 158 of 286

06 Starting and drivingTowing

06158

WARNING

•

Never allow a vehicle to be towed with-

out a driver behind the wheel of the

disabled vehicle.

•

Never remove the key from the ignition

while the vehicle is moving. The steering

wheel could lock, making it impossible

to steer the vehicle.

•

When the engine is not running, steering

resistance and the effort needed to

apply the brakes will be great.

•

Never attempt to tow a vehicle with a

dead battery at night.CAUTION

•

Check with state and local authorities

before attempting this type of towing,

as vehicles being towed are subject to

regulations regarding maximum towing

speed, length and type of towing

device, lighting, marker flags, etc.

•

Never attempt to push- or tow-start a

vehicle with a dead battery. This would

inject unburned fuel into the three-way

catalytic converter(s), causing over-

heating, backfiring, and damage, see

page 159 for instructions on jump star-

ting the vehicle.

Towing vehicles with front wheel driveVolvo recommends the use of flat bed equip-

ment for towing vehicles with front wheel drive.

If wheel lift equipment must be used, please

use extreme caution to help avoid damage to

the vehicle.

In this case, the vehicle should be towed with

the rear wheels on the ground if at all possible.

If it is absolutely necessary to tow the vehicle

with the front wheels on the ground, please

refer to the towing information on the previous

page.•

Sling-type equipment applied at the front

will damage radiator and air conditioning

lines.

•

It is equally important not to use sling-type

equipment at the rear or apply lifting equip-

ment inside the rear wheels; serious dam-

age to the rear axle may result.

•

If the vehicle is being towed on a flat bed

truck, the towing eyelets must not be used

to secure the vehicle on the flat bed. Con-

sult the tow truck operator.

WARNING

•

Remember that the power brakes and

power steering will not function when

engine is not running. The braking and

steering systems will function but the

brake pedal pressure required is

3 – 5 times above normal and greater

steering effort must be exerted.

•

The towing eyelets must not be used for

pulling the vehicle out of a ditch or for

any similar purpose involving severe

strain. Do not use the towing eyelets to

pull the vehicle up onto a flat bed tow

truck.

Page 162 of 286

06 Starting and drivingDetachable trailer hitch

06162

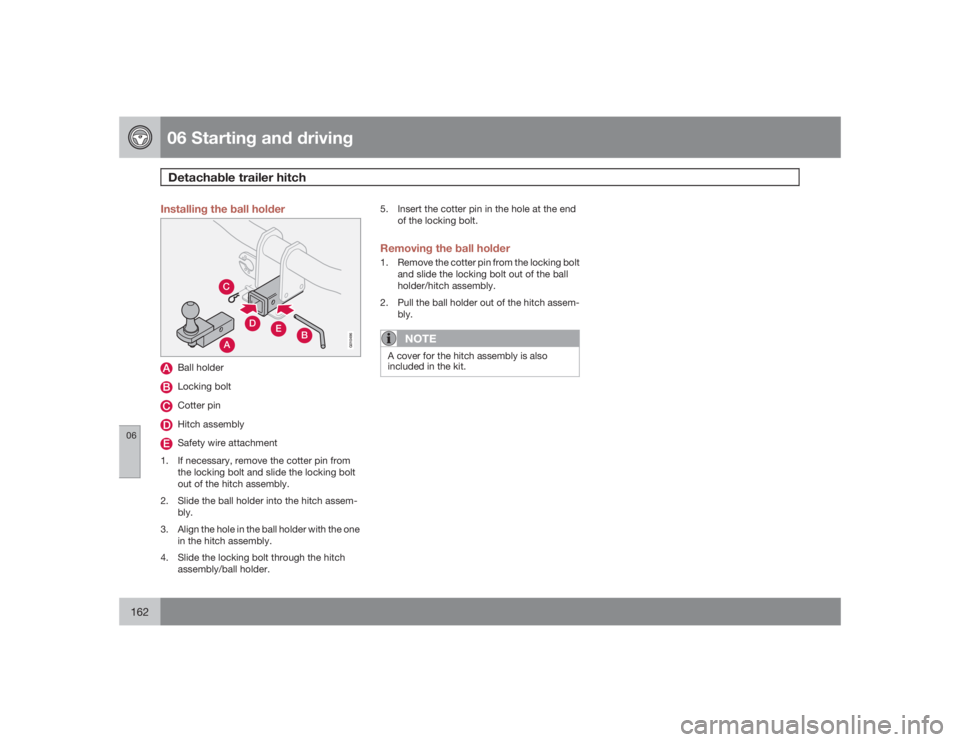

Installing the ball holder

AC

E

D

B

G010496

Ball holderLocking boltCotter pinHitch assemblySafety wire attachment

1. If necessary, remove the cotter pin from

the locking bolt and slide the locking bolt

out of the hitch assembly.

2. Slide the ball holder into the hitch assem-

bly.

3. Align the hole in the ball holder with the one

in the hitch assembly.

4. Slide the locking bolt through the hitch

assembly/ball holder.5. Insert the cotter pin in the hole at the end

of the locking bolt.

Removing the ball holder1. Remove the cotter pin from the locking bolt

and slide the locking bolt out of the ball

holder/hitch assembly.

2. Pull the ball holder out of the hitch assem-

bly.

NOTE

A cover for the hitch assembly is also

included in the kit.

Page 167 of 286

06 Starting and driving

Blind Spot Information System (BLIS)–option

06

167

when the system is switched off, and a text

message is displayed.

•

BLIS can be switched on again by pressing

the button. The indicator light in the button

will illuminate and a new text message will

be displayed. Press the READ button, see

page 60, to erase the message.

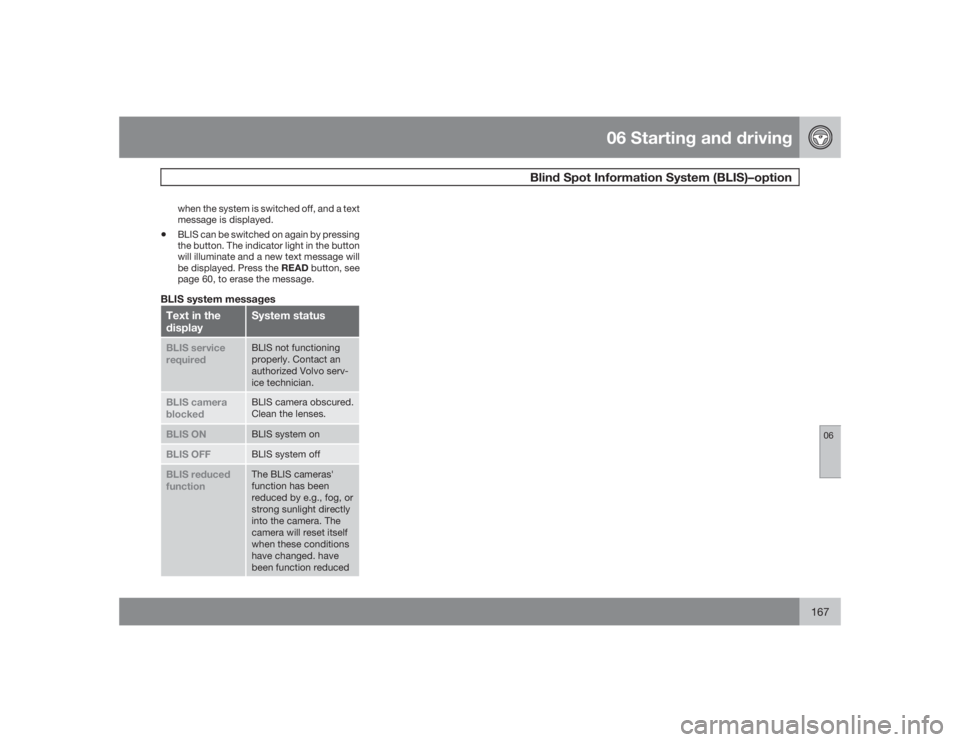

BLIS system messagesText in the

display

System status

BLIS service

required

BLIS not functioning

properly. Contact an

authorized Volvo serv-

ice technician.

BLIS camera

blocked

BLIS camera obscured.

Clean the lenses.

BLIS ON

BLIS system on

BLIS OFF

BLIS system off

BLIS reduced

function

The BLIS cameras'

function has been

reduced by e.g., fog, or

strong sunlight directly

into the camera. The

camera will reset itself

when these conditions

have changed. have

been function reduced

Page 186 of 286

07 Wheels and tiresSnow chains, snow tires, studded tires

07186

Snow chainsSnow chains can be used on your Volvo with

the following restrictions:•

Snow chains should be installed on front

wheels only. Use only Volvo approved

snow chains.

•

If accessory, aftermarket or "custom" tires

and wheels are installed and are of a size

different than the original tires and wheels,

chains in some cases CANNOT be used.

Sufficient clearances between chains and

brakes, suspension and body components

must be maintained.

•

Some strap-on type chains will interfere

with brake components and therefore

CANNOT be used.

•

All Wheel Drive models: Snow chains

should only be installed on the front

wheels. Only chains adapted for AWD

models should be used.

Consult your Volvo retailer for additional snow

chain information.

CAUTION

•

Check local regulations regarding the

use of snow chains before installing.

•

Always follow the chain manufacturer's

installation instructions carefully. Install

chains as tightly as possible and

retighten periodically.

•

Never exceed the chain manufacturer's

specified maximum speed limit. (Under

no circumstances should you exceed

31 mph (50 km/h).

•

Avoid bumps, holes or sharp turns

when driving with snow chains.

•

The handling of the vehicle can be

adversely affected when driving with

chains. Avoid fast or sharp turns as well

as locked wheel braking.

Snow tires, studded tiresTires for winter use:•

Owners who live in or regularly commute

through areas with sustained periods of

snow or icy driving conditions are strongly

advised to fit suitable winter tires to help

retain the highest degree of traction.

•

It is important to install winter tires on all

four wheels to help retain traction during

cornering, braking, and accelerating. Fail-ure to do so could reduce traction to an

unsafe level or adversely affect handling.

•

Do not mix tires of different design as this

could also negatively affect overall tire road

grip.

•

Winter tires wear more quickly on dry roads

in warm weather. They should be removed

when the winter driving season has ended.

•

Studded tires should be run-in 300–

600 miles (500–1000 km) during which the

car should be driven as smoothly as pos-

sible to give the studs the opportunity to

seat properly in the tires. The tires should

have the same rotational direction

throughout their entire lifetime.NOTE

Please consult state or provincial regula-

tions restricting the use of studded winter

tires before installing such tires.

Page 188 of 286

07 Wheels and tiresWheel nuts

07188

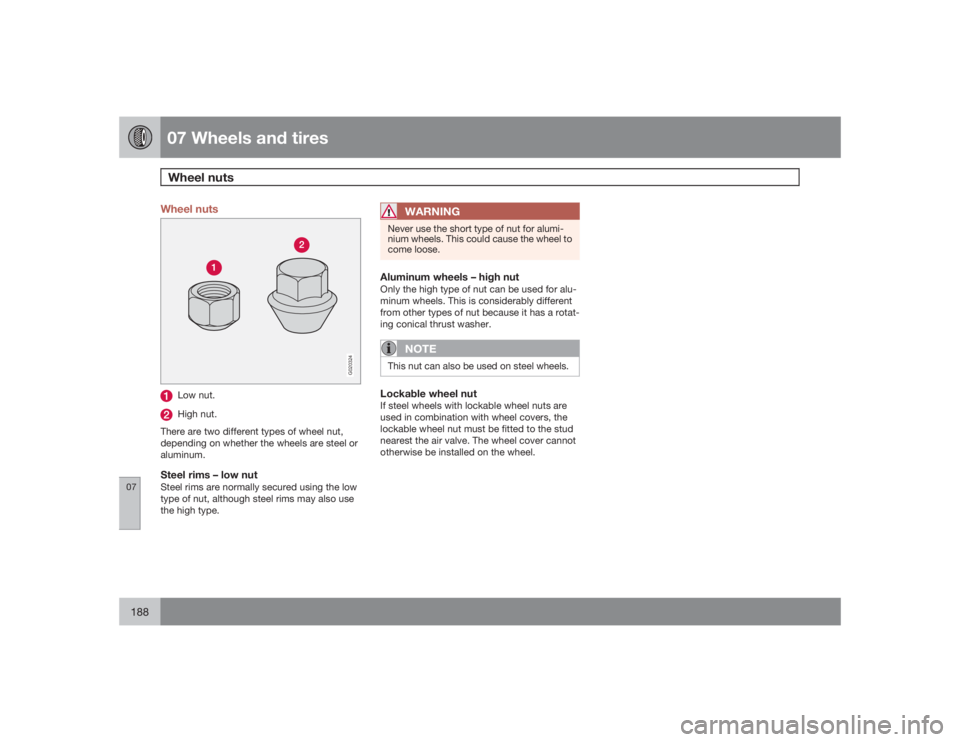

Wheel nuts

G020324

Low nut.High nut.

There are two different types of wheel nut,

depending on whether the wheels are steel or

aluminum.

Steel rims – low nutSteel rims are normally secured using the low

type of nut, although steel rims may also use

the high type.

WARNING

Never use the short type of nut for alumi-

nium wheels. This could cause the wheel to

come loose.Aluminum wheels – high nutOnly the high type of nut can be used for alu-

minum wheels. This is considerably different

from other types of nut because it has a rotat-

ing conical thrust washer.

NOTE

This nut can also be used on steel wheels.Lockable wheel nutIf steel wheels with lockable wheel nuts are

used in combination with wheel covers, the

lockable wheel nut must be fitted to the stud

nearest the air valve. The wheel cover cannot

otherwise be installed on the wheel.

Page 190 of 286

07 Wheels and tiresChanging a wheel

07190

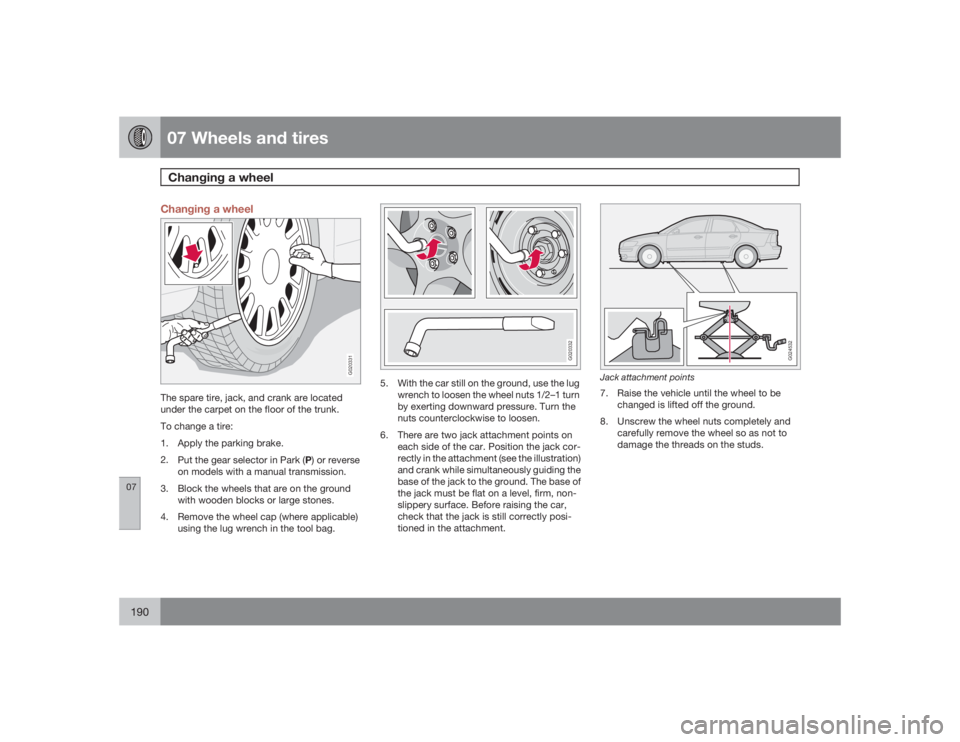

Changing a wheel

G020331

The spare tire, jack, and crank are located

under the carpet on the floor of the trunk.

To change a tire:

1. Apply the parking brake.

2.

Put the gear selector in Park (P) or reverse

on models with a manual transmission.

3. Block the wheels that are on the ground

with wooden blocks or large stones.

4. Remove the wheel cap (where applicable)

using the lug wrench in the tool bag.

G020332

5. With the car still on the ground, use the lug

wrench to loosen the wheel nuts 1/2–1 turn

by exerting downward pressure. Turn the

nuts counterclockwise to loosen.

6. There are two jack attachment points on

each side of the car. Position the jack cor-

rectly in the attachment (see the illustration)

and crank while simultaneously guiding the

base of the jack to the ground. The base of

the jack must be flat on a level, firm, non-

slippery surface. Before raising the car,

check that the jack is still correctly posi-

tioned in the attachment.

G024532

Jack attachment points7. Raise the vehicle until the wheel to be

changed is lifted off the ground.

8. Unscrew the wheel nuts completely and

carefully remove the wheel so as not to

damage the threads on the studs.

Page 191 of 286

07 Wheels and tires

Changing a wheel

07

191

WARNING

•

The jack must correctly engage the jack

attachment.

•

Be sure the jack is on a firm, level, non-

slippery surface.

•

Never allow any part of your body to be

extended under a car supported by a

jack.

•

Use the jack intended for the car when

changing a tire. For any other job, use

stands to support the car.

•

Apply the parking brake and put the

gear selector in the Park (P) position or

reverse on models with a manual trans-

mission.

•

Block the wheels standing on the

ground, use rigid wooden blocks or

large stones.

•

The jack should be kept well-greased

and clean, and should not be damaged.

•

No objects should be placed between

the base of jack and the ground, or

between the jack and the attachment

bar on the vehicle.

Installing the wheel1. Clean the contact surfaces on the wheel

and hub.

2. Lift the wheel and place it on the hub.

3. Install the wheel nuts and tighten hand-

tight. Using the lug wrench, tighten cross-

wise until all nuts are snug.

4. Lower the vehicle to the ground and alter-

nately tighten the bolts crosswise to

81 ft. lbs. (110 Nm).

5. Install the wheel cap (where applicable).Returning the jack to its storage space

G029335

The jack (certain models) and tools should be

returned to their correct storage places after

use.•

On vehicles equipped with a jack and

spare wheel, the jack should be cranked

down to the position shown in the illustra-

tion.

•

On vehicles equipped with the tire sealing

system, the jack should be cranked down

as far as possible and returned to its stor-

age position in the foam block.WARNING

The jack and any tools should always be

returned to their proper storage compart-

ments after use to help keep them securely

in place in the event of sudden braking, etc.

Page 195 of 286

07 Wheels and tires

Tire Sealing System

07�`�`195

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

WARNING

If the pressure remains below 22 psi (1.8

bar) after approximately seven minutes, turn

off the compressor. In this case, the hole is

too large to be sealed and the vehicle should

not be driven.12. Switch off the compressor and disconnect

the electrical wire from the 12-volt socket.

13. Unscrew the hose from the tire’s inflation

valve and reinstall the valve cap.

14. Immediately drive the vehicle for approxi-

mately 2 miles (3 km) at a maximum speed

of 50 mph (80 km/h) to distribute the seal-

ing compound in the tire.

NOTE

•

Safely stow the tire sealing system in a

convenient place as it will soon be used

again to check the tire’s inflation pres-

sure.

•

The empty bottle of sealing compound

cannot be removed from the bottle

holder. Consult a trained and qualified

Volvo service technician to have the

bottle removed and properly disposed

of.WARNING

If heavy vibrations, unsteady steering

behavior, or noises should occur while driv-

ing, reduce speed and park the vehicle in a

safe place. Recheck the tire for bumps,

cracks, or other visible damage, and

recheck its inflation pressure. If the pressure

is below 19 psi (1.3 bar), do not continue

driving. Have the vehicle towed to a trained

and qualified Volvo service technician.Stage 2: Checking inflation pressure1. Connect the tire sealing system as descri-

bed in stage 1.

2. Refer to the inflation pressure tablesfor the

correct inflation pressure. If the tire needs

to be inflated, start the tire sealing system’s

compressor. If necessary, release air fromthe tire by turning the air release knob

counterclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

WARNING

If you interrupt your trip for more than 1

hour, check the inflation pressure in the

damaged tire again before continuing.Replacing the sealing compound

containerThe sealing compound container must be

replaced if:•

the tire sealing system has been used to

repair a tire

•

the container’s expiration date has passed

(see the date on decal).

Page 196 of 286

07 Wheels and tiresTire Sealing System

07196

NOTE

•

After use, the sealing compound bottle,

the hose, and certain other system

components must be replaced. Please

consult your Volvo retailer for replace-

ment parts.

•

If the sealing compound bottle’s expi-

ration date has passed, please take it to

a Volvo retailer or a recycling station

that can properly dispose of harmful

substances.

Inflating tiresThe tire sealing system can be used to inflate

the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in posi-

tion0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s infla-

tion valve and screw the hose connector

onto the valve as tightly as possible by

hand.

5. Connect the electrical wire to the nearest

12-volt socket in the vehicle.6. Start the vehicle’s engine.

WARNING

•The vehicle’s engine should be running

when the tire sealing system is used to

avoid battery drain. Therefore, be sure

the vehicle is parked in a well ventilated

place, or outdoors, before using the sys-

tem.•Children should never be left unattended

in the vehicle when the engine is running.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to

get a clear reading from the pressure

gauge.

8. Refer to the tire inflation tables for the cor-

rect inflation pressure. If the tire needs to

be inflated, start the tire sealing system’s

compressor (press the on/off switch to

position I). If necessary, release air from the

tire by turning the air release knob coun-

terclockwise.

CAUTION

The compressor should not be used for

more than 10 minutes at a time to avoid

overheating.

9. Turn off the compressor (press the on/off

switch to position 0) when the correct infla-

tion pressure has been reached.

10. Unscrew the hose from the tire’s inflation

valve and reinstall the valve cap.

11. Disconnect the electrical wire from the

12-volt socket.

Page 203 of 286

08 Car care

Washing and cleaning the car

08�`�`203

CAUTION

•

During high pressure washing, the

spray mouthpiece must never be closer

to the vehicle than 13" (30 cm). Do not

spray into the locks.

•

Dirt, snow, etc., on the headlights can

reduce lighting capacity considerably.

Clean the headlights regularly, for

example when refueling.

•

When washing or steam cleaning the

engine, avoid spraying water or steam

directly on the electrical components or

toward the rear side of the engine.

•

Always close the moonroof (option) and

sun shade before washing your vehicle.

•

Never use abrasive cleaning agents on

the moonroof.

•

Never use wax on the rubber seals

around the moonroof.

Automatic washing – simple and quickWe do NOT recommend washing your car in an

automatic wash during the first six months

(because the paint will not have hardened suf-

ficiently).

An automatic wash is a simple and quick way

to clean your car, but it is worth remembering

that it may not be as thorough as when you

yourself go over the car with sponge and water.Keeping the underbody clean is most impor-

tant, especially in the winter. Some automatic

washers do not have facilities for washing the

underbody.

CAUTION

•

Before driving into an automatic car

wash, turn off the optional rain sensor

to avoid damaging the windshield wip-

ers.

•

Make sure that side view mirrors, auxil-

iary lamps, etc, are secure, and that any

antenna(s) are retracted or removed.

Otherwise there is risk of the machine

dislodging them

•

Chromed wheels: Clean chrome-

plated wheels using the same deter-

gents used for the body of the vehicle.

Aggressive wheel-cleaning agents can

permanently stain chrome-plated

wheels.WARNING

•

When the car is driven immediately after

being washed, apply the brakes several

times in order to remove any moisture

from the brake linings.

•

Engine cleaning agents should not be

used when the engine is warm. This

constitutes a fire risk.

Exterior lightingCondensation may form temporarily on the

inside of the lenses of exterior lights such as

headlights, fog lights, or taillights. This is nor-

mal and the lights are designed to withstand

moisture. Normally, condensation will dissi-

pate after the lights have been on for a short

time.Polishing and Waxing•

Normally, polishing is not required during

the first year after delivery, however, wax-

ing may be beneficial.

•

Before applying polish or wax the vehicle

must be washed and dried. Tar spots can

be removed with kerosene or tar remover.

Difficult spots may require a fine rubbing

compound.

•

After polishing use liquid or paste wax.

•

Several commercially available products

contain both polish and wax.

•

Waxing alone does not substitute for pol-

ishing a dull surface.

•

A wide range of polymer-based waxes can

be purchased today. These waxes are easy

to use and produce a long-lasting, high-

gloss finish that protects the bodywork

against oxidation, road dirt and fading.

•

Do not polish or wax your vehicle in direct

sunlight (the surface of the vehicle should

not be warmer than 113 °F (45 °C).