lock VOLVO S60 2014 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2014, Model line: S60, Model: VOLVO S60 2014Pages: 386, PDF Size: 11.24 MB

Page 306 of 386

08 Wheels and tires

Snow chains, snow tires, studded tires

08

304

Winter driving conditions

Snow chainsSnow chains can be used on your Volvo with the following restrictions:• Snow chains should be installed on front wheels only. Use only Volvo approvedsnow chains.

• If accessory, aftermarket or "custom"tires and wheels are installed and are of asize different than the original tires andwheels, chains in some cases CANNOTbe used. Sufficient clearances betweenchains and brakes, suspension and bodycomponents must be maintained.

• Some strap-on type chains will interferewith brake components and thereforeCANNOT be used.

• All Wheel Drive models

: Snow chains

should only be installed on the frontwheels.

• Certain size tires may not allow theassembly of snow chains/traction devi-ces.

Consult your Volvo retailer for additional

snow chain information.

CAUTION

• Check local regulations regarding the use of snow chains before installing.

• Use single-sided snow chains only.

• Always follow the chain manufactur-er's installation instructions carefully.Install chains as tightly as possible andretighten periodically.

• Never exceed the chain manufactur-er's specified maximum speed limit.(Under no circumstances should youexceed 31 mph (50 km/h).

• Avoid bumps, holes or sharp turnswhen driving with snow chains.

• The handling of the vehicle can beadversely affected when driving withchains. Avoid fast or sharp turns aswell as locked wheel braking.

Snow tires, studded tires 1

Tires for winter use:

•

Owners who live in or regularly commute through areas with sustained periods ofsnow or icy driving conditions arestrongly advised to fit suitable winter tires to help retain the highest degree of trac-tion.

• It is important to install winter tires on allfour wheels to help retain traction duringcornering, braking, and accelerating. Fail-ure to do so could reduce traction to anunsafe level or adversely affect handling.

• Do not mix tires of different design as thiscould also negatively affect overall tireroad grip.

• Winter tires wear more quickly on dryroads in warm weather. They should beremoved when the winter driving seasonhas ended.

• Studded tires should be run-in 300 – 600 miles (500 – 1000 km) during whichthe vehicle should be driven as smoothlyas possible to give the studs the opportu-nity to seat properly in the tires. The tiresshould have the same rotational directionthroughout their entire lifetime.

NOTE

Please consult state or provincial regula- tions restricting the use of studded wintertires before installing such tires.

1

Where permitted

Page 312 of 386

08 Wheels and tires

Tire Sealing System*

08

310* Option/accessory, for more information, see Introduction.

speed of 50 mph (80 km/h) to distribute the sealing compound in the tire.

CAUTION

If your vehicle is equipped with the Tire Pressure Monitoring System (TPMS), theuse of the sealing compound may lead toincorrect tire pressure readings or in rarecases, damage to the tire pressure sensor.Use the tire sealing system to check andadjust the damaged tire's inflation pres-sure.

NOTE

• Safely stow the tire sealing system in a convenient place as it will soon beused again to check the tire’s inflationpressure.

• The empty bottle of sealing compoundcannot be removed from the bottleholder. Consult a trained and qualifiedVolvo service technician to have thebottle removed and properly disposedof.

WARNING

If heavy vibrations, unsteady steering behavior, or noises should occur whiledriving, reduce speed and park the vehiclein a safe place. Recheck the tire forbumps, cracks, or other visible damage,and recheck its inflation pressure. If thepressure is below 19 psi (1.3 bar), do notcontinue driving. Have the vehicle towedto a trained and qualified Volvo servicetechnician.

Stage 2: Checking inflation pressure1. Connect the tire sealing system as

described in stage 1.

2. Refer to the inflation pressure table in this chapter for the correct inflation pressure. If the tire needs to be inflated, start thetire sealing system’s compressor. If nec-essary, release air from the tire by turningthe air release knob counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

WARNING

If you interrupt your trip for more than 1 hour, check the inflation pressure in thedamaged tire again before continuing.

Replacing the sealing compound container

The sealing compound container must be replaced if:

• the tire sealing system has been used to repair a tire

• the container’s expiration date haspassed (see the date on decal).

NOTE

• After use, the sealing compound bot- tle, the hose, and certain other systemcomponents must be replaced. Pleaseconsult your Volvo retailer for replace-ment parts.

• If the sealing compound bottle’s expi-ration date has passed, please take itto a Volvo retailer or a recycling stationthat can properly dispose of harmfulsubstances.

Page 313 of 386

08 Wheels and tires

Tire Sealing System*

08

* Option/accessory, for more information, see Introduction.311

Inflating tires

The tire sealing system can be used to inflate the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.

Ensure that the on/off switch is in position0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s inflation valve and screw the hose con- nector onto the valve as tightly as possi-ble by hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

6. Start the vehicle’s engine.WARNING

• The vehicle’s engine should be running when the tire sealing system is used toavoid battery drain. Therefore, be surethe vehicle is parked in a well ventilatedplace, or outdoors, before using thesystem. The parking brake should besecurely applied and the gear selectorshould be in the

P (park) position.

• Children should never be left unatten-ded in the vehicle when the engine isrunning.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to get a clear reading from the pressuregauge.

8. Refer to the tire inflation table in this chapter for the correct inflation pressure.If the tire needs to be inflated, start thetire sealing system’s compressor (pressthe on/off switch to position I). If neces-sary, release air from the tire by turningthe air release knob counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

9. Turn off the compressor (press the on/off switch to position 0) when the correct

inflation pressure has been reached.

10. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

CAUTION

•After pumping the tires, always reinstall the valve cap to help avoid damage tothe valve from dirt, gravel, etc.

• Use plastic valve caps only. Metal capscould corrode and become difficult toremove.

11. Disconnect the electrical wire from the

12-volt socket.

Page 315 of 386

08 Wheels and tires

Changing a wheel

08

* Option/accessory, for more information, see Introduction.313

CAUTION

The vehicle must never be driven with more than one temporary spare wheel.

Taking out the spare wheel1. Release the bag's retaining straps.

2. Lift the bag out of the vehicle and remove

the spare wheel from the bag.

3. Fold up the floor hatch in the trunk.

4. Remove the jack* and tools* from the foam block and change the wheels (see the instructions in the following section"Changing a wheel").

5. After changing wheels, return the jack and tools to the foam block and close thefloor hatch.

6. If possible, place the wheel with the punctured tire in the bag.

7. If there is a wheel in the bag, strap the bag securely in place in the trunk.

WARNING

•If there is a wheel in the bag, the bag must be securely restrained using itsstraps and the load anchoring eyelets inthe trunk. Carefully follow the instruc-tions on page 312

• If the wheel with the punctured tire istoo big to fit in the bag, it should besecurely restrained in the trunk usingsuitable straps, a net for anchoringcargo, etc.

Changing a wheel1. Apply the parking brake and put the gear

selector in P.

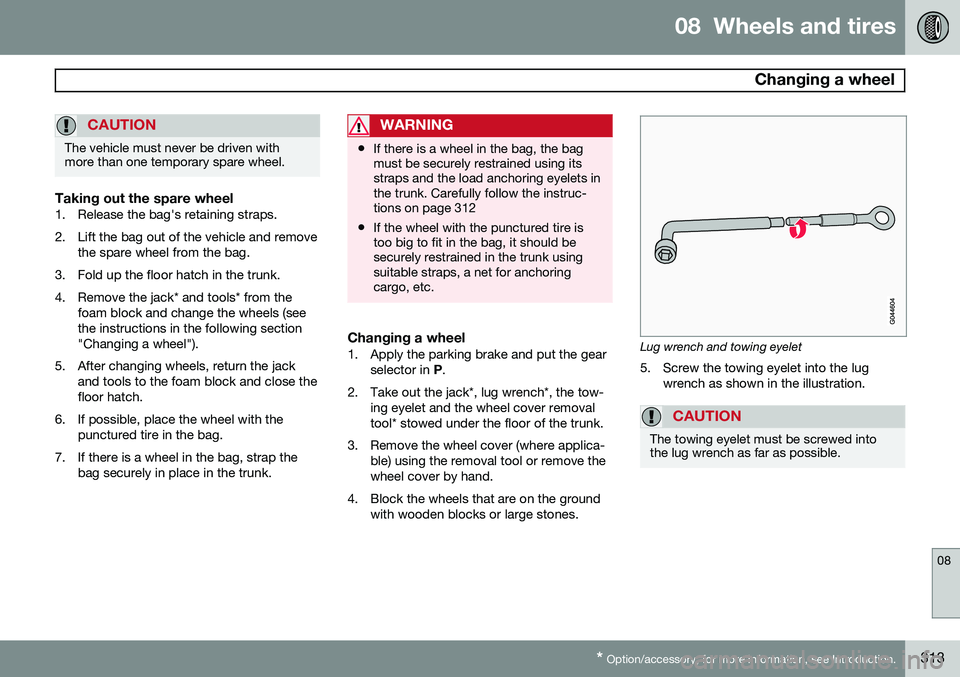

2. Take out the jack*, lug wrench*, the tow- ing eyelet and the wheel cover removal tool* stowed under the floor of the trunk.

3. Remove the wheel cover (where applica- ble) using the removal tool or remove thewheel cover by hand.

4. Block the wheels that are on the ground with wooden blocks or large stones.Lug wrench and towing eyelet

5. Screw the towing eyelet into the lug wrench as shown in the illustration.

CAUTION

The towing eyelet must be screwed into the lug wrench as far as possible.

Page 316 of 386

08 Wheels and tires

Changing a wheel

08

314

6. With the vehicle still on the ground, usethe lug wrench/towing eyelet to loosen the wheel nuts ½ – 1 turn by exertingdownward (counterclockwise) pressure.

Jack attachment points

7. There are two jack attachment points on each side of the vehicle. Position the jack correctly in the attachment (see the illus-tration) and crank while simultaneouslyguiding the base of the jack to theground. The base of the jack must be flaton a level, firm, non-slippery surface.Before raising the vehicle, check that thejack is still correctly positioned in theattachment.

8. Raise the vehicle until the wheel to be changed is lifted off the ground.

9. Unscrew the wheel nuts completely and remove the wheel.

WARNING

•The jack must correctly engage the jack attachment.

• Be sure the jack is on a firm, level,non-slippery surface.

• Never allow any part of your body tobe extended under a vehicle suppor-ted by a jack.

• Use the jack intended for the vehiclewhen changing a tire. For any otherjob, use stands to support the vehicle.

• Apply the parking brake and put thegear selector in the Park (

P) position.

• Block the wheels standing on theground, use rigid wooden blocks orlarge stones.

• The jack should be kept well-greasedand clean, and should not be dam-aged.

• No objects should be placed betweenthe base of jack and the ground, orbetween the jack and the attachmentbar on the vehicle.

Page 327 of 386

09 Maintenance and specifications

Hood and engine compartment09

325

Opening and closing the hood

Turn the handle located under the left side of the dash approximately 20-25degrees clockwise to release the hoodlock.

Lift the hood slightly. Press the release control (located under the right front edgeof the hood) to the left, and lift the hood.

WARNING

Check that the hood locks properly when closed.

Engine compartment, overview

Coolant expansion tank

Power steering fluid reservoir

Dipstick-engine oil

Filler cap-engine oil

Cover over brake fluid reservoir

Battery

Relay/fuse box

Washer fluid reservoirThe appearance of the engine compartment may vary depending on engine model.

WARNING

The cooling fan (located at the front of the engine compartment, behind the radiator)may start or continue to operate (for up to6 minutes) after the engine has beenswitched off.

WARNING

Before performing any operations in the engine compartment, the ignition shouldalways be completely switched off (inmode

0, see page 87) and there should be

no remote keys in the passenger compart-ment. The gear selector should be in the P

(park) position. If the engine has been run-ning, wait until it has cooled before touch-ing any components in the engine com-partment. The distributor ignition system operates at very high voltages. Special safety precau-tions must be followed to prevent injury.Always turn the ignition off when:

• Replacing distributor ignition compo- nents e.g. plugs, coil, etc.

• Do not touch any part of the distributorignition system while the engine is run-ning. This may result in unintendedmovements and body injury.

Page 333 of 386

09 Maintenance and specifications

Replacing bulbs09

331

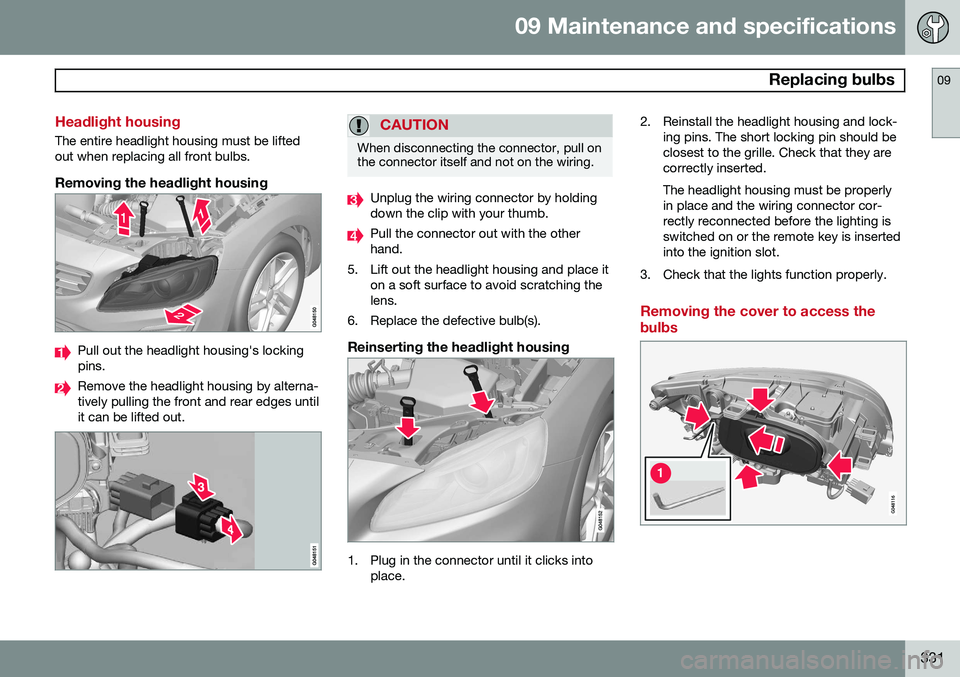

Headlight housing

The entire headlight housing must be lifted out when replacing all front bulbs.

Removing the headlight housing

Pull out the headlight housing's locking pins.

Remove the headlight housing by alterna- tively pulling the front and rear edges untilit can be lifted out.

CAUTION

When disconnecting the connector, pull on the connector itself and not on the wiring.

Unplug the wiring connector by holding down the clip with your thumb.

Pull the connector out with the other hand.

5. Lift out the headlight housing and place it on a soft surface to avoid scratching thelens.

6. Replace the defective bulb(s).

Reinserting the headlight housing

1. Plug in the connector until it clicks into place. 2. Reinstall the headlight housing and lock-

ing pins. The short locking pin should be closest to the grille. Check that they arecorrectly inserted. The headlight housing must be properly in place and the wiring connector cor-rectly reconnected before the lighting isswitched on or the remote key is insertedinto the ignition slot.

3. Check that the lights function properly.

Removing the cover to access the bulbs

Page 334 of 386

09 Maintenance and specifications

Replacing bulbs 09

332

NOTE

Before starting to replace a bulb, see page 330.

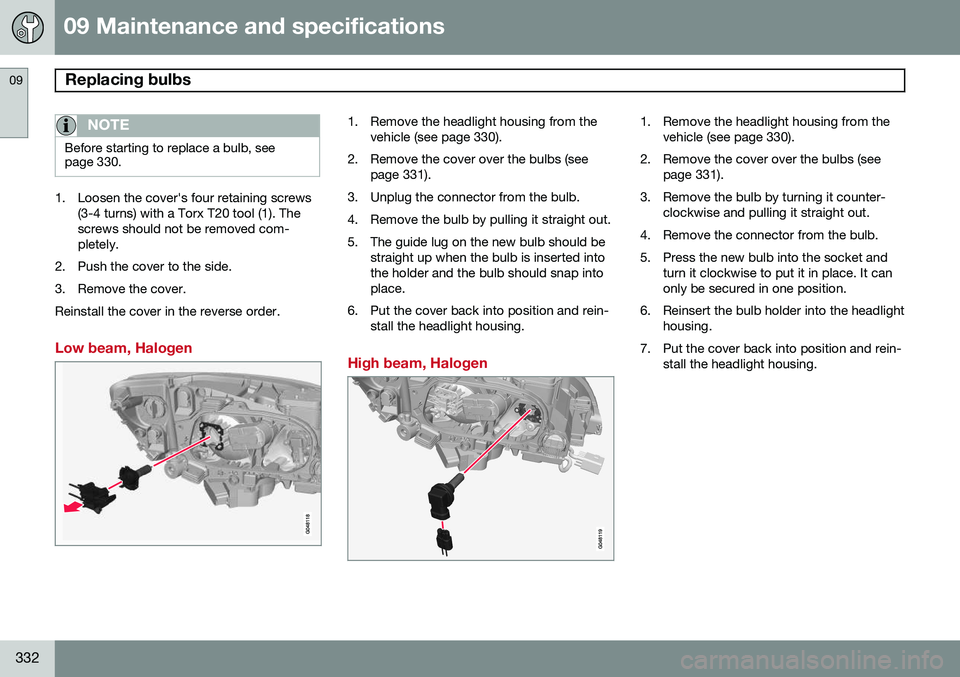

1. Loosen the cover's four retaining screws(3-4 turns) with a Torx T20 tool (1). The screws should not be removed com-pletely.

2. Push the cover to the side.

3. Remove the cover.Reinstall the cover in the reverse order.

Low beam, Halogen

1. Remove the headlight housing from the vehicle (see page 330).

2. Remove the cover over the bulbs (see page 331).

3. Unplug the connector from the bulb.

4. Remove the bulb by pulling it straight out.

5. The guide lug on the new bulb should be straight up when the bulb is inserted into the holder and the bulb should snap intoplace.

6. Put the cover back into position and rein- stall the headlight housing.

High beam, Halogen

1. Remove the headlight housing from the vehicle (see page 330).

2. Remove the cover over the bulbs (see page 331).

3. Remove the bulb by turning it counter- clockwise and pulling it straight out.

4. Remove the connector from the bulb.

5. Press the new bulb into the socket and turn it clockwise to put it in place. It can only be secured in one position.

6. Reinsert the bulb holder into the headlight housing.

7. Put the cover back into position and rein- stall the headlight housing.

Page 335 of 386

09 Maintenance and specifications

Replacing bulbs09

333

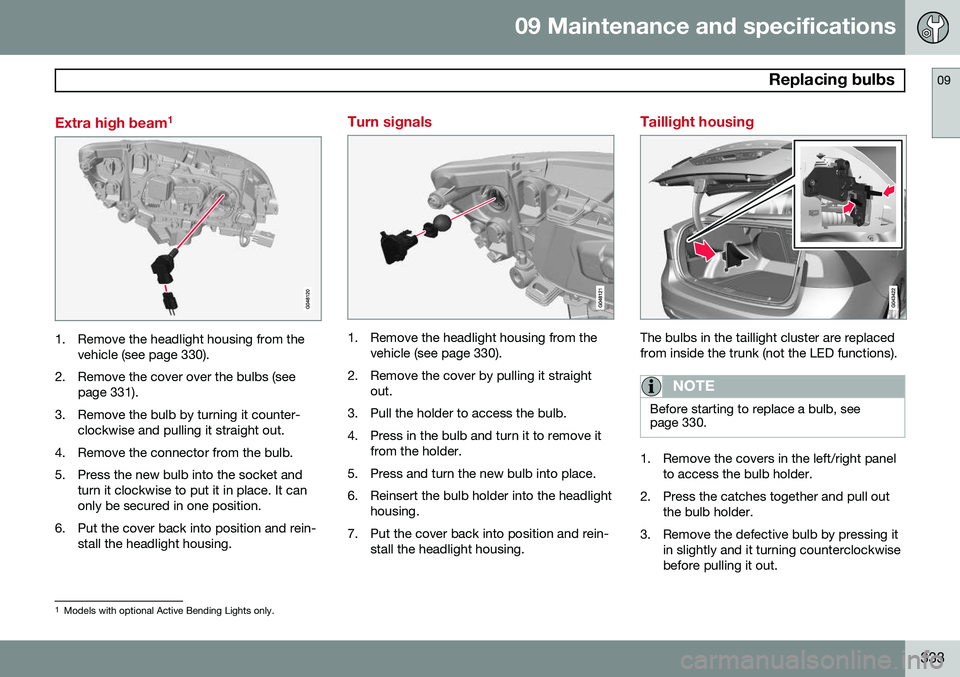

Extra high beam1

1. Remove the headlight housing from the

vehicle (see page 330).

2. Remove the cover over the bulbs (see page 331).

3. Remove the bulb by turning it counter- clockwise and pulling it straight out.

4. Remove the connector from the bulb.

5. Press the new bulb into the socket and turn it clockwise to put it in place. It can only be secured in one position.

6. Put the cover back into position and rein- stall the headlight housing.

Turn signals

1. Remove the headlight housing from thevehicle (see page 330).

2. Remove the cover by pulling it straight out.

3. Pull the holder to access the bulb.

4. Press in the bulb and turn it to remove it from the holder.

5. Press and turn the new bulb into place.

6. Reinsert the bulb holder into the headlight housing.

7. Put the cover back into position and rein- stall the headlight housing.

Taillight housing

The bulbs in the taillight cluster are replaced from inside the trunk (not the LED functions).

NOTE

Before starting to replace a bulb, see page 330.

1. Remove the covers in the left/right panel to access the bulb holder.

2. Press the catches together and pull out the bulb holder.

3. Remove the defective bulb by pressing it in slightly and it turning counterclockwise before pulling it out.

1Models with optional Active Bending Lights only.

Page 336 of 386

09 Maintenance and specifications

Replacing bulbs 09

334

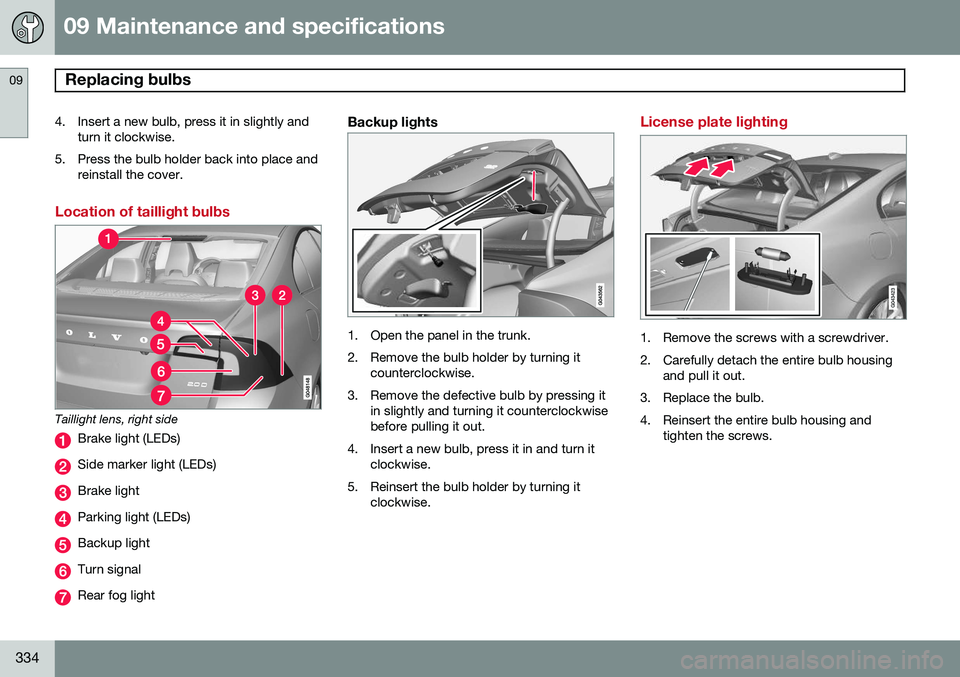

4. Insert a new bulb, press it in slightly andturn it clockwise.

5. Press the bulb holder back into place and reinstall the cover.

Location of taillight bulbs

Taillight lens, right side

Brake light (LEDs)

Side marker light (LEDs)

Brake light

Parking light (LEDs)

Backup light

Turn signal

Rear fog light

Backup lights

1. Open the panel in the trunk.

2. Remove the bulb holder by turning itcounterclockwise.

3. Remove the defective bulb by pressing it in slightly and turning it counterclockwise before pulling it out.

4. Insert a new bulb, press it in and turn it clockwise.

5. Reinsert the bulb holder by turning it clockwise.

License plate lighting

1. Remove the screws with a screwdriver.

2. Carefully detach the entire bulb housing and pull it out.

3. Replace the bulb.

4. Reinsert the entire bulb housing and tighten the screws.