remove VOLVO S60 2016 Owner´s Manual

[x] Cancel search | Manufacturer: VOLVO, Model Year: 2016, Model line: S60, Model: VOLVO S60 2016Pages: 392, PDF Size: 10.04 MB

Page 311 of 392

09 Wheels and tires

09

}}

309

the system is temporarily unavailable. It should become operational again shortly.

Related information

•

Tire Monitor – messages (p. 309)

Tire Monitor – messages

When low tire pressure has been detected, a message will be displayed and the tire pres-sure warning telltale in the instrument panel

will illuminate.

Erasing warning messagesTo erase a low tire pressure message and turn off the telltale:

1. Use a tire pressure gauge to check the

inflation pressure of all four tires (see the article "Tire inflation – checking pres-sure").

2. Re-inflate the tires to the correct pressure (consult the tire pressure placard locatedon the driver's side B-pillar (the structuralmember at the side of the vehicle, at therear of the driver's door opening) or theinflation pressure table, see Tire inflation –pressure table (p. 297).

3. Recalibrate Tire Monitor, see Calibrating Tire Monitor (p. 308).

NOTE

To help avoid incorrect tire inflation pres- sure, only inflate the tires when they arecold. The tires are considered to be coldwhen they have the same temperature asthe surrounding (ambient) air. This tem-perature is normally reached after the vehi-cle has been parked for at least 3 hours.After driving a distance of approximately1 mile (1.6 km), the tires are considered tobe hot.

CAUTION

•After inflating the tires, always reinstall the valve cap to help avoid damage tothe valve from dirt, gravel, etc.

• Use plastic valve caps only. Metalcaps could corrode and become diffi-cult to remove.

WARNING

•

Incorrect inflation pressure could lead to tire failure, resulting in a loss of con-trol of the vehicle.

• Tire monitoring systems cannot indi-cate sudden tire damage caused byexternal factors (e.g., a blowout) inadvance.

Page 313 of 392

09 Wheels and tires

09

* Option/accessory, for more information, see Introduction.311

WARNING

• After using the tire sealing system, the vehicle should not be driven fartherthan approximately 120 miles (200km).

• Have the tire inspected by a trainedand qualified Volvo service technicianas soon as possible to determine if itcan be permanently repaired or mustbe replaced.

• The vehicle should not be driven fasterthan 50 mph (80 km/h) while using atire that has been temporarily repairedwith the tire sealing system.

• After using the tire sealing system,drive carefully and avoid abrupt steer-ing maneuvers and sudden stops.

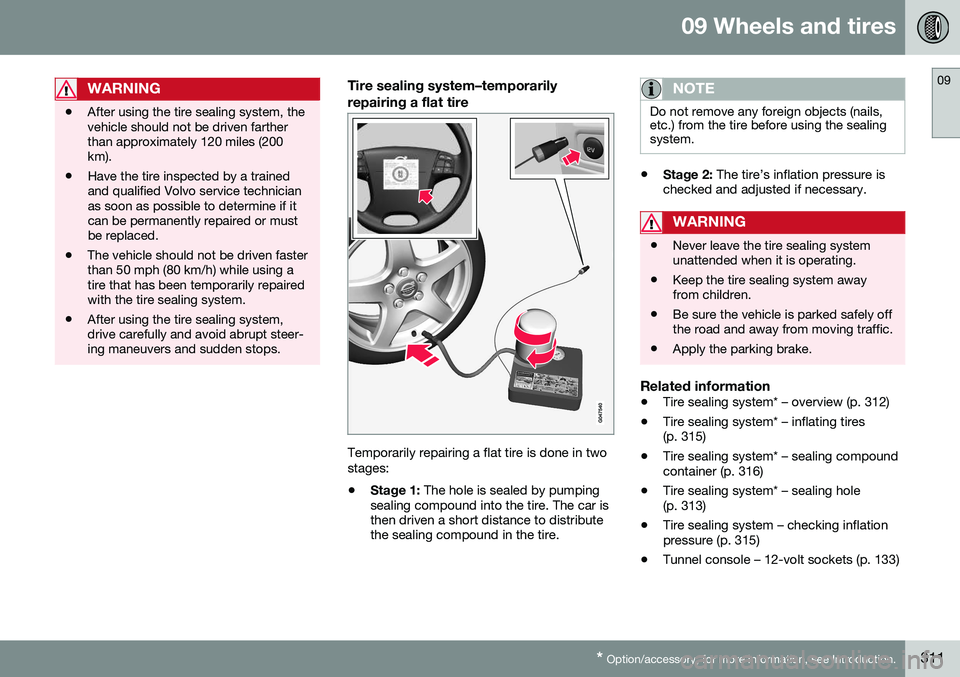

Tire sealing system–temporarily repairing a flat tire

Temporarily repairing a flat tire is done in two stages:

• Stage 1:

The hole is sealed by pumping

sealing compound into the tire. The car is then driven a short distance to distributethe sealing compound in the tire.

NOTE

Do not remove any foreign objects (nails, etc.) from the tire before using the sealingsystem.

• Stage 2:

The tire’s inflation pressure is

checked and adjusted if necessary.

WARNING

• Never leave the tire sealing system unattended when it is operating.

• Keep the tire sealing system awayfrom children.

• Be sure the vehicle is parked safely offthe road and away from moving traffic.

• Apply the parking brake.

Related information

•

Tire sealing system* – overview (p. 312)

• Tire sealing system* – inflating tires (p. 315)

• Tire sealing system* – sealing compoundcontainer (p. 316)

• Tire sealing system* – sealing hole(p. 313)

• Tire sealing system – checking inflationpressure (p. 315)

• Tunnel console – 12-volt sockets (p. 133)

Page 315 of 392

09 Wheels and tires

09

}}

* Option/accessory, for more information, see Introduction.313

Tire sealing system* – sealing hole

The tire sealing system can be used to tem- porarily seal a hole in the tread surface of atire.

Stage 1: Sealing the hole1. Peel off the speed limit sticker and affix it

to the steering wheel hub where it will beclearly visible to the driver.

2. Ensure that the on/off switch is in posi- tion 0 (the 0 side of the switch should be

pressed down).

WARNING

Contact with the sealing compound may cause skin irritation. If contact occurs,wash the affected area immediately withsoap and water.

3. Unscrew the orange cover over the bottle holder and unscrew the cap on the bottle of sealing compound.

NOTE

Do not break the seal on the bottle. This occurs automatically when the bottle isscrewed into the holder.

4. Screw the bottle into the bottle holder.

WARNING

The bottle is equipped with a catch to keep it securely in place and help preventsealing compound leakage. Once in place,the bottle cannot be unscrewed. This mustbe done by a trained and qualified Volvoservice technician.

5. Remove the valve cap from the tire’sinflation valve and screw the tire sealing system’s hose connector onto the valveas tightly as possible by hand.

6. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

NOTE

Be sure that none of the other 12-volt sockets is being used while the compres-sor is in operation.

7. Start the vehicle’s engine.

WARNING

The vehicle´s engine should be running when the tire sealing system is used toavoid battery drain. Therefore, be sure thevehicle is parked in a well ventilated place,or outdoors, before using the system.

8. Start the tire sealing system’s compres- sor by pressing the on/off switch to posi- tion I.

Page 316 of 392

||

09 Wheels and tires

09

314

WARNING

•Never stand next to the tire being infla- ted when the compressor is in opera-tion.

• If cracks, bubbles, etc. form on the tire,switch off the compressor immediately.

• If there is visible damage to the sidewallor the rim, the tire cannot be repaired.The vehicle should not be driven if thisoccurs. Contact a towing service orVolvo On Call Roadside Assistance ifapplicable.

NOTE

The air pressure gauge will temporarily show an increase in pressure to approxi-mately 88 psi (6 bar) while the sealingcompound is being pumped into the tire.The pressure should return to a normallevel after approximately 30 seconds.

9. Within seven minutes, inflate the tire to

between 22—44 psi (1.8—3.0 bar). Switch off the compressor briefly to get aclear reading from the pressure gauge.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

WARNING

If the pressure remains below 22 psi (1.8 bar) after approximately sevenminutes, turn off the compressor. In thiscase, the hole is too large to be sealed andthe vehicle should not be driven.

10. Switch off the compressor and discon-nect the electrical wire from the 12-volt socket.

11. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

CAUTION

•After inflating the tires, always reinstall the valve cap to help avoid damage tothe valve from dirt, gravel, etc.

• Use plastic valve caps only. Metal capscould corrode and become difficult toremove.

12. Immediately drive the vehicle for approxi-

mately 2 miles (3 km) at a maximum speed of 50 mph (80 km/h) to distributethe sealing compound in the tire.

CAUTION

If your vehicle is equipped with the Tire Pressure Monitoring System (TPMS), theuse of the sealing compound may lead toincorrect tire pressure readings or in rarecases, damage to the tire pressure sensor.Use the tire sealing system to check andadjust the damaged tire's inflation pres-sure.

NOTE

•Safely stow the tire sealing system in a convenient place as it will soon beused again to check the tire’s inflationpressure.

• The empty bottle of sealing compoundcannot be removed from the bottleholder. Consult a trained and qualifiedVolvo service technician to have thebottle removed and properly disposedof.

WARNING

If heavy vibrations, unsteady steering behavior, or noises should occur whiledriving, reduce speed and park the vehiclein a safe place. Recheck the tire forbumps, cracks, or other visible damage,and recheck its inflation pressure. If thepressure is below 19 psi (1.3 bar), do notcontinue driving. Have the vehicle towedto a trained and qualified Volvo servicetechnician.

Page 317 of 392

09 Wheels and tires

09

}}

* Option/accessory, for more information, see Introduction.315

Tire sealing system – checking inflation pressure

The tire sealing system can also be used to check the tires' inflation pressure.

Stage 2: Checking inflation pressure1. Connect the tire sealing system as

described in stage 1, see Tire sealing

system* – sealing hole (p. 313).

2. Refer to the inflation pressure table in this chapter for the correct inflation pressure.If the tire needs to be inflated, start thetire sealing system’s compressor. If nec-essary, release air from the tire by turningthe air release knob counterclockwise.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

WARNING

If you interrupt your trip for more than 1 hour, check the inflation pressure in thedamaged tire again before continuing.

Tire sealing system* – inflating tires

The tire sealing system can be used to inflate the tires. To do so:

1. Park the car in a safe place.

2. The compressor should be switched off.Ensure that the on/off switch is in position0 (the 0 side of the switch should be

pressed down).

3. Take out the electrical wire and hose.

4. Remove the valve cap from the tire’s inflation valve and screw the hose con- nector onto the valve as tightly as possi-ble by hand.

5. Connect the electrical wire to the nearest 12-volt socket in the vehicle.

6. Start the vehicle’s engine.WARNING

• The vehicle’s engine should be running when the tire sealing system is used toavoid battery drain. Therefore, be surethe vehicle is parked in a well ventilatedplace, or outdoors, before using thesystem. The parking brake should besecurely applied and the gear selectorshould be in the

P (park) position.

• Children should never be left unatten-ded in the vehicle when the engine isrunning.

7. Check the tire’s inflation pressure on the

gauge. Switch off the compressor briefly to get a clear reading from the pressuregauge.

8. Refer to the tire inflation table in this chapter for the correct inflation pressure.If the tire needs to be inflated, start thetire sealing system’s compressor (pressthe on/off switch to position I). If neces-sary, release air from the tire by turningthe air release knob counterclockwise.

Page 318 of 392

09 Wheels and tires

09

316* Option/accessory, for more information, see Introduction.

CAUTION

The compressor should not be used for more than 10 minutes at a time to avoidoverheating.

9. Turn off the compressor (press the on/off

switch to position 0) when the correct

inflation pressure has been reached.

10. Unscrew the hose from the tire’s inflation valve and reinstall the valve cap.

CAUTION

•After inflating the tires, always reinstall the valve cap to help avoid damage tothe valve from dirt, gravel, etc.

• Use plastic valve caps only. Metal capscould corrode and become difficult toremove.

11. Disconnect the electrical wire from the

12-volt socket.

Tire sealing system* – sealing compound container

The sealing compound container must be replaced if the tire sealing system has beenused to repair a tire or if the container’s expi-ration date has passed (see the date ondecal).

Replacing the sealing compound container

NOTE

•After use, the sealing compound bot- tle, the hose, and certain other systemcomponents must be replaced. Pleaseconsult your Volvo retailer for replace-ment parts.

• If the sealing compound bottle’s expi-ration date has passed, please take itto a Volvo retailer or a recycling stationthat can properly dispose of harmfulsubstances.

Page 330 of 392

10 Maintenance and servicing

10

328

CAUTION

•If necessary, top up the cooling sys- tem with Volvo Genuine Coolant/Anti-freeze only (a 50/50 mix of water andantifreeze).

• Different types of antifreeze/coolantmay not be mixed.

• If the cooling system is drained, itshould be flushed with clean water orpremixed anti-freeze before it is refilledwith the correct mixture of water/anti-freeze.

• The cooling system must always bekept filled to the correct level, and thelevel must be between the

MIN and

MAX marks. If it is not kept filled, there

can be high local temperatures in theengine which could result in damage.Check coolant regularly!

• Do not top up with water only. Thisreduces the rust-protective and anti-freeze qualities of the coolant and hasa lower boiling point. It can also causedamage to the cooling system if itshould freeze.

• Do not use chlorinated tap water in thevehicle's cooling system.

WARNING

•Never remove the expansion tank cap while the engine is warm. Wait until theengine cools.

• If it is necessary to top off the coolantwhen the engine is warm, unscrew theexpansion tank cap slowly so that theoverpressure dissipates.

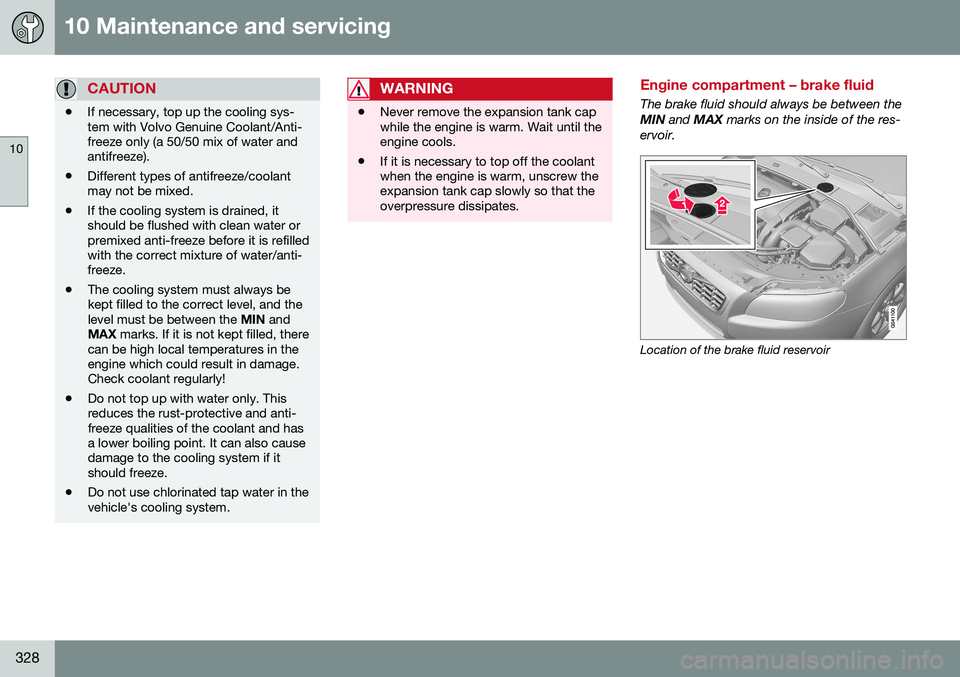

Engine compartment – brake fluid

The brake fluid should always be between the MIN

and MAX marks on the inside of the res-

ervoir.

Location of the brake fluid reservoir

Page 331 of 392

10 Maintenance and servicing

10

}}

329

Checking the levelThe fluid reservoir is concealed under the round cover at the rear of the engine com-partment. The round cover must be removedfirst before the reservoir cap can beaccessed. Check, without removing the cap, that there is sufficient fluid in the reservoir. Fluid type: DOT 4 boiling point >536 °F

(>280 °C).Replace : The fluid should be replaced

according to the intervals specified in the Warranty and Service Records Informationbooklet. When driving under extremely hard condi- tions (mountain driving, etc), it may be neces-sary to replace the fluid more often. Consult atrained and qualified Volvo service technician. Always entrust brake fluid changing to a trained and qualified Volvo service technician.

WARNING

• If the fluid level is below the

MIN mark

in the reservoir or if a brake-related message is shown in the informationdisplay: DO NOT DRIVE . Have the car

towed to a trained and qualified Volvoservice technician and have the brakesystem inspected.

• Dot 4 should never be mixed with anyother type of brake fluid.

Filling1. Turn and open the cover.

2. Unscrew the reservoir cap and fill the

fluid. The level must be between the MIN

and MAX marks.

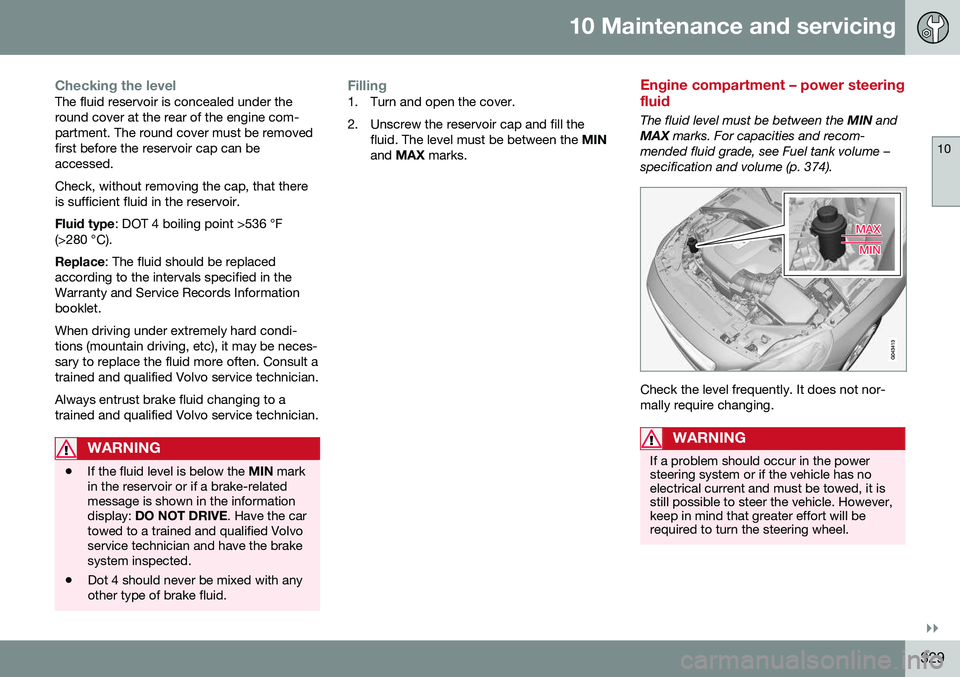

Engine compartment – power steering fluid

The fluid level must be between the MIN and

MAX marks. For capacities and recom-

mended fluid grade, see Fuel tank volume – specification and volume (p. 374).

Check the level frequently. It does not nor- mally require changing.

WARNING

If a problem should occur in the power steering system or if the vehicle has noelectrical current and must be towed, it isstill possible to steer the vehicle. However,keep in mind that greater effort will berequired to turn the steering wheel.

Page 333 of 392

10 Maintenance and servicing

10

}}

* Option/accessory, for more information, see Introduction.331

CAUTION

Never touch the glass of bulbs with your fingers. Grease and oils from your fingersvaporize in the heat and will leave adeposit on the reflector, which will damageit.

WARNING

• The engine should not be running when changing bulbs.

• If the engine has been running justprior to replacing bulbs in the head-light housing, please keep in mind thatcomponents in the engine compart-ment will be hot.

WARNING

•

Active Bending Lights* – due to the high voltage used by these headlights,these bulbs should only be replacedby a trained and qualified Volvo serv-ice technician.

• Turn off the lights and remove theremote key from the ignition beforechanging any bulbs.

Related information

•

Bulbs – headlight housing (p. 331)

• Bulbs – taillight housing (p. 336)

• Bulbs – vanity mirror lighting (p. 337)

• Bulbs – license plate lighting (p. 336)

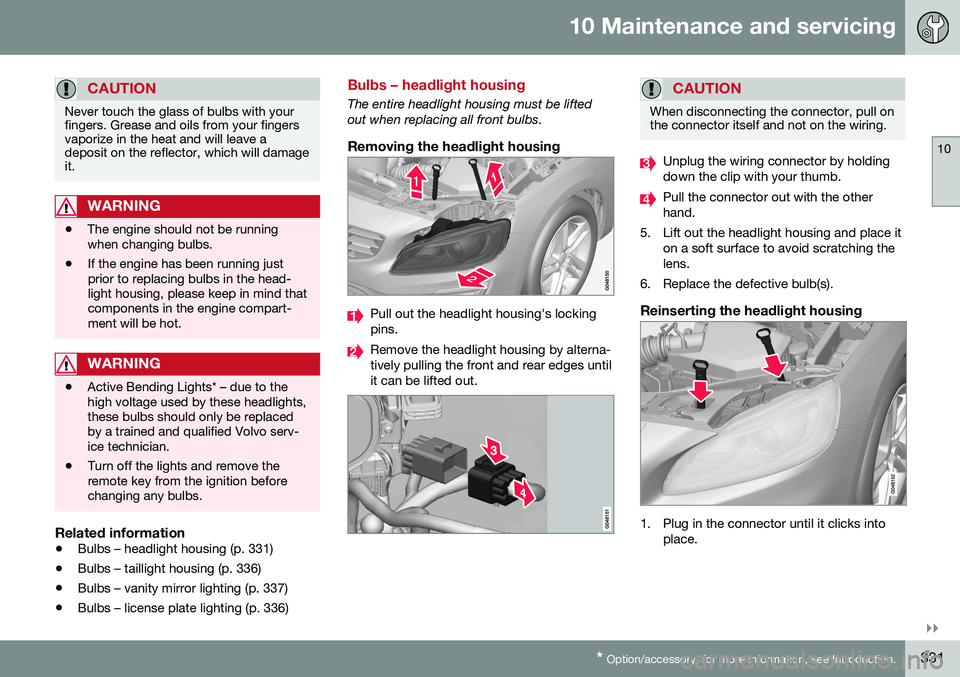

Bulbs – headlight housing

The entire headlight housing must be lifted out when replacing all front bulbs.

Removing the headlight housing

Pull out the headlight housing's locking pins.

Remove the headlight housing by alterna- tively pulling the front and rear edges untilit can be lifted out.

CAUTION

When disconnecting the connector, pull on the connector itself and not on the wiring.

Unplug the wiring connector by holding down the clip with your thumb.

Pull the connector out with the other hand.

5. Lift out the headlight housing and place it on a soft surface to avoid scratching thelens.

6. Replace the defective bulb(s).

Reinserting the headlight housing

1. Plug in the connector until it clicks into place.

Page 334 of 392

||

10 Maintenance and servicing

10

332

2. Reinstall the headlight housing and lock-ing pins. The short locking pin should be closest to the grille. Check that they arecorrectly inserted. The headlight housing must be properly in place and the wiring connector cor-rectly reconnected before the lighting isswitched on or the remote key is insertedinto the ignition slot.

3. Check that the lights function properly.

Related information

• Bulbs – introduction (p. 330)

• Bulbs – cover (p. 332)

• Bulbs – specifications (p. 337)

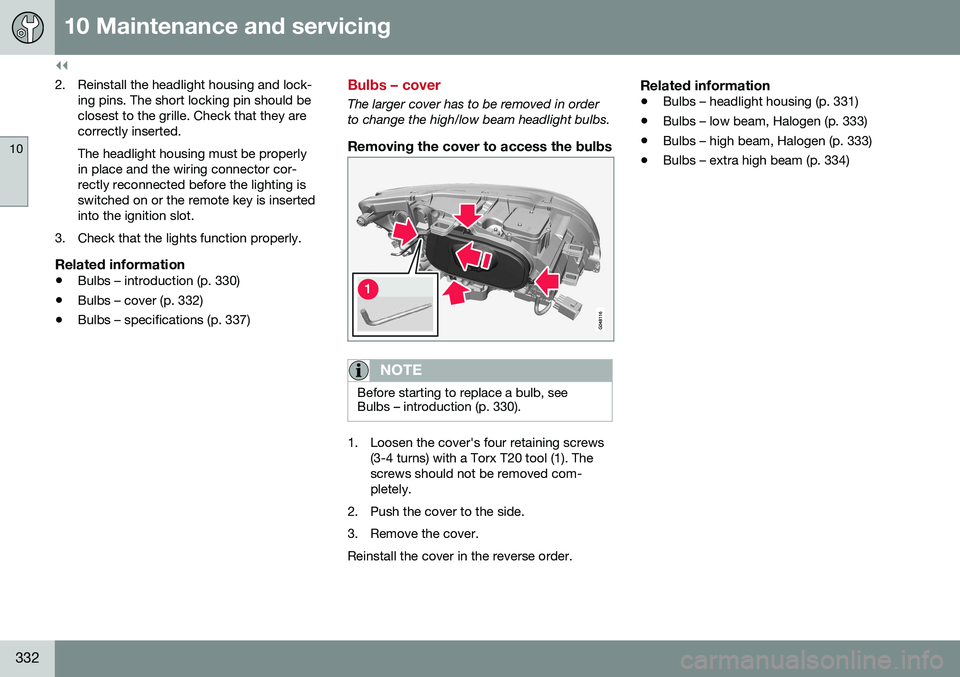

Bulbs – cover

The larger cover has to be removed in order to change the high/low beam headlight bulbs.

Removing the cover to access the bulbs

NOTE

Before starting to replace a bulb, see Bulbs – introduction (p. 330).

1. Loosen the cover's four retaining screws

(3-4 turns) with a Torx T20 tool (1). The screws should not be removed com-pletely.

2. Push the cover to the side.

3. Remove the cover.Reinstall the cover in the reverse order.

Related information

• Bulbs – headlight housing (p. 331)

• Bulbs – low beam, Halogen (p. 333)

• Bulbs – high beam, Halogen (p. 333)

• Bulbs – extra high beam (p. 334)